Heat Exchanger Seals: Criteria for Selection and Performance

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Seal Technology Evolution and Objectives

Heat exchanger seal technology has evolved significantly over the past century, transitioning from rudimentary designs to sophisticated engineered solutions. The earliest heat exchanger seals, developed in the early 1900s, were primarily mechanical seals utilizing basic materials like asbestos and rubber. These primitive designs often suffered from reliability issues, frequent leakage, and short operational lifespans, particularly when exposed to extreme temperatures or corrosive media.

The mid-20th century marked a pivotal shift with the introduction of synthetic elastomers and advanced metallurgy, enabling seals to withstand more challenging operating conditions. The 1960s and 1970s witnessed the development of fluoroelastomer compounds and metal-to-metal seals, significantly enhancing performance in high-temperature applications. This period also saw the emergence of standardized testing protocols and industry specifications for heat exchanger seals.

By the 1980s and 1990s, computational fluid dynamics and finite element analysis began transforming seal design, allowing engineers to model and predict seal behavior under various operating conditions before physical prototyping. This era also introduced composite materials and advanced coating technologies that dramatically improved seal longevity and chemical resistance.

The early 21st century has been characterized by the integration of smart technologies into seal systems. Modern heat exchanger seals increasingly incorporate sensors for real-time monitoring of parameters such as temperature, pressure, and wear. This evolution toward "intelligent seals" enables predictive maintenance strategies and optimized performance across varying operational conditions.

Current technological objectives in heat exchanger seal development focus on several key areas. Energy efficiency remains paramount, with research directed toward minimizing friction and thermal losses at seal interfaces. Environmental sustainability drives the development of non-toxic, recyclable seal materials that comply with increasingly stringent global regulations while maintaining performance integrity.

Operational reliability under extreme conditions represents another critical objective, particularly for applications in aerospace, deep-sea operations, and nuclear facilities where seal failure can have catastrophic consequences. Engineers are pursuing designs capable of withstanding ultra-high temperatures, cryogenic environments, and highly corrosive media while maintaining seal integrity.

Miniaturization presents another significant challenge, especially for compact heat exchangers in electronics cooling and medical devices. The industry is working toward seals that maintain effectiveness at micro-scales without compromising on reliability or lifespan. Additionally, cost-effectiveness remains a persistent goal, with efforts to develop manufacturing techniques that reduce production costs while maintaining or improving seal performance characteristics.

The mid-20th century marked a pivotal shift with the introduction of synthetic elastomers and advanced metallurgy, enabling seals to withstand more challenging operating conditions. The 1960s and 1970s witnessed the development of fluoroelastomer compounds and metal-to-metal seals, significantly enhancing performance in high-temperature applications. This period also saw the emergence of standardized testing protocols and industry specifications for heat exchanger seals.

By the 1980s and 1990s, computational fluid dynamics and finite element analysis began transforming seal design, allowing engineers to model and predict seal behavior under various operating conditions before physical prototyping. This era also introduced composite materials and advanced coating technologies that dramatically improved seal longevity and chemical resistance.

The early 21st century has been characterized by the integration of smart technologies into seal systems. Modern heat exchanger seals increasingly incorporate sensors for real-time monitoring of parameters such as temperature, pressure, and wear. This evolution toward "intelligent seals" enables predictive maintenance strategies and optimized performance across varying operational conditions.

Current technological objectives in heat exchanger seal development focus on several key areas. Energy efficiency remains paramount, with research directed toward minimizing friction and thermal losses at seal interfaces. Environmental sustainability drives the development of non-toxic, recyclable seal materials that comply with increasingly stringent global regulations while maintaining performance integrity.

Operational reliability under extreme conditions represents another critical objective, particularly for applications in aerospace, deep-sea operations, and nuclear facilities where seal failure can have catastrophic consequences. Engineers are pursuing designs capable of withstanding ultra-high temperatures, cryogenic environments, and highly corrosive media while maintaining seal integrity.

