Heat Exchanger in Industrial Refrigeration: Efficiency Metrics

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Refrigeration Heat Exchanger Background and Objectives

Heat exchangers have been fundamental components in industrial refrigeration systems since the early 20th century, evolving from simple tube designs to today's sophisticated plate, shell-and-tube, and microchannel configurations. This technological progression has been driven by the continuous pursuit of higher energy efficiency, reduced environmental impact, and improved system performance in increasingly demanding industrial applications.

The refrigeration industry has witnessed significant transformations over the past decades, particularly in response to regulatory changes concerning refrigerants. The phase-out of CFCs and HCFCs due to their ozone depletion potential, followed by the gradual reduction of HFCs under the Kigali Amendment to the Montreal Protocol, has necessitated continuous adaptation of heat exchanger designs to accommodate new refrigerants with different thermodynamic properties.

Current technological trends in industrial refrigeration heat exchangers focus on enhancing heat transfer coefficients while minimizing pressure drops, reducing material usage through more efficient geometries, and developing surface enhancements that promote turbulence without excessive energy penalties. The miniaturization of heat exchangers has also gained prominence, allowing for more compact system designs without compromising thermal performance.

The primary objective of this technical research is to establish comprehensive efficiency metrics for heat exchangers in industrial refrigeration applications. These metrics must account for thermal performance, pressure drop characteristics, material utilization efficiency, refrigerant charge minimization, and long-term reliability under varying operating conditions. Additionally, the metrics should consider manufacturing complexity and associated costs to provide a holistic evaluation framework.

Another critical goal is to identify the correlation between heat exchanger design parameters and system-level energy efficiency. This includes understanding how heat exchanger performance affects compressor power consumption, defrost frequency requirements, and overall coefficient of performance (COP) across different operating regimes and refrigerant types.

The research also aims to explore emerging technologies that could revolutionize industrial refrigeration heat exchange, including advanced manufacturing techniques like additive manufacturing, novel materials with enhanced thermal conductivity, and surface modifications at the micro and nano scales that can significantly alter heat transfer characteristics.

By establishing standardized efficiency metrics and identifying technological pathways for improvement, this research seeks to provide industry stakeholders with actionable insights for developing next-generation heat exchangers that meet increasingly stringent energy efficiency requirements while accommodating the transition to low-GWP refrigerants and addressing the specific challenges of industrial refrigeration applications.

The refrigeration industry has witnessed significant transformations over the past decades, particularly in response to regulatory changes concerning refrigerants. The phase-out of CFCs and HCFCs due to their ozone depletion potential, followed by the gradual reduction of HFCs under the Kigali Amendment to the Montreal Protocol, has necessitated continuous adaptation of heat exchanger designs to accommodate new refrigerants with different thermodynamic properties.

Current technological trends in industrial refrigeration heat exchangers focus on enhancing heat transfer coefficients while minimizing pressure drops, reducing material usage through more efficient geometries, and developing surface enhancements that promote turbulence without excessive energy penalties. The miniaturization of heat exchangers has also gained prominence, allowing for more compact system designs without compromising thermal performance.

The primary objective of this technical research is to establish comprehensive efficiency metrics for heat exchangers in industrial refrigeration applications. These metrics must account for thermal performance, pressure drop characteristics, material utilization efficiency, refrigerant charge minimization, and long-term reliability under varying operating conditions. Additionally, the metrics should consider manufacturing complexity and associated costs to provide a holistic evaluation framework.

Another critical goal is to identify the correlation between heat exchanger design parameters and system-level energy efficiency. This includes understanding how heat exchanger performance affects compressor power consumption, defrost frequency requirements, and overall coefficient of performance (COP) across different operating regimes and refrigerant types.

The research also aims to explore emerging technologies that could revolutionize industrial refrigeration heat exchange, including advanced manufacturing techniques like additive manufacturing, novel materials with enhanced thermal conductivity, and surface modifications at the micro and nano scales that can significantly alter heat transfer characteristics.

By establishing standardized efficiency metrics and identifying technological pathways for improvement, this research seeks to provide industry stakeholders with actionable insights for developing next-generation heat exchangers that meet increasingly stringent energy efficiency requirements while accommodating the transition to low-GWP refrigerants and addressing the specific challenges of industrial refrigeration applications.

