Cost vs Benefit Analysis of Modern Heat Exchanger Upgrades

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Evolution and Objectives

Heat exchangers have undergone significant evolution since their industrial inception in the late 19th century. Initially designed as simple tube-and-shell configurations, these thermal transfer devices have transformed into sophisticated systems incorporating advanced materials, complex geometries, and intelligent control mechanisms. The progression from rudimentary designs to modern configurations has been driven by increasing demands for energy efficiency, space optimization, and environmental sustainability across various industries including power generation, chemical processing, HVAC, and food production.

The technological trajectory of heat exchangers has been marked by several pivotal innovations. The 1920s-1940s saw the standardization of shell-and-tube designs, while the post-war industrial boom accelerated development of plate heat exchangers. The energy crisis of the 1970s catalyzed research into high-efficiency designs, leading to compact heat exchangers with enhanced surface areas. Recent decades have witnessed the emergence of microchannel technology, 3D-printed geometries, and smart heat exchangers with integrated sensors and control systems.

Current technological trends in heat exchanger development focus on four primary areas: material science advancements, geometric optimization, manufacturing innovations, and integration with digital systems. Novel materials such as advanced polymers, graphene-enhanced surfaces, and specialized metal alloys are extending operational parameters while reducing weight and cost. Computational fluid dynamics has enabled unprecedented optimization of flow patterns and heat transfer surfaces, resulting in designs that approach theoretical efficiency limits.

The primary objectives of modern heat exchanger upgrades center on maximizing return on investment through enhanced performance metrics. These include increased thermal efficiency (targeting 85-95% effectiveness), reduced pressure drop (minimizing pumping power requirements by 15-30%), extended service life (from typical 10-15 years to 20-25 years), and decreased maintenance frequency. Additional objectives include footprint reduction, enabling retrofitting in space-constrained environments, and compliance with increasingly stringent environmental regulations regarding refrigerants and manufacturing processes.

Future development trajectories aim to address persistent challenges in fouling mitigation, materials compatibility with aggressive process fluids, and further efficiency improvements. The integration of self-cleaning mechanisms, real-time performance monitoring, and predictive maintenance capabilities represents the frontier of heat exchanger technology. These advancements are expected to deliver lifecycle cost reductions of 20-40% compared to conventional systems, providing compelling economic justification for upgrade investments despite higher initial capital expenditure.

The technological trajectory of heat exchangers has been marked by several pivotal innovations. The 1920s-1940s saw the standardization of shell-and-tube designs, while the post-war industrial boom accelerated development of plate heat exchangers. The energy crisis of the 1970s catalyzed research into high-efficiency designs, leading to compact heat exchangers with enhanced surface areas. Recent decades have witnessed the emergence of microchannel technology, 3D-printed geometries, and smart heat exchangers with integrated sensors and control systems.

Current technological trends in heat exchanger development focus on four primary areas: material science advancements, geometric optimization, manufacturing innovations, and integration with digital systems. Novel materials such as advanced polymers, graphene-enhanced surfaces, and specialized metal alloys are extending operational parameters while reducing weight and cost. Computational fluid dynamics has enabled unprecedented optimization of flow patterns and heat transfer surfaces, resulting in designs that approach theoretical efficiency limits.

The primary objectives of modern heat exchanger upgrades center on maximizing return on investment through enhanced performance metrics. These include increased thermal efficiency (targeting 85-95% effectiveness), reduced pressure drop (minimizing pumping power requirements by 15-30%), extended service life (from typical 10-15 years to 20-25 years), and decreased maintenance frequency. Additional objectives include footprint reduction, enabling retrofitting in space-constrained environments, and compliance with increasingly stringent environmental regulations regarding refrigerants and manufacturing processes.

