Transparent Oxides’ Application in Self-Cleaning Materials

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Oxides Evolution and Research Objectives

Transparent oxides have emerged as a cornerstone technology in the development of self-cleaning materials, with their evolution spanning several decades of scientific advancement. The journey began in the 1960s with initial discoveries of photocatalytic properties in certain metal oxides, but it wasn't until the 1970s that researchers at the University of Tokyo first documented the self-cleaning effect of titanium dioxide (TiO₂) under UV light exposure. This discovery laid the foundation for what would become a revolutionary approach to surface engineering.

The 1990s marked a significant acceleration in transparent oxide research, particularly with the commercialization of the first self-cleaning glass products utilizing TiO₂ coatings. These early applications demonstrated two primary mechanisms: photocatalytic decomposition of organic contaminants and superhydrophilicity, which allows water to spread evenly across surfaces, washing away decomposed matter.

Recent technological advancements have expanded beyond TiO₂ to include other transparent oxides such as zinc oxide (ZnO), tungsten oxide (WO₃), and various composite materials that exhibit enhanced photocatalytic efficiency and broader spectrum light absorption capabilities. The incorporation of dopants and the development of nanostructured morphologies have further revolutionized the field, enabling functionality under visible light rather than solely UV radiation.

The current research landscape is characterized by efforts to overcome persistent challenges in transparent oxide applications, including durability under harsh environmental conditions, cost-effective large-scale production methods, and the optimization of optical properties to maintain transparency while maximizing self-cleaning efficiency. Additionally, researchers are exploring the integration of these materials with other functional components to create multifunctional surfaces.

Our technical objectives in this domain are multifaceted. First, we aim to develop transparent oxide formulations that demonstrate robust self-cleaning performance under ambient light conditions, eliminating the need for UV exposure. Second, we seek to enhance the durability of these coatings to withstand at least five years of environmental exposure without significant degradation in performance. Third, we intend to optimize manufacturing processes to reduce production costs by approximately 30%, making these technologies more commercially viable.

Furthermore, we are investigating novel composite structures that combine transparent oxides with other functional materials to create surfaces with additional properties beyond self-cleaning, such as anti-fogging, anti-bacterial, and self-healing capabilities. The ultimate goal is to establish a comprehensive technology platform that can be adapted to various substrate materials and application environments, from architectural glass to automotive finishes and consumer electronics.

The 1990s marked a significant acceleration in transparent oxide research, particularly with the commercialization of the first self-cleaning glass products utilizing TiO₂ coatings. These early applications demonstrated two primary mechanisms: photocatalytic decomposition of organic contaminants and superhydrophilicity, which allows water to spread evenly across surfaces, washing away decomposed matter.

Recent technological advancements have expanded beyond TiO₂ to include other transparent oxides such as zinc oxide (ZnO), tungsten oxide (WO₃), and various composite materials that exhibit enhanced photocatalytic efficiency and broader spectrum light absorption capabilities. The incorporation of dopants and the development of nanostructured morphologies have further revolutionized the field, enabling functionality under visible light rather than solely UV radiation.

The current research landscape is characterized by efforts to overcome persistent challenges in transparent oxide applications, including durability under harsh environmental conditions, cost-effective large-scale production methods, and the optimization of optical properties to maintain transparency while maximizing self-cleaning efficiency. Additionally, researchers are exploring the integration of these materials with other functional components to create multifunctional surfaces.

Our technical objectives in this domain are multifaceted. First, we aim to develop transparent oxide formulations that demonstrate robust self-cleaning performance under ambient light conditions, eliminating the need for UV exposure. Second, we seek to enhance the durability of these coatings to withstand at least five years of environmental exposure without significant degradation in performance. Third, we intend to optimize manufacturing processes to reduce production costs by approximately 30%, making these technologies more commercially viable.

Furthermore, we are investigating novel composite structures that combine transparent oxides with other functional materials to create surfaces with additional properties beyond self-cleaning, such as anti-fogging, anti-bacterial, and self-healing capabilities. The ultimate goal is to establish a comprehensive technology platform that can be adapted to various substrate materials and application environments, from architectural glass to automotive finishes and consumer electronics.

