Heat Exchanger Piping Design: Optimizing Thermal Performance

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Evolution and Design Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century. Initially designed as simple tube-and-shell configurations, these thermal transfer devices have undergone substantial transformations driven by industrial demands for higher efficiency, reduced footprint, and enhanced performance. The evolution trajectory shows a clear progression from rudimentary designs to sophisticated systems incorporating advanced materials and complex flow geometries.

The 1950s marked a pivotal era with the introduction of plate heat exchangers, revolutionizing thermal efficiency capabilities. By the 1970s, compact heat exchangers emerged, addressing space constraints in various applications. The digital revolution of the 1990s introduced computational fluid dynamics (CFD) modeling, enabling engineers to simulate and optimize heat exchanger performance before physical prototyping, significantly reducing development cycles and costs.

Recent advancements have focused on micro-channel heat exchangers and additive manufacturing techniques, allowing for previously impossible geometries that maximize heat transfer surface area while minimizing pressure drop. These innovations have pushed thermal efficiency boundaries, with some modern designs achieving effectiveness ratings exceeding 95% compared to the 60-70% common in mid-century designs.

The primary objectives in heat exchanger piping design center on optimizing thermal performance while balancing several critical factors. Maximizing heat transfer coefficients remains paramount, typically achieved through strategic flow arrangement, turbulence promotion, and surface area optimization. Simultaneously, minimizing pressure drop is essential to reduce pumping power requirements and operational costs, creating an inherent design trade-off that engineers must navigate.

Material selection represents another crucial design objective, with considerations extending beyond thermal conductivity to include corrosion resistance, fouling susceptibility, and cost-effectiveness. Modern designs increasingly incorporate composite materials and specialized coatings to address these multifaceted requirements.

Compactness and weight reduction have become increasingly important design goals, particularly in aerospace, automotive, and portable applications where space and weight constraints are significant. This has driven innovation in flow path design and manufacturing techniques to achieve higher heat transfer rates per unit volume.

Energy efficiency and sustainability objectives have gained prominence in recent years, with designs focusing on minimizing thermal losses, recovering waste heat, and reducing the environmental impact of both manufacturing and operation. These objectives align with global energy conservation initiatives and increasingly stringent regulatory requirements across industries.

The 1950s marked a pivotal era with the introduction of plate heat exchangers, revolutionizing thermal efficiency capabilities. By the 1970s, compact heat exchangers emerged, addressing space constraints in various applications. The digital revolution of the 1990s introduced computational fluid dynamics (CFD) modeling, enabling engineers to simulate and optimize heat exchanger performance before physical prototyping, significantly reducing development cycles and costs.

Recent advancements have focused on micro-channel heat exchangers and additive manufacturing techniques, allowing for previously impossible geometries that maximize heat transfer surface area while minimizing pressure drop. These innovations have pushed thermal efficiency boundaries, with some modern designs achieving effectiveness ratings exceeding 95% compared to the 60-70% common in mid-century designs.

The primary objectives in heat exchanger piping design center on optimizing thermal performance while balancing several critical factors. Maximizing heat transfer coefficients remains paramount, typically achieved through strategic flow arrangement, turbulence promotion, and surface area optimization. Simultaneously, minimizing pressure drop is essential to reduce pumping power requirements and operational costs, creating an inherent design trade-off that engineers must navigate.

Material selection represents another crucial design objective, with considerations extending beyond thermal conductivity to include corrosion resistance, fouling susceptibility, and cost-effectiveness. Modern designs increasingly incorporate composite materials and specialized coatings to address these multifaceted requirements.

Compactness and weight reduction have become increasingly important design goals, particularly in aerospace, automotive, and portable applications where space and weight constraints are significant. This has driven innovation in flow path design and manufacturing techniques to achieve higher heat transfer rates per unit volume.

Energy efficiency and sustainability objectives have gained prominence in recent years, with designs focusing on minimizing thermal losses, recovering waste heat, and reducing the environmental impact of both manufacturing and operation. These objectives align with global energy conservation initiatives and increasingly stringent regulatory requirements across industries.

Market Analysis for Advanced Heat Exchange Systems

The global market for advanced heat exchange systems is experiencing robust growth, driven by increasing demands for energy efficiency across multiple industries. Current market valuations indicate the heat exchanger market reached approximately $16.5 billion in 2022 and is projected to grow at a CAGR of 6.2% through 2030. This growth trajectory is particularly pronounced in regions with stringent energy efficiency regulations such as Europe and North America, while emerging economies in Asia-Pacific represent the fastest-growing markets due to rapid industrialization.

