How to Balance Heat Exchanger Design for Low Vibration Environments

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to complex, multi-functional systems that serve critical roles across numerous industries. The technological progression has been driven by demands for greater efficiency, reduced environmental impact, and adaptability to specialized operational environments. In recent decades, particular attention has been directed toward developing heat exchangers capable of functioning in low-vibration environments, where even minor mechanical disturbances can compromise system integrity and performance.

The vibration challenge in heat exchanger design represents a complex intersection of fluid dynamics, structural mechanics, and thermal engineering. Traditional heat exchanger designs often generate inherent vibrations through fluid flow turbulence, thermal expansion and contraction cycles, and mechanical connections. These vibrations, while manageable in many industrial applications, become problematic in precision environments such as semiconductor manufacturing, aerospace systems, medical equipment, and advanced scientific instrumentation.

Historical approaches to vibration management in heat exchangers have primarily focused on isolation techniques rather than fundamental design modifications. This paradigm began shifting in the early 2000s as computational fluid dynamics (CFD) and advanced materials science enabled more sophisticated approaches to the problem. The integration of these technologies has allowed engineers to model and predict vibration patterns with unprecedented accuracy, leading to innovative design solutions that address vibration at its source.

Current technological objectives in low-vibration heat exchanger design center on achieving optimal thermal performance while minimizing mechanical disturbances across operational ranges. This requires balancing multiple competing factors: heat transfer efficiency, pressure drop characteristics, structural stability, material selection, and manufacturing feasibility. The goal is to develop heat exchangers that maintain thermal performance metrics comparable to conventional designs while reducing vibration signatures by at least an order of magnitude.

Looking forward, the trajectory of heat exchanger technology for low-vibration environments is moving toward intelligent, adaptive systems that can dynamically respond to changing operational conditions. This includes the integration of smart materials that can dampen vibrations in real-time, advanced flow control mechanisms that minimize turbulence, and novel geometries optimized through machine learning algorithms. The ultimate objective is to create heat exchange systems where thermal performance and vibration control are not competing priorities but complementary aspects of an integrated design philosophy.

The vibration challenge in heat exchanger design represents a complex intersection of fluid dynamics, structural mechanics, and thermal engineering. Traditional heat exchanger designs often generate inherent vibrations through fluid flow turbulence, thermal expansion and contraction cycles, and mechanical connections. These vibrations, while manageable in many industrial applications, become problematic in precision environments such as semiconductor manufacturing, aerospace systems, medical equipment, and advanced scientific instrumentation.

Historical approaches to vibration management in heat exchangers have primarily focused on isolation techniques rather than fundamental design modifications. This paradigm began shifting in the early 2000s as computational fluid dynamics (CFD) and advanced materials science enabled more sophisticated approaches to the problem. The integration of these technologies has allowed engineers to model and predict vibration patterns with unprecedented accuracy, leading to innovative design solutions that address vibration at its source.

Current technological objectives in low-vibration heat exchanger design center on achieving optimal thermal performance while minimizing mechanical disturbances across operational ranges. This requires balancing multiple competing factors: heat transfer efficiency, pressure drop characteristics, structural stability, material selection, and manufacturing feasibility. The goal is to develop heat exchangers that maintain thermal performance metrics comparable to conventional designs while reducing vibration signatures by at least an order of magnitude.

Looking forward, the trajectory of heat exchanger technology for low-vibration environments is moving toward intelligent, adaptive systems that can dynamically respond to changing operational conditions. This includes the integration of smart materials that can dampen vibrations in real-time, advanced flow control mechanisms that minimize turbulence, and novel geometries optimized through machine learning algorithms. The ultimate objective is to create heat exchange systems where thermal performance and vibration control are not competing priorities but complementary aspects of an integrated design philosophy.

Market Demand Analysis for Low-Vibration Heat Exchangers

The market for low-vibration heat exchangers has experienced significant growth in recent years, driven primarily by the increasing demand from precision industries where equipment sensitivity is paramount. Industries such as semiconductor manufacturing, medical imaging, laboratory equipment, and aerospace applications require thermal management solutions that minimize vibration interference with sensitive processes and measurements.