Market Analysis for Self-Cleaning Materials

The global market for self-cleaning materials has experienced significant growth in recent years, driven by increasing awareness of hygiene, environmental concerns, and the desire for low-maintenance solutions across various industries. The integration of transparent oxides, particularly titanium dioxide (TiO2), into self-cleaning applications has revolutionized this market segment, creating new opportunities and reshaping consumer expectations.

The self-cleaning materials market was valued at approximately $3.5 billion in 2022 and is projected to reach $6.2 billion by 2028, representing a compound annual growth rate (CAGR) of 9.8%. This growth trajectory is supported by expanding applications across construction, automotive, solar panels, and consumer electronics sectors, where transparent oxide-based solutions offer distinct advantages.

Construction remains the dominant application segment, accounting for over 40% of the market share. Self-cleaning glass for windows, facades, and roofing materials has gained substantial traction in commercial buildings, particularly in urban areas with high pollution levels. The automotive industry follows as the second-largest consumer, with self-cleaning windshields and exterior surfaces becoming increasingly standard in premium vehicle models.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% through 2028, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China, Japan, and South Korea.

Consumer demand patterns indicate a strong preference for multifunctional self-cleaning materials that combine photocatalytic properties with additional benefits such as anti-fogging, anti-bacterial, and UV-protection capabilities. This trend has prompted manufacturers to develop advanced formulations incorporating transparent oxides with enhanced performance characteristics.

Price sensitivity remains a significant factor influencing market penetration, particularly in residential applications and developing economies. The cost premium for self-cleaning materials compared to conventional alternatives ranges from 15% to 40%, depending on the application and technology sophistication. However, this gap is gradually narrowing as production scales up and manufacturing processes become more efficient.

Future market growth will be significantly influenced by regulatory frameworks promoting sustainable building materials and energy efficiency. Several countries have introduced standards and certifications for self-cleaning materials, which is expected to drive adoption in public infrastructure projects and commercial developments. Additionally, increasing research funding for advanced materials science is likely to accelerate innovation in transparent oxide applications, potentially expanding the market scope beyond current projections.

The self-cleaning materials market was valued at approximately $3.5 billion in 2022 and is projected to reach $6.2 billion by 2028, representing a compound annual growth rate (CAGR) of 9.8%. This growth trajectory is supported by expanding applications across construction, automotive, solar panels, and consumer electronics sectors, where transparent oxide-based solutions offer distinct advantages.

Construction remains the dominant application segment, accounting for over 40% of the market share. Self-cleaning glass for windows, facades, and roofing materials has gained substantial traction in commercial buildings, particularly in urban areas with high pollution levels. The automotive industry follows as the second-largest consumer, with self-cleaning windshields and exterior surfaces becoming increasingly standard in premium vehicle models.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed by North America (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% through 2028, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China, Japan, and South Korea.

Consumer demand patterns indicate a strong preference for multifunctional self-cleaning materials that combine photocatalytic properties with additional benefits such as anti-fogging, anti-bacterial, and UV-protection capabilities. This trend has prompted manufacturers to develop advanced formulations incorporating transparent oxides with enhanced performance characteristics.

Price sensitivity remains a significant factor influencing market penetration, particularly in residential applications and developing economies. The cost premium for self-cleaning materials compared to conventional alternatives ranges from 15% to 40%, depending on the application and technology sophistication. However, this gap is gradually narrowing as production scales up and manufacturing processes become more efficient.

Future market growth will be significantly influenced by regulatory frameworks promoting sustainable building materials and energy efficiency. Several countries have introduced standards and certifications for self-cleaning materials, which is expected to drive adoption in public infrastructure projects and commercial developments. Additionally, increasing research funding for advanced materials science is likely to accelerate innovation in transparent oxide applications, potentially expanding the market scope beyond current projections.

Technical Barriers and Global Development Status

Despite significant advancements in transparent oxide-based self-cleaning materials, several technical barriers continue to impede widespread commercial adoption. The durability of these coatings remains a primary challenge, with many current formulations showing degradation under prolonged UV exposure or mechanical abrasion. This limitation significantly restricts their application in high-traffic areas or outdoor environments where longevity is crucial.