Industrial applications constitute the largest market segment, accounting for nearly 40% of the total market share. Within this segment, chemical processing, oil and gas, and power generation industries are the primary consumers of advanced heat exchange technologies. The HVAC sector follows closely, representing approximately 25% of market demand, with commercial buildings and data centers driving significant adoption of high-efficiency heat exchange systems.

Market trends reveal a growing preference for compact heat exchangers that offer superior thermal performance while minimizing space requirements. Plate heat exchangers, in particular, have seen a market share increase of 15% over the past five years, gradually replacing traditional shell-and-tube designs in many applications. This shift is primarily attributed to their higher efficiency-to-size ratio and lower maintenance requirements.

Sustainability concerns are reshaping market dynamics, with over 70% of new installations prioritizing energy efficiency and reduced environmental impact. This has accelerated the development and adoption of advanced materials and designs that optimize thermal performance while minimizing resource consumption. Manufacturers report that customers increasingly specify maximum allowable pressure drops and minimum heat transfer coefficients in their procurement requirements.

Competitive analysis reveals a market dominated by established players like Alfa Laval, Kelvion, and Danfoss, who collectively hold approximately 35% market share. However, specialized manufacturers focusing on application-specific optimized designs are gaining traction, particularly in high-value sectors such as pharmaceutical processing and renewable energy systems. These niche players typically command premium pricing based on performance advantages rather than competing on cost.

Regional market analysis indicates that while North America and Europe represent mature markets with steady growth rates of 4-5%, the Asia-Pacific region is experiencing accelerated adoption at 8-9% annually. China alone accounts for approximately 22% of global demand, driven by extensive industrial development and increasing focus on energy efficiency in manufacturing processes. Middle Eastern markets show particular interest in corrosion-resistant designs suitable for desalination and petrochemical applications.

Industrial applications constitute the largest market segment, accounting for nearly 40% of the total market share. Within this segment, chemical processing, oil and gas, and power generation industries are the primary consumers of advanced heat exchange technologies. The HVAC sector follows closely, representing approximately 25% of market demand, with commercial buildings and data centers driving significant adoption of high-efficiency heat exchange systems.

Market trends reveal a growing preference for compact heat exchangers that offer superior thermal performance while minimizing space requirements. Plate heat exchangers, in particular, have seen a market share increase of 15% over the past five years, gradually replacing traditional shell-and-tube designs in many applications. This shift is primarily attributed to their higher efficiency-to-size ratio and lower maintenance requirements.

Sustainability concerns are reshaping market dynamics, with over 70% of new installations prioritizing energy efficiency and reduced environmental impact. This has accelerated the development and adoption of advanced materials and designs that optimize thermal performance while minimizing resource consumption. Manufacturers report that customers increasingly specify maximum allowable pressure drops and minimum heat transfer coefficients in their procurement requirements.

Competitive analysis reveals a market dominated by established players like Alfa Laval, Kelvion, and Danfoss, who collectively hold approximately 35% market share. However, specialized manufacturers focusing on application-specific optimized designs are gaining traction, particularly in high-value sectors such as pharmaceutical processing and renewable energy systems. These niche players typically command premium pricing based on performance advantages rather than competing on cost.

Regional market analysis indicates that while North America and Europe represent mature markets with steady growth rates of 4-5%, the Asia-Pacific region is experiencing accelerated adoption at 8-9% annually. China alone accounts for approximately 22% of global demand, driven by extensive industrial development and increasing focus on energy efficiency in manufacturing processes. Middle Eastern markets show particular interest in corrosion-resistant designs suitable for desalination and petrochemical applications.

Current Piping Design Challenges and Limitations

Heat exchanger piping design faces numerous challenges that limit optimal thermal performance in modern industrial applications. Traditional piping configurations often struggle with uneven flow distribution, particularly in parallel-flow arrangements where preferential flow paths create thermal inefficiencies. This phenomenon results in reduced heat transfer rates and creates localized hot or cold spots that compromise overall system performance.

Pressure drop management remains a significant limitation in current designs. Engineers must constantly balance the trade-off between enhanced heat transfer (which typically requires turbulent flow) and acceptable pressure losses that impact pumping power requirements and operational costs. This balance becomes increasingly difficult to achieve as systems scale up or face space constraints.