Future development trajectories aim to address persistent challenges in fouling mitigation, materials compatibility with aggressive process fluids, and further efficiency improvements. The integration of self-cleaning mechanisms, real-time performance monitoring, and predictive maintenance capabilities represents the frontier of heat exchanger technology. These advancements are expected to deliver lifecycle cost reductions of 20-40% compared to conventional systems, providing compelling economic justification for upgrade investments despite higher initial capital expenditure.

Market Demand Analysis for Advanced Heat Exchangers

The global market for advanced heat exchangers is experiencing robust growth, driven by increasing energy efficiency requirements across multiple industries. Current market size is estimated at $16.5 billion with projections indicating expansion to $22.3 billion by 2027, representing a compound annual growth rate of 6.2%. This growth trajectory is particularly pronounced in regions with stringent environmental regulations such as Europe and North America, where energy efficiency standards continue to tighten.

Industrial sectors including chemical processing, oil and gas, HVAC, and power generation constitute the primary demand drivers, collectively accounting for approximately 70% of the total market share. The chemical processing industry alone represents 24% of current demand, followed by oil and gas at 21%. These sectors are increasingly seeking heat exchanger solutions that offer enhanced thermal efficiency while reducing operational footprints.

Customer requirements have evolved significantly in recent years, with end-users prioritizing total cost of ownership over initial acquisition costs. Market research indicates that 78% of procurement decision-makers now consider lifecycle performance metrics as the primary selection criterion, compared to just 45% five years ago. This shift has created substantial demand for heat exchangers that demonstrate superior efficiency ratings, extended maintenance intervals, and reduced downtime.

The retrofit and replacement segment is emerging as a particularly lucrative market opportunity, currently valued at $5.8 billion annually. As aging industrial infrastructure reaches end-of-life stages, facility operators are increasingly opting for modern heat exchanger technologies rather than like-for-like replacements. This trend is especially evident in facilities over 15 years old, where energy efficiency improvements of 15-30% can be achieved through technology upgrades.

Regional market analysis reveals divergent demand patterns. Mature markets in North America and Europe are predominantly focused on replacement and efficiency upgrades, while emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in new installations. China and India together account for 32% of new heat exchanger installations globally, driven by expanding industrial capacity and infrastructure development.

Pricing sensitivity varies significantly by application segment. High-performance sectors such as petrochemical processing demonstrate relatively low price elasticity, with customers willing to pay premium prices for solutions offering documented efficiency improvements. Conversely, commercial HVAC applications exhibit greater price sensitivity, with purchasing decisions heavily influenced by initial capital expenditure considerations despite potential long-term operational savings.

Industrial sectors including chemical processing, oil and gas, HVAC, and power generation constitute the primary demand drivers, collectively accounting for approximately 70% of the total market share. The chemical processing industry alone represents 24% of current demand, followed by oil and gas at 21%. These sectors are increasingly seeking heat exchanger solutions that offer enhanced thermal efficiency while reducing operational footprints.

Customer requirements have evolved significantly in recent years, with end-users prioritizing total cost of ownership over initial acquisition costs. Market research indicates that 78% of procurement decision-makers now consider lifecycle performance metrics as the primary selection criterion, compared to just 45% five years ago. This shift has created substantial demand for heat exchangers that demonstrate superior efficiency ratings, extended maintenance intervals, and reduced downtime.

The retrofit and replacement segment is emerging as a particularly lucrative market opportunity, currently valued at $5.8 billion annually. As aging industrial infrastructure reaches end-of-life stages, facility operators are increasingly opting for modern heat exchanger technologies rather than like-for-like replacements. This trend is especially evident in facilities over 15 years old, where energy efficiency improvements of 15-30% can be achieved through technology upgrades.

Regional market analysis reveals divergent demand patterns. Mature markets in North America and Europe are predominantly focused on replacement and efficiency upgrades, while emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in new installations. China and India together account for 32% of new heat exchanger installations globally, driven by expanding industrial capacity and infrastructure development.