Miniaturization presents another significant challenge, especially for compact heat exchangers in electronics cooling and medical devices. The industry is working toward seals that maintain effectiveness at micro-scales without compromising on reliability or lifespan. Additionally, cost-effectiveness remains a persistent goal, with efforts to develop manufacturing techniques that reduce production costs while maintaining or improving seal performance characteristics.

Market Requirements Analysis for Industrial Sealing Solutions

The industrial sealing solutions market for heat exchangers is experiencing robust growth driven by increasing demand across multiple sectors including oil and gas, chemical processing, power generation, and HVAC systems. Current market analysis indicates that the global heat exchanger seals market is expanding at a compound annual growth rate of approximately 5-6%, with particularly strong performance in regions undergoing rapid industrialization such as Southeast Asia and parts of South America.

Customer requirements for heat exchanger seals have evolved significantly in recent years, with end-users prioritizing longer service life, reduced maintenance intervals, and improved reliability under extreme operating conditions. Industries operating in high-temperature environments (above 200°C) or with corrosive media are demanding sealing solutions that can withstand these challenging conditions while maintaining integrity and preventing leakage.

Environmental regulations and sustainability initiatives are reshaping market demands, with a growing preference for sealing solutions that minimize fugitive emissions and comply with increasingly stringent environmental standards such as EPA Method 21 and TA-Luft VDI 2440. This regulatory pressure is particularly acute in chemical processing and petrochemical industries, where leak detection and repair (LDAR) programs have become standard practice.

Cost considerations remain paramount in purchasing decisions, with total cost of ownership (TCO) increasingly displacing initial acquisition cost as the primary economic factor. End-users are demonstrating willingness to invest in premium sealing solutions when vendors can demonstrate superior performance metrics such as extended mean time between maintenance (MTBM) and reduced downtime costs.

Material compatibility requirements have become more complex as process fluids become more diverse and aggressive. The market shows strong demand for seals resistant to a wide range of chemicals, with fluoroelastomers and perfluoroelastomers gaining market share despite their premium pricing. For high-temperature applications, graphite-based and ceramic sealing solutions are experiencing increased adoption rates.

Customization capabilities are increasingly valued by end-users, with many requiring sealing solutions tailored to specific equipment configurations and operating parameters. This trend favors suppliers with strong engineering capabilities and flexible manufacturing processes who can provide application-specific solutions rather than generic offerings.

Digital transformation is beginning to influence market requirements, with growing interest in smart sealing solutions that incorporate sensors for condition monitoring and predictive maintenance capabilities. While still representing a small segment of the overall market, these IoT-enabled sealing solutions command premium pricing and are expected to see accelerated adoption as industrial digitalization continues.

Customer requirements for heat exchanger seals have evolved significantly in recent years, with end-users prioritizing longer service life, reduced maintenance intervals, and improved reliability under extreme operating conditions. Industries operating in high-temperature environments (above 200°C) or with corrosive media are demanding sealing solutions that can withstand these challenging conditions while maintaining integrity and preventing leakage.

Environmental regulations and sustainability initiatives are reshaping market demands, with a growing preference for sealing solutions that minimize fugitive emissions and comply with increasingly stringent environmental standards such as EPA Method 21 and TA-Luft VDI 2440. This regulatory pressure is particularly acute in chemical processing and petrochemical industries, where leak detection and repair (LDAR) programs have become standard practice.

Cost considerations remain paramount in purchasing decisions, with total cost of ownership (TCO) increasingly displacing initial acquisition cost as the primary economic factor. End-users are demonstrating willingness to invest in premium sealing solutions when vendors can demonstrate superior performance metrics such as extended mean time between maintenance (MTBM) and reduced downtime costs.

Material compatibility requirements have become more complex as process fluids become more diverse and aggressive. The market shows strong demand for seals resistant to a wide range of chemicals, with fluoroelastomers and perfluoroelastomers gaining market share despite their premium pricing. For high-temperature applications, graphite-based and ceramic sealing solutions are experiencing increased adoption rates.

Customization capabilities are increasingly valued by end-users, with many requiring sealing solutions tailored to specific equipment configurations and operating parameters. This trend favors suppliers with strong engineering capabilities and flexible manufacturing processes who can provide application-specific solutions rather than generic offerings.