Material selection presents another critical challenge. Conventional materials like carbon steel, copper, and aluminum each have inherent limitations regarding thermal conductivity, corrosion resistance, and mechanical strength at elevated temperatures. These limitations restrict application ranges and necessitate frequent maintenance or replacement, particularly in aggressive operating environments involving high temperatures or corrosive fluids.

Fouling and scaling represent persistent operational challenges that significantly degrade thermal performance over time. Current piping designs often lack effective self-cleaning mechanisms or accessibility features for maintenance, resulting in substantial efficiency losses. Industry data indicates that fouling can reduce heat transfer efficiency by 10-50% within months of operation in certain applications.

Geometric constraints pose substantial design limitations, particularly in retrofit applications or compact installation spaces. Engineers frequently must compromise optimal thermal design principles to accommodate spatial limitations, resulting in sub-optimal flow patterns, increased pressure drops, and reduced heat transfer coefficients.

Temperature-induced stress and thermal expansion management remain problematic in many current designs. Differential expansion between piping components can lead to mechanical failures, leakage at joints, and premature system deterioration. Traditional expansion joints and flexible connections add complexity and potential failure points to the system.

Manufacturing limitations also restrict innovation in piping design. Complex geometries that could theoretically enhance thermal performance often prove prohibitively expensive or impossible to fabricate using conventional manufacturing techniques. This manufacturing constraint forces designers to rely on simpler, less efficient geometries that can be readily produced.

Computational modeling limitations further complicate design optimization. While CFD (Computational Fluid Dynamics) tools have advanced significantly, accurately predicting multiphase flow behavior, phase change phenomena, and long-term fouling effects remains challenging. This modeling gap creates uncertainty in performance predictions and often leads to conservative designs with built-in inefficiencies.

Pressure drop management remains a significant limitation in current designs. Engineers must constantly balance the trade-off between enhanced heat transfer (which typically requires turbulent flow) and acceptable pressure losses that impact pumping power requirements and operational costs. This balance becomes increasingly difficult to achieve as systems scale up or face space constraints.

Material selection presents another critical challenge. Conventional materials like carbon steel, copper, and aluminum each have inherent limitations regarding thermal conductivity, corrosion resistance, and mechanical strength at elevated temperatures. These limitations restrict application ranges and necessitate frequent maintenance or replacement, particularly in aggressive operating environments involving high temperatures or corrosive fluids.

Fouling and scaling represent persistent operational challenges that significantly degrade thermal performance over time. Current piping designs often lack effective self-cleaning mechanisms or accessibility features for maintenance, resulting in substantial efficiency losses. Industry data indicates that fouling can reduce heat transfer efficiency by 10-50% within months of operation in certain applications.

Geometric constraints pose substantial design limitations, particularly in retrofit applications or compact installation spaces. Engineers frequently must compromise optimal thermal design principles to accommodate spatial limitations, resulting in sub-optimal flow patterns, increased pressure drops, and reduced heat transfer coefficients.

Temperature-induced stress and thermal expansion management remain problematic in many current designs. Differential expansion between piping components can lead to mechanical failures, leakage at joints, and premature system deterioration. Traditional expansion joints and flexible connections add complexity and potential failure points to the system.

Manufacturing limitations also restrict innovation in piping design. Complex geometries that could theoretically enhance thermal performance often prove prohibitively expensive or impossible to fabricate using conventional manufacturing techniques. This manufacturing constraint forces designers to rely on simpler, less efficient geometries that can be readily produced.

Computational modeling limitations further complicate design optimization. While CFD (Computational Fluid Dynamics) tools have advanced significantly, accurately predicting multiphase flow behavior, phase change phenomena, and long-term fouling effects remains challenging. This modeling gap creates uncertainty in performance predictions and often leads to conservative designs with built-in inefficiencies.

State-of-the-Art Piping Configuration Solutions

01 Enhanced pipe design for improved heat transfer

Various pipe designs can significantly improve heat transfer efficiency in heat exchangers. These designs include modified internal structures, specialized surface treatments, and optimized geometries that increase the contact area between the fluid and pipe walls. Such enhancements promote turbulent flow, reduce thermal resistance, and maximize heat exchange capacity while minimizing pressure drop across the system.- Enhanced pipe design for improved heat transfer: Various pipe designs can enhance heat transfer efficiency in heat exchangers. These include specialized geometries, surface modifications, and structural innovations that increase the contact area between the fluid and pipe walls. Features such as corrugated surfaces, spiral configurations, or internal fins promote turbulent flow, reducing boundary layer effects and improving overall thermal performance while minimizing pressure drop.