Market Demand Analysis for High-Efficiency Heat Exchangers

The global market for high-efficiency heat exchangers in industrial refrigeration has experienced significant growth over the past decade, driven primarily by increasing energy costs and stringent environmental regulations. Current market analysis indicates that the industrial refrigeration sector accounts for approximately 15% of global energy consumption in industrial processes, creating substantial demand for energy-efficient solutions.

Market research reveals that industries are increasingly prioritizing heat exchangers with higher Coefficient of Performance (COP) ratings and lower energy consumption profiles. This shift is particularly evident in food processing, pharmaceutical manufacturing, and chemical production sectors, where refrigeration represents a major operational cost component. The demand for high-efficiency heat exchangers is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader industrial equipment market.

Regional analysis shows varying demand patterns, with mature markets like North America and Europe focusing on replacement and efficiency upgrades of existing systems. Meanwhile, rapidly industrializing regions in Asia-Pacific and Latin America are driving new installation demand, with China and India leading in market expansion rates. These emerging markets are expected to contribute over 40% of global demand growth in the coming five years.

Energy cost sensitivity has become a primary market driver, with end-users increasingly evaluating heat exchangers based on lifecycle cost rather than initial capital expenditure. Market surveys indicate that industrial customers are willing to pay a premium of up to 30% for heat exchangers that demonstrate energy efficiency improvements of 20% or greater, with return on investment expectations typically set at 2-3 years.

Regulatory influences are reshaping market demands significantly. The phasedown of hydrofluorocarbon (HFC) refrigerants under the Kigali Amendment to the Montreal Protocol has accelerated the transition toward natural refrigerants and low-GWP alternatives, creating new technical requirements for heat exchanger designs. Additionally, minimum energy performance standards (MEPS) in major markets have established efficiency thresholds that are driving innovation and market differentiation.

Customer requirements are evolving beyond pure efficiency metrics to include considerations of physical footprint reduction, maintenance accessibility, and integration with smart monitoring systems. The industrial Internet of Things (IIoT) is creating new market segments for connected heat exchangers that offer predictive maintenance capabilities and real-time efficiency optimization, with this premium segment growing at nearly twice the rate of conventional systems.

Market research reveals that industries are increasingly prioritizing heat exchangers with higher Coefficient of Performance (COP) ratings and lower energy consumption profiles. This shift is particularly evident in food processing, pharmaceutical manufacturing, and chemical production sectors, where refrigeration represents a major operational cost component. The demand for high-efficiency heat exchangers is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader industrial equipment market.

Regional analysis shows varying demand patterns, with mature markets like North America and Europe focusing on replacement and efficiency upgrades of existing systems. Meanwhile, rapidly industrializing regions in Asia-Pacific and Latin America are driving new installation demand, with China and India leading in market expansion rates. These emerging markets are expected to contribute over 40% of global demand growth in the coming five years.

Energy cost sensitivity has become a primary market driver, with end-users increasingly evaluating heat exchangers based on lifecycle cost rather than initial capital expenditure. Market surveys indicate that industrial customers are willing to pay a premium of up to 30% for heat exchangers that demonstrate energy efficiency improvements of 20% or greater, with return on investment expectations typically set at 2-3 years.

Regulatory influences are reshaping market demands significantly. The phasedown of hydrofluorocarbon (HFC) refrigerants under the Kigali Amendment to the Montreal Protocol has accelerated the transition toward natural refrigerants and low-GWP alternatives, creating new technical requirements for heat exchanger designs. Additionally, minimum energy performance standards (MEPS) in major markets have established efficiency thresholds that are driving innovation and market differentiation.

Customer requirements are evolving beyond pure efficiency metrics to include considerations of physical footprint reduction, maintenance accessibility, and integration with smart monitoring systems. The industrial Internet of Things (IIoT) is creating new market segments for connected heat exchangers that offer predictive maintenance capabilities and real-time efficiency optimization, with this premium segment growing at nearly twice the rate of conventional systems.

Current Technology Status and Efficiency Challenges

The global industrial refrigeration market has witnessed significant advancements in heat exchanger technology over the past decade. Current state-of-the-art heat exchangers employ various designs including shell-and-tube, plate, microchannel, and spiral configurations, each optimized for specific applications within industrial refrigeration systems. The efficiency of these systems is typically measured using metrics such as the Overall Heat Transfer Coefficient (U-value), approach temperature, pressure drop, and Energy Efficiency Ratio (EER).

