Heat Exchanger vs Combustion Furnace: Efficiency Standard

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchange Technology Evolution and Objectives

Heat exchange technology has evolved significantly since the early 20th century, transitioning from rudimentary designs to sophisticated systems that maximize thermal efficiency. The initial development focused on basic shell-and-tube heat exchangers, which provided limited efficiency but established fundamental principles of heat transfer between fluids. By mid-century, plate heat exchangers emerged, offering improved surface area-to-volume ratios and enhanced thermal performance.

The 1970s energy crisis catalyzed innovation in heat exchange technology, driving research toward minimizing energy losses and optimizing thermal transfer coefficients. This period saw the introduction of compact heat exchangers and the refinement of materials resistant to high temperatures and corrosion, significantly extending operational lifespans and reliability.

Recent decades have witnessed revolutionary advancements in heat exchanger design, including microchannel technology, 3D-printed geometries, and smart heat exchange systems with integrated sensors for real-time monitoring and adjustment. These innovations have dramatically improved efficiency metrics, with modern systems achieving thermal effectiveness ratings exceeding 95% in optimal conditions.

In contrast, combustion furnace technology has followed a parallel but distinct evolutionary path. Traditional furnaces operated at thermal efficiencies of 50-70%, with substantial heat loss through exhaust gases. Modern high-efficiency furnaces incorporate condensing technology to capture latent heat from water vapor in exhaust gases, pushing efficiency ratings above 90%.

The primary objective in comparing heat exchangers and combustion furnaces is establishing standardized efficiency metrics that accurately reflect real-world performance across diverse operational conditions. Current standards often fail to account for variable load conditions, seasonal fluctuations, and system degradation over time, leading to performance gaps between laboratory ratings and field results.

Technical goals include developing comprehensive efficiency standards that incorporate both steady-state and dynamic performance parameters, creating unified testing protocols applicable across different system scales and applications, and establishing clear methodologies for lifecycle efficiency assessment that account for maintenance requirements and component degradation.

Additional objectives focus on quantifying environmental impact metrics alongside traditional efficiency measures, integrating renewable energy compatibility into standard evaluations, and developing predictive models that can accurately forecast system performance under variable conditions. These advancements aim to provide industry stakeholders with more reliable comparative data for system selection and optimization.

The 1970s energy crisis catalyzed innovation in heat exchange technology, driving research toward minimizing energy losses and optimizing thermal transfer coefficients. This period saw the introduction of compact heat exchangers and the refinement of materials resistant to high temperatures and corrosion, significantly extending operational lifespans and reliability.

Recent decades have witnessed revolutionary advancements in heat exchanger design, including microchannel technology, 3D-printed geometries, and smart heat exchange systems with integrated sensors for real-time monitoring and adjustment. These innovations have dramatically improved efficiency metrics, with modern systems achieving thermal effectiveness ratings exceeding 95% in optimal conditions.

In contrast, combustion furnace technology has followed a parallel but distinct evolutionary path. Traditional furnaces operated at thermal efficiencies of 50-70%, with substantial heat loss through exhaust gases. Modern high-efficiency furnaces incorporate condensing technology to capture latent heat from water vapor in exhaust gases, pushing efficiency ratings above 90%.

The primary objective in comparing heat exchangers and combustion furnaces is establishing standardized efficiency metrics that accurately reflect real-world performance across diverse operational conditions. Current standards often fail to account for variable load conditions, seasonal fluctuations, and system degradation over time, leading to performance gaps between laboratory ratings and field results.

Technical goals include developing comprehensive efficiency standards that incorporate both steady-state and dynamic performance parameters, creating unified testing protocols applicable across different system scales and applications, and establishing clear methodologies for lifecycle efficiency assessment that account for maintenance requirements and component degradation.

Additional objectives focus on quantifying environmental impact metrics alongside traditional efficiency measures, integrating renewable energy compatibility into standard evaluations, and developing predictive models that can accurately forecast system performance under variable conditions. These advancements aim to provide industry stakeholders with more reliable comparative data for system selection and optimization.

Market Analysis for Energy-Efficient Heating Systems

The global market for energy-efficient heating systems has experienced significant growth over the past decade, driven by increasing energy costs, environmental regulations, and growing consumer awareness about sustainability. The market size for energy-efficient heating technologies reached approximately $125 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2030.