Pricing sensitivity varies significantly by application segment. High-performance sectors such as petrochemical processing demonstrate relatively low price elasticity, with customers willing to pay premium prices for solutions offering documented efficiency improvements. Conversely, commercial HVAC applications exhibit greater price sensitivity, with purchasing decisions heavily influenced by initial capital expenditure considerations despite potential long-term operational savings.

Current Technological Landscape and Barriers

The global heat exchanger market has witnessed significant technological advancements in recent years, with the current landscape characterized by a shift toward energy-efficient and sustainable solutions. Traditional shell-and-tube heat exchangers, while still widely used, are gradually being supplemented or replaced by more advanced designs such as plate, spiral, and printed circuit heat exchangers. These modern variants offer enhanced thermal efficiency, reduced footprint, and improved performance under varying operational conditions.

Industry data indicates that the heat exchanger market reached approximately $16.5 billion in 2022 and is projected to grow at a CAGR of 6.2% through 2030. This growth is primarily driven by increasing industrial automation, stringent environmental regulations, and the rising demand for energy-efficient systems across manufacturing, chemical processing, HVAC, and power generation sectors.

Despite technological progress, several significant barriers impede widespread adoption of modern heat exchanger upgrades. The foremost challenge is the substantial initial capital investment required, which can be 30-50% higher than conventional systems. This creates a significant hurdle for small and medium enterprises with limited financial resources, despite the long-term operational benefits.

Technical integration challenges also present considerable obstacles. Retrofitting existing systems with modern heat exchangers often necessitates comprehensive redesign of adjacent processes and control systems. The complexity of integration increases exponentially in facilities with legacy infrastructure, where compatibility issues frequently arise between new heat exchange technologies and existing equipment.

Material limitations constitute another critical barrier. Advanced heat exchangers frequently require specialized materials to withstand extreme operating conditions, corrosive media, or high-pressure environments. The availability and cost of these materials—including high-grade stainless steel, titanium alloys, and specialized polymers—can significantly impact project feasibility and return on investment calculations.

Operational expertise represents a frequently overlooked barrier. Modern heat exchangers with enhanced features require specialized knowledge for optimal operation and maintenance. The shortage of qualified personnel familiar with advanced heat exchange technologies creates implementation challenges, particularly in regions with limited access to technical training resources.

Regulatory compliance adds another layer of complexity, with varying standards across different regions creating uncertainty for multinational operations. The absence of harmonized global standards for heat exchanger performance and safety certification complicates technology selection and implementation decisions, particularly for organizations operating across multiple jurisdictions.

Industry data indicates that the heat exchanger market reached approximately $16.5 billion in 2022 and is projected to grow at a CAGR of 6.2% through 2030. This growth is primarily driven by increasing industrial automation, stringent environmental regulations, and the rising demand for energy-efficient systems across manufacturing, chemical processing, HVAC, and power generation sectors.

Despite technological progress, several significant barriers impede widespread adoption of modern heat exchanger upgrades. The foremost challenge is the substantial initial capital investment required, which can be 30-50% higher than conventional systems. This creates a significant hurdle for small and medium enterprises with limited financial resources, despite the long-term operational benefits.

Technical integration challenges also present considerable obstacles. Retrofitting existing systems with modern heat exchangers often necessitates comprehensive redesign of adjacent processes and control systems. The complexity of integration increases exponentially in facilities with legacy infrastructure, where compatibility issues frequently arise between new heat exchange technologies and existing equipment.

Material limitations constitute another critical barrier. Advanced heat exchangers frequently require specialized materials to withstand extreme operating conditions, corrosive media, or high-pressure environments. The availability and cost of these materials—including high-grade stainless steel, titanium alloys, and specialized polymers—can significantly impact project feasibility and return on investment calculations.

Operational expertise represents a frequently overlooked barrier. Modern heat exchangers with enhanced features require specialized knowledge for optimal operation and maintenance. The shortage of qualified personnel familiar with advanced heat exchange technologies creates implementation challenges, particularly in regions with limited access to technical training resources.

