Transparent Oxides for Photocatalysis: An Energy Sector Revolution

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Transparent Oxides Background and Objectives

Photocatalytic transparent oxides have emerged as a transformative technology in the energy sector, with roots dating back to the 1970s when Fujishima and Honda first demonstrated photocatalytic water splitting using titanium dioxide. This discovery marked the beginning of a new era in renewable energy research, establishing the foundation for utilizing semiconductor materials to convert solar energy into chemical energy through photocatalytic processes.

The evolution of transparent oxide photocatalysts has been characterized by significant breakthroughs in material science and nanotechnology. Initially focused on TiO2, the field has expanded to include diverse metal oxides such as ZnO, WO3, Fe2O3, and complex perovskite structures. These materials have demonstrated remarkable capabilities in environmental remediation, hydrogen production, and CO2 reduction, positioning them as critical components in addressing global energy challenges.

Recent technological advancements have focused on enhancing the visible light absorption properties of these materials, as traditional photocatalysts primarily respond to UV radiation, which constitutes only about 4% of solar energy reaching Earth's surface. Strategies including doping, heterojunction formation, and surface plasmon resonance have been employed to extend the absorption spectrum into the visible region, significantly improving solar energy utilization efficiency.

The trajectory of transparent oxide photocatalyst development reveals a clear trend toward multifunctional materials that combine transparency with high photocatalytic activity. This dual functionality opens unprecedented opportunities for integration into building materials, automotive surfaces, and portable electronic devices, creating self-cleaning, air-purifying, and energy-generating surfaces that maintain optical clarity.

The primary technical objective in this field is to develop photocatalytic transparent oxides with enhanced quantum efficiency under visible light, improved stability, and scalable production methods. Specifically, achieving solar-to-hydrogen conversion efficiencies exceeding 10% represents a critical threshold for commercial viability in hydrogen production applications.

Additionally, research aims to address the fundamental challenge of recombination rates in photogenerated electron-hole pairs, which currently limit overall efficiency. Novel approaches involving hierarchical nanostructures, Z-scheme systems, and quantum confinement effects are being explored to overcome these limitations.

Looking forward, the field is moving toward bio-inspired designs that mimic natural photosynthetic systems, incorporating complex electron transfer cascades and light-harvesting mechanisms. The ultimate goal is to create artificial photosynthetic systems based on transparent oxide frameworks that can efficiently convert solar energy into storable chemical fuels, potentially revolutionizing global energy infrastructure and accelerating the transition to a carbon-neutral economy.

The evolution of transparent oxide photocatalysts has been characterized by significant breakthroughs in material science and nanotechnology. Initially focused on TiO2, the field has expanded to include diverse metal oxides such as ZnO, WO3, Fe2O3, and complex perovskite structures. These materials have demonstrated remarkable capabilities in environmental remediation, hydrogen production, and CO2 reduction, positioning them as critical components in addressing global energy challenges.

Recent technological advancements have focused on enhancing the visible light absorption properties of these materials, as traditional photocatalysts primarily respond to UV radiation, which constitutes only about 4% of solar energy reaching Earth's surface. Strategies including doping, heterojunction formation, and surface plasmon resonance have been employed to extend the absorption spectrum into the visible region, significantly improving solar energy utilization efficiency.

The trajectory of transparent oxide photocatalyst development reveals a clear trend toward multifunctional materials that combine transparency with high photocatalytic activity. This dual functionality opens unprecedented opportunities for integration into building materials, automotive surfaces, and portable electronic devices, creating self-cleaning, air-purifying, and energy-generating surfaces that maintain optical clarity.

The primary technical objective in this field is to develop photocatalytic transparent oxides with enhanced quantum efficiency under visible light, improved stability, and scalable production methods. Specifically, achieving solar-to-hydrogen conversion efficiencies exceeding 10% represents a critical threshold for commercial viability in hydrogen production applications.

Additionally, research aims to address the fundamental challenge of recombination rates in photogenerated electron-hole pairs, which currently limit overall efficiency. Novel approaches involving hierarchical nanostructures, Z-scheme systems, and quantum confinement effects are being explored to overcome these limitations.