Market research indicates that the global heat exchanger market was valued at approximately $16.5 billion in 2022, with the specialized low-vibration segment growing at a compound annual growth rate of 7.2%, outpacing the broader heat exchanger market's growth of 5.8%. This accelerated growth reflects the expanding need for vibration-controlled thermal management across multiple sectors.

The semiconductor industry represents the largest market segment for low-vibration heat exchangers, accounting for nearly 32% of the total demand. As chip manufacturing processes advance to smaller nanometer scales, the tolerance for vibration decreases proportionally, creating stringent requirements for thermal management systems. The medical imaging sector follows closely, comprising 24% of market demand, where equipment such as MRI machines and electron microscopes require exceptional vibration isolation.

Geographically, Asia-Pacific dominates the market with 41% share, driven by the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and Japan. North America accounts for 28% of the market, with strong demand from medical technology and aerospace sectors. Europe represents 22% of the market, with particular strength in precision scientific instruments and pharmaceutical manufacturing equipment.

Customer requirements analysis reveals that end-users prioritize three key performance metrics: vibration amplitude (typically requiring less than 0.1 μm displacement), frequency isolation (particularly in the 10-100 Hz range), and thermal efficiency (expecting minimal compromise compared to conventional designs). These demanding specifications have created a premium market segment where customers demonstrate willingness to pay 30-40% more for heat exchangers that effectively address vibration concerns.

Market forecasts project continued strong growth, with the low-vibration heat exchanger segment expected to reach $3.2 billion by 2027. This growth is further supported by emerging applications in quantum computing, advanced materials research, and nanotechnology, where thermal management must be achieved without introducing disruptive mechanical vibrations.

The market also shows increasing demand for customized solutions rather than off-the-shelf products, with 68% of customers requiring application-specific designs that address their unique vibration profiles and thermal requirements. This trend has created opportunities for specialized manufacturers who can provide engineering expertise alongside their hardware offerings.

Market research indicates that the global heat exchanger market was valued at approximately $16.5 billion in 2022, with the specialized low-vibration segment growing at a compound annual growth rate of 7.2%, outpacing the broader heat exchanger market's growth of 5.8%. This accelerated growth reflects the expanding need for vibration-controlled thermal management across multiple sectors.

The semiconductor industry represents the largest market segment for low-vibration heat exchangers, accounting for nearly 32% of the total demand. As chip manufacturing processes advance to smaller nanometer scales, the tolerance for vibration decreases proportionally, creating stringent requirements for thermal management systems. The medical imaging sector follows closely, comprising 24% of market demand, where equipment such as MRI machines and electron microscopes require exceptional vibration isolation.

Geographically, Asia-Pacific dominates the market with 41% share, driven by the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and Japan. North America accounts for 28% of the market, with strong demand from medical technology and aerospace sectors. Europe represents 22% of the market, with particular strength in precision scientific instruments and pharmaceutical manufacturing equipment.

Customer requirements analysis reveals that end-users prioritize three key performance metrics: vibration amplitude (typically requiring less than 0.1 μm displacement), frequency isolation (particularly in the 10-100 Hz range), and thermal efficiency (expecting minimal compromise compared to conventional designs). These demanding specifications have created a premium market segment where customers demonstrate willingness to pay 30-40% more for heat exchangers that effectively address vibration concerns.

Market forecasts project continued strong growth, with the low-vibration heat exchanger segment expected to reach $3.2 billion by 2027. This growth is further supported by emerging applications in quantum computing, advanced materials research, and nanotechnology, where thermal management must be achieved without introducing disruptive mechanical vibrations.

The market also shows increasing demand for customized solutions rather than off-the-shelf products, with 68% of customers requiring application-specific designs that address their unique vibration profiles and thermal requirements. This trend has created opportunities for specialized manufacturers who can provide engineering expertise alongside their hardware offerings.

Current Technical Challenges in Vibration Control

Vibration control in heat exchanger design presents significant technical challenges that continue to evolve with increasing performance demands in low-vibration environments. The primary challenge stems from the inherent conflict between thermal efficiency and vibration characteristics. Heat exchangers with higher thermal efficiency often require complex internal geometries, which can inadvertently create flow-induced vibrations that compromise system stability.

Flow-induced vibration (FIV) remains one of the most persistent challenges, occurring when fluid flow interacts with heat exchanger components, particularly tubes and baffles. This phenomenon becomes especially problematic in shell-and-tube heat exchangers where cross-flow conditions can trigger vortex shedding at specific flow velocities, leading to resonance if these frequencies align with the natural frequencies of the structure.