Regulatory compliance adds another layer of complexity, with varying standards across different regions creating uncertainty for multinational operations. The absence of harmonized global standards for heat exchanger performance and safety certification complicates technology selection and implementation decisions, particularly for organizations operating across multiple jurisdictions.

Modern Heat Exchanger Upgrade Solutions

01 Cost-benefit analysis methodologies for heat exchanger upgrades

Various methodologies can be employed to evaluate the cost versus benefit of heat exchanger upgrades. These include financial analysis tools that calculate return on investment, payback periods, and life cycle cost assessments. Advanced software solutions can simulate different upgrade scenarios to predict energy savings, operational improvements, and financial outcomes before implementation, helping decision-makers optimize their investment in heat exchanger technology.- Cost-benefit analysis methodologies for heat exchanger upgrades: Various methodologies and systems are available for conducting cost-benefit analyses of heat exchanger upgrades. These approaches involve evaluating the initial investment costs against potential energy savings, maintenance cost reductions, and performance improvements. The analysis typically includes calculating return on investment (ROI), payback periods, and long-term financial benefits of upgrading heat exchange systems in industrial applications.

- Energy efficiency improvements through heat exchanger design modifications: Heat exchanger upgrades that focus on design modifications can significantly improve energy efficiency and reduce operational costs. These modifications include changes to tube configurations, surface area enhancements, material upgrades, and flow path optimizations. Such improvements can lead to better heat transfer rates, reduced pressure drops, and lower energy consumption, resulting in substantial cost savings over the operational life of the equipment.

- Predictive maintenance and monitoring systems for heat exchangers: Implementation of predictive maintenance and monitoring systems for heat exchangers can optimize the cost-benefit ratio of upgrades. These systems use sensors, data analytics, and machine learning algorithms to monitor performance parameters, predict failures, and schedule maintenance activities. By preventing unexpected downtime and extending equipment life, these systems enhance the return on investment for heat exchanger upgrades.

- Material innovations for enhanced heat exchanger performance: Advanced materials can significantly improve the cost-benefit profile of heat exchanger upgrades. Corrosion-resistant alloys, composite materials, and specialized coatings extend equipment lifespan and reduce maintenance requirements. These material innovations also enhance heat transfer efficiency, allowing for more compact designs and reduced material usage, which can lower both capital and operational expenses.

- Digital simulation and optimization tools for heat exchanger upgrades: Digital simulation and optimization tools enable more accurate assessment of heat exchanger upgrade benefits. Computational fluid dynamics (CFD), digital twins, and process simulation software allow engineers to model different upgrade scenarios and predict performance improvements before implementation. These tools help identify the most cost-effective upgrade options by simulating operational conditions and calculating expected returns on investment.

02 Energy efficiency improvements through heat exchanger design modifications

Specific design modifications to heat exchangers can significantly improve energy efficiency and reduce operational costs. These modifications include enhanced tube geometries, improved flow distribution, advanced materials with better thermal conductivity, and optimized fin designs. Such upgrades can increase heat transfer rates while reducing pressure drop, resulting in lower energy consumption and operational costs that often justify the initial investment through long-term savings.Expand Specific Solutions03 Predictive maintenance and monitoring systems for optimizing heat exchanger performance

Implementation of advanced monitoring and predictive maintenance systems can optimize heat exchanger performance and extend equipment lifespan. These systems use sensors, data analytics, and machine learning algorithms to detect performance degradation, predict failures, and schedule maintenance before costly breakdowns occur. The investment in such technologies typically yields benefits through reduced downtime, lower maintenance costs, and extended equipment life, providing favorable cost-benefit outcomes.Expand Specific Solutions04 Environmental and regulatory compliance benefits of heat exchanger upgrades