Digital transformation is beginning to influence market requirements, with growing interest in smart sealing solutions that incorporate sensors for condition monitoring and predictive maintenance capabilities. While still representing a small segment of the overall market, these IoT-enabled sealing solutions command premium pricing and are expected to see accelerated adoption as industrial digitalization continues.

Current Seal Technologies and Performance Limitations

Heat exchanger seals currently employ a variety of technologies, each with specific performance characteristics and limitations. Mechanical face seals represent the most widely adopted solution, utilizing a stationary and rotating face that create a thin fluid film between them. While these seals offer excellent reliability in moderate operating conditions, they struggle with extreme temperatures exceeding 400°C and high-pressure differentials above 30 bar, where face distortion and material degradation become significant concerns.

Labyrinth seals provide a non-contact alternative through a series of intricate pathways that restrict fluid flow. Their primary advantage lies in minimal maintenance requirements and excellent longevity. However, they exhibit relatively high leakage rates compared to contact seals, particularly when subjected to pressure fluctuations, and their effectiveness diminishes considerably with shaft misalignment exceeding 0.5mm.

Brush seals, consisting of densely packed metallic bristles, have gained prominence in high-temperature applications. These seals accommodate thermal expansion and minor shaft movements effectively, but their performance degrades over time due to bristle wear, typically requiring replacement after 8,000-10,000 operating hours in demanding environments.

Floating ring seals utilize pressure-balanced rings that "float" between the shaft and housing. Their self-adjusting capability makes them suitable for applications with shaft runout, but they struggle with maintaining seal integrity during rapid thermal transients and exhibit increased leakage rates at low operating pressures below 5 bar.

Elastomeric seals, including O-rings and gaskets, provide excellent sealing in low to moderate temperature applications (typically below 200°C). Their primary limitations include material degradation when exposed to aggressive process fluids and significant performance deterioration when subjected to thermal cycling, leading to compression set and reduced sealing effectiveness.

Composite seals incorporating graphite, PTFE, and ceramic materials attempt to address the limitations of single-material designs. While offering improved chemical resistance and temperature capabilities, these seals often suffer from delamination under cyclic loading conditions and exhibit inconsistent performance across varying operating parameters.

The performance limitations across all current seal technologies center around several critical factors: temperature resistance, pressure handling capability, chemical compatibility, and dynamic response to mechanical disturbances. Most existing solutions force engineers to prioritize certain performance aspects while accepting compromises in others, highlighting the need for more versatile sealing technologies that can maintain effectiveness across broader operating envelopes.

Labyrinth seals provide a non-contact alternative through a series of intricate pathways that restrict fluid flow. Their primary advantage lies in minimal maintenance requirements and excellent longevity. However, they exhibit relatively high leakage rates compared to contact seals, particularly when subjected to pressure fluctuations, and their effectiveness diminishes considerably with shaft misalignment exceeding 0.5mm.

Brush seals, consisting of densely packed metallic bristles, have gained prominence in high-temperature applications. These seals accommodate thermal expansion and minor shaft movements effectively, but their performance degrades over time due to bristle wear, typically requiring replacement after 8,000-10,000 operating hours in demanding environments.

Floating ring seals utilize pressure-balanced rings that "float" between the shaft and housing. Their self-adjusting capability makes them suitable for applications with shaft runout, but they struggle with maintaining seal integrity during rapid thermal transients and exhibit increased leakage rates at low operating pressures below 5 bar.

Elastomeric seals, including O-rings and gaskets, provide excellent sealing in low to moderate temperature applications (typically below 200°C). Their primary limitations include material degradation when exposed to aggressive process fluids and significant performance deterioration when subjected to thermal cycling, leading to compression set and reduced sealing effectiveness.

Composite seals incorporating graphite, PTFE, and ceramic materials attempt to address the limitations of single-material designs. While offering improved chemical resistance and temperature capabilities, these seals often suffer from delamination under cyclic loading conditions and exhibit inconsistent performance across varying operating parameters.

