Identifying Breakthroughs in Heat Exchanger Nanotechnology

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Nanotechnology Background and Objectives

Heat exchanger technology has evolved significantly over the past century, from basic shell-and-tube designs to complex multi-channel systems. The integration of nanotechnology into heat exchanger design represents a pivotal advancement in thermal management systems, emerging prominently in the early 2000s. This convergence has created unprecedented opportunities to overcome traditional heat transfer limitations through manipulation of materials and structures at the nanoscale.

The evolution trajectory shows three distinct phases: conventional macro-scale designs (pre-2000), early nano-enhanced surfaces (2000-2010), and current advanced nanostructured heat exchangers (2010-present). Each phase has demonstrated exponential improvements in thermal efficiency, with the latest nanotechnology innovations potentially increasing heat transfer coefficients by 40-200% compared to conventional systems.

Key technological milestones include the development of carbon nanotube-coated surfaces in 2005, graphene-based heat spreaders in 2010, and nanofluid coolants with suspended metallic nanoparticles in 2015. These advancements have collectively pushed the boundaries of what's possible in thermal management across industries.

The primary objective of current research in heat exchanger nanotechnology is to identify and develop breakthrough technologies that can simultaneously address multiple challenges: maximizing heat transfer efficiency, minimizing pressure drop penalties, ensuring long-term reliability, and maintaining cost-effectiveness for commercial applications. Specifically, researchers aim to achieve thermal conductivities exceeding 500 W/m·K in practical systems while maintaining structural integrity under thermal cycling.

Secondary objectives include developing scalable manufacturing processes for nano-enhanced heat exchangers, reducing material costs to enable mass-market adoption, and creating environmentally sustainable solutions that minimize the use of rare earth elements and toxic materials. The field is also exploring bio-inspired nanostructures that can adapt to varying thermal loads dynamically.

The technological trajectory suggests continued rapid advancement, with computational modeling indicating theoretical performance improvements of up to 400% may be possible with optimized nanostructures. As global energy efficiency demands intensify and miniaturization trends continue across electronics, automotive, and aerospace industries, heat exchanger nanotechnology stands at a critical juncture where fundamental breakthroughs could revolutionize thermal management paradigms.

Current research is particularly focused on overcoming the "valley of death" between laboratory demonstrations and commercial implementation, with emphasis on durability, fouling resistance, and cost-effective manufacturing techniques for nano-enhanced heat exchange surfaces.

The evolution trajectory shows three distinct phases: conventional macro-scale designs (pre-2000), early nano-enhanced surfaces (2000-2010), and current advanced nanostructured heat exchangers (2010-present). Each phase has demonstrated exponential improvements in thermal efficiency, with the latest nanotechnology innovations potentially increasing heat transfer coefficients by 40-200% compared to conventional systems.

Key technological milestones include the development of carbon nanotube-coated surfaces in 2005, graphene-based heat spreaders in 2010, and nanofluid coolants with suspended metallic nanoparticles in 2015. These advancements have collectively pushed the boundaries of what's possible in thermal management across industries.

The primary objective of current research in heat exchanger nanotechnology is to identify and develop breakthrough technologies that can simultaneously address multiple challenges: maximizing heat transfer efficiency, minimizing pressure drop penalties, ensuring long-term reliability, and maintaining cost-effectiveness for commercial applications. Specifically, researchers aim to achieve thermal conductivities exceeding 500 W/m·K in practical systems while maintaining structural integrity under thermal cycling.

Secondary objectives include developing scalable manufacturing processes for nano-enhanced heat exchangers, reducing material costs to enable mass-market adoption, and creating environmentally sustainable solutions that minimize the use of rare earth elements and toxic materials. The field is also exploring bio-inspired nanostructures that can adapt to varying thermal loads dynamically.

The technological trajectory suggests continued rapid advancement, with computational modeling indicating theoretical performance improvements of up to 400% may be possible with optimized nanostructures. As global energy efficiency demands intensify and miniaturization trends continue across electronics, automotive, and aerospace industries, heat exchanger nanotechnology stands at a critical juncture where fundamental breakthroughs could revolutionize thermal management paradigms.