Heat exchanger upgrades can provide significant benefits related to environmental performance and regulatory compliance. Modern designs can reduce emissions, improve energy efficiency, and minimize waste heat, helping facilities meet increasingly stringent environmental regulations. While these upgrades require initial investment, they can prevent costly fines, reduce carbon taxes, improve corporate sustainability metrics, and potentially qualify for government incentives or tax benefits, creating a positive cost-benefit outcome.Expand Specific Solutions05 Integration of smart technologies and automation in heat exchanger systems

Incorporating smart technologies and automation into heat exchanger systems can provide substantial cost benefits despite higher initial investment. These technologies include automated cleaning systems, self-adjusting flow controls, digital twins for performance simulation, and integration with facility-wide energy management systems. Such upgrades enable real-time optimization, reduce manual intervention, and allow for adaptive operation based on changing conditions, resulting in improved efficiency, reduced maintenance costs, and extended equipment life.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The heat exchanger upgrade market is currently in a growth phase, with increasing demand driven by energy efficiency regulations and sustainability initiatives. The market size is estimated to exceed $10 billion globally, with projected annual growth of 5-7%. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Danfoss A/S and Modine Manufacturing have developed highly efficient micro-channel heat exchangers, while companies such as Gree Electric, Haier Smart Home, and Samsung Electronics are integrating smart controls and IoT capabilities into their systems. Academic institutions like Xi'an Jiaotong University are contributing fundamental research, while specialized players including Saint-Gobain Ceramics & Plastics and Resonac Holdings are advancing material science applications for enhanced thermal performance and durability.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed proprietary "G-Win" heat exchanger technology that incorporates innovative tube geometry and enhanced fin designs. Their solution features internally grooved copper tubes with optimized refrigerant flow patterns that improve heat transfer coefficients by 25-30% compared to smooth tubes. Gree's cost-benefit analysis demonstrates that while their advanced heat exchangers increase material costs by approximately 8-12%, the improved efficiency reduces energy consumption by 15-20% in air conditioning applications. Their manufacturing approach includes precision tube expansion techniques that ensure optimal thermal contact between tubes and fins, minimizing thermal resistance. Gree has implemented comprehensive lifecycle cost analysis showing that their premium heat exchangers typically recover the additional investment within 2-3 years through reduced energy costs, with cumulative savings of 30-40% over a 10-year operational period for residential and commercial HVAC systems.

Strengths: Excellent energy efficiency improvements; relatively modest cost premium compared to performance gains; proven reliability in diverse operating conditions; compatible with existing manufacturing infrastructure. Weaknesses: Still relies on copper which faces price volatility; moderate weight reduction compared to all-aluminum designs; requires precise manufacturing control to achieve optimal performance.

Danfoss A/S

Technical Solution: Danfoss has developed Micro Plate Heat Exchanger (MPHE) technology that represents a significant advancement over traditional brazed plate heat exchangers. Their innovative dimple pattern design increases turbulence in the flow channels, enhancing heat transfer efficiency by up to 10% while reducing material usage by 30%. Danfoss's cost-benefit analysis shows that their MPHE technology delivers a 20-25% reduction in refrigerant charge and up to 30% reduction in pressure drop compared to conventional designs. The company has implemented advanced manufacturing processes that optimize material distribution, resulting in more efficient heat transfer surfaces while maintaining mechanical integrity. Their economic models demonstrate that despite a 10-15% premium in initial cost, the improved efficiency yields energy savings that typically provide ROI within 18-24 months in commercial refrigeration and HVAC applications.

Strengths: Exceptional heat transfer efficiency; reduced material and refrigerant requirements; lower pressure drop leading to reduced pumping costs; compact design suitable for space-constrained applications. Weaknesses: Higher initial investment; requires more precise manufacturing tolerances; potential challenges in servicing and cleaning in certain applications.