The performance limitations across all current seal technologies center around several critical factors: temperature resistance, pressure handling capability, chemical compatibility, and dynamic response to mechanical disturbances. Most existing solutions force engineers to prioritize certain performance aspects while accepting compromises in others, highlighting the need for more versatile sealing technologies that can maintain effectiveness across broader operating envelopes.

Contemporary Seal Selection Methodologies and Criteria

01 Material selection for heat exchanger seals

The selection of appropriate materials for heat exchanger seals is critical for ensuring optimal performance and longevity. Materials must be chosen based on their resistance to temperature extremes, chemical compatibility with process fluids, and ability to maintain integrity under pressure fluctuations. Advanced elastomers, fluoropolymers, and composite materials offer enhanced durability and sealing properties in challenging operating environments. The material selection process should consider thermal expansion coefficients, compression set resistance, and aging characteristics to prevent leakage and maintain efficiency.- Material selection for heat exchanger seals: The selection of appropriate materials for heat exchanger seals is critical for ensuring optimal performance and longevity. Materials must withstand operating temperatures, pressure differentials, and chemical exposure specific to the application. Factors such as thermal expansion, compression set resistance, and compatibility with process fluids must be considered. Advanced elastomers, composites, and metal alloys are commonly used based on their specific properties and the operating environment of the heat exchanger.

- Performance monitoring and evaluation systems: Systems for monitoring and evaluating the performance of heat exchanger seals help maintain operational efficiency and prevent failures. These systems utilize sensors to track parameters such as temperature, pressure, and leakage rates in real-time. Advanced monitoring solutions incorporate predictive analytics to forecast potential seal failures before they occur, allowing for scheduled maintenance rather than emergency repairs. Performance evaluation metrics include thermal efficiency, pressure drop, and seal integrity over time under various operating conditions.

- Design optimization for thermal and mechanical stress: Optimizing heat exchanger seal designs involves balancing thermal expansion considerations with mechanical stress resistance. Computational fluid dynamics and finite element analysis are employed to simulate operating conditions and identify potential failure points. Design features such as floating seal arrangements, bellows configurations, and multi-layer sealing systems help accommodate thermal cycling and mechanical stresses. Proper groove dimensions, seal compression ratios, and installation clearances are critical factors that influence overall performance and reliability.

- Environmental and operational condition adaptability: Heat exchanger seals must adapt to varying environmental and operational conditions to maintain effectiveness. Seals designed for extreme temperature applications incorporate special materials and configurations to prevent degradation. For corrosive environments, chemically resistant compounds and protective coatings extend seal life. Pressure fluctuation management features include self-adjusting mechanisms and pressure-balanced designs. Adaptability to process fluid variations and contamination resistance are also important considerations for maintaining seal integrity across different operating scenarios.

- Maintenance protocols and replacement criteria: Establishing effective maintenance protocols and clear replacement criteria for heat exchanger seals is essential for operational reliability. Inspection schedules should be based on operating conditions, seal materials, and historical performance data. Visual indicators of seal degradation include discoloration, hardening, cracking, and deformation. Performance-based replacement triggers include decreased heat transfer efficiency, increased pressure drop, or detection of leakage. Proper installation techniques, torque specifications, and surface preparation procedures significantly impact seal longevity and system performance.

02 Performance monitoring and evaluation systems

Advanced monitoring and evaluation systems are essential for assessing heat exchanger seal performance in real-time. These systems utilize sensors, data analytics, and predictive algorithms to detect early signs of seal degradation or failure. Continuous monitoring allows for timely maintenance interventions, preventing catastrophic failures and unplanned downtime. Performance parameters typically monitored include temperature differentials, pressure drops, flow rates, and thermal efficiency. Integration with plant-wide control systems enables comprehensive performance optimization and extends seal service life through adaptive operational adjustments.Expand Specific Solutions03 Environmental and operating condition considerations