- Material selection for thermal conductivity optimization: The choice of materials significantly impacts heat exchanger performance. High thermal conductivity materials like copper, aluminum alloys, and specialized composites facilitate efficient heat transfer. Advanced materials with enhanced thermal properties can be incorporated into piping systems to maximize heat exchange rates while maintaining structural integrity under varying temperature and pressure conditions.

- Flow configuration and distribution systems: Optimizing fluid flow patterns within heat exchanger piping systems enhances thermal performance. This includes counter-flow arrangements, uniform flow distribution mechanisms, and strategic placement of baffles or distributors. Proper flow configuration minimizes dead zones, reduces fouling, and ensures maximum temperature differential across the heat exchange surface, resulting in improved overall efficiency.

- Insulation and thermal barrier technologies: Effective insulation and thermal barrier systems prevent unwanted heat loss or gain in heat exchanger piping. Advanced insulation materials, vacuum-sealed barriers, and reflective coatings help maintain desired temperature gradients. Strategic insulation placement ensures that heat is transferred only where intended, improving system efficiency and reducing energy consumption in heating or cooling applications.

- Monitoring and control systems for thermal performance: Integrated monitoring and control technologies optimize heat exchanger operation under varying conditions. These include temperature sensors, flow meters, and automated control systems that adjust parameters in real-time. Advanced diagnostic tools can detect performance degradation, enabling predictive maintenance and ensuring consistent thermal efficiency throughout the heat exchanger's operational life.

02 Thermal insulation and coating technologies

The application of specialized thermal insulation materials and coatings to heat exchanger piping can significantly impact thermal performance. These technologies help minimize unwanted heat loss or gain, prevent condensation issues, and protect against corrosion. Advanced insulation systems and selective coatings can be tailored to specific operating conditions, enhancing overall system efficiency and extending equipment lifespan.Expand Specific Solutions03 Flow configuration and distribution optimization

Optimizing the flow configuration and distribution within heat exchanger piping systems significantly impacts thermal performance. This includes strategic placement of baffles, flow distributors, and header designs that ensure uniform fluid distribution. Proper flow management reduces dead zones, prevents channeling, and minimizes fouling while maximizing the effective heat transfer area and maintaining optimal fluid velocities throughout the system.Expand Specific Solutions04 Material selection for thermal conductivity

The choice of materials for heat exchanger piping plays a crucial role in thermal performance. High thermal conductivity materials facilitate efficient heat transfer, while corrosion-resistant alloys ensure longevity in aggressive environments. Advanced composite materials and metal alloys can be selected based on specific application requirements, balancing thermal efficiency with mechanical strength, pressure ratings, and cost considerations.Expand Specific Solutions05 Monitoring and control systems for performance optimization

Implementation of advanced monitoring and control systems enables real-time optimization of heat exchanger piping thermal performance. These systems utilize temperature sensors, flow meters, and pressure transducers to continuously assess performance metrics. Automated control algorithms can adjust flow rates, bypass configurations, and other parameters to maintain optimal thermal efficiency under varying operating conditions, while predictive maintenance capabilities help prevent performance degradation.Expand Specific Solutions

Leading Manufacturers and Engineering Firms

The heat exchanger piping design market is currently in a growth phase, with increasing demand driven by energy efficiency requirements across industries. The global market size is estimated to exceed $20 billion, expanding at approximately 6% CAGR. From a technological maturity perspective, established players like Mitsubishi Heavy Industries, Danfoss, and Daikin Industries lead with advanced thermal optimization solutions, while companies such as Sanhua Micro Channel and Wieland-Werke are pioneering micro-channel heat exchanger technologies. Samsung Electronics and LG Electronics are integrating smart controls into their systems, while academic institutions like Southeast University and University of Tokyo contribute fundamental research. The competitive landscape shows a mix of traditional HVAC manufacturers evolving alongside specialized heat exchanger technology firms, with increasing focus on sustainability and energy efficiency.

Hangzhou Sanhua Micro Channel Heat Exchanger Co., Ltd.