Despite technological progress, industrial refrigeration heat exchangers face several critical challenges. Energy efficiency remains a primary concern, with most systems operating at 60-75% of their theoretical maximum efficiency. This efficiency gap represents significant potential for improvement and energy savings across the industry. Fouling and scaling continue to plague heat exchanger performance, reducing thermal efficiency by up to 30% in systems without proper maintenance protocols.

Material limitations present another substantial challenge. While advanced materials like titanium alloys and specialized polymers offer improved corrosion resistance and thermal properties, their widespread adoption is hindered by cost considerations. Most industrial installations still rely on traditional materials such as copper, aluminum, and stainless steel, which have inherent limitations in extreme operating conditions.

Refrigerant transitions pose a significant technical hurdle. The global phase-down of hydrofluorocarbons (HFCs) has accelerated the adoption of natural refrigerants like ammonia, CO2, and hydrocarbons. However, these alternatives often require redesigned heat exchangers to accommodate their unique thermodynamic properties and safety requirements. This transition necessitates substantial engineering modifications to existing systems.

Geographically, heat exchanger technology development shows distinct patterns. North America and Europe lead in innovation focused on energy efficiency and environmental compliance, while Asian manufacturers, particularly in China and South Korea, have made significant strides in cost-effective manufacturing techniques. Japan continues to excel in miniaturization and precision engineering of compact heat exchangers.

The integration of digital technologies represents both a challenge and opportunity. Advanced monitoring systems using IoT sensors can now track heat exchanger performance in real-time, but the industry struggles with standardization of these technologies and effective utilization of the resulting data streams. Predictive maintenance algorithms show promise but require further refinement to achieve reliable performance across varied operating conditions.

Climate change impacts have introduced additional challenges, with systems designed for specific temperature ranges now operating outside their optimal conditions due to increasing ambient temperatures and more frequent extreme weather events. This necessitates more robust and adaptable heat exchanger designs capable of maintaining efficiency across wider operating parameters.

Despite technological progress, industrial refrigeration heat exchangers face several critical challenges. Energy efficiency remains a primary concern, with most systems operating at 60-75% of their theoretical maximum efficiency. This efficiency gap represents significant potential for improvement and energy savings across the industry. Fouling and scaling continue to plague heat exchanger performance, reducing thermal efficiency by up to 30% in systems without proper maintenance protocols.

Material limitations present another substantial challenge. While advanced materials like titanium alloys and specialized polymers offer improved corrosion resistance and thermal properties, their widespread adoption is hindered by cost considerations. Most industrial installations still rely on traditional materials such as copper, aluminum, and stainless steel, which have inherent limitations in extreme operating conditions.

Refrigerant transitions pose a significant technical hurdle. The global phase-down of hydrofluorocarbons (HFCs) has accelerated the adoption of natural refrigerants like ammonia, CO2, and hydrocarbons. However, these alternatives often require redesigned heat exchangers to accommodate their unique thermodynamic properties and safety requirements. This transition necessitates substantial engineering modifications to existing systems.

Geographically, heat exchanger technology development shows distinct patterns. North America and Europe lead in innovation focused on energy efficiency and environmental compliance, while Asian manufacturers, particularly in China and South Korea, have made significant strides in cost-effective manufacturing techniques. Japan continues to excel in miniaturization and precision engineering of compact heat exchangers.

The integration of digital technologies represents both a challenge and opportunity. Advanced monitoring systems using IoT sensors can now track heat exchanger performance in real-time, but the industry struggles with standardization of these technologies and effective utilization of the resulting data streams. Predictive maintenance algorithms show promise but require further refinement to achieve reliable performance across varied operating conditions.

Climate change impacts have introduced additional challenges, with systems designed for specific temperature ranges now operating outside their optimal conditions due to increasing ambient temperatures and more frequent extreme weather events. This necessitates more robust and adaptable heat exchanger designs capable of maintaining efficiency across wider operating parameters.