The operating environment significantly impacts heat exchanger seal selection and performance. Factors such as extreme temperatures, pressure cycling, chemical exposure, and mechanical vibration must be thoroughly evaluated during the design phase. Seals must be specified to withstand the specific conditions of their application, including corrosive media, thermal cycling, and pressure fluctuations. Environmental considerations also extend to regulatory compliance, emissions control, and energy efficiency requirements. Proper assessment of these conditions ensures optimal seal performance and prevents premature failures that could lead to system inefficiencies or safety hazards.Expand Specific Solutions04 Installation and maintenance best practices

Proper installation and maintenance procedures are crucial for maximizing heat exchanger seal performance and service life. Installation techniques must ensure correct alignment, appropriate torque application, and proper surface preparation to prevent leakage paths. Regular maintenance protocols should include inspection schedules, cleaning procedures, and replacement criteria based on operating hours or performance degradation indicators. Preventive maintenance strategies, such as condition-based monitoring and scheduled replacements, help avoid unexpected failures and extend equipment life. Training for maintenance personnel on seal-specific handling and installation techniques is essential for consistent performance.Expand Specific Solutions05 Innovative seal designs and technologies

Technological advancements in heat exchanger seal design continue to improve performance and reliability. Innovations include multi-layer composite seals, self-adjusting mechanisms that compensate for wear, and smart seals with embedded sensors for condition monitoring. Advanced manufacturing techniques such as precision molding and 3D printing enable complex geometries that optimize sealing force distribution. Novel designs incorporate features like anti-extrusion rings, pressure-energized lips, and thermal expansion compensation mechanisms. These innovations address traditional failure modes while extending service intervals and improving overall heat exchanger efficiency under demanding operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The heat exchanger seal market is currently in a growth phase, driven by increasing demand for energy-efficient thermal management solutions across industries. The global market size is estimated to exceed $3 billion, with a projected CAGR of 5-7% through 2028. Technologically, the field shows varying maturity levels, with companies like MAHLE International, Valeo Thermal Systems, and DuPont leading innovation in high-performance sealing materials. Major players including Mitsubishi Hitachi Power Systems and Robert Bosch GmbH are advancing seal technologies for extreme operating conditions, while specialized manufacturers like Baltimore Aircoil and Modine Manufacturing focus on application-specific solutions. The competitive landscape features both diversified industrial conglomerates and specialized thermal management companies, with increasing emphasis on sustainable materials and designs that enhance energy efficiency.

MAHLE International GmbH

Technical Solution: MAHLE has developed a comprehensive heat exchanger seal technology portfolio centered around their "Thermal Interface Optimization" approach. Their selection methodology evaluates operational parameters including temperature range, pressure cycling, fluid compatibility, and installation constraints. For automotive applications, MAHLE employs their proprietary XNBR (carboxylated nitrile butadiene rubber) compounds with nano-scale fillers that provide superior resistance to coolant permeation while maintaining flexibility across -40°C to 160°C operating ranges[1]. Their industrial heat exchangers utilize a multi-layer sealing system with PTFE primary seals backed by elastomeric energizers, providing both chemical resistance and mechanical compliance. MAHLE's performance validation includes accelerated aging tests simulating 10+ years of service, with documented cases showing less than 2% degradation in sealing force. Their selection criteria emphasizes total cost of ownership, incorporating not only initial material costs but also installation complexity, maintenance requirements, and expected service life. For high-temperature applications, MAHLE has developed ceramic-reinforced silicone compounds that maintain integrity up to 300°C while providing electrical isolation properties critical in EV thermal management systems[2].

Strengths: Exceptional chemical compatibility across a wide range of coolants and heat transfer fluids; superior compression set resistance maintaining sealing force over extended periods; comprehensive material selection guide based on application-specific requirements. Weaknesses: Higher material costs compared to standard elastomers; more complex installation procedures for multi-layer sealing systems; limited availability of certain specialized compounds.

Valeo, Inc.

