How to Enhance Heat Exchanger Integration in Smart Grids

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchanger technology has evolved significantly over the past century, from basic shell-and-tube designs to advanced compact and micro-channel configurations. The integration of heat exchangers within energy systems has traditionally focused on maximizing thermal efficiency through improved materials and geometries. However, with the emergence of smart grids as decentralized, data-driven energy networks, heat exchanger technology stands at a critical evolutionary juncture requiring fundamental rethinking of its role and functionality.

The historical trajectory of heat exchanger development has been primarily driven by industrial demands for higher efficiency, reduced footprint, and lower material costs. Recent advancements have introduced enhanced surface technologies, novel manufacturing methods like additive manufacturing, and composite materials that significantly improve thermal performance. These innovations have laid the groundwork for the next generation of heat exchangers that must function as intelligent components within interconnected energy systems.

Smart grids represent a paradigm shift in energy management, characterized by bidirectional energy flows, real-time data analytics, and adaptive control systems. Within this context, heat exchangers are evolving from passive thermal components to active elements capable of responding dynamically to changing grid conditions. This transformation necessitates the integration of sensing capabilities, communication protocols, and autonomous control mechanisms into heat exchanger design and operation.

The primary technical objective for enhanced heat exchanger integration in smart grids is to develop adaptive thermal management systems that optimize energy recovery and distribution across multiple nodes of the grid. This includes the ability to modulate thermal transfer rates in response to fluctuating energy availability, particularly from renewable sources, and varying demand patterns. Additionally, these systems must facilitate thermal energy storage and release with minimal losses to support grid stability during peak demand periods.

Another critical objective is the development of standardized communication interfaces that enable heat exchangers to participate in grid-level energy optimization algorithms. This requires establishing protocols for data exchange between thermal systems and electrical components of the smart grid, creating a unified framework for holistic energy management that transcends traditional boundaries between thermal and electrical domains.

Looking forward, the technology trajectory points toward increasingly autonomous heat exchange systems with predictive capabilities based on machine learning algorithms. These systems will anticipate grid conditions and optimize their operation accordingly, potentially incorporating phase-change materials and thermochemical processes to enhance energy density and efficiency. The ultimate goal is to create a seamlessly integrated thermal-electrical grid ecosystem that maximizes renewable energy utilization while minimizing carbon emissions and operational costs.

The historical trajectory of heat exchanger development has been primarily driven by industrial demands for higher efficiency, reduced footprint, and lower material costs. Recent advancements have introduced enhanced surface technologies, novel manufacturing methods like additive manufacturing, and composite materials that significantly improve thermal performance. These innovations have laid the groundwork for the next generation of heat exchangers that must function as intelligent components within interconnected energy systems.

Smart grids represent a paradigm shift in energy management, characterized by bidirectional energy flows, real-time data analytics, and adaptive control systems. Within this context, heat exchangers are evolving from passive thermal components to active elements capable of responding dynamically to changing grid conditions. This transformation necessitates the integration of sensing capabilities, communication protocols, and autonomous control mechanisms into heat exchanger design and operation.

The primary technical objective for enhanced heat exchanger integration in smart grids is to develop adaptive thermal management systems that optimize energy recovery and distribution across multiple nodes of the grid. This includes the ability to modulate thermal transfer rates in response to fluctuating energy availability, particularly from renewable sources, and varying demand patterns. Additionally, these systems must facilitate thermal energy storage and release with minimal losses to support grid stability during peak demand periods.

Another critical objective is the development of standardized communication interfaces that enable heat exchangers to participate in grid-level energy optimization algorithms. This requires establishing protocols for data exchange between thermal systems and electrical components of the smart grid, creating a unified framework for holistic energy management that transcends traditional boundaries between thermal and electrical domains.

Looking forward, the technology trajectory points toward increasingly autonomous heat exchange systems with predictive capabilities based on machine learning algorithms. These systems will anticipate grid conditions and optimize their operation accordingly, potentially incorporating phase-change materials and thermochemical processes to enhance energy density and efficiency. The ultimate goal is to create a seamlessly integrated thermal-electrical grid ecosystem that maximizes renewable energy utilization while minimizing carbon emissions and operational costs.