Cost-effectiveness presents another substantial barrier, as the production of high-quality transparent oxide coatings often involves expensive precursors and sophisticated deposition techniques such as chemical vapor deposition (CVD) or magnetron sputtering. These processes require specialized equipment and controlled environments, making large-scale manufacturing economically challenging for many potential applications.

The performance consistency of self-cleaning properties across varying environmental conditions also remains problematic. Many transparent oxide coatings exhibit reduced efficiency in low-light conditions or during prolonged periods of darkness, limiting their practical utility in certain geographical regions or indoor applications.

Globally, research and development in transparent oxide self-cleaning materials show distinct regional patterns. Japan and South Korea lead in commercial applications, with companies like Toto Ltd. and Samsung incorporating these technologies into consumer products. Their focus has primarily been on photocatalytic TiO2-based coatings for building materials and household appliances.

European research institutions, particularly in Germany and the UK, have concentrated on fundamental research into novel transparent oxide compositions and hybrid materials. The European Union's Horizon programs have funded significant research into environmentally friendly production methods and enhanced durability formulations.

In North America, development has focused on specialized high-performance applications, particularly in aerospace and automotive industries. Research at institutions like MIT and Stanford has explored advanced deposition techniques and multi-functional coatings that combine self-cleaning with other properties such as anti-icing or anti-fogging capabilities.

China has rapidly emerged as a major player, with substantial government investment in both research and manufacturing infrastructure. Chinese research has particularly emphasized cost reduction strategies and mass production techniques, potentially positioning the country as a future leader in commercialization.

Developing nations, while generally consumers rather than developers of this technology, represent significant potential markets, particularly for applications in solar energy harvesting where dust accumulation significantly impacts efficiency in arid regions.

Cost-effectiveness presents another substantial barrier, as the production of high-quality transparent oxide coatings often involves expensive precursors and sophisticated deposition techniques such as chemical vapor deposition (CVD) or magnetron sputtering. These processes require specialized equipment and controlled environments, making large-scale manufacturing economically challenging for many potential applications.

The performance consistency of self-cleaning properties across varying environmental conditions also remains problematic. Many transparent oxide coatings exhibit reduced efficiency in low-light conditions or during prolonged periods of darkness, limiting their practical utility in certain geographical regions or indoor applications.

Globally, research and development in transparent oxide self-cleaning materials show distinct regional patterns. Japan and South Korea lead in commercial applications, with companies like Toto Ltd. and Samsung incorporating these technologies into consumer products. Their focus has primarily been on photocatalytic TiO2-based coatings for building materials and household appliances.

European research institutions, particularly in Germany and the UK, have concentrated on fundamental research into novel transparent oxide compositions and hybrid materials. The European Union's Horizon programs have funded significant research into environmentally friendly production methods and enhanced durability formulations.

In North America, development has focused on specialized high-performance applications, particularly in aerospace and automotive industries. Research at institutions like MIT and Stanford has explored advanced deposition techniques and multi-functional coatings that combine self-cleaning with other properties such as anti-icing or anti-fogging capabilities.

China has rapidly emerged as a major player, with substantial government investment in both research and manufacturing infrastructure. Chinese research has particularly emphasized cost reduction strategies and mass production techniques, potentially positioning the country as a future leader in commercialization.

Developing nations, while generally consumers rather than developers of this technology, represent significant potential markets, particularly for applications in solar energy harvesting where dust accumulation significantly impacts efficiency in arid regions.

Current Self-Cleaning Technology Solutions

01 Transparent Conductive Oxide (TCO) Materials

Transparent conductive oxides are materials that combine electrical conductivity with optical transparency. These materials, including indium tin oxide (ITO), zinc oxide (ZnO), and aluminum-doped zinc oxide (AZO), are widely used in electronic displays, solar cells, and touch screens. Their unique properties allow for the transmission of light while conducting electricity, making them essential components in optoelectronic devices.- Transparent Conductive Oxide (TCO) Materials: Transparent conductive oxides are materials that combine electrical conductivity with optical transparency. These materials are typically metal oxides such as indium tin oxide (ITO), zinc oxide (ZnO), and aluminum-doped zinc oxide (AZO). They are widely used in electronic displays, solar cells, and touch screens due to their unique combination of properties. The manufacturing processes for these materials often involve deposition techniques like sputtering or chemical vapor deposition to achieve optimal transparency and conductivity.