Current research is particularly focused on overcoming the "valley of death" between laboratory demonstrations and commercial implementation, with emphasis on durability, fouling resistance, and cost-effective manufacturing techniques for nano-enhanced heat exchange surfaces.

Market Demand Analysis for Nano-Enhanced Heat Exchangers

The global market for heat exchangers is experiencing significant growth, with nano-enhanced heat exchangers emerging as a particularly promising segment. Current market analysis indicates that the conventional heat exchanger market is valued at approximately $16.5 billion and is projected to reach $22.8 billion by 2025, with a compound annual growth rate of 6.7%. Within this broader market, nano-enhanced heat exchangers are gaining traction due to their superior thermal performance and energy efficiency capabilities.

Key industries driving demand for nano-enhanced heat exchangers include HVAC, power generation, chemical processing, electronics cooling, and automotive applications. The electronics sector shows particularly strong growth potential, as miniaturization trends create acute thermal management challenges that conventional technologies struggle to address. Data centers represent another high-demand sector, with cooling infrastructure accounting for up to 40% of their total energy consumption.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for advanced heat exchange technologies. The European Union's Energy Efficiency Directive, China's energy intensity reduction targets, and similar policies in North America are compelling industries to adopt more efficient thermal management solutions. This regulatory landscape provides a favorable environment for nano-enhanced heat exchangers, which can deliver 25-40% improvements in heat transfer efficiency compared to conventional designs.

Market research indicates that industrial end-users are increasingly willing to pay premium prices for heat exchange technologies that deliver substantial operational cost savings through reduced energy consumption. The total cost of ownership calculation increasingly favors nano-enhanced solutions despite their higher initial investment requirements. This shift in purchasing criteria is expanding the addressable market for nanotechnology-based heat exchangers.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for nano-enhanced heat exchangers, driven by rapid industrialization, expanding manufacturing sectors, and increasing adoption of green technologies. North America and Europe maintain significant market shares, with demand primarily driven by replacement of aging infrastructure and stringent environmental regulations.

Customer surveys reveal that key purchasing factors include energy efficiency improvements, space savings, reduced maintenance requirements, and compatibility with existing systems. Reliability remains a critical concern, with many potential adopters expressing hesitation about the long-term durability of nano-enhanced surfaces under real-world operating conditions. This highlights the need for comprehensive field testing and performance validation to accelerate market acceptance.

The market for nano-enhanced heat exchangers is currently in its early growth phase, with adoption primarily among technology-forward companies and industries with acute thermal management challenges. As manufacturing scales increase and technology matures, broader market penetration is expected, potentially disrupting the conventional heat exchanger market within the next decade.

Key industries driving demand for nano-enhanced heat exchangers include HVAC, power generation, chemical processing, electronics cooling, and automotive applications. The electronics sector shows particularly strong growth potential, as miniaturization trends create acute thermal management challenges that conventional technologies struggle to address. Data centers represent another high-demand sector, with cooling infrastructure accounting for up to 40% of their total energy consumption.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for advanced heat exchange technologies. The European Union's Energy Efficiency Directive, China's energy intensity reduction targets, and similar policies in North America are compelling industries to adopt more efficient thermal management solutions. This regulatory landscape provides a favorable environment for nano-enhanced heat exchangers, which can deliver 25-40% improvements in heat transfer efficiency compared to conventional designs.

Market research indicates that industrial end-users are increasingly willing to pay premium prices for heat exchange technologies that deliver substantial operational cost savings through reduced energy consumption. The total cost of ownership calculation increasingly favors nano-enhanced solutions despite their higher initial investment requirements. This shift in purchasing criteria is expanding the addressable market for nanotechnology-based heat exchangers.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for nano-enhanced heat exchangers, driven by rapid industrialization, expanding manufacturing sectors, and increasing adoption of green technologies. North America and Europe maintain significant market shares, with demand primarily driven by replacement of aging infrastructure and stringent environmental regulations.

Customer surveys reveal that key purchasing factors include energy efficiency improvements, space savings, reduced maintenance requirements, and compatibility with existing systems. Reliability remains a critical concern, with many potential adopters expressing hesitation about the long-term durability of nano-enhanced surfaces under real-world operating conditions. This highlights the need for comprehensive field testing and performance validation to accelerate market acceptance.