Smart Grid Market Demand Analysis

The global smart grid market is experiencing significant growth, driven by the increasing demand for efficient energy management systems and the integration of renewable energy sources. According to recent market research, the smart grid market is projected to reach $92.2 billion by 2026, growing at a CAGR of 16.9% from 2021. This growth is particularly relevant for heat exchanger integration, as these components play a crucial role in energy recovery and thermal management within smart grid systems.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulatory bodies implementing policies that mandate improved energy utilization in power systems. This regulatory push has created a substantial market demand for advanced heat exchanger technologies that can enhance the overall efficiency of smart grids. The European Union's Energy Efficiency Directive and similar regulations in North America and Asia have established clear targets for energy savings, directly influencing the adoption of heat exchanger integration solutions.

The transition toward decentralized energy generation presents a significant market opportunity for heat exchanger integration. As distributed energy resources (DERs) become more prevalent, the need for efficient thermal management at multiple points within the grid increases. Market analysis indicates that regions with high penetration of renewable energy sources, such as Northern Europe, California, and parts of China, show the strongest demand for advanced heat exchanger solutions that can manage the variable thermal loads associated with renewable generation.

Industrial and commercial sectors represent the largest market segments for heat exchanger integration in smart grids. These sectors consume approximately 60% of global electricity production and have the most to gain from improved energy efficiency. The demand is particularly strong in energy-intensive industries such as manufacturing, data centers, and chemical processing, where even marginal improvements in energy recovery can translate to substantial cost savings.

The market for smart grid heat exchanger solutions is also being driven by urbanization trends and the development of smart cities. Urban areas, with their concentrated energy demands and complex infrastructure, require sophisticated thermal management solutions. The concept of district heating and cooling networks, integrated with smart grid technologies, has gained significant traction in densely populated regions, creating a specialized market niche for advanced heat exchanger systems.

Consumer awareness and demand for sustainable energy solutions have created a pull factor in the market. End-users are increasingly willing to invest in technologies that reduce energy consumption and carbon footprint. This trend is reflected in the growing market for residential and small commercial smart grid solutions that incorporate heat recovery systems, with annual growth rates exceeding 20% in some regions.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulatory bodies implementing policies that mandate improved energy utilization in power systems. This regulatory push has created a substantial market demand for advanced heat exchanger technologies that can enhance the overall efficiency of smart grids. The European Union's Energy Efficiency Directive and similar regulations in North America and Asia have established clear targets for energy savings, directly influencing the adoption of heat exchanger integration solutions.

The transition toward decentralized energy generation presents a significant market opportunity for heat exchanger integration. As distributed energy resources (DERs) become more prevalent, the need for efficient thermal management at multiple points within the grid increases. Market analysis indicates that regions with high penetration of renewable energy sources, such as Northern Europe, California, and parts of China, show the strongest demand for advanced heat exchanger solutions that can manage the variable thermal loads associated with renewable generation.

Industrial and commercial sectors represent the largest market segments for heat exchanger integration in smart grids. These sectors consume approximately 60% of global electricity production and have the most to gain from improved energy efficiency. The demand is particularly strong in energy-intensive industries such as manufacturing, data centers, and chemical processing, where even marginal improvements in energy recovery can translate to substantial cost savings.

The market for smart grid heat exchanger solutions is also being driven by urbanization trends and the development of smart cities. Urban areas, with their concentrated energy demands and complex infrastructure, require sophisticated thermal management solutions. The concept of district heating and cooling networks, integrated with smart grid technologies, has gained significant traction in densely populated regions, creating a specialized market niche for advanced heat exchanger systems.

Consumer awareness and demand for sustainable energy solutions have created a pull factor in the market. End-users are increasingly willing to invest in technologies that reduce energy consumption and carbon footprint. This trend is reflected in the growing market for residential and small commercial smart grid solutions that incorporate heat recovery systems, with annual growth rates exceeding 20% in some regions.

Current Integration Challenges

The integration of heat exchangers into smart grid systems presents several significant technical challenges that currently impede optimal implementation. Traditional heat exchangers were designed for conventional power systems with predictable load patterns, making them ill-suited for the dynamic nature of smart grids that incorporate intermittent renewable energy sources. This fundamental mismatch creates operational inefficiencies and reduces overall system performance.

Interoperability issues represent a major obstacle, as existing heat exchanger systems often utilize proprietary communication protocols that cannot seamlessly interface with modern smart grid management systems. The lack of standardized communication frameworks prevents real-time data exchange between heat exchangers and grid control centers, limiting the potential for dynamic load balancing and demand response capabilities.