Technical Solution: Sanhua has developed proprietary micro-channel heat exchanger technology that features flat multi-port tubes with small hydraulic diameters (0.5-1.5mm), significantly increasing heat transfer surface area while reducing material usage by up to 40%. Their innovative parallel flow design optimizes refrigerant distribution through precisely engineered manifolds that ensure uniform flow across all channels. Sanhua's heat exchangers incorporate specialized louvered fins with optimized geometries that enhance air-side heat transfer coefficients while minimizing pressure drop. Their manufacturing process includes vacuum brazing technology that creates superior metallurgical bonds between components, reducing thermal resistance at joints. Sanhua has also pioneered corrosion-resistant coatings specifically designed for micro-channel heat exchangers that extend operational lifespan in harsh environments while maintaining thermal performance.

Strengths: Industry-leading micro-channel technology with superior material efficiency, excellent thermal performance in compact designs, and advanced manufacturing capabilities. Weaknesses: More susceptible to fouling in certain applications compared to traditional tube designs, and potentially higher repair costs when damage occurs.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has pioneered advanced heat exchanger designs with their patented multi-pass, multi-circuit heat exchanger technology that optimizes refrigerant distribution. Their innovative approach includes micro-channel heat exchangers with specially designed tube geometries that enhance heat transfer coefficients by up to 40% compared to conventional designs. Daikin's heat exchanger piping incorporates variable refrigerant flow (VRF) technology with electronic expansion valves that continuously adjust refrigerant flow rates based on real-time thermal load demands. Their systems feature optimized tube-fin configurations with hydrophilic coatings that improve condensate drainage and maintain thermal efficiency over time. Daikin has also developed specialized header designs that ensure uniform refrigerant distribution across multiple parallel circuits, minimizing pressure drops while maximizing heat transfer efficiency.

Strengths: Superior refrigerant distribution technology, advanced micro-channel designs, and integrated control systems that adapt to varying thermal loads. Weaknesses: Higher initial manufacturing costs and more complex installation requirements compared to conventional systems. Some designs may require specialized maintenance procedures.

Critical Patents in Heat Transfer Enhancement

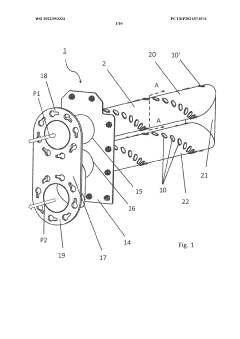

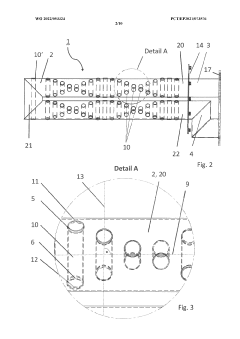

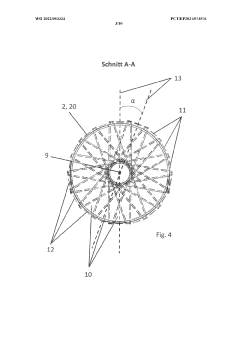

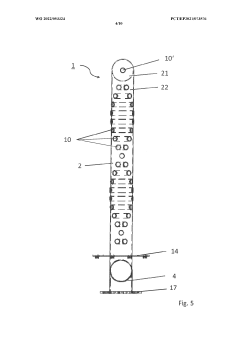

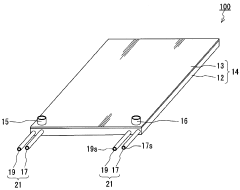

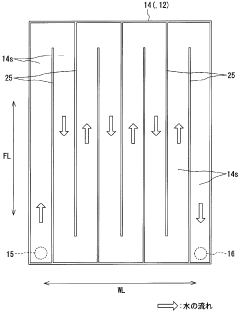

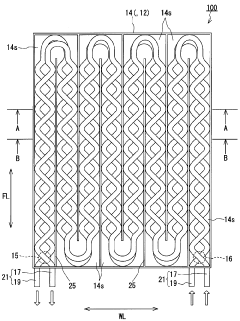

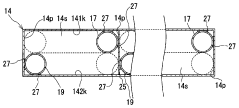

Heat exchanger

PatentWO2022053324A1

Innovation

- A heat exchanger design featuring a heat exchanger tube with multiple penetrating tubes, arranged helically or at an angle, increasing the surface area and creating a swirling effect for enhanced heat transfer, with fluid-tight connections to prevent mixing and ensure efficient heat exchange.