Heat exchangers and combustion furnaces represent two distinct approaches to heating, each with different market dynamics. Heat exchanger technologies have gained substantial market share, particularly in regions with stringent emission standards such as the European Union, where the market has grown by 8.2% annually since 2018. Their appeal stems from higher operational efficiency, with modern heat exchangers achieving efficiency ratings of 90-98% compared to traditional combustion furnaces' 65-85%.

The commercial building sector constitutes the largest market segment for energy-efficient heating systems, accounting for 42% of total installations. Residential applications follow at 38%, with industrial applications comprising the remaining 20%. Regional adoption varies significantly, with Northern European countries leading in heat exchanger adoption rates (68% of new installations), while North America maintains a more balanced market with combustion systems still representing 55% of new installations.

Consumer purchasing decisions are increasingly influenced by total cost of ownership rather than initial investment costs. While heat exchangers typically require 20-30% higher upfront investment than comparable combustion furnaces, their reduced operational costs deliver payback periods averaging 3-5 years in moderate climates and 2-3 years in colder regions.

Government incentives and regulatory frameworks have become critical market drivers. The European Green Deal and similar initiatives in North America and Asia have established clear efficiency standards that favor heat exchanger technologies. Tax incentives for energy-efficient systems have stimulated market growth, with countries offering rebates ranging from 10-30% of installation costs for systems meeting specific efficiency thresholds.

Market forecasts indicate that heat exchanger technologies will continue gaining market share, potentially reaching 65% of global heating system installations by 2030. This shift is accelerated by technological improvements reducing manufacturing costs and increasing efficiency. The retrofit market presents substantial opportunities, with an estimated 70% of existing buildings in developed economies operating heating systems below current efficiency standards.

Emerging markets, particularly in Asia-Pacific, represent the fastest-growing segment with 12.4% annual growth, driven by rapid urbanization and increasing middle-class consumer awareness of energy efficiency benefits. These markets are adopting newer technologies directly, often leapfrogging older combustion-based systems.

Heat exchangers and combustion furnaces represent two distinct approaches to heating, each with different market dynamics. Heat exchanger technologies have gained substantial market share, particularly in regions with stringent emission standards such as the European Union, where the market has grown by 8.2% annually since 2018. Their appeal stems from higher operational efficiency, with modern heat exchangers achieving efficiency ratings of 90-98% compared to traditional combustion furnaces' 65-85%.

The commercial building sector constitutes the largest market segment for energy-efficient heating systems, accounting for 42% of total installations. Residential applications follow at 38%, with industrial applications comprising the remaining 20%. Regional adoption varies significantly, with Northern European countries leading in heat exchanger adoption rates (68% of new installations), while North America maintains a more balanced market with combustion systems still representing 55% of new installations.

Consumer purchasing decisions are increasingly influenced by total cost of ownership rather than initial investment costs. While heat exchangers typically require 20-30% higher upfront investment than comparable combustion furnaces, their reduced operational costs deliver payback periods averaging 3-5 years in moderate climates and 2-3 years in colder regions.

Government incentives and regulatory frameworks have become critical market drivers. The European Green Deal and similar initiatives in North America and Asia have established clear efficiency standards that favor heat exchanger technologies. Tax incentives for energy-efficient systems have stimulated market growth, with countries offering rebates ranging from 10-30% of installation costs for systems meeting specific efficiency thresholds.

Market forecasts indicate that heat exchanger technologies will continue gaining market share, potentially reaching 65% of global heating system installations by 2030. This shift is accelerated by technological improvements reducing manufacturing costs and increasing efficiency. The retrofit market presents substantial opportunities, with an estimated 70% of existing buildings in developed economies operating heating systems below current efficiency standards.

Emerging markets, particularly in Asia-Pacific, represent the fastest-growing segment with 12.4% annual growth, driven by rapid urbanization and increasing middle-class consumer awareness of energy efficiency benefits. These markets are adopting newer technologies directly, often leapfrogging older combustion-based systems.

Current Technical Challenges in Heat Exchange vs Combustion

The global energy landscape is witnessing a critical shift toward more efficient and environmentally sustainable heating technologies. Heat exchangers and combustion furnaces represent two fundamentally different approaches to thermal energy generation and transfer, each facing distinct technical challenges in the pursuit of higher efficiency standards.