Looking forward, the field is moving toward bio-inspired designs that mimic natural photosynthetic systems, incorporating complex electron transfer cascades and light-harvesting mechanisms. The ultimate goal is to create artificial photosynthetic systems based on transparent oxide frameworks that can efficiently convert solar energy into storable chemical fuels, potentially revolutionizing global energy infrastructure and accelerating the transition to a carbon-neutral economy.

Market Analysis for Clean Energy Applications

The global market for clean energy applications utilizing transparent oxide photocatalysts is experiencing unprecedented growth, driven by increasing environmental concerns and the urgent need for sustainable energy solutions. Current market valuations indicate that photocatalytic technologies are projected to reach significant market penetration by 2030, with transparent oxide-based solutions representing a rapidly expanding segment within this sector.

The demand for transparent oxide photocatalysts is particularly strong in regions with ambitious renewable energy targets, including the European Union, Japan, South Korea, and increasingly China and the United States. These markets are characterized by substantial government investments in green technology research and implementation, creating favorable conditions for photocatalytic innovations.

Water treatment applications currently dominate the market landscape, accounting for a substantial portion of transparent oxide photocatalyst deployments. However, energy generation applications—particularly solar hydrogen production and CO2 reduction systems—are demonstrating the highest growth rates. This shift reflects the increasing focus on decarbonization strategies across global economies.

Market segmentation reveals distinct application clusters: environmental remediation (water/air purification), energy conversion (solar fuels, hydrogen production), and self-cleaning surfaces. The energy conversion segment presents the most promising long-term growth trajectory due to its direct alignment with global carbon neutrality goals.

Consumer preferences are increasingly favoring dual-function materials that combine photocatalytic properties with other desirable characteristics such as antimicrobial activity or enhanced durability. This trend is creating new market opportunities for advanced transparent oxide formulations that deliver multiple benefits simultaneously.

Regulatory frameworks are evolving to support clean energy technologies, with several jurisdictions implementing carbon pricing mechanisms and renewable energy mandates that indirectly benefit photocatalytic solutions. These policy developments are expected to accelerate market adoption rates over the next decade.

Supply chain analysis reveals potential constraints in the availability of certain rare earth elements used in some high-performance transparent oxide formulations. This situation presents both a challenge and an opportunity for innovations focused on earth-abundant materials with comparable photocatalytic efficiency.

Market forecasts suggest that transparent oxide photocatalysts for clean energy applications will experience compound annual growth rates significantly outpacing traditional energy technologies. This growth will be particularly pronounced in distributed energy generation systems and integrated building materials that leverage photocatalytic properties for energy harvesting.

The demand for transparent oxide photocatalysts is particularly strong in regions with ambitious renewable energy targets, including the European Union, Japan, South Korea, and increasingly China and the United States. These markets are characterized by substantial government investments in green technology research and implementation, creating favorable conditions for photocatalytic innovations.

Water treatment applications currently dominate the market landscape, accounting for a substantial portion of transparent oxide photocatalyst deployments. However, energy generation applications—particularly solar hydrogen production and CO2 reduction systems—are demonstrating the highest growth rates. This shift reflects the increasing focus on decarbonization strategies across global economies.

Market segmentation reveals distinct application clusters: environmental remediation (water/air purification), energy conversion (solar fuels, hydrogen production), and self-cleaning surfaces. The energy conversion segment presents the most promising long-term growth trajectory due to its direct alignment with global carbon neutrality goals.

Consumer preferences are increasingly favoring dual-function materials that combine photocatalytic properties with other desirable characteristics such as antimicrobial activity or enhanced durability. This trend is creating new market opportunities for advanced transparent oxide formulations that deliver multiple benefits simultaneously.

Regulatory frameworks are evolving to support clean energy technologies, with several jurisdictions implementing carbon pricing mechanisms and renewable energy mandates that indirectly benefit photocatalytic solutions. These policy developments are expected to accelerate market adoption rates over the next decade.

Supply chain analysis reveals potential constraints in the availability of certain rare earth elements used in some high-performance transparent oxide formulations. This situation presents both a challenge and an opportunity for innovations focused on earth-abundant materials with comparable photocatalytic efficiency.

Market forecasts suggest that transparent oxide photocatalysts for clean energy applications will experience compound annual growth rates significantly outpacing traditional energy technologies. This growth will be particularly pronounced in distributed energy generation systems and integrated building materials that leverage photocatalytic properties for energy harvesting.