Thermal storage integration challenges further complicate heat exchanger deployment in smart grids. Current heat exchanger designs typically lack the sophisticated control mechanisms needed to effectively coordinate with thermal storage systems, which are essential for managing the variability of renewable energy generation. This coordination gap results in missed opportunities for energy conservation and load shifting during peak demand periods.

Sensor technology limitations present another significant barrier. Many deployed heat exchangers utilize outdated monitoring systems that provide insufficient granularity of temperature, pressure, and flow data. Without advanced sensing capabilities, smart grid operators cannot implement predictive maintenance strategies or optimize heat transfer efficiency based on real-time conditions, leading to preventable energy losses and equipment failures.

Scalability concerns emerge as existing heat exchanger installations struggle to accommodate the growing complexity of smart grid architectures. As distributed energy resources proliferate across the grid, heat exchangers must handle increasingly variable thermal loads while maintaining efficiency. Current designs often lack the modular flexibility required to scale operations according to fluctuating grid demands.

Cybersecurity vulnerabilities represent an emerging challenge as heat exchangers become more connected to digital infrastructure. Many legacy systems were designed with minimal security considerations, creating potential entry points for cyber attacks that could compromise both energy efficiency and grid stability. The absence of robust authentication mechanisms and encrypted communications channels leaves these critical components exposed to unauthorized access.

Regulatory and standardization gaps further impede progress, as existing frameworks often fail to address the unique requirements of heat exchanger integration in smart grid environments. Without clear technical standards and certification processes, manufacturers face uncertainty when developing next-generation solutions, slowing innovation and market adoption of advanced heat exchange technologies for smart grid applications.

Interoperability issues represent a major obstacle, as existing heat exchanger systems often utilize proprietary communication protocols that cannot seamlessly interface with modern smart grid management systems. The lack of standardized communication frameworks prevents real-time data exchange between heat exchangers and grid control centers, limiting the potential for dynamic load balancing and demand response capabilities.

Thermal storage integration challenges further complicate heat exchanger deployment in smart grids. Current heat exchanger designs typically lack the sophisticated control mechanisms needed to effectively coordinate with thermal storage systems, which are essential for managing the variability of renewable energy generation. This coordination gap results in missed opportunities for energy conservation and load shifting during peak demand periods.

Sensor technology limitations present another significant barrier. Many deployed heat exchangers utilize outdated monitoring systems that provide insufficient granularity of temperature, pressure, and flow data. Without advanced sensing capabilities, smart grid operators cannot implement predictive maintenance strategies or optimize heat transfer efficiency based on real-time conditions, leading to preventable energy losses and equipment failures.

Scalability concerns emerge as existing heat exchanger installations struggle to accommodate the growing complexity of smart grid architectures. As distributed energy resources proliferate across the grid, heat exchangers must handle increasingly variable thermal loads while maintaining efficiency. Current designs often lack the modular flexibility required to scale operations according to fluctuating grid demands.

Cybersecurity vulnerabilities represent an emerging challenge as heat exchangers become more connected to digital infrastructure. Many legacy systems were designed with minimal security considerations, creating potential entry points for cyber attacks that could compromise both energy efficiency and grid stability. The absence of robust authentication mechanisms and encrypted communications channels leaves these critical components exposed to unauthorized access.

Regulatory and standardization gaps further impede progress, as existing frameworks often fail to address the unique requirements of heat exchanger integration in smart grid environments. Without clear technical standards and certification processes, manufacturers face uncertainty when developing next-generation solutions, slowing innovation and market adoption of advanced heat exchange technologies for smart grid applications.

Existing Integration Solutions

01 Heat exchanger design optimization

Optimization of heat exchanger designs focuses on improving thermal efficiency through innovative structural configurations. This includes enhanced surface geometries, flow path modifications, and material selection to maximize heat transfer rates while minimizing pressure drop. These optimizations can significantly improve overall system performance and energy efficiency in various industrial applications.- Heat exchanger design optimization: Optimization of heat exchanger designs focuses on improving thermal efficiency through innovative structural configurations. This includes enhanced surface geometries, flow path modifications, and material selection to maximize heat transfer rates while minimizing pressure drops. Advanced computational methods are employed to model and simulate heat exchanger performance under various operating conditions, leading to more compact and efficient designs.