Heat exchangers currently struggle with several significant technical limitations. The primary challenge lies in the trade-off between heat transfer efficiency and pressure drop. As designs attempt to maximize surface area for heat transfer through complex geometries, they inevitably increase fluid resistance, requiring more pumping power and potentially negating efficiency gains. This relationship becomes particularly problematic in compact heat exchangers where space constraints exacerbate these competing factors.

Material limitations present another substantial hurdle. While high thermal conductivity materials like copper and aluminum offer excellent heat transfer properties, they face corrosion issues in certain environments and may be cost-prohibitive for large-scale applications. Advanced materials such as specialized alloys and composites show promise but remain expensive and difficult to manufacture at scale.

Fouling and scaling represent persistent operational challenges that significantly degrade heat exchanger performance over time. These phenomena reduce thermal conductivity and increase pressure drop, with current mitigation strategies often requiring system downtime and chemical treatments that raise environmental concerns.

For combustion furnaces, incomplete combustion remains a fundamental efficiency barrier. Despite decades of advancement, achieving complete fuel oxidation while maintaining optimal operating conditions continues to challenge engineers. This inefficiency directly translates to wasted fuel and increased emissions of carbon monoxide and unburned hydrocarbons.

Heat loss through exhaust gases constitutes another major efficiency drain in combustion systems. While heat recovery technologies like economizers and regenerative systems exist, they add complexity, cost, and maintenance requirements that many installations cannot justify economically.

Combustion control systems face increasing demands for precision as efficiency standards tighten. The ability to maintain optimal air-fuel ratios across varying load conditions requires sophisticated sensing and control technologies that many existing systems lack. This challenge becomes particularly acute when using alternative or variable-quality fuels.

Both technologies confront the challenge of integration with renewable energy systems. Heat exchangers must adapt to the intermittent nature of renewable heat sources, while combustion furnaces need to accommodate renewable or low-carbon fuels without sacrificing performance or requiring extensive modifications.

Regulatory pressures continue to evolve, with increasingly stringent emissions standards forcing both technologies to balance efficiency improvements against emissions control measures that may themselves consume energy or reduce overall system efficiency.

Heat exchangers currently struggle with several significant technical limitations. The primary challenge lies in the trade-off between heat transfer efficiency and pressure drop. As designs attempt to maximize surface area for heat transfer through complex geometries, they inevitably increase fluid resistance, requiring more pumping power and potentially negating efficiency gains. This relationship becomes particularly problematic in compact heat exchangers where space constraints exacerbate these competing factors.

Material limitations present another substantial hurdle. While high thermal conductivity materials like copper and aluminum offer excellent heat transfer properties, they face corrosion issues in certain environments and may be cost-prohibitive for large-scale applications. Advanced materials such as specialized alloys and composites show promise but remain expensive and difficult to manufacture at scale.

Fouling and scaling represent persistent operational challenges that significantly degrade heat exchanger performance over time. These phenomena reduce thermal conductivity and increase pressure drop, with current mitigation strategies often requiring system downtime and chemical treatments that raise environmental concerns.

For combustion furnaces, incomplete combustion remains a fundamental efficiency barrier. Despite decades of advancement, achieving complete fuel oxidation while maintaining optimal operating conditions continues to challenge engineers. This inefficiency directly translates to wasted fuel and increased emissions of carbon monoxide and unburned hydrocarbons.

Heat loss through exhaust gases constitutes another major efficiency drain in combustion systems. While heat recovery technologies like economizers and regenerative systems exist, they add complexity, cost, and maintenance requirements that many installations cannot justify economically.

Combustion control systems face increasing demands for precision as efficiency standards tighten. The ability to maintain optimal air-fuel ratios across varying load conditions requires sophisticated sensing and control technologies that many existing systems lack. This challenge becomes particularly acute when using alternative or variable-quality fuels.

Both technologies confront the challenge of integration with renewable energy systems. Heat exchangers must adapt to the intermittent nature of renewable heat sources, while combustion furnaces need to accommodate renewable or low-carbon fuels without sacrificing performance or requiring extensive modifications.

Regulatory pressures continue to evolve, with increasingly stringent emissions standards forcing both technologies to balance efficiency improvements against emissions control measures that may themselves consume energy or reduce overall system efficiency.