Heat exchanger

PatentWO2007108240A1

Innovation

- A heat exchanger design featuring meandering first and second pipes within a rectangular flow path, where the pipes intersect multiple times along the flow direction, inducing a three-dimensional flow that suppresses thermal boundary layer development and increases the effective length of the pipes, thereby enhancing heat exchange efficiency and allowing for miniaturization.

Materials Science Advancements for Heat Exchangers

Recent advancements in materials science have revolutionized heat exchanger technology, enabling significant improvements in thermal performance, durability, and efficiency. Traditional materials such as carbon steel, stainless steel, and copper alloys are increasingly being supplemented or replaced by innovative alternatives that offer superior properties for specific applications.

Nanomaterial-enhanced surfaces represent one of the most promising developments in this field. Carbon nanotubes and graphene coatings have demonstrated remarkable ability to increase heat transfer coefficients by up to 60% compared to conventional materials. These nanomaterials create microscopic surface features that enhance turbulence at the fluid-solid interface, promoting more efficient thermal exchange while minimizing pressure drop penalties.

Advanced polymer composites are gaining traction for corrosive environments where metal heat exchangers would rapidly deteriorate. Polymer materials reinforced with thermally conductive fillers such as boron nitride or aluminum oxide particles achieve thermal conductivities approaching those of some metals while maintaining excellent chemical resistance. These composites are particularly valuable in chemical processing applications where fluid purity is critical.

High-entropy alloys (HEAs) represent another breakthrough, offering exceptional mechanical properties and corrosion resistance at elevated temperatures. Unlike conventional alloys with one principal element, HEAs contain five or more elements in near-equal proportions, creating unique microstructures that resist degradation in extreme conditions. Recent studies have shown HEAs maintaining structural integrity at temperatures exceeding 800°C while demonstrating thermal conductivity comparable to traditional nickel-based superalloys.

Ceramic matrix composites (CMCs) are increasingly utilized in high-temperature applications, offering thermal stability beyond the capabilities of metallic materials. Silicon carbide and aluminum nitride-based CMCs can operate efficiently at temperatures above 1000°C while resisting oxidation and maintaining dimensional stability. These properties make them ideal for waste heat recovery systems in energy-intensive industries.

Additive manufacturing has enabled the production of complex heat exchanger geometries previously impossible with conventional manufacturing techniques. This technology allows for the creation of optimized flow paths and enhanced surface features that maximize heat transfer while minimizing material usage. 3D-printed heat exchangers using specialized metal alloys have demonstrated up to 40% improvement in thermal performance compared to traditionally manufactured counterparts with identical material composition.

Nanomaterial-enhanced surfaces represent one of the most promising developments in this field. Carbon nanotubes and graphene coatings have demonstrated remarkable ability to increase heat transfer coefficients by up to 60% compared to conventional materials. These nanomaterials create microscopic surface features that enhance turbulence at the fluid-solid interface, promoting more efficient thermal exchange while minimizing pressure drop penalties.

Advanced polymer composites are gaining traction for corrosive environments where metal heat exchangers would rapidly deteriorate. Polymer materials reinforced with thermally conductive fillers such as boron nitride or aluminum oxide particles achieve thermal conductivities approaching those of some metals while maintaining excellent chemical resistance. These composites are particularly valuable in chemical processing applications where fluid purity is critical.

High-entropy alloys (HEAs) represent another breakthrough, offering exceptional mechanical properties and corrosion resistance at elevated temperatures. Unlike conventional alloys with one principal element, HEAs contain five or more elements in near-equal proportions, creating unique microstructures that resist degradation in extreme conditions. Recent studies have shown HEAs maintaining structural integrity at temperatures exceeding 800°C while demonstrating thermal conductivity comparable to traditional nickel-based superalloys.

Ceramic matrix composites (CMCs) are increasingly utilized in high-temperature applications, offering thermal stability beyond the capabilities of metallic materials. Silicon carbide and aluminum nitride-based CMCs can operate efficiently at temperatures above 1000°C while resisting oxidation and maintaining dimensional stability. These properties make them ideal for waste heat recovery systems in energy-intensive industries.

Additive manufacturing has enabled the production of complex heat exchanger geometries previously impossible with conventional manufacturing techniques. This technology allows for the creation of optimized flow paths and enhanced surface features that maximize heat transfer while minimizing material usage. 3D-printed heat exchangers using specialized metal alloys have demonstrated up to 40% improvement in thermal performance compared to traditionally manufactured counterparts with identical material composition.