Key Innovations in Heat Transfer Technology

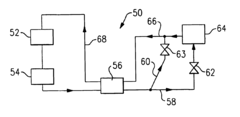

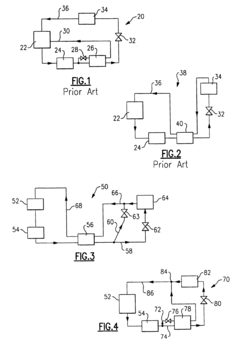

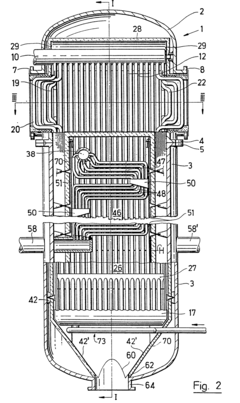

Refrigerant system performance enhancement by use of additional heat exchanger

PatentInactiveUS6826918B1

Innovation

- The refrigerant flow is split into main and secondary paths downstream of the condenser, with an auxiliary heat exchanger positioned downstream, allowing for distinct configurations of flow splitting and recombination, which enables cooling without the need for compressor modifications, similar to economizer cycles but with reduced costs.

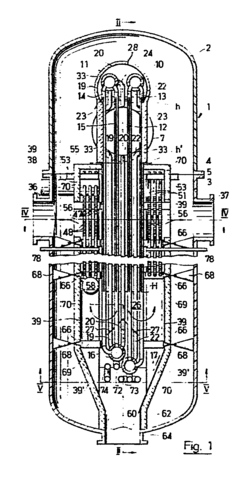

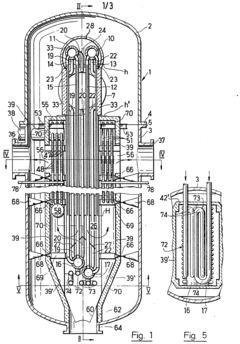

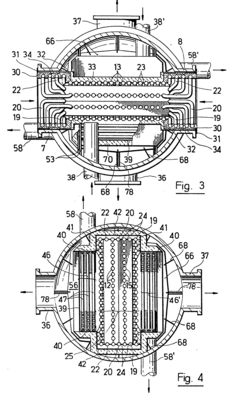

Heat-transfer apparatus for cooling gases contaminated with particles

PatentInactiveEP0085131A1

Innovation

- The design features a simpler structure allowing for easy access and maintenance by removing the chute for top and bottom viewing, using multiple riser shafts with flatter cross-sections, suspending chute walls for easy removal without upper pressure vessel separation, and dividing the heat exchanger into sections for easy inspection and repair, with sootblowers able to guide through pressure vessel walls.

ROI Calculation Methodologies for Heat Exchanger Upgrades

Calculating the Return on Investment (ROI) for heat exchanger upgrades requires a structured methodology that accounts for both direct financial benefits and indirect operational improvements. Traditional ROI calculations often fall short when applied to heat exchanger technologies, as they fail to capture the full spectrum of benefits that extend beyond immediate energy savings.

The most comprehensive approach begins with establishing a clear baseline of current performance metrics, including energy consumption, maintenance costs, downtime frequency, and operational efficiency. This baseline serves as the reference point against which all improvements will be measured. Historical data spanning at least 12-24 months provides the most reliable foundation for these calculations.

For capital expenditure assessment, the Total Cost of Ownership (TCO) methodology proves particularly effective for heat exchanger upgrades. This approach incorporates initial purchase costs, installation expenses, commissioning costs, and projected maintenance requirements over the equipment's lifecycle. Advanced TCO models also factor in the residual value of existing equipment and potential disposal costs.

Energy efficiency gains represent the primary financial benefit in most upgrade scenarios. The Net Present Value (NPV) calculation should incorporate projected energy savings based on improved thermal efficiency, reduced pumping power requirements, and decreased auxiliary system loads. Industry benchmarks suggest modern plate heat exchangers can deliver 20-35% energy efficiency improvements over older shell-and-tube designs in comparable applications.