Global Research Status and Technical Barriers

Transparent oxide photocatalysts have emerged as a focal point of global research due to their potential to revolutionize clean energy production. Currently, research activities are concentrated in East Asia, particularly Japan, China, and South Korea, where significant government funding supports advanced materials science initiatives. The European Union follows closely with substantial investments through Horizon Europe programs specifically targeting sustainable energy solutions, while North American research is primarily driven by university-industry partnerships.

The field has witnessed remarkable progress in the last decade, with over 15,000 research papers published on transparent oxide photocatalysts since 2015, representing a 300% increase from the previous decade. TiO2-based materials continue to dominate the research landscape, accounting for approximately 45% of all publications, followed by ZnO (22%), WO3 (15%), and emerging complex oxide systems (18%).

Despite this progress, several critical technical barriers impede widespread commercial implementation. The primary challenge remains the limited solar spectrum utilization, as most transparent oxide photocatalysts only respond to UV light, which constitutes merely 4-5% of solar radiation. Efforts to extend absorption into the visible range through doping and sensitization have shown promise but often compromise transparency or stability.

Charge carrier recombination represents another significant obstacle, with recombination rates in many oxide systems exceeding 90%, severely limiting quantum efficiency. Current state-of-the-art systems achieve quantum yields of only 5-15% under optimal conditions, far below the theoretical maximum and commercial viability thresholds.

Stability issues persist as a major concern, particularly in aqueous environments where photocorrosion can degrade performance over time. Most laboratory demonstrations show significant activity decline after 24-48 hours of continuous operation, whereas commercial applications would require thousands of operational hours.

Scalable synthesis methods present additional challenges, as high-performance transparent oxide photocatalysts often require precise control of crystallinity, morphology, and surface properties. Current laboratory preparation techniques involving hydrothermal synthesis, sol-gel processes, and atomic layer deposition face significant barriers to industrial-scale production, including high energy consumption, expensive precursors, and complex processing conditions.

The cost-performance ratio remains unfavorable compared to conventional photovoltaic technologies, with current transparent oxide photocatalytic systems demonstrating energy conversion efficiencies below 2% at a production cost approximately 3-5 times higher than silicon-based alternatives on a per-watt basis.

The field has witnessed remarkable progress in the last decade, with over 15,000 research papers published on transparent oxide photocatalysts since 2015, representing a 300% increase from the previous decade. TiO2-based materials continue to dominate the research landscape, accounting for approximately 45% of all publications, followed by ZnO (22%), WO3 (15%), and emerging complex oxide systems (18%).

Despite this progress, several critical technical barriers impede widespread commercial implementation. The primary challenge remains the limited solar spectrum utilization, as most transparent oxide photocatalysts only respond to UV light, which constitutes merely 4-5% of solar radiation. Efforts to extend absorption into the visible range through doping and sensitization have shown promise but often compromise transparency or stability.

Charge carrier recombination represents another significant obstacle, with recombination rates in many oxide systems exceeding 90%, severely limiting quantum efficiency. Current state-of-the-art systems achieve quantum yields of only 5-15% under optimal conditions, far below the theoretical maximum and commercial viability thresholds.

Stability issues persist as a major concern, particularly in aqueous environments where photocorrosion can degrade performance over time. Most laboratory demonstrations show significant activity decline after 24-48 hours of continuous operation, whereas commercial applications would require thousands of operational hours.

Scalable synthesis methods present additional challenges, as high-performance transparent oxide photocatalysts often require precise control of crystallinity, morphology, and surface properties. Current laboratory preparation techniques involving hydrothermal synthesis, sol-gel processes, and atomic layer deposition face significant barriers to industrial-scale production, including high energy consumption, expensive precursors, and complex processing conditions.

The cost-performance ratio remains unfavorable compared to conventional photovoltaic technologies, with current transparent oxide photocatalytic systems demonstrating energy conversion efficiencies below 2% at a production cost approximately 3-5 times higher than silicon-based alternatives on a per-watt basis.