- Process integration with heat recovery systems: Integration of heat exchangers within larger process systems enables effective energy recovery and utilization. These systems capture waste heat from industrial processes and redirect it to other parts of the operation where thermal energy is required. This approach significantly reduces overall energy consumption, improves system efficiency, and decreases operational costs while minimizing environmental impact through reduced emissions.

- Multi-stream heat exchanger networks: Multi-stream heat exchanger networks allow for complex thermal integration between multiple process streams. These networks optimize heat transfer between hot and cold streams across an entire facility, maximizing energy recovery. Advanced pinch analysis and mathematical optimization techniques are employed to determine the optimal arrangement of heat exchangers, minimizing both capital investment and energy requirements while meeting process constraints.

- Smart control systems for heat exchanger networks: Intelligent control systems enhance heat exchanger performance through real-time monitoring and adjustment. These systems employ sensors, controllers, and advanced algorithms to optimize operating parameters based on changing process conditions. Machine learning and predictive analytics enable proactive maintenance, fault detection, and dynamic optimization of heat transfer efficiency, resulting in more stable operation and extended equipment life.

- Compact and modular heat exchanger solutions: Compact and modular heat exchanger designs address space constraints and flexibility requirements in modern industrial applications. These solutions feature high surface area-to-volume ratios, enabling efficient heat transfer in limited spaces. Modular configurations allow for scalability, easier maintenance, and simplified installation or replacement. Advanced manufacturing techniques, including additive manufacturing, enable complex geometries that further enhance heat transfer performance.

02 Process integration with heat recovery systems

Integration of heat exchangers within larger process systems enables effective heat recovery and utilization. By capturing waste heat from one process and transferring it to another, these integrated systems significantly reduce energy consumption and operational costs. Advanced control strategies ensure optimal heat distribution across multiple process streams, maximizing overall thermal efficiency of industrial operations.Expand Specific Solutions03 Compact and modular heat exchanger solutions

Compact and modular heat exchanger designs address space constraints while maintaining high thermal performance. These solutions feature standardized components that can be easily assembled, disassembled, and scaled according to specific requirements. The modular approach facilitates maintenance, reduces installation time, and allows for flexible system expansion or reconfiguration as operational needs change.Expand Specific Solutions04 Advanced materials and manufacturing techniques

Implementation of advanced materials and manufacturing techniques enhances heat exchanger performance and durability. Novel materials with superior thermal conductivity, corrosion resistance, and mechanical properties extend operational lifespan in harsh environments. Additive manufacturing and precision fabrication methods enable complex geometries that were previously impossible, resulting in more efficient heat transfer surfaces and reduced material usage.Expand Specific Solutions05 Smart control systems for heat exchanger networks

Integration of smart control systems optimizes the operation of heat exchanger networks through real-time monitoring and adaptive control strategies. These systems employ sensors, predictive algorithms, and automated valves to maintain optimal thermal performance under varying conditions. Dynamic adjustment of flow rates and temperatures ensures maximum energy efficiency while preventing fouling and other operational issues that could reduce heat transfer effectiveness.Expand Specific Solutions

Key Industry Players

The heat exchanger integration in smart grids market is currently in a growth phase, with increasing adoption driven by energy efficiency demands and grid modernization initiatives. The market size is expanding rapidly, projected to reach significant value as utilities and energy providers seek optimized thermal management solutions. Technologically, the field shows varying maturity levels across players. Industry leaders like Modine Manufacturing and DENSO Corp demonstrate advanced integration capabilities, while companies such as Webasto and MAHLE International focus on specialized thermal management solutions. Energy giants including Saudi Aramco and utility providers like Guangdong Power Grid are investing in smart grid infrastructure that incorporates these technologies. Academic institutions like Tsinghua University and Northeast Electric Power University are contributing research advancements, while technology companies like Samsung Electronics and Intel are developing supporting digital infrastructure components.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive heat exchanger integration framework for smart grid applications called "ThermalGrid+" that leverages their extensive experience in industrial-scale thermal management. Their approach focuses on large-scale waste heat recovery from power generation and industrial processes, with specialized heat exchangers designed to operate in extreme temperature environments (from -40°C to +650°C). The company has implemented advanced materials science innovations, including ceramic-metallic composite heat transfer surfaces that demonstrate exceptional thermal conductivity while resisting corrosion and fouling. Their system incorporates predictive thermal load balancing algorithms that can forecast heat availability and demand across integrated industrial parks and nearby communities, optimizing the routing of thermal energy through a network of strategically placed heat exchangers. Saudi Aramco's solution includes proprietary heat transfer fluids with enhanced thermal properties that improve overall system efficiency by approximately 22% compared to conventional systems.