Maintenance cost reductions constitute another significant ROI component. The Preventive Maintenance Value (PMV) methodology quantifies savings from reduced cleaning frequency, extended service intervals, and decreased parts replacement. For fouling-resistant designs, these savings often account for 15-25% of the total ROI.

Operational benefits require more sophisticated valuation techniques. The Production Impact Assessment (PIA) framework quantifies the financial value of reduced downtime, increased production capacity, and improved product quality. This methodology converts operational improvements into monetary terms by calculating the revenue impact of each percentage point increase in Overall Equipment Effectiveness (OEE).

Environmental compliance benefits should be monetized using the Regulatory Cost Avoidance (RCA) model, which estimates the financial value of reduced emissions, improved waste heat recovery, and decreased water consumption. This approach is particularly relevant as environmental regulations continue to tighten globally.

The Payback Period remains a useful supplementary metric but should be enhanced with Risk-Adjusted Return calculations that incorporate sensitivity analysis for energy price fluctuations, production volume variations, and potential regulatory changes. Most modern heat exchanger upgrades demonstrate payback periods of 12-36 months, depending on application specifics and operating conditions.

The most comprehensive approach begins with establishing a clear baseline of current performance metrics, including energy consumption, maintenance costs, downtime frequency, and operational efficiency. This baseline serves as the reference point against which all improvements will be measured. Historical data spanning at least 12-24 months provides the most reliable foundation for these calculations.

For capital expenditure assessment, the Total Cost of Ownership (TCO) methodology proves particularly effective for heat exchanger upgrades. This approach incorporates initial purchase costs, installation expenses, commissioning costs, and projected maintenance requirements over the equipment's lifecycle. Advanced TCO models also factor in the residual value of existing equipment and potential disposal costs.

Energy efficiency gains represent the primary financial benefit in most upgrade scenarios. The Net Present Value (NPV) calculation should incorporate projected energy savings based on improved thermal efficiency, reduced pumping power requirements, and decreased auxiliary system loads. Industry benchmarks suggest modern plate heat exchangers can deliver 20-35% energy efficiency improvements over older shell-and-tube designs in comparable applications.

Maintenance cost reductions constitute another significant ROI component. The Preventive Maintenance Value (PMV) methodology quantifies savings from reduced cleaning frequency, extended service intervals, and decreased parts replacement. For fouling-resistant designs, these savings often account for 15-25% of the total ROI.

Operational benefits require more sophisticated valuation techniques. The Production Impact Assessment (PIA) framework quantifies the financial value of reduced downtime, increased production capacity, and improved product quality. This methodology converts operational improvements into monetary terms by calculating the revenue impact of each percentage point increase in Overall Equipment Effectiveness (OEE).

Environmental compliance benefits should be monetized using the Regulatory Cost Avoidance (RCA) model, which estimates the financial value of reduced emissions, improved waste heat recovery, and decreased water consumption. This approach is particularly relevant as environmental regulations continue to tighten globally.

The Payback Period remains a useful supplementary metric but should be enhanced with Risk-Adjusted Return calculations that incorporate sensitivity analysis for energy price fluctuations, production volume variations, and potential regulatory changes. Most modern heat exchanger upgrades demonstrate payback periods of 12-36 months, depending on application specifics and operating conditions.

Energy Efficiency Standards and Compliance Requirements

Energy efficiency standards for heat exchangers have evolved significantly over the past decade, creating a complex regulatory landscape that directly impacts upgrade decisions. The U.S. Department of Energy (DOE) has established minimum efficiency requirements through its Appliance and Equipment Standards Program, which mandates specific performance metrics for various types of heat exchange systems. These standards typically require minimum Coefficient of Performance (COP) values ranging from 2.5 to 4.0 depending on system type and application.