Material selection presents another significant challenge. Materials with excellent thermal conductivity often have different mechanical damping properties than those optimized for vibration control. Engineers must balance thermal performance against vibration damping capabilities, particularly in applications where temperature gradients are extreme, causing differential thermal expansion that can exacerbate vibration issues.

Mounting and support systems for heat exchangers introduce additional complexity. Traditional rigid mounting systems may transmit vibrations throughout connected systems, while flexible mounts that reduce vibration transmission may compromise thermal performance by introducing unwanted thermal resistance at connection points. This creates a design paradox where vibration isolation and thermal efficiency work against each other.

Computational modeling of vibration in heat exchangers remains imperfect despite advances in simulation technology. Current fluid-structure interaction (FSI) models struggle to accurately predict complex vibration patterns in multi-phase flows or under transient operating conditions. This modeling gap forces designers to incorporate excessive safety margins, often resulting in overdesigned systems that sacrifice efficiency for reliability.

Miniaturization trends in various industries compound these challenges. As heat exchangers become more compact to meet space constraints, their natural frequencies typically increase, making them more susceptible to high-frequency vibrations from nearby equipment. This is particularly problematic in precision manufacturing environments where even microscopic vibrations can impact product quality.

Monitoring and predictive maintenance systems for vibration control face limitations in harsh operating environments. Sensors must withstand extreme temperatures and potentially corrosive fluids while maintaining sensitivity to subtle changes in vibration signatures that might indicate developing problems. Current sensor technologies often force compromises between durability, sensitivity, and cost-effectiveness.

Flow-induced vibration (FIV) remains one of the most persistent challenges, occurring when fluid flow interacts with heat exchanger components, particularly tubes and baffles. This phenomenon becomes especially problematic in shell-and-tube heat exchangers where cross-flow conditions can trigger vortex shedding at specific flow velocities, leading to resonance if these frequencies align with the natural frequencies of the structure.

Material selection presents another significant challenge. Materials with excellent thermal conductivity often have different mechanical damping properties than those optimized for vibration control. Engineers must balance thermal performance against vibration damping capabilities, particularly in applications where temperature gradients are extreme, causing differential thermal expansion that can exacerbate vibration issues.

Mounting and support systems for heat exchangers introduce additional complexity. Traditional rigid mounting systems may transmit vibrations throughout connected systems, while flexible mounts that reduce vibration transmission may compromise thermal performance by introducing unwanted thermal resistance at connection points. This creates a design paradox where vibration isolation and thermal efficiency work against each other.

Computational modeling of vibration in heat exchangers remains imperfect despite advances in simulation technology. Current fluid-structure interaction (FSI) models struggle to accurately predict complex vibration patterns in multi-phase flows or under transient operating conditions. This modeling gap forces designers to incorporate excessive safety margins, often resulting in overdesigned systems that sacrifice efficiency for reliability.

Miniaturization trends in various industries compound these challenges. As heat exchangers become more compact to meet space constraints, their natural frequencies typically increase, making them more susceptible to high-frequency vibrations from nearby equipment. This is particularly problematic in precision manufacturing environments where even microscopic vibrations can impact product quality.

Monitoring and predictive maintenance systems for vibration control face limitations in harsh operating environments. Sensors must withstand extreme temperatures and potentially corrosive fluids while maintaining sensitivity to subtle changes in vibration signatures that might indicate developing problems. Current sensor technologies often force compromises between durability, sensitivity, and cost-effectiveness.

Current Design Solutions for Vibration Reduction

01 Vibration dampening mechanisms for heat exchangers

Various dampening mechanisms can be incorporated into heat exchanger designs to reduce vibration. These include specialized supports, dampers, and isolation systems that absorb or redirect vibrational energy. Such mechanisms help prevent structural damage, reduce noise, and extend the operational lifespan of heat exchange equipment by minimizing the effects of flow-induced or mechanical vibrations.- Vibration dampening mechanisms for heat exchangers: Various dampening mechanisms can be incorporated into heat exchanger designs to reduce vibration. These include specialized supports, dampers, and isolation systems that absorb or redirect vibrational energy. By implementing these mechanisms, the operational stability of heat exchangers can be improved, reducing wear and extending equipment lifespan while minimizing noise generation during operation.