- Transparent Oxide Semiconductors: Transparent oxide semiconductors are materials that exhibit semiconductor properties while maintaining optical transparency. These materials, including amorphous indium gallium zinc oxide (IGZO) and zinc tin oxide (ZTO), are used in thin-film transistors for display applications. They offer advantages such as high electron mobility, good stability, and compatibility with low-temperature processing. Research in this area focuses on improving electrical performance, stability, and developing new compositions with enhanced properties.

- Transparent Oxide Coatings for Glass and Ceramics: Transparent oxide coatings are applied to glass and ceramic surfaces to impart specific properties such as UV protection, anti-reflection, self-cleaning, or heat reflection. These coatings typically consist of metal oxides like titanium dioxide, silicon dioxide, or tin oxide. They can be applied through various methods including sol-gel processes, spray pyrolysis, or physical vapor deposition. The thickness and composition of these coatings are carefully controlled to maintain transparency while achieving the desired functional properties.

- Manufacturing Processes for Transparent Oxide Films: Various manufacturing processes are employed to produce transparent oxide films with controlled properties. These include sputtering, chemical vapor deposition, atomic layer deposition, sol-gel methods, and spray pyrolysis. Each technique offers different advantages in terms of film quality, deposition rate, cost, and scalability. Process parameters such as temperature, pressure, and precursor composition significantly influence the structural, optical, and electrical properties of the resulting oxide films. Innovations in manufacturing processes focus on reducing costs, improving uniformity, and enabling large-area deposition.

- Applications of Transparent Oxides in Electronic and Optical Devices: Transparent oxides find applications in various electronic and optical devices including solar cells, light-emitting diodes, flat panel displays, smart windows, and touch screens. Their unique combination of optical transparency and electrical functionality makes them essential components in modern optoelectronic technology. Recent developments include flexible transparent electrodes, high-performance thin-film transistors, and energy-efficient smart windows. Research continues to expand the application scope of transparent oxides by tailoring their properties for specific device requirements and exploring new device architectures.

02 Fabrication Methods for Transparent Oxide Films

Various deposition techniques are employed to create transparent oxide films with controlled properties. These methods include sputtering, chemical vapor deposition (CVD), sol-gel processing, and atomic layer deposition (ALD). Each technique offers different advantages in terms of film quality, thickness control, and scalability. Post-deposition treatments such as annealing can further enhance the transparency and conductivity of these oxide films.Expand Specific Solutions03 Transparent Oxide Semiconductors

Transparent oxide semiconductors represent a class of materials that combine semiconductor properties with optical transparency. Materials such as amorphous indium gallium zinc oxide (a-IGZO) and zinc tin oxide (ZTO) are used in thin-film transistors for display applications. These semiconductors offer advantages including high electron mobility, good stability, and compatibility with low-temperature processing, enabling their use in flexible electronics.Expand Specific Solutions04 Transparent Oxide Applications in Optics and Photonics

Transparent oxides play crucial roles in optical and photonic devices. They are used as anti-reflective coatings, optical filters, and waveguides. Materials like titanium dioxide (TiO2) and silicon dioxide (SiO2) provide specific refractive indices and transmission properties for optical applications. These oxides can be engineered to manipulate light through interference effects, enabling applications in lenses, mirrors, and specialized optical components.Expand Specific Solutions05 Doping and Modification of Transparent Oxides

The properties of transparent oxides can be tailored through doping and compositional modifications. Introducing elements such as aluminum, gallium, or fluorine into zinc oxide, or niobium into titanium dioxide, can enhance conductivity while maintaining transparency. Co-doping strategies and the creation of composite oxide structures allow for fine-tuning of electrical, optical, and mechanical properties to meet specific application requirements.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The transparent oxides market for self-cleaning materials is in a growth phase, with increasing adoption across construction, automotive, and electronics sectors. The market is projected to reach approximately $3-4 billion by 2025, driven by rising demand for low-maintenance surfaces and energy-efficient buildings. Technology maturity varies significantly among key players: established companies like TOTO Ltd. and Saint-Gobain have commercialized advanced photocatalytic coatings, while Samsung Display and SCHOTT AG focus on specialized applications in electronics and glass. Research institutions including Fraunhofer-Gesellschaft and SRI International are developing next-generation transparent oxide formulations with enhanced durability and functionality. Emerging players like Arl Designs and Signify Holding are introducing innovative applications, particularly in smart surfaces and IoT-integrated self-cleaning technologies.