Comparative Analysis of Current Efficiency Standards

01 Heat recovery systems for combustion furnaces

Heat recovery systems are designed to capture and utilize waste heat from combustion furnaces, significantly improving overall thermal efficiency. These systems typically incorporate heat exchangers that transfer heat from exhaust gases to incoming air or water, reducing fuel consumption and operational costs. Advanced designs include multi-stage heat recovery units that can achieve higher efficiency rates by extracting heat at different temperature levels throughout the exhaust stream.- Heat recovery systems for combustion furnaces: Heat recovery systems are designed to capture and utilize waste heat from combustion furnaces, significantly improving overall efficiency. These systems typically incorporate heat exchangers that transfer thermal energy from exhaust gases to incoming air or water, reducing fuel consumption and operational costs. Advanced designs may include multiple heat exchange stages, condensing technology to recover latent heat, and automated controls to optimize heat transfer based on operating conditions.

- Enhanced heat exchanger designs for improved thermal transfer: Specialized heat exchanger designs can significantly improve thermal transfer efficiency in combustion systems. These innovations include finned tube arrangements, turbulence-inducing geometries, and advanced materials with superior thermal conductivity. Some designs feature extended surface areas, optimized flow patterns to reduce pressure drop, and anti-fouling surfaces that maintain performance over time. These enhancements maximize heat transfer while minimizing the physical footprint of the exchanger.

- Combustion control systems for furnace efficiency: Advanced combustion control systems optimize the air-fuel ratio and combustion parameters to maximize furnace efficiency. These systems employ sensors to monitor oxygen levels, temperature, and combustion products in real-time, allowing precise adjustment of operating conditions. Some implementations include staged combustion, pulse firing, and variable speed blowers to match heat output with demand. Smart controls can adapt to changing conditions, fuel properties, and load requirements while minimizing emissions.

- Waste gas recirculation and exhaust management: Recirculating flue gases and managing exhaust streams can substantially improve combustion efficiency and reduce emissions. These techniques involve redirecting a portion of exhaust gases back into the combustion chamber to control flame temperature and improve heat distribution. Advanced systems may incorporate catalytic converters, condensing economizers, or multi-stage heat recovery. This approach not only increases thermal efficiency but also reduces NOx formation and other pollutants while capturing additional usable energy.

- Integrated furnace and heat exchanger systems: Integrated designs that combine furnace and heat exchanger components into unified systems offer significant efficiency advantages. These compact arrangements minimize heat loss between components, reduce thermal mass, and optimize space utilization. Some integrated systems feature modular construction for scalability, condensing technology to capture latent heat, and materials selected for specific operating environments. The integration allows for optimized flow paths, reduced pressure drops, and more effective heat transfer across the entire system.

02 Enhanced heat exchanger designs for furnace applications

Specialized heat exchanger designs can significantly improve combustion furnace efficiency. These include finned tube exchangers, plate exchangers, and shell-and-tube configurations optimized for high-temperature environments. Key innovations focus on maximizing surface area for heat transfer while minimizing pressure drop and flow resistance. Materials selection is critical, with advanced alloys and ceramics enabling operation in corrosive environments and at higher temperatures, further improving heat transfer efficiency and system durability.Expand Specific Solutions03 Combustion control systems for efficiency optimization

Advanced combustion control systems utilize sensors, microprocessors, and precision fuel delivery mechanisms to optimize the air-fuel ratio and combustion parameters in real-time. These systems can adjust burner operation based on load demands, ambient conditions, and exhaust gas analysis, ensuring optimal efficiency across varying operating conditions. Integrated controls that coordinate multiple system components, including fans, dampers, and fuel valves, can maintain peak efficiency while reducing emissions and extending equipment life.Expand Specific Solutions04 Condensing heat exchanger technology

Condensing heat exchangers extract additional thermal energy by cooling exhaust gases below their dew point, recovering both sensible and latent heat. This technology can increase efficiency by 10-15% compared to conventional systems by capturing energy that would otherwise be lost in water vapor. Corrosion-resistant materials and specialized drainage systems are incorporated to handle the acidic condensate produced during operation. These systems are particularly effective in applications where return water or air temperatures are relatively low.Expand Specific Solutions05 Integration of renewable energy with combustion systems

Hybrid systems that integrate renewable energy sources with traditional combustion furnaces can significantly improve overall system efficiency. These designs may incorporate solar thermal preheating, biomass co-firing, or waste heat utilization from other processes. Smart control systems enable seamless switching or blending between energy sources based on availability and demand. This approach reduces fossil fuel consumption while maintaining reliable heating capacity and can be particularly effective in industrial applications with variable load profiles.Expand Specific Solutions