Current Efficiency Measurement Methodologies

01 Design optimization for heat exchanger efficiency

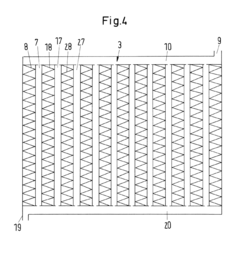

Various design optimizations can significantly improve heat exchanger efficiency. These include modifications to the physical structure, such as optimized tube arrangements, enhanced fin designs, and improved flow patterns. By carefully engineering these elements, heat transfer can be maximized while minimizing pressure drops. These design improvements help to increase the overall thermal efficiency of the heat exchanger system.- Design optimization for heat exchanger efficiency: Various design modifications can significantly improve heat exchanger efficiency. These include optimizing the geometry of heat transfer surfaces, improving flow distribution, and enhancing the overall structure to minimize pressure drops and thermal resistance. Advanced design techniques focus on creating configurations that maximize the contact area between fluids while maintaining optimal flow characteristics, resulting in more efficient heat transfer and reduced energy consumption.

- Enhanced heat transfer surfaces and materials: The selection of materials and surface treatments plays a crucial role in heat exchanger efficiency. High thermal conductivity materials, specialized coatings, and surface modifications such as fins, corrugations, or micro-channels can significantly improve heat transfer rates. These enhancements increase the effective surface area and create turbulence in the fluid flow, leading to better thermal performance while maintaining acceptable pressure drops across the heat exchanger.

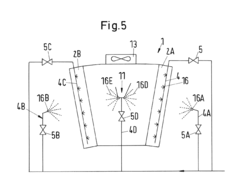

- Flow optimization and distribution techniques: Proper flow distribution and management within heat exchangers significantly impacts their efficiency. Techniques include the implementation of flow distributors, baffles, and optimized channel designs to ensure uniform fluid distribution and prevent dead zones or short-circuiting. Advanced computational fluid dynamics modeling helps in designing flow paths that minimize pressure drops while maximizing heat transfer, resulting in more energy-efficient operation and reduced pumping power requirements.

- Control systems and operational strategies: Intelligent control systems and operational strategies can significantly enhance heat exchanger efficiency. These include adaptive control algorithms, variable flow rate management, and real-time performance monitoring systems. By continuously adjusting operational parameters based on changing conditions and requirements, these systems ensure that heat exchangers operate at optimal efficiency points, reducing energy consumption and extending equipment life while maintaining desired thermal performance.

- Fouling mitigation and maintenance techniques: Fouling is a major factor affecting heat exchanger efficiency over time. Various techniques have been developed to mitigate fouling, including specialized surface treatments, self-cleaning mechanisms, and improved maintenance protocols. Anti-fouling coatings, periodic cleaning procedures, and design features that reduce deposit accumulation help maintain optimal heat transfer rates throughout the operational life of the equipment, reducing the frequency of maintenance shutdowns and preserving energy efficiency.

02 Surface enhancement techniques

Surface enhancement techniques involve modifying the heat transfer surfaces to increase efficiency. This includes adding micro-structures, applying special coatings, or incorporating extended surfaces like fins. These modifications increase the effective heat transfer area and can create turbulence in the fluid flow, which breaks down boundary layers and enhances heat transfer. Surface treatments can also reduce fouling, which maintains efficiency over longer operational periods.Expand Specific Solutions03 Flow control and distribution systems

Proper flow control and distribution systems are crucial for heat exchanger efficiency. These include baffles, distributors, and flow regulators that ensure uniform fluid distribution across the heat transfer surfaces. By optimizing flow patterns and reducing dead zones or bypass flows, these systems maximize the contact between fluids and heat transfer surfaces. Advanced flow control mechanisms can adapt to changing operating conditions to maintain optimal efficiency.Expand Specific Solutions04 Material selection for improved thermal conductivity

The choice of materials significantly impacts heat exchanger efficiency. High thermal conductivity materials like copper, aluminum alloys, and specialized composites can enhance heat transfer rates. Advanced materials may also offer benefits such as corrosion resistance, reduced fouling, or lighter weight. The selection of appropriate materials must balance thermal performance with considerations of cost, durability, and compatibility with the process fluids.Expand Specific Solutions05 Monitoring and control systems for efficiency maintenance