Computational Fluid Dynamics Simulation Techniques

Computational Fluid Dynamics (CFD) has revolutionized heat exchanger design by providing detailed insights into fluid flow and heat transfer phenomena that were previously unobservable through traditional experimental methods. Modern CFD simulation techniques employ sophisticated numerical algorithms to solve the governing equations of fluid dynamics, including the Navier-Stokes equations, energy conservation equations, and turbulence models.

The mesh generation process represents a critical step in CFD simulation of heat exchangers. Structured meshes offer computational efficiency but may struggle with complex geometries, while unstructured meshes provide greater flexibility for intricate piping configurations. Hybrid meshing approaches have emerged as an optimal solution, combining structured meshes in near-wall regions with unstructured meshes in the bulk flow domain.

Turbulence modeling remains one of the most challenging aspects of heat exchanger CFD simulations. The k-ε model has been widely adopted for industrial applications due to its reasonable accuracy and computational efficiency. However, for more complex flow phenomena such as flow separation and recirculation zones common in heat exchanger piping, more advanced models like the k-ω SST (Shear Stress Transport) or Large Eddy Simulation (LES) approaches yield superior results at the cost of increased computational resources.

Multiphase flow simulations have become increasingly important for heat exchangers involving phase change phenomena. The Volume of Fluid (VOF) method and Eulerian-Eulerian approaches enable engineers to predict critical parameters such as phase distribution, interfacial heat transfer coefficients, and pressure drop characteristics across complex piping networks.

Conjugate heat transfer modeling represents another significant advancement, allowing simultaneous simulation of conduction through solid components and convection in fluid regions. This capability is particularly valuable for optimizing material selection and wall thickness in heat exchanger piping systems, as it captures the thermal resistance effects across the entire assembly.

High-performance computing has dramatically expanded the scope and scale of CFD simulations for heat exchanger design. Parallel processing techniques utilizing GPU acceleration have reduced simulation times from weeks to hours, enabling parametric studies and optimization workflows that were previously impractical. Cloud-based CFD platforms have further democratized access to these advanced simulation capabilities, allowing smaller organizations to leverage sophisticated analysis tools without significant hardware investments.

Validation and verification protocols have evolved to ensure CFD simulation accuracy for heat exchanger applications. These typically involve benchmark comparisons against analytical solutions for simplified cases, followed by experimental validation using techniques such as Particle Image Velocimetry (PIV) and infrared thermography to verify flow patterns and temperature distributions in prototype designs.

The mesh generation process represents a critical step in CFD simulation of heat exchangers. Structured meshes offer computational efficiency but may struggle with complex geometries, while unstructured meshes provide greater flexibility for intricate piping configurations. Hybrid meshing approaches have emerged as an optimal solution, combining structured meshes in near-wall regions with unstructured meshes in the bulk flow domain.

Turbulence modeling remains one of the most challenging aspects of heat exchanger CFD simulations. The k-ε model has been widely adopted for industrial applications due to its reasonable accuracy and computational efficiency. However, for more complex flow phenomena such as flow separation and recirculation zones common in heat exchanger piping, more advanced models like the k-ω SST (Shear Stress Transport) or Large Eddy Simulation (LES) approaches yield superior results at the cost of increased computational resources.

Multiphase flow simulations have become increasingly important for heat exchangers involving phase change phenomena. The Volume of Fluid (VOF) method and Eulerian-Eulerian approaches enable engineers to predict critical parameters such as phase distribution, interfacial heat transfer coefficients, and pressure drop characteristics across complex piping networks.

Conjugate heat transfer modeling represents another significant advancement, allowing simultaneous simulation of conduction through solid components and convection in fluid regions. This capability is particularly valuable for optimizing material selection and wall thickness in heat exchanger piping systems, as it captures the thermal resistance effects across the entire assembly.

High-performance computing has dramatically expanded the scope and scale of CFD simulations for heat exchanger design. Parallel processing techniques utilizing GPU acceleration have reduced simulation times from weeks to hours, enabling parametric studies and optimization workflows that were previously impractical. Cloud-based CFD platforms have further democratized access to these advanced simulation capabilities, allowing smaller organizations to leverage sophisticated analysis tools without significant hardware investments.

Validation and verification protocols have evolved to ensure CFD simulation accuracy for heat exchanger applications. These typically involve benchmark comparisons against analytical solutions for simplified cases, followed by experimental validation using techniques such as Particle Image Velocimetry (PIV) and infrared thermography to verify flow patterns and temperature distributions in prototype designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!