Strengths: Unparalleled experience with industrial-scale heat exchange systems and substantial R&D resources for developing advanced materials and thermal transfer technologies. Their solutions are exceptionally robust and designed for decades of continuous operation. Weaknesses: Primary focus on oil and gas applications may limit optimization for purely electrical smart grid environments, and solutions may be overengineered for smaller-scale implementations.

DENSO Corp.

Technical Solution: DENSO has developed an innovative heat exchanger integration system for smart grids called "E-Thermal Network" that builds upon their automotive thermal management expertise. Their solution features compact, high-efficiency plate heat exchangers with enhanced turbulence promoters that increase heat transfer rates while minimizing pressure drop. DENSO's system incorporates cascaded heat recovery networks that can extract thermal energy across multiple temperature gradients, maximizing overall system efficiency. The company has pioneered micro-channel heat exchangers with optimized flow distribution manifolds that achieve up to 30% higher heat transfer coefficients compared to conventional designs. Their technology includes intelligent thermal routing capabilities that dynamically adjust flow paths based on real-time demand signals from the grid, enabling responsive load management during peak periods. DENSO has also developed specialized heat exchanger coatings that significantly reduce fouling in open-loop systems, extending maintenance intervals and maintaining consistent performance.

Strengths: Exceptional manufacturing precision and quality control processes developed through automotive industry experience, resulting in highly reliable and efficient heat exchanger designs. Their compact solutions are ideal for distributed energy resource integration. Weaknesses: Less experience with utility-scale implementations compared to dedicated power industry players, and their solutions may require adaptation for very large-scale applications.