Technical Solution: Valeo has established a systematic approach to heat exchanger seal technology through their Thermal Systems division. Their methodology centers on application-specific material selection combined with advanced design optimization. For automotive heat exchangers, Valeo employs proprietary elastomer blends with optimized shore hardness profiles that maintain sealing performance across extreme temperature variations (-40°C to 180°C). Their "Thermal Cycling Resistance" (TCR) technology incorporates variable cross-section designs that accommodate differential thermal expansion between dissimilar materials while maintaining contact pressure[1]. For EV thermal management systems, Valeo has developed electrically-insulating seals with enhanced thermal conductivity, addressing the unique requirements of battery cooling systems. Their selection criteria incorporates comprehensive compatibility testing with modern coolant formulations, including long-term exposure tests demonstrating less than 5% volume change after 3,000 hours of immersion[2]. Valeo's performance validation includes both laboratory testing and field trials, with documented cases showing zero-leakage performance after 300,000 km in automotive applications. Their manufacturing process employs precision injection molding with in-line quality control, ensuring dimensional accuracy within ±0.03mm for critical sealing surfaces.

Strengths: Excellent thermal cycling resistance with proven field performance; comprehensive material compatibility database for various coolants and heat transfer fluids; advanced design optimization tools that predict seal performance under various operating conditions. Weaknesses: Higher tooling costs for complex seal geometries; limited standardization across product lines requiring application-specific designs; more stringent installation requirements compared to basic sealing solutions.

Critical Patents and Innovations in Sealing Materials

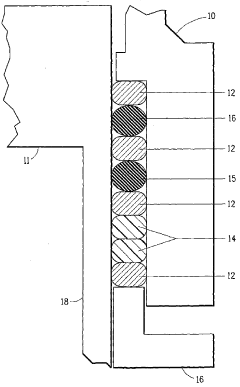

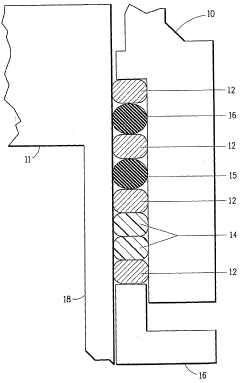

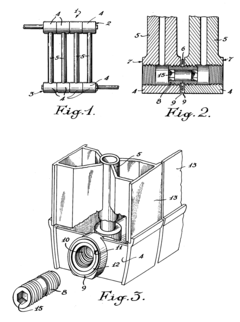

Improved heat exchanger seal

PatentWO2007064920A1

Innovation

- A multilayer seal assembly comprising non-extrudable packing layers, elastomeric O-rings, and braided plastic packing layers with elastomeric cores, allowing for thermal cycling and improved load distribution, is used between the tubesheet and casing to create a flexible and effective seal.

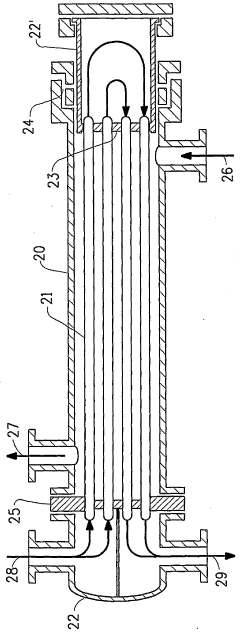

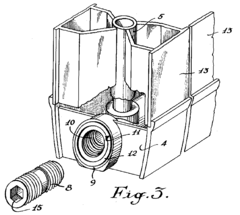

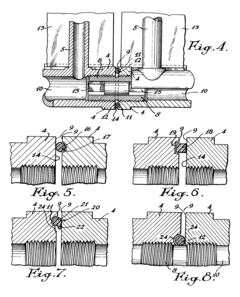

Heat exchanger with a seal

PatentInactiveEP0518843A1

Innovation

- A sealing device featuring flexible elastic seals with adapted grooves and shapes, such as circular, torus, or rectangular sections, inserted into grooves on one segment face and applied against a flat face of an adjacent segment, allowing for radial clearance to absorb differential expansion and movement without losing sealing effectiveness, using materials like synthetic rubber or silicone.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchanger seals extends far beyond operational efficiency, encompassing the entire lifecycle from manufacturing to disposal. Traditional sealing materials often contain fluoropolymers, elastomers, and metals that require significant energy inputs during production and may release harmful compounds during manufacturing processes. The extraction of raw materials for these seals, particularly specialized metals and synthetic compounds, contributes to habitat destruction, water pollution, and carbon emissions.