TOTO Ltd.

Technical Solution: TOTO Ltd. has pioneered the development of transparent oxide-based self-cleaning materials through their proprietary HYDROTECT technology. This technology utilizes titanium dioxide (TiO2) transparent oxide coatings that activate under UV light exposure to break down organic matter and contaminants on surfaces. The photocatalytic process creates superhydrophilic properties, causing water to spread evenly across the surface rather than forming droplets, which helps wash away decomposed dirt particles. TOTO has successfully implemented this technology in various products including bathroom fixtures, exterior building materials, and glass surfaces. Their advanced manufacturing process ensures uniform nano-scale TiO2 deposition, maximizing photocatalytic efficiency while maintaining optical transparency. Recent innovations include visible light-responsive formulations incorporating nitrogen-doped TiO2 and other metal oxides that extend functionality beyond UV-dependent applications, allowing self-cleaning properties to work effectively in indoor environments with limited UV exposure.

Strengths: Industry-leading photocatalytic efficiency with proven commercial applications across multiple product categories. Long-lasting durability with documented performance exceeding 10 years in exterior applications. Weaknesses: Traditional formulations require UV light activation, limiting indoor effectiveness. Higher production costs compared to conventional materials, affecting mass market adoption.

Nanjing Tech University

Technical Solution: Nanjing Tech University has developed innovative transparent oxide-based self-cleaning materials through their Advanced Functional Materials Research Center. Their approach focuses on hierarchically structured nanocomposites combining titanium dioxide with other transparent metal oxides like zinc oxide and tin oxide. Their proprietary hydrothermal synthesis method creates highly crystalline anatase TiO2 nanostructures with exposed high-energy {001} facets, significantly enhancing photocatalytic efficiency. The university's researchers have pioneered black titanium dioxide synthesis techniques that introduce oxygen vacancies and Ti3+ species into the crystal structure, dramatically improving visible light absorption. Their recent innovations include graphene-TiO2 nanocomposites that facilitate rapid electron transfer and reduce recombination rates, enhancing quantum efficiency under both UV and visible light. Additionally, they've developed F-doped TiO2 transparent films with superhydrophobic properties that create lotus-effect self-cleaning surfaces combining both photocatalytic decomposition and water repellency mechanisms. These materials have been successfully tested in architectural glass, textile coatings, and solar panel cover applications, demonstrating enhanced durability and performance compared to conventional TiO2-only systems.

Strengths: Innovative approaches to visible light activation through defect engineering and heterojunction formation. Multifunctional surfaces combining photocatalytic and superhydrophobic properties. Weaknesses: Some technologies remain in laboratory development phase with limited large-scale production. Durability of modified oxide structures under real-world conditions requires further optimization.

Key Patents and Scientific Breakthroughs

Self-cleaning system and window-glass

PatentInactiveUS8147971B2

Innovation

- A translucent self-cleaning system with a light-emitting device and a photo-catalytic layer, where the light-emitting device is positioned near the translucent substrate to reduce the required light flux and allow activation of the self-cleaning effect at any time, including cloudy days, using a predefined wavelength range that is transmitted through the substrate.

Durable transparent self-cleaning coating based on self-assembly and interpenetrating network and preparation method

PatentInactiveCN116904051A

Innovation

- A coating composed of PU-PMMA layer and silica layer based on self-assembly and interpenetrating network is used to build a mushroom-shaped columnar micro-nano structure on the coating surface, combined with fluorine-modified nano-silica, to form a double layer Structure to improve surface hydrophobicity and wear resistance.

Environmental Impact Assessment

The application of transparent oxides in self-cleaning materials represents a significant advancement in sustainable technology, necessitating thorough environmental impact assessment. These materials, while offering substantial benefits in reducing maintenance and cleaning chemical usage, present complex environmental considerations throughout their lifecycle.