Sophisticated monitoring and control systems help maintain heat exchanger efficiency over time. These include sensors for temperature, pressure, and flow rate measurement, coupled with automated control systems that can adjust operating parameters in real-time. Predictive maintenance algorithms can detect efficiency degradation and schedule cleaning or maintenance before significant performance loss occurs. These systems ensure that heat exchangers operate at optimal efficiency throughout their service life.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The industrial refrigeration heat exchanger market is in a growth phase, with increasing demand for energy-efficient cooling solutions driving innovation. The global market is expanding steadily as industries prioritize sustainability and operational efficiency. Technologically, the sector shows varying maturity levels, with established players like Daikin Industries, Mitsubishi Electric, and Siemens leading conventional technologies, while companies such as Nelumbo and HRL Laboratories push boundaries with advanced materials and designs. Major manufacturers including LG Electronics, Samsung, and Panasonic are investing in smart heat exchanger technologies, while specialized firms like SWEP International and Hudson Technologies focus on application-specific innovations. Research institutions such as Fraunhofer-Gesellschaft and the University of Tokyo are contributing to efficiency breakthroughs, creating a competitive landscape balanced between incremental improvements and disruptive innovations.

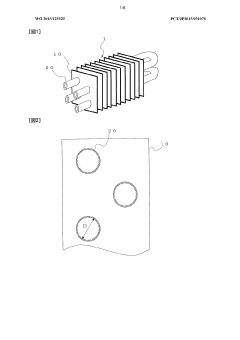

DAIKIN INDUSTRIES Ltd.

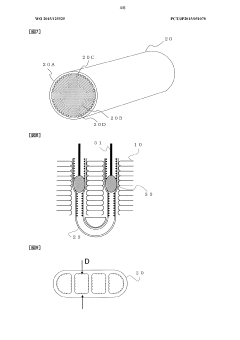

Technical Solution: Daikin has developed advanced microchannel heat exchangers that utilize aluminum flat tubes with multiple small-diameter channels to enhance heat transfer efficiency. Their proprietary "e-Series" heat exchangers incorporate optimized refrigerant flow paths and enhanced fin designs that increase surface area contact with air. Daikin's systems employ variable refrigerant flow (VRF) technology that precisely controls refrigerant distribution based on load demands, achieving up to 30% higher energy efficiency ratios compared to conventional systems. Their heat exchangers feature specialized coatings that prevent corrosion and fouling, maintaining performance over extended operational periods. Daikin has also pioneered the integration of IoT sensors for real-time monitoring of heat exchanger performance metrics, allowing for predictive maintenance and efficiency optimization.

Strengths: Industry-leading energy efficiency ratings, advanced materials research, and comprehensive performance monitoring capabilities. Weaknesses: Higher initial investment costs compared to conventional systems and proprietary technology that may limit compatibility with third-party components.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed their "Zubadan" heat exchanger technology specifically designed for industrial refrigeration applications operating in extreme temperature conditions. Their flash injection circuit system optimizes refrigerant flow by separating liquid and gas phases, significantly improving heat transfer efficiency. Mitsubishi's heat exchangers incorporate diamond-shaped refrigerant pathways that create turbulent flow patterns, enhancing heat transfer coefficients by up to 25% compared to conventional designs. Their systems utilize advanced defrost control algorithms that minimize energy waste during defrost cycles, a critical efficiency factor in industrial refrigeration. Mitsubishi also employs specialized copper tubes with internal grooves that increase surface area and heat transfer rates while maintaining structural integrity under high-pressure conditions.

Strengths: Exceptional cold-climate performance, sophisticated defrost cycle management, and robust construction suitable for industrial environments. Weaknesses: Complex installation requirements and higher maintenance costs for specialized components.

Core Heat Transfer Enhancement Technologies

Heat exchanger and refrigerating cycle device

PatentWO2015125525A1

Innovation

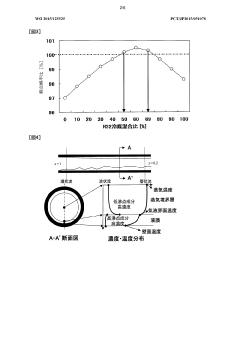

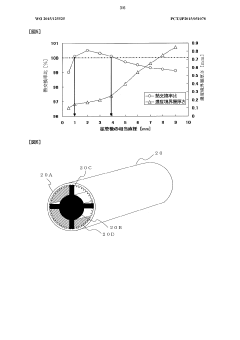

- The heat exchanger features heat transfer tubes with an equivalent diameter of 1 mm ≤ D ≤ 3.9 mm and a weight ratio of HFC32 between 50% to 69% in the refrigerant mixture, reducing the concentration boundary layer thickness and improving heat transfer performance without pressure loss.