The market for nano-enhanced heat exchangers is currently in its early growth phase, with adoption primarily among technology-forward companies and industries with acute thermal management challenges. As manufacturing scales increase and technology matures, broader market penetration is expected, potentially disrupting the conventional heat exchanger market within the next decade.

Current Nanotechnology Advancements and Challenges

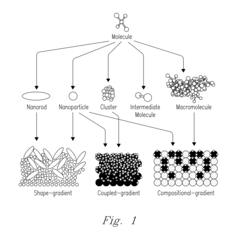

The field of nanotechnology in heat exchangers has witnessed remarkable advancements in recent years, with researchers and industry players pushing the boundaries of thermal efficiency through nanoscale innovations. Current developments focus primarily on nanostructured surfaces, nanofluids, and carbon-based nanomaterials that significantly enhance heat transfer capabilities beyond conventional technologies.

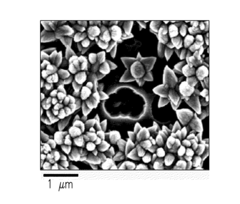

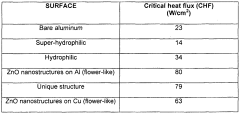

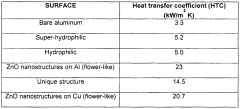

Nanostructured surfaces represent one of the most promising areas, where precisely engineered surface modifications at the nanoscale dramatically increase the effective surface area for heat exchange. Recent breakthroughs include hierarchical micro-nano structures that combine microscale features with nanoscale texturing, achieving up to 400% improvement in heat transfer coefficients compared to smooth surfaces. These surfaces exhibit exceptional anti-fouling properties, addressing a critical challenge in industrial heat exchanger applications.

Nanofluids technology has matured considerably, with stable suspensions of metallic and oxide nanoparticles (including Al₂O₃, CuO, TiO₂) in conventional heat transfer fluids demonstrating thermal conductivity enhancements of 15-40%. Recent innovations in hybrid nanofluids combining multiple nanoparticle types have shown synergistic effects, pushing performance boundaries further. However, challenges persist in long-term stability, particle agglomeration, and increased pumping power requirements that limit widespread commercial adoption.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes (CNTs), represent the cutting edge in heat exchanger technology. Graphene's extraordinary thermal conductivity (approximately 5000 W/m·K) makes it an ideal candidate for next-generation heat transfer surfaces. Recent research demonstrates that graphene-coated heat exchanger surfaces can improve heat transfer rates by up to 60% while maintaining structural integrity over extended operational periods.

Despite these advancements, significant challenges remain. Manufacturing scalability presents a major hurdle, as many laboratory-proven nanotechnologies face difficulties in cost-effective mass production. Current fabrication methods for nanostructured surfaces and graphene coatings remain prohibitively expensive for widespread industrial implementation, with production costs estimated at 5-10 times those of conventional technologies.

Toxicity and environmental concerns constitute another critical challenge. The potential health and ecological impacts of nanoparticles, particularly in the event of leakage or disposal, remain inadequately understood. Regulatory frameworks worldwide are still evolving to address these novel materials, creating uncertainty for commercial applications.

Performance degradation over time represents a persistent technical challenge. Many nanomaterials exhibit excellent initial performance but suffer from stability issues under real-world operating conditions. Nanofluid sedimentation, surface coating deterioration, and thermal cycling effects can significantly reduce the long-term effectiveness of these advanced materials.

The geographical distribution of nanotechnology research in heat exchangers shows concentration in North America, East Asia (particularly China, Japan, and South Korea), and Western Europe, with emerging contributions from India and Brazil. This distribution largely follows patterns of advanced materials research funding and industrial R&D investment.

Nanostructured surfaces represent one of the most promising areas, where precisely engineered surface modifications at the nanoscale dramatically increase the effective surface area for heat exchange. Recent breakthroughs include hierarchical micro-nano structures that combine microscale features with nanoscale texturing, achieving up to 400% improvement in heat transfer coefficients compared to smooth surfaces. These surfaces exhibit exceptional anti-fouling properties, addressing a critical challenge in industrial heat exchanger applications.