Core Technologies Analysis

Heat exchanger arrangement

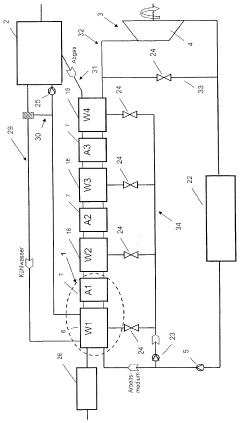

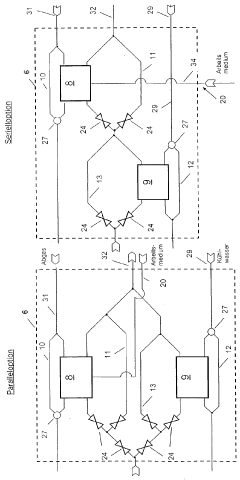

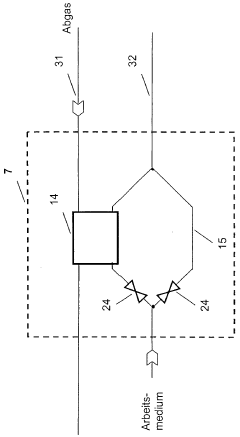

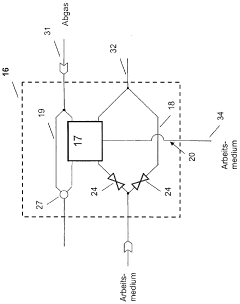

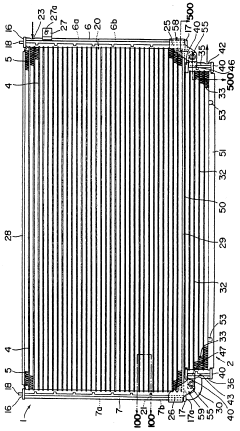

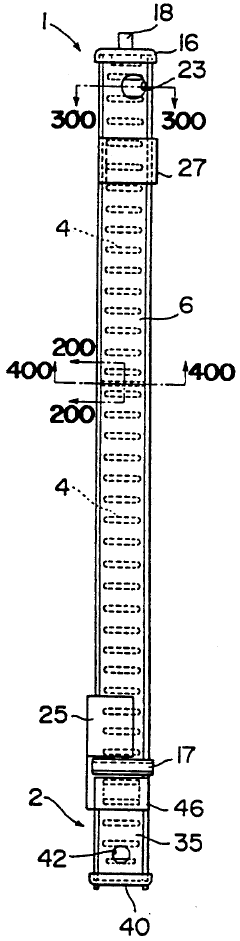

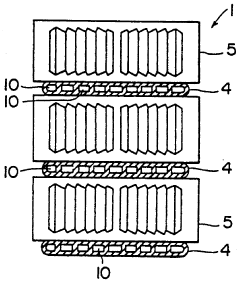

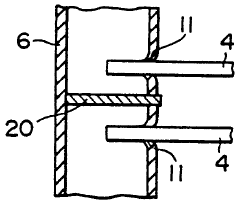

PatentWO2008034540A1

Innovation

- The proposed heat exchanger arrangement improves heat transfer efficiency by using a combination of high-temperature and low-temperature circuits, with strategically placed heat exchangers, pumps, and control devices like flaps and throttle elements to regulate the flow of coolant, exhaust gas, and working medium, optimizing the thermal energy transfer and kinetic energy conversion.

Heat exchanger apparatus having fluid coupled primary heat exchanger unit and auxiliary heat exchanger unit

PatentInactiveUS5197538A

Innovation

- A heat exchanger configuration comprising a primary and auxiliary heat exchanger connected via brackets and a connecting pipe, allowing for adjustable tube lengths and configurations to enhance structural support and prevent deformation, while maintaining heat exchanging efficiency.

Energy Efficiency Standards

Energy efficiency standards play a crucial role in the integration of heat exchangers within smart grid systems. These standards establish the minimum performance requirements that heat exchange technologies must meet, ensuring optimal energy utilization across the grid infrastructure. Currently, international standards such as ISO 50001 for energy management systems provide overarching frameworks, while more specific standards like ASHRAE 90.1 and EN 15316 address heat exchange efficiency in building systems connected to smart grids.

The evolution of these standards reflects growing recognition of heat exchangers as critical components in energy conservation. Recent updates to efficiency standards have begun incorporating smart functionality requirements, mandating capabilities for real-time monitoring, automated adjustment based on grid conditions, and interoperability with other smart grid components. These developments represent a significant shift from traditional static efficiency metrics toward dynamic performance evaluation in varying operational scenarios.

Regulatory bodies across major markets have established increasingly stringent efficiency thresholds for heat exchange systems. The European Union's Ecodesign Directive has implemented minimum efficiency requirements for heat exchangers in various applications, with planned increases in stringency through 2030. Similarly, the U.S. Department of Energy has established progressive efficiency standards with particular emphasis on heat recovery systems integrated with smart grid infrastructure.

Compliance verification methodologies have also evolved substantially, moving beyond laboratory testing to include field performance monitoring through IoT-enabled sensors and analytics. This shift enables continuous verification of heat exchanger performance under actual operating conditions within smart grid environments, providing valuable data for both regulatory compliance and system optimization.

The economic impact of these standards has been significant, with studies indicating that advanced heat exchangers meeting current efficiency standards can reduce energy consumption by 15-30% compared to conventional systems. However, implementation challenges remain, particularly regarding the harmonization of standards across different regions and the development of appropriate testing protocols for novel heat exchange technologies designed specifically for smart grid applications.

Future trends in energy efficiency standards for heat exchangers in smart grids point toward more granular performance metrics, including responsiveness to grid signals, contribution to demand response capabilities, and resilience during grid stress events. Additionally, lifecycle assessment approaches are increasingly being incorporated into standards, considering not only operational efficiency but also embodied energy and end-of-life considerations.

The evolution of these standards reflects growing recognition of heat exchangers as critical components in energy conservation. Recent updates to efficiency standards have begun incorporating smart functionality requirements, mandating capabilities for real-time monitoring, automated adjustment based on grid conditions, and interoperability with other smart grid components. These developments represent a significant shift from traditional static efficiency metrics toward dynamic performance evaluation in varying operational scenarios.

Regulatory bodies across major markets have established increasingly stringent efficiency thresholds for heat exchange systems. The European Union's Ecodesign Directive has implemented minimum efficiency requirements for heat exchangers in various applications, with planned increases in stringency through 2030. Similarly, the U.S. Department of Energy has established progressive efficiency standards with particular emphasis on heat recovery systems integrated with smart grid infrastructure.