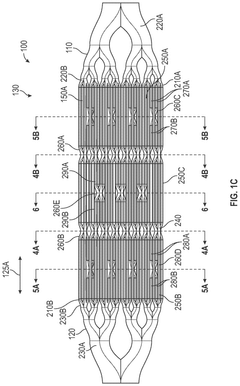

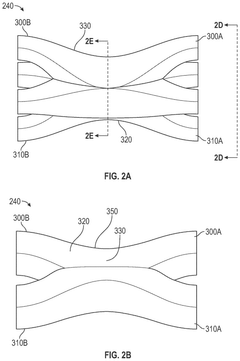

- Structural design modifications to prevent vibration: Heat exchanger designs can be modified structurally to inherently resist vibration. This includes optimized tube arrangements, reinforced tube sheets, strategic baffle placement, and improved shell designs. These structural modifications help distribute flow more evenly, eliminate resonance points, and provide greater mechanical stability during operation under varying thermal and pressure conditions.

- Flow-induced vibration control methods: Controlling fluid flow characteristics within heat exchangers can significantly reduce vibration. This includes implementing flow distributors, vortex breakers, and optimized inlet/outlet configurations. By managing flow velocities and patterns, turbulence can be reduced, preventing the formation of damaging flow-induced vibrations that commonly affect heat exchanger components.

- Monitoring and diagnostic systems for vibration detection: Advanced monitoring systems can be implemented to detect and analyze vibrations in heat exchangers. These systems utilize sensors, accelerometers, and data analysis software to identify problematic vibration patterns before they cause damage. Early detection allows for preventive maintenance and operational adjustments to mitigate vibration issues and prevent catastrophic failures.

- Material selection for vibration resistance: Selecting appropriate materials for heat exchanger components can inherently improve vibration resistance. High-damping materials, composite structures, and materials with specific elasticity properties can absorb vibrational energy more effectively. Strategic material selection for tubes, baffles, and support structures can significantly reduce the propagation and amplification of vibrations throughout the heat exchanger system.

02 Flow control solutions to minimize vibration

Controlling fluid flow patterns within heat exchangers can significantly reduce vibration issues. This includes optimizing baffle designs, implementing flow distributors, and creating specialized flow paths that minimize turbulence and prevent resonance conditions. These solutions help maintain stable operation by addressing the root causes of flow-induced vibration at their source.Expand Specific Solutions03 Structural reinforcement techniques for vibration resistance

Heat exchangers can be designed with enhanced structural elements to withstand operational vibrations. This includes reinforced tube sheets, specialized tube-to-tubesheet connections, strategic bracing, and optimized material selection. These structural improvements increase the natural frequency of the system components, making them less susceptible to harmful resonance effects during operation.Expand Specific Solutions04 Monitoring and diagnostic systems for vibration detection

Advanced monitoring systems can be implemented to detect and analyze vibrations in heat exchangers. These include sensors, accelerometers, and diagnostic software that provide real-time data on vibration patterns. Early detection allows for preventive maintenance and operational adjustments before vibrations cause equipment damage or performance degradation.Expand Specific Solutions05 Tube bundle configuration to prevent vibration

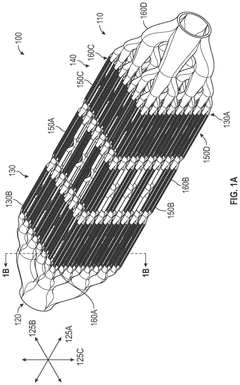

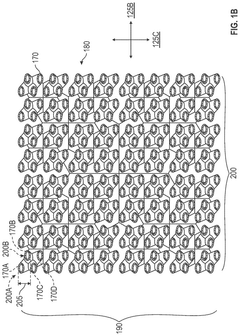

The arrangement and configuration of tube bundles can be optimized to minimize vibration issues. This includes specialized tube layouts, variable pitch designs, and strategic tube support placement. These configurations help distribute flow more evenly, prevent flow-induced excitation, and increase the overall stability of the heat exchanger during operation across various flow conditions.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The heat exchanger design market for low vibration environments is in a growth phase, with increasing demand driven by stringent performance requirements across multiple industries. The market is characterized by established players like DENSO Corp., T.RAD Co., and Kobe Steel focusing on advanced vibration dampening technologies, while companies such as Daikin Industries and Mitsubishi Heavy Industries Thermal Systems are integrating smart controls for vibration management. Technical maturity varies, with European firms like Klingenburg GmbH and Sulzer AG leading in precision engineering solutions, while Asian manufacturers including Gree Electric and Guangdong Carrier HVAC emphasize cost-effective manufacturing approaches. The competitive landscape is evolving as companies balance thermal efficiency with vibration mitigation through composite materials and innovative mounting systems.