The production phase of transparent oxide coatings involves energy-intensive processes and potential emissions. Manufacturing techniques such as chemical vapor deposition and sol-gel methods require considerable energy inputs, contributing to carbon footprints. Additionally, precursor chemicals used in synthesis may include volatile organic compounds and metal-containing solutions that pose environmental risks if improperly managed.

During the use phase, transparent oxide self-cleaning surfaces demonstrate notable positive environmental impacts. By maintaining cleanliness through photocatalytic reactions rather than chemical cleaners, these materials significantly reduce water consumption and eliminate the release of detergents and cleaning agents into wastewater systems. Studies indicate that buildings with self-cleaning facades can reduce cleaning-related water usage by up to 70% compared to conventional surfaces.

Atmospheric interactions of these materials warrant careful consideration. While photocatalytic oxides like TiO2 decompose organic pollutants and potentially contribute to air purification, questions remain about reaction byproducts and their environmental fate. Research suggests that under certain conditions, intermediate compounds formed during photocatalysis may themselves require environmental monitoring.

End-of-life considerations reveal both challenges and opportunities. The durability of transparent oxide coatings typically extends product lifecycles, reducing waste generation. However, the composite nature of many self-cleaning materials complicates recycling processes. The presence of nanoscale oxides may require specialized handling protocols to prevent environmental release during disposal or recycling operations.

Lifecycle assessment studies comparing transparent oxide self-cleaning materials to conventional alternatives generally indicate net environmental benefits, particularly in scenarios with high maintenance requirements. The reduced need for cleaning chemicals, water conservation, and extended material lifespans typically outweigh production-related impacts. However, these assessments vary significantly based on application context, geographic location, and specific oxide formulations.

Regulatory frameworks addressing these materials continue to evolve, with increasing focus on nanomaterial safety and lifecycle management. Future environmental impact mitigation strategies should prioritize green synthesis methods, renewable energy integration in manufacturing, and development of recycling protocols specific to composite materials containing transparent oxides.

The production phase of transparent oxide coatings involves energy-intensive processes and potential emissions. Manufacturing techniques such as chemical vapor deposition and sol-gel methods require considerable energy inputs, contributing to carbon footprints. Additionally, precursor chemicals used in synthesis may include volatile organic compounds and metal-containing solutions that pose environmental risks if improperly managed.

During the use phase, transparent oxide self-cleaning surfaces demonstrate notable positive environmental impacts. By maintaining cleanliness through photocatalytic reactions rather than chemical cleaners, these materials significantly reduce water consumption and eliminate the release of detergents and cleaning agents into wastewater systems. Studies indicate that buildings with self-cleaning facades can reduce cleaning-related water usage by up to 70% compared to conventional surfaces.

Atmospheric interactions of these materials warrant careful consideration. While photocatalytic oxides like TiO2 decompose organic pollutants and potentially contribute to air purification, questions remain about reaction byproducts and their environmental fate. Research suggests that under certain conditions, intermediate compounds formed during photocatalysis may themselves require environmental monitoring.

End-of-life considerations reveal both challenges and opportunities. The durability of transparent oxide coatings typically extends product lifecycles, reducing waste generation. However, the composite nature of many self-cleaning materials complicates recycling processes. The presence of nanoscale oxides may require specialized handling protocols to prevent environmental release during disposal or recycling operations.

Lifecycle assessment studies comparing transparent oxide self-cleaning materials to conventional alternatives generally indicate net environmental benefits, particularly in scenarios with high maintenance requirements. The reduced need for cleaning chemicals, water conservation, and extended material lifespans typically outweigh production-related impacts. However, these assessments vary significantly based on application context, geographic location, and specific oxide formulations.

Regulatory frameworks addressing these materials continue to evolve, with increasing focus on nanomaterial safety and lifecycle management. Future environmental impact mitigation strategies should prioritize green synthesis methods, renewable energy integration in manufacturing, and development of recycling protocols specific to composite materials containing transparent oxides.

Durability and Performance Metrics

The durability and performance of transparent oxide-based self-cleaning materials represent critical factors determining their commercial viability and practical applications. Current industry standards require these materials to maintain their self-cleaning properties for a minimum of 3-5 years under normal environmental conditions, though premium applications often demand 7-10 year performance guarantees.