Compliance verification methodologies have also evolved substantially, moving beyond laboratory testing to include field performance monitoring through IoT-enabled sensors and analytics. This shift enables continuous verification of heat exchanger performance under actual operating conditions within smart grid environments, providing valuable data for both regulatory compliance and system optimization.

The economic impact of these standards has been significant, with studies indicating that advanced heat exchangers meeting current efficiency standards can reduce energy consumption by 15-30% compared to conventional systems. However, implementation challenges remain, particularly regarding the harmonization of standards across different regions and the development of appropriate testing protocols for novel heat exchange technologies designed specifically for smart grid applications.

Future trends in energy efficiency standards for heat exchangers in smart grids point toward more granular performance metrics, including responsiveness to grid signals, contribution to demand response capabilities, and resilience during grid stress events. Additionally, lifecycle assessment approaches are increasingly being incorporated into standards, considering not only operational efficiency but also embodied energy and end-of-life considerations.

Grid Resilience Strategies

Grid resilience strategies for heat exchanger integration in smart grids must address multiple vulnerabilities while enhancing system performance. The implementation of redundant heat exchange pathways represents a fundamental approach, allowing thermal energy transfer to continue even when individual components fail. These redundant systems can be designed with varying capacities, enabling partial operation during disruptions while maintaining critical thermal services to priority sectors.

Decentralized heat exchange networks significantly improve grid resilience by reducing dependency on centralized infrastructure. This distributed architecture limits the impact radius of localized failures and allows for autonomous operation of subsections during wider system disturbances. Advanced implementations incorporate microgrids with dedicated heat exchange capabilities that can operate in island mode when necessary.

Real-time monitoring and predictive maintenance systems form another critical resilience layer. By deploying sensor networks throughout heat exchange infrastructure, operators can detect anomalies before they escalate into failures. Machine learning algorithms analyzing temperature patterns, flow rates, and pressure differentials can predict potential component failures days or weeks in advance, allowing for scheduled maintenance rather than emergency repairs.

Adaptive control systems enhance resilience through dynamic load balancing and resource allocation. During extreme weather events or unexpected demand surges, these systems automatically redistribute thermal loads across available heat exchangers, preventing overloading and subsequent failures. The most sophisticated implementations incorporate weather forecasting data to proactively adjust operations before conditions deteriorate.

Physical hardening measures remain essential for protecting heat exchange infrastructure against environmental threats. This includes weatherproofing components against extreme temperatures, reinforcing structures against high winds, and elevating critical equipment in flood-prone areas. Newer designs incorporate modular components that can be rapidly replaced following damage, minimizing downtime.

Cyber-physical security protocols protect against both digital and physical threats to heat exchanger systems. As these components become increasingly connected within smart grids, they present potential attack vectors for malicious actors. Implementing air-gapped control systems for critical components, encrypted communications, and physical access restrictions creates multiple security layers that significantly enhance overall grid resilience.

Decentralized heat exchange networks significantly improve grid resilience by reducing dependency on centralized infrastructure. This distributed architecture limits the impact radius of localized failures and allows for autonomous operation of subsections during wider system disturbances. Advanced implementations incorporate microgrids with dedicated heat exchange capabilities that can operate in island mode when necessary.

Real-time monitoring and predictive maintenance systems form another critical resilience layer. By deploying sensor networks throughout heat exchange infrastructure, operators can detect anomalies before they escalate into failures. Machine learning algorithms analyzing temperature patterns, flow rates, and pressure differentials can predict potential component failures days or weeks in advance, allowing for scheduled maintenance rather than emergency repairs.

Adaptive control systems enhance resilience through dynamic load balancing and resource allocation. During extreme weather events or unexpected demand surges, these systems automatically redistribute thermal loads across available heat exchangers, preventing overloading and subsequent failures. The most sophisticated implementations incorporate weather forecasting data to proactively adjust operations before conditions deteriorate.

Physical hardening measures remain essential for protecting heat exchange infrastructure against environmental threats. This includes weatherproofing components against extreme temperatures, reinforcing structures against high winds, and elevating critical equipment in flood-prone areas. Newer designs incorporate modular components that can be rapidly replaced following damage, minimizing downtime.

Cyber-physical security protocols protect against both digital and physical threats to heat exchanger systems. As these components become increasingly connected within smart grids, they present potential attack vectors for malicious actors. Implementing air-gapped control systems for critical components, encrypted communications, and physical access restrictions creates multiple security layers that significantly enhance overall grid resilience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!