Leading Manufacturers and Industry Competition Landscape

The heat exchanger versus combustion furnace efficiency landscape is currently in a mature growth phase, with an estimated global market size of $25-30 billion. Leading companies like Carrier, Lennox, and Rheem are driving innovation in heat exchanger technology, while Kyung Dong Navien and Ebner Industrieofenbau are advancing high-efficiency combustion systems. The technical maturity varies significantly: heat exchangers have reached higher efficiency plateaus (with Heatric and Air Liquide pioneering compact designs), while combustion furnaces are undergoing transformation through smart controls and hybrid systems (led by Johnson Controls and Mitsubishi Electric). Academic-industry partnerships, particularly involving Xi'an Jiaotong University and Zhejiang University of Technology, are accelerating efficiency breakthroughs in both technologies.

Carrier Corp.

Technical Solution: Carrier has pioneered hybrid heating systems that intelligently combine heat exchanger and combustion furnace technologies to optimize efficiency across varying operating conditions. Their Infinity® series utilizes a dual-fuel approach with a proprietary algorithm that automatically switches between a high-efficiency heat pump (coefficient of performance up to 5.0) and a modulating gas furnace (up to 98.5% AFUE) based on outdoor temperature, energy costs, and heating demand. This adaptive system achieves annual energy savings of 25-40% compared to traditional furnace-only systems. Carrier's technology incorporates variable-speed blower motors that precisely match airflow to heating requirements, reducing energy consumption by up to 80% compared to single-speed motors. Their heat exchangers feature a proprietary WeatherExpert® design with microchannel technology that increases heat transfer efficiency by up to 30% while reducing refrigerant volume requirements by up to 50% compared to conventional tube-and-fin designs.

Strengths: Adaptive dual-fuel technology optimizes efficiency across varying conditions, high AFUE ratings (up to 98.5%), sophisticated control algorithms, and reduced operating costs. Weaknesses: Higher upfront costs than single-technology systems, increased system complexity requiring specialized installation and maintenance, and performance heavily dependent on climate zone.

Heatric Ltd.

Technical Solution: Heatric specializes in diffusion-bonded heat exchangers (PCHE) technology that offers superior thermal efficiency compared to traditional combustion furnaces. Their proprietary manufacturing process creates monolithic, all-metal heat exchangers with microscopic flow passages that maximize heat transfer surface area while minimizing volume. This technology achieves thermal effectiveness of up to 98% compared to conventional furnace systems that typically operate at 70-85% efficiency. Heatric's systems can withstand extreme pressures (up to 650 bar) and temperatures (-200°C to 900°C), making them suitable for demanding industrial applications where traditional combustion furnaces would be inefficient or impractical. Their compact design reduces footprint by up to 85% compared to shell and tube exchangers, while providing enhanced resistance to thermal fatigue and pressure cycling.

Strengths: Superior thermal efficiency (up to 98%), extreme pressure and temperature tolerance, compact design (up to 85% smaller footprint), and excellent durability. Weaknesses: Higher initial capital investment compared to conventional furnaces, limited to specific industrial applications, and requires specialized manufacturing capabilities.

Key Patents and Innovations in Thermal Efficiency

Combustion system

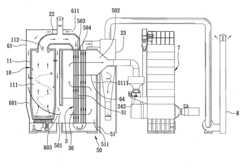

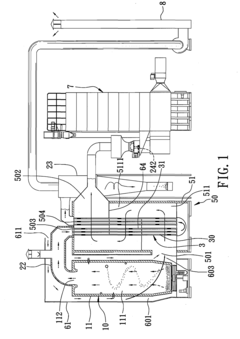

PatentInactiveUS20090056705A1

Innovation

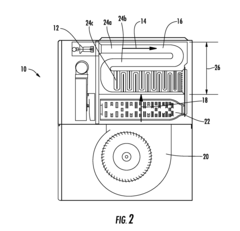

- A combustion system design where a heat exchanger housing is positioned outwardly of the plenum housing, featuring a tube-bundled structure and baffles to create a tortuous path for enhanced heat exchange between exhaust gas and ambient air, with a manifold interconnecting the furnace and heat exchanger gas outlets.