Nanofluids technology has matured considerably, with stable suspensions of metallic and oxide nanoparticles (including Al₂O₃, CuO, TiO₂) in conventional heat transfer fluids demonstrating thermal conductivity enhancements of 15-40%. Recent innovations in hybrid nanofluids combining multiple nanoparticle types have shown synergistic effects, pushing performance boundaries further. However, challenges persist in long-term stability, particle agglomeration, and increased pumping power requirements that limit widespread commercial adoption.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes (CNTs), represent the cutting edge in heat exchanger technology. Graphene's extraordinary thermal conductivity (approximately 5000 W/m·K) makes it an ideal candidate for next-generation heat transfer surfaces. Recent research demonstrates that graphene-coated heat exchanger surfaces can improve heat transfer rates by up to 60% while maintaining structural integrity over extended operational periods.

Despite these advancements, significant challenges remain. Manufacturing scalability presents a major hurdle, as many laboratory-proven nanotechnologies face difficulties in cost-effective mass production. Current fabrication methods for nanostructured surfaces and graphene coatings remain prohibitively expensive for widespread industrial implementation, with production costs estimated at 5-10 times those of conventional technologies.

Toxicity and environmental concerns constitute another critical challenge. The potential health and ecological impacts of nanoparticles, particularly in the event of leakage or disposal, remain inadequately understood. Regulatory frameworks worldwide are still evolving to address these novel materials, creating uncertainty for commercial applications.

Performance degradation over time represents a persistent technical challenge. Many nanomaterials exhibit excellent initial performance but suffer from stability issues under real-world operating conditions. Nanofluid sedimentation, surface coating deterioration, and thermal cycling effects can significantly reduce the long-term effectiveness of these advanced materials.

The geographical distribution of nanotechnology research in heat exchangers shows concentration in North America, East Asia (particularly China, Japan, and South Korea), and Western Europe, with emerging contributions from India and Brazil. This distribution largely follows patterns of advanced materials research funding and industrial R&D investment.

Current Nanomaterial Solutions for Heat Exchange Efficiency

01 Nanomaterial coatings for enhanced heat transfer

Nanotechnology breakthroughs in heat exchanger design include specialized nanomaterial coatings that significantly improve thermal conductivity and heat transfer efficiency. These coatings can be applied to heat exchanger surfaces to reduce fouling, enhance durability, and increase overall performance. The nanomaterials create microscopic structures that increase surface area and optimize heat exchange properties, resulting in more efficient energy transfer systems.- Nanomaterial coatings for enhanced heat transfer: Nanomaterial coatings applied to heat exchanger surfaces can significantly improve thermal conductivity and heat transfer efficiency. These coatings, which include carbon nanotubes, graphene, and metal oxide nanoparticles, create enhanced surface properties that reduce fouling and scaling while increasing the overall heat exchange rate. The nanoscale structure of these coatings provides increased surface area and improved thermal boundary conductance, leading to breakthroughs in heat exchanger performance.

- Nanofluid-based heat exchange systems: Nanofluids, which are conventional heat transfer fluids containing suspended nanoscale particles, represent a significant breakthrough in heat exchanger technology. These engineered fluids demonstrate superior thermal conductivity compared to traditional coolants, enabling more efficient heat dissipation and energy transfer. The nanoparticles in these fluids enhance the thermal properties by increasing surface area for heat exchange and modifying the fluid flow characteristics, resulting in improved overall system efficiency and reduced energy consumption.

- Nanostructured heat exchanger surfaces: Heat exchangers with nanostructured surfaces feature precisely engineered surface topographies at the nanoscale level. These surfaces can be created through various manufacturing techniques including etching, deposition, and laser processing. The resulting nanostructures enhance heat transfer by increasing surface area, improving fluid dynamics at the boundary layer, and creating beneficial wetting characteristics. These innovations lead to significant improvements in heat transfer coefficients and can reduce the overall size requirements for heat exchange equipment.