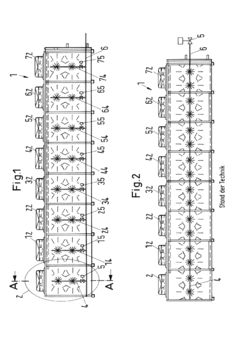

Heat exchanger and method for wetting heat exchangers

PatentActiveEP2696159A1

Innovation

- A heat exchanger with multiple modules, each equipped with independent wetting devices that can be selectively activated to optimize cooling capacity and reduce energy consumption, allowing for precise temperature control and extended service life by sequential wetting of modules.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchangers in industrial refrigeration systems extends far beyond operational efficiency metrics. Refrigeration systems traditionally utilize refrigerants with significant global warming potential (GWP) and ozone depletion potential (ODP). Modern heat exchanger designs are increasingly focused on compatibility with natural refrigerants such as ammonia, CO2, and hydrocarbons, which offer substantially lower environmental impact compared to traditional hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs).

Energy consumption represents another critical environmental consideration, as industrial refrigeration systems account for approximately 15-20% of global industrial electricity usage. Enhanced heat exchanger efficiency directly translates to reduced energy requirements, subsequently lowering greenhouse gas emissions from power generation. Studies indicate that optimized heat exchanger designs can reduce system energy consumption by 20-30%, representing significant carbon footprint reductions across industrial applications.

Material selection for heat exchangers also carries substantial sustainability implications. Traditional materials like copper and aluminum, while offering excellent thermal conductivity, require energy-intensive mining and processing. Emerging sustainable alternatives include recycled metals, bio-based composites, and advanced alloys designed for extended operational lifespans. Life cycle assessment (LCA) methodologies are increasingly employed to evaluate the comprehensive environmental impact of heat exchanger materials from production through disposal.

Water consumption presents another environmental challenge, particularly in water-cooled systems. Advanced heat exchanger designs incorporate water conservation features such as closed-loop systems, water treatment for reuse, and alternative cooling mediums. Dry cooling technologies and hybrid systems that minimize water usage during peak demand periods are gaining prominence in water-stressed regions.

End-of-life considerations for heat exchangers have received growing attention within sustainability frameworks. Design for disassembly, material recovery, and recyclability are becoming standard considerations in modern heat exchanger development. Manufacturers are implementing take-back programs and exploring circular economy models to extend product lifecycles and minimize waste generation.

Regulatory frameworks worldwide are increasingly mandating environmental performance standards for refrigeration equipment. The Kigali Amendment to the Montreal Protocol, European F-Gas Regulation, and various national energy efficiency standards directly impact heat exchanger design requirements. Forward-thinking manufacturers are proactively exceeding these standards, positioning environmental performance as a competitive advantage rather than merely a compliance requirement.

Energy consumption represents another critical environmental consideration, as industrial refrigeration systems account for approximately 15-20% of global industrial electricity usage. Enhanced heat exchanger efficiency directly translates to reduced energy requirements, subsequently lowering greenhouse gas emissions from power generation. Studies indicate that optimized heat exchanger designs can reduce system energy consumption by 20-30%, representing significant carbon footprint reductions across industrial applications.

Material selection for heat exchangers also carries substantial sustainability implications. Traditional materials like copper and aluminum, while offering excellent thermal conductivity, require energy-intensive mining and processing. Emerging sustainable alternatives include recycled metals, bio-based composites, and advanced alloys designed for extended operational lifespans. Life cycle assessment (LCA) methodologies are increasingly employed to evaluate the comprehensive environmental impact of heat exchanger materials from production through disposal.

Water consumption presents another environmental challenge, particularly in water-cooled systems. Advanced heat exchanger designs incorporate water conservation features such as closed-loop systems, water treatment for reuse, and alternative cooling mediums. Dry cooling technologies and hybrid systems that minimize water usage during peak demand periods are gaining prominence in water-stressed regions.

End-of-life considerations for heat exchangers have received growing attention within sustainability frameworks. Design for disassembly, material recovery, and recyclability are becoming standard considerations in modern heat exchanger development. Manufacturers are implementing take-back programs and exploring circular economy models to extend product lifecycles and minimize waste generation.