Furnace heat exchanger

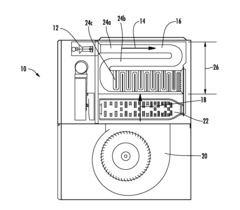

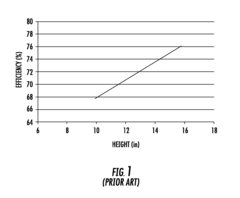

PatentInactiveUS20120088200A1

Innovation

- A primary heat exchanger with one or more passes, configured to achieve a higher efficiency-to-height ratio of 7.0 to 8.1 points per inch, utilizing a serpentine path and irregularities such as corrugations in its design, allowing for reduced size and material usage while maintaining efficiency.

Environmental Impact Assessment and Sustainability Metrics

The environmental impact of heat exchangers versus combustion furnaces represents a critical consideration in modern industrial applications. Heat exchangers demonstrate significantly lower direct emissions, producing virtually no on-site pollutants during operation compared to combustion furnaces which generate substantial NOx, SOx, particulate matter, and greenhouse gases. This fundamental difference creates an immediate environmental advantage for heat exchanger systems in applications where either technology could be deployed.

Carbon footprint analysis reveals that heat exchangers typically reduce greenhouse gas emissions by 40-60% compared to equivalent combustion furnaces when considering full lifecycle impacts. However, this advantage varies considerably depending on the energy source powering the heat exchanger. When powered by renewable electricity, heat exchangers can achieve near-zero operational carbon emissions, while natural gas or coal-powered electricity significantly diminishes this benefit.

Water consumption metrics also favor heat exchangers in most applications, with closed-loop systems requiring minimal ongoing water input compared to many combustion processes. This advantage becomes particularly significant in water-stressed regions where industrial water usage faces increasing regulatory and resource constraints.

Sustainability certification standards increasingly recognize these differences, with systems like LEED, BREEAM, and industrial-specific frameworks awarding higher ratings to heat exchanger implementations. These certification advantages translate to tangible business benefits beyond direct operational efficiency, including regulatory compliance positioning and corporate sustainability reporting.

Lifecycle assessment (LCA) methodology reveals that heat exchangers typically demonstrate superior environmental performance across multiple impact categories including acidification potential, eutrophication potential, and photochemical ozone creation potential. The primary environmental drawback for heat exchangers appears in the manufacturing phase, where specialized materials and precision manufacturing processes can create higher embodied energy compared to simpler combustion systems.

Regulatory compliance trajectories strongly favor heat exchanger technology as emissions standards continue to tighten globally. Many jurisdictions have established phase-out timelines for certain combustion technologies, particularly in urban and environmentally sensitive areas, creating a clear sustainability advantage for heat exchanger adoption in forward-looking facility planning.

Circular economy considerations are increasingly important, with heat exchangers offering superior end-of-life recyclability for their primary components, particularly when designed with disassembly and material recovery in mind. This contrasts with combustion furnaces which often contain more composite materials and contaminated components that complicate recycling efforts.

Carbon footprint analysis reveals that heat exchangers typically reduce greenhouse gas emissions by 40-60% compared to equivalent combustion furnaces when considering full lifecycle impacts. However, this advantage varies considerably depending on the energy source powering the heat exchanger. When powered by renewable electricity, heat exchangers can achieve near-zero operational carbon emissions, while natural gas or coal-powered electricity significantly diminishes this benefit.

Water consumption metrics also favor heat exchangers in most applications, with closed-loop systems requiring minimal ongoing water input compared to many combustion processes. This advantage becomes particularly significant in water-stressed regions where industrial water usage faces increasing regulatory and resource constraints.

Sustainability certification standards increasingly recognize these differences, with systems like LEED, BREEAM, and industrial-specific frameworks awarding higher ratings to heat exchanger implementations. These certification advantages translate to tangible business benefits beyond direct operational efficiency, including regulatory compliance positioning and corporate sustainability reporting.

Lifecycle assessment (LCA) methodology reveals that heat exchangers typically demonstrate superior environmental performance across multiple impact categories including acidification potential, eutrophication potential, and photochemical ozone creation potential. The primary environmental drawback for heat exchangers appears in the manufacturing phase, where specialized materials and precision manufacturing processes can create higher embodied energy compared to simpler combustion systems.

Regulatory compliance trajectories strongly favor heat exchanger technology as emissions standards continue to tighten globally. Many jurisdictions have established phase-out timelines for certain combustion technologies, particularly in urban and environmentally sensitive areas, creating a clear sustainability advantage for heat exchanger adoption in forward-looking facility planning.