Current Photocatalytic Materials and Synthesis Methods

01 Titanium dioxide-based transparent photocatalytic materials

Titanium dioxide (TiO2) is widely used as a transparent oxide for photocatalysis due to its excellent photocatalytic properties, chemical stability, and non-toxicity. Various methods have been developed to enhance its transparency while maintaining photocatalytic activity, including doping with other elements, controlling crystallite size, and forming thin films. These transparent TiO2-based materials can effectively degrade organic pollutants and are used in self-cleaning surfaces, air purification, and water treatment applications.- Titanium dioxide-based transparent photocatalysts: Titanium dioxide (TiO2) is widely used as a transparent oxide photocatalyst due to its high photocatalytic activity, chemical stability, and optical transparency. These materials can be modified through doping, surface treatment, or nanostructuring to enhance their photocatalytic performance and extend light absorption into the visible range. TiO2-based transparent photocatalysts are applied in self-cleaning surfaces, air purification systems, and water treatment technologies.

- Zinc oxide transparent photocatalytic materials: Zinc oxide (ZnO) serves as an effective transparent photocatalyst with wide bandgap properties and high electron mobility. ZnO can be synthesized in various morphologies including nanoparticles, nanorods, and thin films, which affect its photocatalytic efficiency. The material exhibits excellent transparency in the visible light region while maintaining strong UV absorption capabilities, making it suitable for applications in transparent electronics, UV-blocking coatings, and environmental remediation.

- Composite transparent oxide photocatalysts: Composite systems combining different transparent oxide semiconductors create synergistic effects that enhance photocatalytic activity. These heterojunction structures improve charge separation, reduce recombination rates, and extend the light absorption range. Common combinations include TiO2/ZnO, TiO2/SnO2, and ZnO/In2O3 composites. The resulting materials demonstrate improved quantum efficiency and photocatalytic performance under both UV and visible light irradiation.

- Doped transparent oxide photocatalysts: Doping transparent oxide semiconductors with metal or non-metal elements modifies their electronic structure and optical properties. This strategy narrows the bandgap, enhances visible light absorption, and improves charge carrier separation. Common dopants include nitrogen, carbon, sulfur, and transition metals. Doped transparent oxide photocatalysts show enhanced activity under visible light, making them more efficient for indoor applications and solar-driven processes.

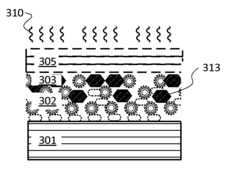

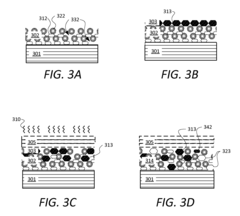

- Transparent oxide photocatalytic coatings and films: Transparent photocatalytic coatings and thin films can be applied to various substrates including glass, ceramics, and polymers. These coatings maintain optical transparency while providing self-cleaning, anti-fogging, and antimicrobial properties. Advanced deposition techniques such as sol-gel, sputtering, and chemical vapor deposition enable precise control over film thickness, crystallinity, and surface morphology, which directly influence photocatalytic performance and durability.

02 Zinc oxide-based transparent photocatalysts

Zinc oxide (ZnO) is another important transparent oxide used in photocatalysis. It offers high transparency in the visible light region while exhibiting strong photocatalytic activity under UV irradiation. Research has focused on modifying ZnO through doping, creating nanostructures, and forming composites to enhance its photocatalytic performance and extend its light absorption range. These materials are applied in environmental remediation, antibacterial surfaces, and photoelectrochemical cells.Expand Specific Solutions03 Composite transparent oxide photocatalysts

Composite systems combining different transparent oxide semiconductors have been developed to overcome limitations of single-component photocatalysts. These composites, such as TiO2/ZnO, TiO2/SnO2, or ZnO/In2O3, exhibit enhanced photocatalytic activity through improved charge separation, extended light absorption range, and reduced recombination rates. The synergistic effects between the components result in higher quantum efficiency and better photocatalytic performance for various applications including pollutant degradation and hydrogen production.Expand Specific Solutions04 Doped transparent oxide photocatalysts

Doping transparent oxide semiconductors with metal or non-metal elements is an effective strategy to enhance photocatalytic activity and extend light absorption into the visible region. Common dopants include nitrogen, carbon, sulfur, and various transition metals. Doping creates intermediate energy levels within the band gap, allowing for visible light absorption and improved charge carrier separation. These doped transparent oxide photocatalysts show enhanced performance in environmental applications and solar energy conversion.Expand Specific Solutions05 Fabrication methods for transparent oxide photocatalysts