During operational phases, seal leakage represents a critical environmental concern. Even minor leakages of process fluids—especially in chemical, petrochemical, and power generation industries—can introduce toxins into surrounding ecosystems. Modern seal designs increasingly incorporate leak detection systems and secondary containment features to mitigate these risks, demonstrating the industry's growing environmental consciousness.

Energy consumption associated with seal friction and maintenance activities presents another sustainability challenge. Higher friction seals require more pumping energy, directly increasing the carbon footprint of operations. Progressive manufacturers now prioritize low-friction seal designs that maintain integrity while reducing energy requirements, with some reporting energy savings of 5-15% compared to conventional alternatives.

The disposal and end-of-life management of heat exchanger seals present significant sustainability concerns. Non-biodegradable materials can persist in landfills for centuries, while incineration of certain seal compounds may release harmful emissions. Forward-thinking organizations have implemented seal recycling programs, particularly for metal components, and are exploring biodegradable alternatives for appropriate applications.

Regulatory frameworks increasingly influence seal selection criteria, with legislation like the EU's REACH regulations and various clean water acts worldwide imposing stricter requirements on material composition and leakage tolerances. These regulations have accelerated innovation in environmentally friendly seal technologies, including bio-based elastomers and water-based lubricants that reduce environmental impact without compromising performance.

Carbon footprint considerations now factor prominently in seal selection processes. Life cycle assessment (LCA) methodologies help quantify environmental impacts across the entire value chain, enabling engineers to make more sustainable choices. Some manufacturers have begun publishing environmental product declarations (EPDs) for their sealing solutions, providing transparency regarding embodied carbon and other environmental indicators.

Water conservation represents another critical dimension of seal sustainability. In water-intensive industries, the selection of appropriate seals can significantly reduce water consumption through minimized leakage and optimized cooling requirements. Advanced dry-running seal technologies have emerged as particularly valuable in water-stressed regions, eliminating the need for water-based flush systems while maintaining reliable performance.

During operational phases, seal leakage represents a critical environmental concern. Even minor leakages of process fluids—especially in chemical, petrochemical, and power generation industries—can introduce toxins into surrounding ecosystems. Modern seal designs increasingly incorporate leak detection systems and secondary containment features to mitigate these risks, demonstrating the industry's growing environmental consciousness.

Energy consumption associated with seal friction and maintenance activities presents another sustainability challenge. Higher friction seals require more pumping energy, directly increasing the carbon footprint of operations. Progressive manufacturers now prioritize low-friction seal designs that maintain integrity while reducing energy requirements, with some reporting energy savings of 5-15% compared to conventional alternatives.

The disposal and end-of-life management of heat exchanger seals present significant sustainability concerns. Non-biodegradable materials can persist in landfills for centuries, while incineration of certain seal compounds may release harmful emissions. Forward-thinking organizations have implemented seal recycling programs, particularly for metal components, and are exploring biodegradable alternatives for appropriate applications.

Regulatory frameworks increasingly influence seal selection criteria, with legislation like the EU's REACH regulations and various clean water acts worldwide imposing stricter requirements on material composition and leakage tolerances. These regulations have accelerated innovation in environmentally friendly seal technologies, including bio-based elastomers and water-based lubricants that reduce environmental impact without compromising performance.

Carbon footprint considerations now factor prominently in seal selection processes. Life cycle assessment (LCA) methodologies help quantify environmental impacts across the entire value chain, enabling engineers to make more sustainable choices. Some manufacturers have begun publishing environmental product declarations (EPDs) for their sealing solutions, providing transparency regarding embodied carbon and other environmental indicators.

Water conservation represents another critical dimension of seal sustainability. In water-intensive industries, the selection of appropriate seals can significantly reduce water consumption through minimized leakage and optimized cooling requirements. Advanced dry-running seal technologies have emerged as particularly valuable in water-stressed regions, eliminating the need for water-based flush systems while maintaining reliable performance.