Circular economy considerations are increasingly important, with heat exchangers offering superior end-of-life recyclability for their primary components, particularly when designed with disassembly and material recovery in mind. This contrasts with combustion furnaces which often contain more composite materials and contaminated components that complicate recycling efforts.

Regulatory Framework and Compliance Requirements

The regulatory landscape governing heat exchangers and combustion furnaces has evolved significantly over the past decades, driven by increasing concerns about energy efficiency and environmental impact. At the international level, the International Organization for Standardization (ISO) has established ISO 50001 for energy management systems, which provides a framework for organizations to develop policies for more efficient energy use, including thermal systems like heat exchangers and combustion furnaces.

In the United States, the Department of Energy (DOE) has implemented minimum efficiency standards for various heating equipment under the Energy Policy and Conservation Act. These standards are periodically updated through a rulemaking process that involves stakeholder input and technical analysis. The Environmental Protection Agency (EPA) complements these efforts through programs like ENERGY STAR, which certifies high-efficiency equipment that exceeds minimum standards.

The European Union has established the Ecodesign Directive (2009/125/EC), which sets mandatory ecological requirements for energy-using and energy-related products. Specifically for industrial heating systems, the Medium Combustion Plant Directive (MCPD) regulates emissions from combustion plants with a rated thermal input between 1 and 50 MW, affecting both heat exchangers and combustion furnaces in industrial applications.

Compliance verification methods differ significantly between heat exchangers and combustion furnaces. Heat exchanger efficiency is typically measured through heat transfer effectiveness, pressure drop characteristics, and overall thermal performance. Testing protocols such as ASME PTC 12.5 and AHRI Standard 400 provide standardized methods for performance evaluation. For combustion furnaces, efficiency standards focus on fuel utilization efficiency (AFUE), combustion efficiency, and emissions levels, with testing procedures outlined in standards like ANSI Z21.47 and UL 795.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches that consider not only operational efficiency but also manufacturing impacts and end-of-life disposal. The EU's Circular Economy Action Plan exemplifies this trend, promoting design for durability, reusability, and recyclability of industrial equipment including thermal systems.

Industry stakeholders must navigate an increasingly complex compliance landscape that varies by region and application. Manufacturers are required to maintain detailed technical documentation demonstrating conformity with applicable standards, while end-users must ensure proper installation, operation, and maintenance to maintain compliance throughout the equipment lifecycle. Non-compliance can result in significant penalties, market access restrictions, and reputational damage.

In the United States, the Department of Energy (DOE) has implemented minimum efficiency standards for various heating equipment under the Energy Policy and Conservation Act. These standards are periodically updated through a rulemaking process that involves stakeholder input and technical analysis. The Environmental Protection Agency (EPA) complements these efforts through programs like ENERGY STAR, which certifies high-efficiency equipment that exceeds minimum standards.

The European Union has established the Ecodesign Directive (2009/125/EC), which sets mandatory ecological requirements for energy-using and energy-related products. Specifically for industrial heating systems, the Medium Combustion Plant Directive (MCPD) regulates emissions from combustion plants with a rated thermal input between 1 and 50 MW, affecting both heat exchangers and combustion furnaces in industrial applications.

Compliance verification methods differ significantly between heat exchangers and combustion furnaces. Heat exchanger efficiency is typically measured through heat transfer effectiveness, pressure drop characteristics, and overall thermal performance. Testing protocols such as ASME PTC 12.5 and AHRI Standard 400 provide standardized methods for performance evaluation. For combustion furnaces, efficiency standards focus on fuel utilization efficiency (AFUE), combustion efficiency, and emissions levels, with testing procedures outlined in standards like ANSI Z21.47 and UL 795.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches that consider not only operational efficiency but also manufacturing impacts and end-of-life disposal. The EU's Circular Economy Action Plan exemplifies this trend, promoting design for durability, reusability, and recyclability of industrial equipment including thermal systems.

Industry stakeholders must navigate an increasingly complex compliance landscape that varies by region and application. Manufacturers are required to maintain detailed technical documentation demonstrating conformity with applicable standards, while end-users must ensure proper installation, operation, and maintenance to maintain compliance throughout the equipment lifecycle. Non-compliance can result in significant penalties, market access restrictions, and reputational damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!