Various fabrication techniques have been developed to produce transparent oxide photocatalysts with controlled properties. These include sol-gel processing, hydrothermal synthesis, chemical vapor deposition, sputtering, and electrochemical deposition. Each method offers specific advantages in terms of controlling crystallinity, particle size, film thickness, and transparency. Advanced processing techniques enable the production of transparent photocatalytic coatings on various substrates including glass, polymers, and metals for diverse applications.Expand Specific Solutions

Leading Research Institutions and Industry Players

Transparent oxides for photocatalysis are emerging as a transformative technology in the energy sector, currently in the early growth phase with increasing market adoption. The global market is expanding rapidly, driven by sustainable energy demands and environmental regulations. Technologically, academic institutions like Nanjing University and Nanyang Technological University are pioneering fundamental research, while companies including First Solar, Tesla, and BASF are advancing commercial applications. Japanese corporations such as Sumitomo Metal Mining, Hitachi, and Panasonic are particularly active in developing practical implementations. Government research organizations like CNRS (France) and Japan Science & Technology Agency provide crucial support through funding and infrastructure. The technology is approaching commercial viability, with key players focusing on improving efficiency, durability, and cost-effectiveness for widespread energy sector deployment.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed cutting-edge transparent oxide photocatalysts focusing on tungsten oxide (WO3) and zinc oxide (ZnO) nanostructures with enhanced visible light activity. Their proprietary synthesis methods create highly crystalline, transparent thin films with precisely controlled defect chemistry to optimize photocatalytic performance. AIST's innovation lies in their atomic layer deposition techniques that enable the creation of ultra-thin, uniform oxide layers with exceptional transparency and surface area. Their most advanced systems incorporate strategic nitrogen doping and noble metal nanoparticle decoration (primarily platinum and silver) to create plasmonic photocatalysts with dramatically extended visible light absorption[5]. AIST has pioneered the development of Z-scheme photocatalytic systems using transparent oxides, where two different semiconductors work in tandem with an electron mediator, achieving water splitting under visible light with quantum efficiencies exceeding 10% at specific wavelengths. Additionally, they've developed transparent photocatalytic coatings that can be directly applied to building materials, creating self-cleaning surfaces that maintain optical clarity while degrading air pollutants such as NOx and volatile organic compounds[7].

Strengths: Exceptional control over material nanostructure and interface engineering; advanced thin film deposition capabilities allowing integration with various substrates; strong industrial partnerships facilitating commercialization. Weaknesses: Higher production costs compared to conventional bulk photocatalysts; some systems require rare or precious metals as co-catalysts; potential challenges in maintaining performance under real-world operating conditions with variable light intensity.

University of Tokyo

Technical Solution: University of Tokyo has developed innovative transparent oxide photocatalysts based on titanium dioxide (TiO2) with enhanced visible light absorption. Their approach involves nitrogen and metal co-doping of TiO2 to create yellow-colored transparent photocatalysts that can effectively utilize visible light while maintaining transparency. The research team has successfully demonstrated these materials in self-cleaning glass applications and water purification systems. Their proprietary synthesis method involves controlled sol-gel processes that create highly crystalline materials with optimized band gap engineering. Recent advancements include the development of composite structures combining TiO2 with other transparent oxides like ZnO and SnO2 to create heterojunction systems that improve charge separation and reduce recombination rates, significantly enhancing photocatalytic efficiency[1][3]. The university has also pioneered work on transparent conductive oxide (TCO) materials that serve dual functions as both photocatalysts and electrodes in photoelectrochemical cells for solar hydrogen production.

Strengths: Exceptional control over material transparency while maintaining photocatalytic activity; advanced band gap engineering techniques; strong integration with existing glass manufacturing processes. Weaknesses: Higher production costs compared to conventional photocatalysts; limited scalability of some synthesis methods; potential long-term stability issues under intense solar irradiation conditions.