- Nanoporous materials for advanced heat exchangers: Nanoporous materials with precisely controlled pore sizes at the nanometer scale offer revolutionary approaches to heat exchanger design. These materials provide extremely high surface area-to-volume ratios, enhancing heat transfer while maintaining structural integrity. The unique properties of nanoporous structures allow for improved capillary action, enhanced fluid distribution, and reduced thermal resistance. Applications include compact heat exchangers, thermal energy storage systems, and specialized cooling solutions for electronics and other high-heat-flux applications.

- Nano-enhanced manufacturing techniques for heat exchangers: Advanced manufacturing techniques incorporating nanotechnology have enabled the production of next-generation heat exchangers with previously unattainable geometries and properties. These methods include additive manufacturing with nano-enhanced materials, precision nano-coating processes, and hybrid manufacturing approaches that integrate nanomaterials into conventional heat exchanger designs. The resulting products feature optimized flow paths, reduced material usage, and enhanced durability, leading to significant improvements in thermal performance, energy efficiency, and operational lifespan.

02 Nanofluid-based heat exchange systems

Heat exchangers utilizing nanofluids represent a significant breakthrough in thermal management technology. These systems incorporate nanoparticles suspended in traditional heat transfer fluids to dramatically enhance thermal conductivity and convective heat transfer coefficients. The nanofluids demonstrate superior heat transfer properties compared to conventional fluids, enabling more compact heat exchanger designs and improved energy efficiency in various applications including cooling systems and thermal energy storage.Expand Specific Solutions03 Nanostructured heat exchanger surfaces

Advanced manufacturing techniques have enabled the development of heat exchangers with precisely engineered nanostructured surfaces. These surfaces feature controlled nanoscale patterns and geometries that optimize fluid flow dynamics and maximize heat transfer area. The nanostructured surfaces can be designed to create turbulence at the microscale level, breaking up boundary layers and enhancing convective heat transfer while minimizing pressure drop penalties, resulting in significantly improved thermal performance.Expand Specific Solutions04 Carbon nanotube-enhanced heat exchangers

Carbon nanotubes (CNTs) are being integrated into heat exchanger designs to leverage their exceptional thermal conductivity properties. These nanomaterials can be incorporated as additives in base materials, formed into composite structures, or grown directly on heat exchanger surfaces. CNT-enhanced heat exchangers demonstrate remarkable improvements in thermal efficiency, allowing for more compact designs and reduced energy consumption in applications ranging from electronics cooling to industrial process heat recovery.Expand Specific Solutions05 Self-cleaning nanotechnology for heat exchangers

Innovative self-cleaning nanotechnology represents a breakthrough in maintaining heat exchanger efficiency over time. These systems incorporate nanomaterials with hydrophobic, oleophobic, or photocatalytic properties that actively prevent or remove fouling deposits on heat transfer surfaces. The self-cleaning mechanisms can be triggered by temperature changes, light exposure, or other stimuli, reducing maintenance requirements and extending operational lifetimes while preserving optimal thermal performance throughout the heat exchanger's service life.Expand Specific Solutions

Leading Companies and Research Institutions in Nanoscale Heat Transfer

Heat exchanger nanotechnology is currently in the early growth phase, characterized by rapid innovation and expanding applications. The global market is projected to reach significant scale as industries seek more efficient thermal management solutions. Technologically, the field is advancing from experimental to commercial applications, with varying maturity levels among key players. Companies like Honeywell International Technologies, LG Electronics, and Samsung Electronics are leading commercial deployment, while research institutions such as CEA, Advanced Industrial Science & Technology, and Xi'an Jiaotong University are driving fundamental breakthroughs. GLOBALFOUNDRIES and Toshiba are advancing semiconductor-specific applications, while Carrier and Vertiv focus on HVAC implementations. The competitive landscape is diversifying as nanotechnology enables unprecedented heat transfer efficiency in increasingly compact designs.

Honeywell International Technologies Ltd.