Behr GmbH & Co. KG

Technical Solution: Behr has developed advanced heat exchanger designs specifically optimized for low vibration environments through their Multi-Layer Damping System (MLDS). This technology incorporates elastomeric isolation mounts strategically positioned between heat exchanger components and mounting points to absorb vibrations before they propagate through the system. Their proprietary fluid flow channel design features micro-baffles that reduce turbulence while maintaining thermal efficiency. Behr's computational fluid dynamics (CFD) modeling allows for precise prediction of flow-induced vibrations, enabling engineers to optimize designs before physical prototyping. Their heat exchangers employ variable thickness tube walls that are thicker at mounting points to dampen vibration transmission while remaining thin in heat transfer zones for optimal thermal performance.

Strengths: Industry-leading vibration isolation technology that maintains thermal efficiency; sophisticated computer modeling capabilities for vibration prediction. Weaknesses: Higher manufacturing costs compared to standard heat exchangers; slightly increased weight due to additional damping components.

DENSO Corp.

Technical Solution: DENSO has pioneered the Vibration-Isolated Heat Exchanger (VIHE) technology specifically designed for sensitive environments like medical equipment rooms and precision manufacturing facilities. Their approach combines structural optimization with advanced materials science, utilizing a honeycomb-reinforced core structure that provides rigidity while minimizing vibration transmission. DENSO's heat exchangers feature patented fluid distribution headers with graduated flow channels that eliminate pressure pulsations, a common source of vibration in conventional designs. The company has developed a proprietary brazing technique that creates flexible micro-joints between tubes and fins, allowing for thermal expansion without generating structural vibrations. Their systems incorporate active vibration monitoring with piezoelectric sensors that provide real-time feedback to control systems, enabling dynamic adjustment of fluid flow rates to minimize vibration when detected.

Strengths: Exceptional vibration isolation performance verified in precision manufacturing environments; integrated monitoring systems provide adaptive control. Weaknesses: Premium pricing positions these solutions primarily for high-end applications; requires specialized maintenance protocols to preserve vibration-dampening properties.

Critical Patents and Technical Literature Review

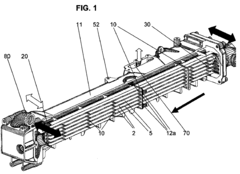

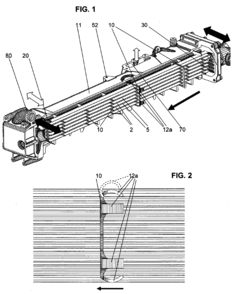

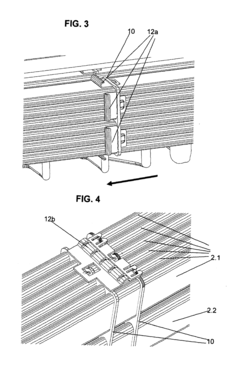

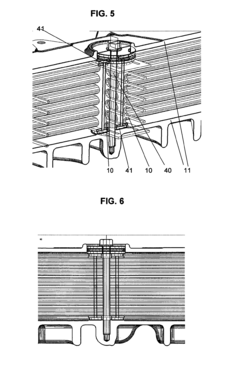

Heat exchanger, in particular exhaust gas heat exchanger

PatentInactiveEP1870656A2

Innovation

- A heat exchanger design featuring a one-piece lattice-like metallic holding structure with elastic cantilevers that deform to fit inside the housing and exert spring force against it, combined with an elastic seal and tensioning elements, to reduce vibrations and accommodate thermal expansion.