Regulatory frameworks worldwide are increasingly mandating environmental performance standards for refrigeration equipment. The Kigali Amendment to the Montreal Protocol, European F-Gas Regulation, and various national energy efficiency standards directly impact heat exchanger design requirements. Forward-thinking manufacturers are proactively exceeding these standards, positioning environmental performance as a competitive advantage rather than merely a compliance requirement.

Standardization and Testing Protocols for Performance Metrics

The standardization of performance metrics for heat exchangers in industrial refrigeration systems is crucial for ensuring consistent evaluation and comparison across different technologies and manufacturers. Currently, several international organizations have established testing protocols that serve as benchmarks for the industry. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has developed Standard 15 and Standard 34, which provide guidelines for safety and refrigerant classification, indirectly influencing efficiency testing methodologies.

The International Organization for Standardization (ISO) offers more direct protocols through ISO 15042 and ISO 5151, which outline testing conditions and procedures for determining the coefficient of performance (COP) and energy efficiency ratio (EER) of heat exchangers. These standards ensure that measurements are taken under comparable conditions, allowing for meaningful benchmarking across different systems and geographical regions.

Testing protocols typically require controlled environments with specific temperature differentials, flow rates, and pressure conditions. The standardized testing procedure involves measuring heat transfer rates, pressure drops, and energy consumption under various operating conditions to generate comprehensive performance curves rather than single-point efficiency values.

For industrial refrigeration applications, the International Institute of Refrigeration (IIR) has established specialized protocols that account for the unique requirements of large-scale systems. These protocols emphasize the importance of measuring performance under partial load conditions, as industrial systems rarely operate at full capacity continuously.

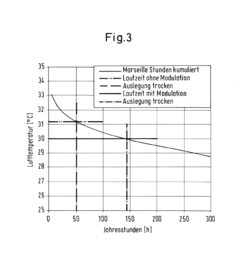

Recent advancements in standardization include the integration of seasonal performance metrics, such as Seasonal Energy Efficiency Ratio (SEER) and Integrated Energy Efficiency Ratio (IEER), which provide more realistic efficiency assessments by considering performance across varying operating conditions throughout the year.

The European Committee for Standardization (CEN) has developed EN 14511 and EN 14825, which are particularly relevant for heat exchangers used in refrigeration systems within the European market. These standards incorporate eco-design requirements and minimum efficiency performance standards (MEPS) that manufacturers must meet to sell their products in the EU.

Emerging testing protocols are beginning to incorporate digital twin technology and computational fluid dynamics (CFD) simulations to complement physical testing, allowing for more comprehensive performance evaluation without the need for extensive physical testing facilities. This hybrid approach is gaining acceptance among certification bodies as simulation technologies become more accurate and reliable.

The International Organization for Standardization (ISO) offers more direct protocols through ISO 15042 and ISO 5151, which outline testing conditions and procedures for determining the coefficient of performance (COP) and energy efficiency ratio (EER) of heat exchangers. These standards ensure that measurements are taken under comparable conditions, allowing for meaningful benchmarking across different systems and geographical regions.

Testing protocols typically require controlled environments with specific temperature differentials, flow rates, and pressure conditions. The standardized testing procedure involves measuring heat transfer rates, pressure drops, and energy consumption under various operating conditions to generate comprehensive performance curves rather than single-point efficiency values.

For industrial refrigeration applications, the International Institute of Refrigeration (IIR) has established specialized protocols that account for the unique requirements of large-scale systems. These protocols emphasize the importance of measuring performance under partial load conditions, as industrial systems rarely operate at full capacity continuously.

Recent advancements in standardization include the integration of seasonal performance metrics, such as Seasonal Energy Efficiency Ratio (SEER) and Integrated Energy Efficiency Ratio (IEER), which provide more realistic efficiency assessments by considering performance across varying operating conditions throughout the year.

The European Committee for Standardization (CEN) has developed EN 14511 and EN 14825, which are particularly relevant for heat exchangers used in refrigeration systems within the European market. These standards incorporate eco-design requirements and minimum efficiency performance standards (MEPS) that manufacturers must meet to sell their products in the EU.

Emerging testing protocols are beginning to incorporate digital twin technology and computational fluid dynamics (CFD) simulations to complement physical testing, allowing for more comprehensive performance evaluation without the need for extensive physical testing facilities. This hybrid approach is gaining acceptance among certification bodies as simulation technologies become more accurate and reliable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!