European regulations, particularly the Ecodesign Directive (2009/125/EC), impose even stricter requirements with minimum seasonal energy efficiency ratios that exceed U.S. standards by approximately 15-20%. Organizations operating globally must navigate these varying requirements when planning heat exchanger upgrades, often necessitating different specifications for equipment deployed in different regions.

The International Organization for Standardization (ISO) provides framework standards such as ISO 16358 for testing and rating heat exchanger performance. These standards ensure consistent measurement methodologies across manufacturers and regions, facilitating meaningful comparisons between different heat exchanger technologies.

Compliance with these standards carries significant financial implications. Non-compliance penalties can range from $100 to $500 per unit per day of violation in the U.S., while EU penalties can reach up to 10% of annual turnover. Beyond direct penalties, non-compliant organizations face market access restrictions, as retailers and distributors increasingly refuse to carry products that don't meet current efficiency standards.

Tax incentives and rebate programs offer substantial financial benefits for organizations upgrading to high-efficiency heat exchangers. The U.S. federal government provides tax credits covering up to 10% of qualified energy efficiency improvements, while many state and utility programs offer additional rebates ranging from $0.15 to $0.60 per kWh saved annually. These incentives can significantly improve ROI calculations for heat exchanger upgrades, sometimes reducing payback periods by 20-30%.

Emerging carbon pricing mechanisms in various jurisdictions add another layer of financial consideration. Organizations with more efficient heat exchange systems can reduce their carbon tax liability or generate tradable credits in cap-and-trade systems. Current carbon prices range from $15 to $125 per ton of CO2 equivalent, depending on the jurisdiction, creating a direct financial incentive for efficiency improvements that reduce greenhouse gas emissions.

Forward-looking organizations must also consider the trajectory of future regulations. Analysis of regulatory trends suggests efficiency requirements will tighten by approximately 5-10% every five years, potentially rendering recently compliant systems non-compliant within a decade. This regulatory progression must be factored into long-term cost-benefit analyses of heat exchanger upgrades.

European regulations, particularly the Ecodesign Directive (2009/125/EC), impose even stricter requirements with minimum seasonal energy efficiency ratios that exceed U.S. standards by approximately 15-20%. Organizations operating globally must navigate these varying requirements when planning heat exchanger upgrades, often necessitating different specifications for equipment deployed in different regions.

The International Organization for Standardization (ISO) provides framework standards such as ISO 16358 for testing and rating heat exchanger performance. These standards ensure consistent measurement methodologies across manufacturers and regions, facilitating meaningful comparisons between different heat exchanger technologies.

Compliance with these standards carries significant financial implications. Non-compliance penalties can range from $100 to $500 per unit per day of violation in the U.S., while EU penalties can reach up to 10% of annual turnover. Beyond direct penalties, non-compliant organizations face market access restrictions, as retailers and distributors increasingly refuse to carry products that don't meet current efficiency standards.

Tax incentives and rebate programs offer substantial financial benefits for organizations upgrading to high-efficiency heat exchangers. The U.S. federal government provides tax credits covering up to 10% of qualified energy efficiency improvements, while many state and utility programs offer additional rebates ranging from $0.15 to $0.60 per kWh saved annually. These incentives can significantly improve ROI calculations for heat exchanger upgrades, sometimes reducing payback periods by 20-30%.

Emerging carbon pricing mechanisms in various jurisdictions add another layer of financial consideration. Organizations with more efficient heat exchange systems can reduce their carbon tax liability or generate tradable credits in cap-and-trade systems. Current carbon prices range from $15 to $125 per ton of CO2 equivalent, depending on the jurisdiction, creating a direct financial incentive for efficiency improvements that reduce greenhouse gas emissions.

Forward-looking organizations must also consider the trajectory of future regulations. Analysis of regulatory trends suggests efficiency requirements will tighten by approximately 5-10% every five years, potentially rendering recently compliant systems non-compliant within a decade. This regulatory progression must be factored into long-term cost-benefit analyses of heat exchanger upgrades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!