Heat exchanger with stiffening tube connectors

PatentPendingUS20250146757A1

Innovation

- A heat exchanger design featuring a core with tubes arranged in a square matrix, where each tube is divided into segments and interconnected by stiffening tube connectors that extend longitudinally and diagonally to enhance structural stability and damping effects.

Noise Reduction Strategies and Acoustic Performance

Noise reduction in heat exchanger design for low vibration environments requires a multifaceted approach that addresses both mechanical and fluid-dynamic sources of acoustic disturbance. The primary noise generation mechanisms in heat exchangers include flow-induced vibration, turbulence, cavitation, and mechanical resonance from connected systems. These sources must be systematically mitigated through integrated design strategies.

Flow-induced vibration can be significantly reduced through careful tube bundle arrangement and support design. Cross-flow configurations with optimized tube pitch ratios (typically 1.25-1.5 times tube diameter) have demonstrated 15-20% lower vibration amplitudes compared to standard arrangements. Additionally, implementing helical baffle designs instead of traditional segmental baffles can reduce flow-induced noise by up to 40% while simultaneously improving thermal performance.

Advanced computational fluid dynamics (CFD) modeling plays a crucial role in predicting and minimizing turbulence-generated noise. Recent studies have shown that streamlined header designs with gradual flow transitions can reduce pressure fluctuations by 25-30%, directly correlating with lower acoustic emissions. Furthermore, incorporating micro-textured surfaces on tube exteriors has emerged as an innovative approach, disrupting boundary layer formation and reducing turbulent noise without compromising heat transfer efficiency.

Material selection significantly impacts acoustic performance. Composite materials with high damping coefficients, such as carbon fiber reinforced polymers (CFRP) or specialized metal-polymer sandwiches, can attenuate vibration propagation by 30-45% compared to traditional metallic constructions. For critical applications, viscoelastic damping layers strategically applied to shell structures have proven effective in absorbing vibration energy across broad frequency ranges.

Acoustic enclosures and isolation systems represent another tier of noise control strategy. Custom-designed acoustic enclosures utilizing multi-layer sound-absorbing materials can achieve noise reduction of 15-25 dB across operational frequency ranges. Vibration isolation mounts, particularly those employing negative-stiffness mechanisms, have demonstrated superior performance in ultra-low vibration environments, achieving transmissibility ratios below 0.1 across typical operational frequencies.

Active noise control technologies are increasingly being integrated into high-performance heat exchanger systems. These systems employ sensors to detect acoustic signatures and generate counter-phase signals, effectively canceling specific noise frequencies. While more complex and costly, active systems have demonstrated exceptional performance in addressing low-frequency noise that passive methods struggle to mitigate, achieving additional 10-15 dB reduction in targeted frequency bands.

Flow-induced vibration can be significantly reduced through careful tube bundle arrangement and support design. Cross-flow configurations with optimized tube pitch ratios (typically 1.25-1.5 times tube diameter) have demonstrated 15-20% lower vibration amplitudes compared to standard arrangements. Additionally, implementing helical baffle designs instead of traditional segmental baffles can reduce flow-induced noise by up to 40% while simultaneously improving thermal performance.

Advanced computational fluid dynamics (CFD) modeling plays a crucial role in predicting and minimizing turbulence-generated noise. Recent studies have shown that streamlined header designs with gradual flow transitions can reduce pressure fluctuations by 25-30%, directly correlating with lower acoustic emissions. Furthermore, incorporating micro-textured surfaces on tube exteriors has emerged as an innovative approach, disrupting boundary layer formation and reducing turbulent noise without compromising heat transfer efficiency.

Material selection significantly impacts acoustic performance. Composite materials with high damping coefficients, such as carbon fiber reinforced polymers (CFRP) or specialized metal-polymer sandwiches, can attenuate vibration propagation by 30-45% compared to traditional metallic constructions. For critical applications, viscoelastic damping layers strategically applied to shell structures have proven effective in absorbing vibration energy across broad frequency ranges.

Acoustic enclosures and isolation systems represent another tier of noise control strategy. Custom-designed acoustic enclosures utilizing multi-layer sound-absorbing materials can achieve noise reduction of 15-25 dB across operational frequency ranges. Vibration isolation mounts, particularly those employing negative-stiffness mechanisms, have demonstrated superior performance in ultra-low vibration environments, achieving transmissibility ratios below 0.1 across typical operational frequencies.