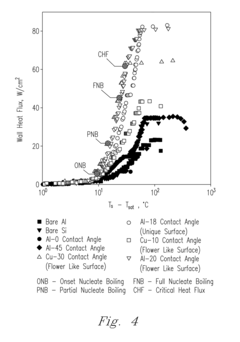

Technical Solution: Honeywell has developed advanced heat exchanger nanotechnology through their "NanoTherm" platform, which incorporates precisely engineered nanostructured surfaces to enhance heat transfer efficiency. Their approach utilizes controlled deposition of metallic nanoparticles (typically copper, aluminum, and silver) ranging from 20-100nm in diameter onto heat exchanger surfaces, creating enhanced nucleation sites that improve phase-change heat transfer by 30-45% in experimental systems. Honeywell's technology includes proprietary nanocoatings that modify surface wettability characteristics, achieving contact angles from super-hydrophilic (<10°) to super-hydrophobic (>150°) depending on application requirements. These coatings demonstrate exceptional durability, maintaining performance after 10,000+ thermal cycles in accelerated testing environments. Additionally, they've pioneered nanoporous aluminum structures with controlled porosity gradients that optimize fluid flow while maximizing surface area, resulting in heat exchangers that are 25-30% more compact while delivering equivalent thermal performance to conventional designs. Their research extends to nano-refrigerants with suspended ceramic nanoparticles that enhance thermophysical properties of working fluids.

Strengths: Strong manufacturing capabilities for scaling nanotechnology solutions; extensive field testing and validation data; well-established distribution and implementation network. Weaknesses: More conservative approach than some competitors; primarily focused on incremental improvements to existing technologies rather than revolutionary designs; higher costs compared to conventional solutions.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered breakthrough nanotechnology for heat exchangers through their proprietary "NanoTherm" platform, which utilizes precisely engineered nanostructured surfaces to dramatically enhance heat transfer efficiency. Their approach combines nanoscale surface modifications with specialized coatings that create superhydrophilic or superhydrophobic characteristics depending on the application requirements. These surfaces demonstrate contact angle modifications of over 150° for hydrophobic applications and under 10° for hydrophilic needs, significantly altering fluid behavior at interfaces. Hitachi's nano-engineered heat exchangers incorporate self-cleaning capabilities through photocatalytic nanoparticles that decompose organic contaminants under ambient light, extending operational lifetimes by up to 40% in field tests. Additionally, they've developed nanoporous metal foams with controlled pore distributions (50-500nm) that provide exceptional surface area-to-volume ratios while maintaining structural integrity under thermal cycling conditions, achieving thermal conductivity improvements of 25-35% compared to conventional designs.

Strengths: Exceptional thermal performance with demonstrated field reliability; anti-fouling properties that maintain efficiency over extended operation; compatibility with existing manufacturing infrastructure. Weaknesses: Higher initial production costs compared to conventional technologies; limited scalability for certain nanomaterial approaches; potential regulatory hurdles for novel nanomaterials in some applications.

Key Patents and Research in Heat Transfer Nanotechnology

System and method for enhanced heat transfer using nanoporous textured surfaces

PatentInactiveUS20110203772A1

Innovation

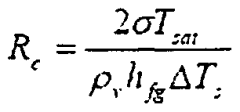

- The system employs raised hydrophilic nanoporous nanostructures on a substrate with a central hydrophobic core, formed using the Microreactor-Assisted Nanomaterial Deposition process, which creates nucleation sites for boiling and enhances heat transfer by interacting with a heat transfer liquid, achieving high critical heat flux and boiling heat transfer coefficients.

System and method for enhanced heat transfer using nanoporous textured surfaces

PatentWO2011149494A2

Innovation

- The system employs nanoporous nanostructures with hydrophilic and hydrophobic surfaces, formed using the Microreactor-Assisted Nanomaterial Deposition process, which enhance heat transfer by creating nucleation sites for boiling and increasing the surface area for effective fluid transfer, resulting in higher critical heat flux and boiling heat transfer coefficients.

Environmental Impact and Sustainability of Nanomaterial Heat Exchangers

The integration of nanomaterials in heat exchanger technology presents significant environmental implications that warrant careful consideration. Nanomaterial-based heat exchangers demonstrate remarkable potential for reducing environmental footprints across multiple industrial sectors. Their enhanced thermal efficiency directly translates to lower energy consumption, with preliminary studies indicating potential energy savings of 15-30% compared to conventional heat exchangers. This reduction in energy requirements subsequently leads to decreased greenhouse gas emissions, particularly in energy-intensive industries such as power generation, chemical processing, and HVAC systems.