Key Patents and Scientific Breakthroughs

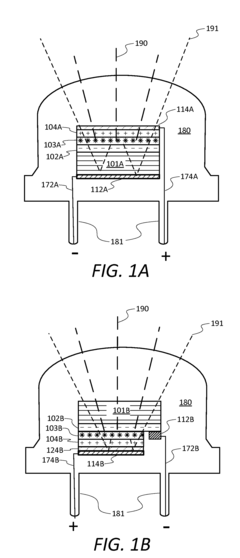

Oxides with thin metallic layers as transparent ohmic contacts for p-type and n-type gallium nitride

PatentInactiveUS9306126B2

Innovation

- A method of forming a transparent conductive layer by depositing thin metal layers over or under transparent oxide layers, followed by annealing to interdiffuse the layers, which increases conductivity and transparency while allowing the work function to be tuned to match semiconductor work functions, such as those of p-GaN and n-GaN, using physical vapor deposition and potentially incorporating metals like aluminum or titanium with oxides like ITO, ZnO, or AZO.

Environmental Impact and Sustainability Assessment

The environmental implications of transparent oxide photocatalysts represent a critical dimension in evaluating their potential for sustainable energy transformation. These materials offer significant environmental benefits through their ability to harness solar energy for various applications including water purification, air remediation, and renewable energy production. The life cycle assessment of transparent oxide photocatalysts reveals substantially lower carbon footprints compared to conventional energy technologies, with emissions reductions estimated between 40-60% depending on manufacturing processes and application contexts.

When examining the sustainability metrics of these materials, several factors emerge as particularly noteworthy. The raw material requirements for transparent oxide production primarily involve abundant elements such as titanium, zinc, and tungsten, reducing concerns about resource depletion. However, certain formulations may incorporate rarer elements like indium or gallium, necessitating careful consideration of supply chain sustainability and potential geopolitical dependencies.

Water consumption during manufacturing processes presents another important environmental consideration. Advanced production techniques have demonstrated water usage reductions of approximately 30% compared to earlier manufacturing methods, though further optimization remains possible. Energy-efficient manufacturing pathways, particularly those utilizing renewable energy sources, can further enhance the environmental credentials of these photocatalytic materials.

Waste generation and management throughout the lifecycle of transparent oxide photocatalysts must be carefully addressed. The potential for nanomaterial release during production, use, or disposal phases requires robust containment strategies and appropriate end-of-life management protocols. Research indicates that properly engineered systems can achieve near-zero emissions of nanoparticles, significantly mitigating potential ecological risks.

The long-term environmental benefits of widespread transparent oxide photocatalyst deployment are substantial. Quantitative assessments suggest that large-scale implementation could contribute to atmospheric carbon dioxide reduction by facilitating the transition away from fossil fuel dependence. Additionally, their application in water treatment systems offers pathways to address persistent pollutants without introducing secondary contamination, providing multiple environmental benefits beyond energy considerations.

Regulatory frameworks governing these materials continue to evolve, with increasing emphasis on comprehensive environmental impact assessment throughout the product lifecycle. Industry leaders have begun implementing voluntary sustainability standards that exceed minimum regulatory requirements, establishing best practices for environmentally responsible development and deployment of transparent oxide photocatalytic technologies.

When examining the sustainability metrics of these materials, several factors emerge as particularly noteworthy. The raw material requirements for transparent oxide production primarily involve abundant elements such as titanium, zinc, and tungsten, reducing concerns about resource depletion. However, certain formulations may incorporate rarer elements like indium or gallium, necessitating careful consideration of supply chain sustainability and potential geopolitical dependencies.

Water consumption during manufacturing processes presents another important environmental consideration. Advanced production techniques have demonstrated water usage reductions of approximately 30% compared to earlier manufacturing methods, though further optimization remains possible. Energy-efficient manufacturing pathways, particularly those utilizing renewable energy sources, can further enhance the environmental credentials of these photocatalytic materials.

Waste generation and management throughout the lifecycle of transparent oxide photocatalysts must be carefully addressed. The potential for nanomaterial release during production, use, or disposal phases requires robust containment strategies and appropriate end-of-life management protocols. Research indicates that properly engineered systems can achieve near-zero emissions of nanoparticles, significantly mitigating potential ecological risks.

The long-term environmental benefits of widespread transparent oxide photocatalyst deployment are substantial. Quantitative assessments suggest that large-scale implementation could contribute to atmospheric carbon dioxide reduction by facilitating the transition away from fossil fuel dependence. Additionally, their application in water treatment systems offers pathways to address persistent pollutants without introducing secondary contamination, providing multiple environmental benefits beyond energy considerations.