Active noise control technologies are increasingly being integrated into high-performance heat exchanger systems. These systems employ sensors to detect acoustic signatures and generate counter-phase signals, effectively canceling specific noise frequencies. While more complex and costly, active systems have demonstrated exceptional performance in addressing low-frequency noise that passive methods struggle to mitigate, achieving additional 10-15 dB reduction in targeted frequency bands.

Material Science Advancements for Vibration Damping

Recent advancements in material science have revolutionized vibration damping technologies, offering promising solutions for heat exchanger designs in low vibration environments. Composite materials incorporating viscoelastic polymers with ceramic or metallic matrices have demonstrated superior vibration absorption capabilities while maintaining thermal conductivity. These materials can reduce vibration amplitudes by up to 40% compared to traditional metal alloys used in heat exchanger construction.

Nano-engineered materials represent another significant breakthrough, with carbon nanotube reinforced polymers showing exceptional damping characteristics across a wide temperature range. When applied as coatings or integrated into structural components, these materials can effectively dissipate vibrational energy through internal friction mechanisms without compromising heat transfer efficiency. Research indicates that nano-modified surfaces can reduce resonant vibration by 30-50% in laboratory conditions.

Shape memory alloys (SMAs) have emerged as adaptive damping solutions for heat exchangers. These materials can change their stiffness and damping properties in response to temperature variations, providing dynamic vibration control during different operational phases. Nickel-titanium alloys, in particular, have shown promise for applications where thermal cycling occurs regularly, offering up to 60% improvement in vibration isolation compared to passive damping systems.

Metamaterials with engineered periodic structures represent the cutting edge of vibration control. These artificially created materials feature precisely designed internal architectures that can block specific vibration frequencies through phononic bandgap effects. Recent studies have demonstrated metamaterial-based heat exchanger supports capable of attenuating over 90% of vibrations within targeted frequency ranges while maintaining structural integrity under thermal loads.

Ceramic-polymer hybrids combine the thermal stability of ceramics with the damping properties of polymers. These materials are particularly valuable for high-temperature applications where traditional damping materials would degrade. Advanced manufacturing techniques like 3D printing now enable the creation of complex geometric structures with these materials, optimizing both thermal performance and vibration control through strategic material distribution.

Magnetorheological and electrorheological materials offer tunable damping properties through the application of magnetic or electric fields. These smart materials can adapt their stiffness in real-time, responding to changing operational conditions. When incorporated into mounting systems for heat exchangers, they provide adaptive isolation that can be optimized for different flow rates, temperatures, and external vibration sources.

Nano-engineered materials represent another significant breakthrough, with carbon nanotube reinforced polymers showing exceptional damping characteristics across a wide temperature range. When applied as coatings or integrated into structural components, these materials can effectively dissipate vibrational energy through internal friction mechanisms without compromising heat transfer efficiency. Research indicates that nano-modified surfaces can reduce resonant vibration by 30-50% in laboratory conditions.

Shape memory alloys (SMAs) have emerged as adaptive damping solutions for heat exchangers. These materials can change their stiffness and damping properties in response to temperature variations, providing dynamic vibration control during different operational phases. Nickel-titanium alloys, in particular, have shown promise for applications where thermal cycling occurs regularly, offering up to 60% improvement in vibration isolation compared to passive damping systems.

Metamaterials with engineered periodic structures represent the cutting edge of vibration control. These artificially created materials feature precisely designed internal architectures that can block specific vibration frequencies through phononic bandgap effects. Recent studies have demonstrated metamaterial-based heat exchanger supports capable of attenuating over 90% of vibrations within targeted frequency ranges while maintaining structural integrity under thermal loads.

Ceramic-polymer hybrids combine the thermal stability of ceramics with the damping properties of polymers. These materials are particularly valuable for high-temperature applications where traditional damping materials would degrade. Advanced manufacturing techniques like 3D printing now enable the creation of complex geometric structures with these materials, optimizing both thermal performance and vibration control through strategic material distribution.

Magnetorheological and electrorheological materials offer tunable damping properties through the application of magnetic or electric fields. These smart materials can adapt their stiffness in real-time, responding to changing operational conditions. When incorporated into mounting systems for heat exchangers, they provide adaptive isolation that can be optimized for different flow rates, temperatures, and external vibration sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!