Maintenance Strategies and Lifecycle Cost Analysis

Effective maintenance strategies for heat exchanger seals are critical for ensuring optimal performance and longevity of these essential components. Preventive maintenance approaches, including regular inspection schedules and condition monitoring, significantly reduce the risk of unexpected failures. These strategies typically involve periodic visual inspections, leak testing, and performance monitoring to detect early signs of seal degradation before catastrophic failure occurs. For critical applications, implementing predictive maintenance using advanced monitoring technologies such as infrared thermography, vibration analysis, and ultrasonic testing can provide real-time data on seal condition, enabling maintenance to be scheduled precisely when needed.

The lifecycle cost analysis of heat exchanger seals must consider multiple factors beyond the initial purchase price. Installation costs, operational expenses, maintenance requirements, and replacement frequency all contribute significantly to the total cost of ownership. High-quality seals with superior materials may command premium prices initially but often deliver substantial savings through extended service life and reduced maintenance needs. For instance, elastomeric seals may require more frequent replacement but have lower upfront costs, while mechanical seals typically offer longer service intervals despite higher initial investment.

Downtime costs represent one of the most significant factors in lifecycle cost calculations. When heat exchanger seals fail, the resulting production interruptions can cost thousands to millions of dollars per hour depending on the application. Therefore, reliability-centered maintenance approaches that prioritize critical equipment can optimize maintenance resources while minimizing costly unplanned downtime. Organizations should develop comprehensive maintenance documentation systems to track seal performance history, failure modes, and maintenance activities, enabling data-driven decisions about seal selection and maintenance intervals.

Training maintenance personnel specifically on heat exchanger seal technologies is another crucial aspect of an effective maintenance strategy. Proper installation techniques, torque specifications, and handling procedures significantly impact seal performance and longevity. Even the highest quality seals will fail prematurely if improperly installed or maintained.

Environmental and operational factors must also be incorporated into maintenance planning. Seals exposed to thermal cycling, aggressive chemicals, or high pressures may require more frequent inspection and replacement. Developing application-specific maintenance protocols that account for these variables optimizes both performance and cost. Organizations should establish clear key performance indicators to measure the effectiveness of their seal maintenance programs, including metrics like mean time between failures, maintenance costs as a percentage of replacement value, and overall equipment effectiveness.

The lifecycle cost analysis of heat exchanger seals must consider multiple factors beyond the initial purchase price. Installation costs, operational expenses, maintenance requirements, and replacement frequency all contribute significantly to the total cost of ownership. High-quality seals with superior materials may command premium prices initially but often deliver substantial savings through extended service life and reduced maintenance needs. For instance, elastomeric seals may require more frequent replacement but have lower upfront costs, while mechanical seals typically offer longer service intervals despite higher initial investment.

Downtime costs represent one of the most significant factors in lifecycle cost calculations. When heat exchanger seals fail, the resulting production interruptions can cost thousands to millions of dollars per hour depending on the application. Therefore, reliability-centered maintenance approaches that prioritize critical equipment can optimize maintenance resources while minimizing costly unplanned downtime. Organizations should develop comprehensive maintenance documentation systems to track seal performance history, failure modes, and maintenance activities, enabling data-driven decisions about seal selection and maintenance intervals.

Training maintenance personnel specifically on heat exchanger seal technologies is another crucial aspect of an effective maintenance strategy. Proper installation techniques, torque specifications, and handling procedures significantly impact seal performance and longevity. Even the highest quality seals will fail prematurely if improperly installed or maintained.

Environmental and operational factors must also be incorporated into maintenance planning. Seals exposed to thermal cycling, aggressive chemicals, or high pressures may require more frequent inspection and replacement. Developing application-specific maintenance protocols that account for these variables optimizes both performance and cost. Organizations should establish clear key performance indicators to measure the effectiveness of their seal maintenance programs, including metrics like mean time between failures, maintenance costs as a percentage of replacement value, and overall equipment effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!