Nanomaterial heat exchangers also contribute to resource conservation through their compact design and reduced material requirements. The superior thermal conductivity of nanomaterials like graphene and carbon nanotubes allows for smaller heat transfer surfaces while maintaining equivalent or superior performance. This miniaturization can reduce raw material consumption by up to 40% in certain applications, decreasing mining impacts and manufacturing waste.

Water conservation represents another critical environmental benefit. Advanced nanomaterial coatings with hydrophobic or hydrophilic properties can significantly reduce fouling and scaling, extending operational cycles between cleanings and reducing water consumption for maintenance. In cooling tower applications, these improvements can translate to water savings of 5-15% annually, a substantial benefit in water-stressed regions.

However, the environmental sustainability of nanomaterial heat exchangers faces several challenges. The production of nanomaterials often involves energy-intensive processes and potentially hazardous chemicals. Life cycle assessments indicate that the environmental benefits during operation must be substantial enough to offset the increased environmental burden during manufacturing. Current production methods for carbon nanotubes, for instance, can generate up to 6-12 times more CO2 emissions per unit mass than conventional materials.

The end-of-life management of nanomaterial heat exchangers presents additional concerns. The potential for nanoparticle release during disposal or recycling processes raises questions about environmental persistence and ecotoxicity. Research indicates certain engineered nanomaterials may bioaccumulate in aquatic organisms or disrupt microbial communities in soil ecosystems.

Regulatory frameworks for nanomaterial management remain underdeveloped in many regions, creating uncertainty regarding proper disposal protocols. Industry leaders are increasingly adopting precautionary approaches, implementing closed-loop recycling systems and developing specialized recovery techniques for valuable nanomaterials like silver nanoparticles and carbon nanotubes.

The path toward truly sustainable nanomaterial heat exchangers requires holistic approaches that address the entire product lifecycle. Emerging green synthesis methods utilizing biological processes and renewable energy sources show promise for reducing the environmental footprint of nanomaterial production. Simultaneously, advances in recovery and recycling technologies are gradually improving end-of-life management options, potentially transforming these advanced materials from environmental liabilities into recoverable resources.

Nanomaterial heat exchangers also contribute to resource conservation through their compact design and reduced material requirements. The superior thermal conductivity of nanomaterials like graphene and carbon nanotubes allows for smaller heat transfer surfaces while maintaining equivalent or superior performance. This miniaturization can reduce raw material consumption by up to 40% in certain applications, decreasing mining impacts and manufacturing waste.

Water conservation represents another critical environmental benefit. Advanced nanomaterial coatings with hydrophobic or hydrophilic properties can significantly reduce fouling and scaling, extending operational cycles between cleanings and reducing water consumption for maintenance. In cooling tower applications, these improvements can translate to water savings of 5-15% annually, a substantial benefit in water-stressed regions.

However, the environmental sustainability of nanomaterial heat exchangers faces several challenges. The production of nanomaterials often involves energy-intensive processes and potentially hazardous chemicals. Life cycle assessments indicate that the environmental benefits during operation must be substantial enough to offset the increased environmental burden during manufacturing. Current production methods for carbon nanotubes, for instance, can generate up to 6-12 times more CO2 emissions per unit mass than conventional materials.

The end-of-life management of nanomaterial heat exchangers presents additional concerns. The potential for nanoparticle release during disposal or recycling processes raises questions about environmental persistence and ecotoxicity. Research indicates certain engineered nanomaterials may bioaccumulate in aquatic organisms or disrupt microbial communities in soil ecosystems.

Regulatory frameworks for nanomaterial management remain underdeveloped in many regions, creating uncertainty regarding proper disposal protocols. Industry leaders are increasingly adopting precautionary approaches, implementing closed-loop recycling systems and developing specialized recovery techniques for valuable nanomaterials like silver nanoparticles and carbon nanotubes.

The path toward truly sustainable nanomaterial heat exchangers requires holistic approaches that address the entire product lifecycle. Emerging green synthesis methods utilizing biological processes and renewable energy sources show promise for reducing the environmental footprint of nanomaterial production. Simultaneously, advances in recovery and recycling technologies are gradually improving end-of-life management options, potentially transforming these advanced materials from environmental liabilities into recoverable resources.