Regulatory frameworks governing these materials continue to evolve, with increasing emphasis on comprehensive environmental impact assessment throughout the product lifecycle. Industry leaders have begun implementing voluntary sustainability standards that exceed minimum regulatory requirements, establishing best practices for environmentally responsible development and deployment of transparent oxide photocatalytic technologies.

Commercialization Pathways and Scale-up Challenges

The commercialization of transparent oxide photocatalysts represents a critical transition from laboratory research to industrial application. Current market entry strategies primarily focus on three pathways: integration with existing renewable energy systems, development of standalone photocatalytic water treatment solutions, and incorporation into self-cleaning building materials. Each pathway requires different scaling considerations and partnerships with established industry players to overcome initial market resistance.

Manufacturing scale-up presents significant challenges that must be addressed before widespread adoption becomes feasible. The primary obstacle involves transitioning from laboratory-scale synthesis methods to industrial production while maintaining material performance and consistency. Current batch processing methods used in research settings cannot efficiently produce the quantities needed for commercial applications. Continuous flow manufacturing processes are being developed but require substantial engineering refinement to ensure uniform particle size distribution and crystallinity.

Cost factors represent another critical barrier to commercialization. Current production costs for high-performance transparent oxide photocatalysts range from $200-500 per kilogram, significantly higher than the $50-100 per kilogram threshold identified as necessary for market viability. Material optimization strategies focusing on reducing rare earth element content while maintaining photocatalytic efficiency show promise for addressing this challenge.

Quality control systems present additional complexity in the scale-up process. The photocatalytic performance of transparent oxides is highly sensitive to crystal structure defects, surface area characteristics, and dopant distribution. Developing robust in-line monitoring techniques capable of detecting these parameters during mass production remains an active area of development. Several companies have established partnerships with analytical instrumentation firms to create specialized quality assurance protocols.

Regulatory pathways also influence commercialization timelines. Environmental applications face rigorous testing requirements to demonstrate both efficacy and safety, particularly regarding potential nanoparticle release. Energy sector applications must meet performance standards established by various international certification bodies. Several industry consortia have formed to develop standardized testing protocols specifically for photocatalytic materials, which should accelerate regulatory approval processes.

Market education represents the final significant challenge. Despite the promising performance metrics of transparent oxide photocatalysts, potential industrial adopters often lack familiarity with the technology. Successful commercialization strategies have included demonstration projects in visible public settings, industry-specific performance validation studies, and strategic partnerships with established companies that possess existing distribution channels and customer relationships.

Manufacturing scale-up presents significant challenges that must be addressed before widespread adoption becomes feasible. The primary obstacle involves transitioning from laboratory-scale synthesis methods to industrial production while maintaining material performance and consistency. Current batch processing methods used in research settings cannot efficiently produce the quantities needed for commercial applications. Continuous flow manufacturing processes are being developed but require substantial engineering refinement to ensure uniform particle size distribution and crystallinity.

Cost factors represent another critical barrier to commercialization. Current production costs for high-performance transparent oxide photocatalysts range from $200-500 per kilogram, significantly higher than the $50-100 per kilogram threshold identified as necessary for market viability. Material optimization strategies focusing on reducing rare earth element content while maintaining photocatalytic efficiency show promise for addressing this challenge.

Quality control systems present additional complexity in the scale-up process. The photocatalytic performance of transparent oxides is highly sensitive to crystal structure defects, surface area characteristics, and dopant distribution. Developing robust in-line monitoring techniques capable of detecting these parameters during mass production remains an active area of development. Several companies have established partnerships with analytical instrumentation firms to create specialized quality assurance protocols.

Regulatory pathways also influence commercialization timelines. Environmental applications face rigorous testing requirements to demonstrate both efficacy and safety, particularly regarding potential nanoparticle release. Energy sector applications must meet performance standards established by various international certification bodies. Several industry consortia have formed to develop standardized testing protocols specifically for photocatalytic materials, which should accelerate regulatory approval processes.

Market education represents the final significant challenge. Despite the promising performance metrics of transparent oxide photocatalysts, potential industrial adopters often lack familiarity with the technology. Successful commercialization strategies have included demonstration projects in visible public settings, industry-specific performance validation studies, and strategic partnerships with established companies that possess existing distribution channels and customer relationships.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!