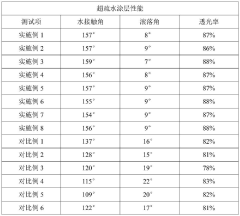

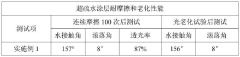

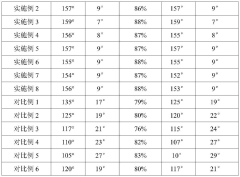

Performance evaluation of these materials follows standardized testing protocols including ISO 27448 for photocatalytic activity, ASTM D7490 for hydrophobic surface properties, and ISO 11507 for weathering resistance. These metrics provide quantifiable measures of effectiveness across different environmental conditions and usage scenarios.

Water contact angle measurements serve as a primary indicator of self-cleaning performance, with superhydrophobic surfaces typically exhibiting angles exceeding 150°. Photocatalytic efficiency is commonly assessed through methylene blue degradation tests, where higher degradation rates correlate with superior self-cleaning capabilities. Transparency retention, measured as percentage light transmission after exposure periods, remains crucial for applications in architectural glazing and solar panels.

Accelerated aging tests reveal that titanium dioxide-based coatings generally maintain 80-85% of their initial performance after simulated 3-year exposure, while zinc oxide formulations typically retain 70-75% efficiency over the same period. Silicon dioxide-based hydrophobic coatings demonstrate superior durability with 90% performance retention but offer less active self-cleaning compared to photocatalytic alternatives.

Environmental factors significantly impact durability profiles, with UV exposure, temperature cycling, and chemical exposure presenting the greatest challenges. Recent advancements in composite oxide formulations have yielded improvements in acid rain resistance, with new-generation materials showing 40% better durability in pH 4.0 environments compared to conventional single-oxide coatings.

Mechanical abrasion resistance remains a persistent challenge, with most transparent oxide coatings showing significant performance degradation after 1,000 cycles in Taber abrasion tests. This limitation has prompted research into hierarchical surface structures and polymer-oxide composites that maintain self-cleaning functionality even after physical surface modification occurs.

Cost-performance analysis indicates that while high-durability formulations command premium pricing (typically 30-50% higher than standard versions), their extended service life and reduced maintenance requirements often result in favorable lifetime value propositions, particularly in difficult-to-access installations such as high-rise buildings and solar farms.

Performance evaluation of these materials follows standardized testing protocols including ISO 27448 for photocatalytic activity, ASTM D7490 for hydrophobic surface properties, and ISO 11507 for weathering resistance. These metrics provide quantifiable measures of effectiveness across different environmental conditions and usage scenarios.

Water contact angle measurements serve as a primary indicator of self-cleaning performance, with superhydrophobic surfaces typically exhibiting angles exceeding 150°. Photocatalytic efficiency is commonly assessed through methylene blue degradation tests, where higher degradation rates correlate with superior self-cleaning capabilities. Transparency retention, measured as percentage light transmission after exposure periods, remains crucial for applications in architectural glazing and solar panels.

Accelerated aging tests reveal that titanium dioxide-based coatings generally maintain 80-85% of their initial performance after simulated 3-year exposure, while zinc oxide formulations typically retain 70-75% efficiency over the same period. Silicon dioxide-based hydrophobic coatings demonstrate superior durability with 90% performance retention but offer less active self-cleaning compared to photocatalytic alternatives.

Environmental factors significantly impact durability profiles, with UV exposure, temperature cycling, and chemical exposure presenting the greatest challenges. Recent advancements in composite oxide formulations have yielded improvements in acid rain resistance, with new-generation materials showing 40% better durability in pH 4.0 environments compared to conventional single-oxide coatings.

Mechanical abrasion resistance remains a persistent challenge, with most transparent oxide coatings showing significant performance degradation after 1,000 cycles in Taber abrasion tests. This limitation has prompted research into hierarchical surface structures and polymer-oxide composites that maintain self-cleaning functionality even after physical surface modification occurs.

Cost-performance analysis indicates that while high-durability formulations command premium pricing (typically 30-50% higher than standard versions), their extended service life and reduced maintenance requirements often result in favorable lifetime value propositions, particularly in difficult-to-access installations such as high-rise buildings and solar farms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!