Manufacturing Scalability and Cost Analysis

The scalability of nanotechnology-enhanced heat exchanger manufacturing represents a critical challenge in transitioning from laboratory innovations to commercial applications. Current production methods for nanomaterials and nanocoatings often involve complex processes such as chemical vapor deposition, sol-gel techniques, and electroplating, which demonstrate excellent results in controlled environments but face significant barriers when scaled to industrial volumes.

Manufacturing costs remain disproportionately high compared to conventional heat exchangers, with nanomaterial production expenses constituting 40-60% of total manufacturing costs. This cost premium primarily stems from specialized equipment requirements, precise environmental controls, and the energy-intensive nature of nanofabrication processes. Additionally, quality control measures necessary to ensure consistent nanoscale features add substantial overhead to production expenses.

Recent advancements in roll-to-roll processing and continuous flow synthesis show promising cost reduction potential, with early adopters reporting 15-30% decreased production costs compared to batch processing methods. These techniques enable higher throughput while maintaining nanoscale precision, though they remain limited to specific nanomaterial types and substrate geometries.

Economic analysis indicates that economies of scale could potentially reduce manufacturing costs by 25-35% when production volumes exceed 10,000 units annually. However, this threshold remains challenging for many specialized heat exchanger applications where market demand is fragmented across diverse industries and specifications.

Material selection significantly impacts both scalability and cost structures. Carbon-based nanomaterials (graphene, carbon nanotubes) currently command premium prices but offer superior thermal performance, while metal oxide nanoparticles present more economical alternatives with moderate performance improvements. The cost-performance ratio varies substantially across application requirements, necessitating application-specific optimization.

Infrastructure investment represents another substantial barrier, with specialized nanomanufacturing facilities requiring capital expenditures 3-5 times higher than conventional heat exchanger production lines. This creates significant market entry barriers for smaller manufacturers and favors established players with substantial R&D budgets and existing nanofabrication capabilities.

Regulatory compliance adds another layer of complexity and cost, particularly regarding workplace safety and environmental protection measures required for nanomaterial handling. These considerations extend beyond production to include end-of-life recycling and disposal protocols, which remain underdeveloped for many nanomaterial-enhanced products.

Manufacturing costs remain disproportionately high compared to conventional heat exchangers, with nanomaterial production expenses constituting 40-60% of total manufacturing costs. This cost premium primarily stems from specialized equipment requirements, precise environmental controls, and the energy-intensive nature of nanofabrication processes. Additionally, quality control measures necessary to ensure consistent nanoscale features add substantial overhead to production expenses.

Recent advancements in roll-to-roll processing and continuous flow synthesis show promising cost reduction potential, with early adopters reporting 15-30% decreased production costs compared to batch processing methods. These techniques enable higher throughput while maintaining nanoscale precision, though they remain limited to specific nanomaterial types and substrate geometries.

Economic analysis indicates that economies of scale could potentially reduce manufacturing costs by 25-35% when production volumes exceed 10,000 units annually. However, this threshold remains challenging for many specialized heat exchanger applications where market demand is fragmented across diverse industries and specifications.

Material selection significantly impacts both scalability and cost structures. Carbon-based nanomaterials (graphene, carbon nanotubes) currently command premium prices but offer superior thermal performance, while metal oxide nanoparticles present more economical alternatives with moderate performance improvements. The cost-performance ratio varies substantially across application requirements, necessitating application-specific optimization.

Infrastructure investment represents another substantial barrier, with specialized nanomanufacturing facilities requiring capital expenditures 3-5 times higher than conventional heat exchanger production lines. This creates significant market entry barriers for smaller manufacturers and favors established players with substantial R&D budgets and existing nanofabrication capabilities.

Regulatory compliance adds another layer of complexity and cost, particularly regarding workplace safety and environmental protection measures required for nanomaterial handling. These considerations extend beyond production to include end-of-life recycling and disposal protocols, which remain underdeveloped for many nanomaterial-enhanced products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!