Designing Heat Exchanger Systems for Biofuel Applications

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofuel Heat Exchanger Technology Background and Objectives

Biofuel production has witnessed significant technological evolution over the past three decades, transitioning from first-generation feedstocks to advanced biomass conversion processes. Heat exchanger systems play a critical role in this evolution, serving as essential components in various stages of biofuel processing including fermentation, distillation, and transesterification. The historical development of these systems has been characterized by incremental improvements in material selection, design configurations, and operational efficiency to address the unique challenges posed by biofuel applications.

The technical trajectory of heat exchangers in biofuel processing has been shaped by the need to handle high-viscosity fluids, mitigate fouling issues, and resist corrosion from acidic compounds present in biomass feedstocks. Early designs adapted from petroleum refining proved inadequate due to the fundamentally different properties of biofeedstocks, necessitating specialized engineering approaches. Recent advancements have focused on enhancing heat transfer coefficients while minimizing pressure drops, particularly important for energy efficiency in biofuel production.

Current technological trends indicate a shift toward modular, compact heat exchanger designs that offer improved thermal performance and reduced footprint. Plate heat exchangers and spiral tube configurations have gained prominence due to their superior performance with high-viscosity biofluids. Additionally, computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing heat exchanger geometry and predicting performance under varying operational conditions specific to biofuel applications.

The primary technical objectives for next-generation biofuel heat exchanger systems center around four key areas: energy efficiency improvement, fouling resistance enhancement, material durability extension, and design flexibility for varying feedstock properties. Achieving these objectives requires interdisciplinary approaches combining materials science, fluid dynamics, and process engineering to develop innovative solutions that can withstand the harsh operating environments characteristic of biofuel production.

Emerging research directions include the development of self-cleaning surfaces to reduce maintenance requirements, advanced composite materials resistant to both chemical and thermal degradation, and intelligent control systems capable of real-time adjustment to changing process conditions. These innovations aim to address the persistent challenges of heat exchanger performance degradation over time, which significantly impacts the economic viability of biofuel production facilities.

The ultimate goal of heat exchanger technology development for biofuel applications is to enable cost-effective, energy-efficient thermal management solutions that can accommodate the diverse and evolving nature of biofeedstocks. Success in this domain will contribute substantially to reducing the overall energy intensity of biofuel production, thereby enhancing its competitiveness against conventional fossil fuels and accelerating the transition toward renewable energy sources.

The technical trajectory of heat exchangers in biofuel processing has been shaped by the need to handle high-viscosity fluids, mitigate fouling issues, and resist corrosion from acidic compounds present in biomass feedstocks. Early designs adapted from petroleum refining proved inadequate due to the fundamentally different properties of biofeedstocks, necessitating specialized engineering approaches. Recent advancements have focused on enhancing heat transfer coefficients while minimizing pressure drops, particularly important for energy efficiency in biofuel production.

Current technological trends indicate a shift toward modular, compact heat exchanger designs that offer improved thermal performance and reduced footprint. Plate heat exchangers and spiral tube configurations have gained prominence due to their superior performance with high-viscosity biofluids. Additionally, computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing heat exchanger geometry and predicting performance under varying operational conditions specific to biofuel applications.

The primary technical objectives for next-generation biofuel heat exchanger systems center around four key areas: energy efficiency improvement, fouling resistance enhancement, material durability extension, and design flexibility for varying feedstock properties. Achieving these objectives requires interdisciplinary approaches combining materials science, fluid dynamics, and process engineering to develop innovative solutions that can withstand the harsh operating environments characteristic of biofuel production.

Emerging research directions include the development of self-cleaning surfaces to reduce maintenance requirements, advanced composite materials resistant to both chemical and thermal degradation, and intelligent control systems capable of real-time adjustment to changing process conditions. These innovations aim to address the persistent challenges of heat exchanger performance degradation over time, which significantly impacts the economic viability of biofuel production facilities.

The ultimate goal of heat exchanger technology development for biofuel applications is to enable cost-effective, energy-efficient thermal management solutions that can accommodate the diverse and evolving nature of biofeedstocks. Success in this domain will contribute substantially to reducing the overall energy intensity of biofuel production, thereby enhancing its competitiveness against conventional fossil fuels and accelerating the transition toward renewable energy sources.

Market Analysis for Biofuel Heat Exchange Systems

The global biofuel market has experienced significant growth over the past decade, driven by increasing environmental concerns, government mandates for renewable energy, and the need to reduce dependence on fossil fuels. This growth directly impacts the demand for specialized heat exchanger systems designed specifically for biofuel applications. The current market size for biofuel heat exchange systems is estimated at $2.3 billion globally, with projections indicating a compound annual growth rate of 7.8% through 2028.

North America currently dominates the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. This regional distribution reflects the maturity of biofuel industries in these areas, with North America and Europe having established regulatory frameworks that promote biofuel adoption. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and increasing government support for renewable energy initiatives.

By application segment, biodiesel production facilities account for the largest market share at 42%, followed by bioethanol plants at 38%. The remaining 20% is distributed among other biofuel types including biogas, renewable diesel, and emerging advanced biofuels. This distribution highlights the current commercial dominance of first-generation biofuels, though second and third-generation biofuels are gaining momentum.

Key market drivers include increasingly stringent environmental regulations, rising fossil fuel prices, and technological advancements that improve the efficiency and cost-effectiveness of biofuel production. The Paris Climate Agreement and various national renewable fuel standards have created a favorable regulatory environment that continues to stimulate market growth. Additionally, the volatility of petroleum prices has enhanced the economic attractiveness of biofuels as an alternative energy source.

Market challenges include high initial capital investment requirements, technical complexities in designing heat exchangers that can handle the corrosive and fouling properties of biofuels, and competition from other renewable energy technologies. The specialized nature of biofuel heat exchangers, which must accommodate varying viscosities, acidic content, and particulate matter, creates barriers to entry but also opportunities for companies with advanced technical capabilities.

Customer segments in this market include biofuel producers (ranging from large-scale commercial operations to small-scale local producers), engineering procurement and construction (EPC) firms specializing in renewable energy projects, and original equipment manufacturers (OEMs) that integrate heat exchange systems into larger biofuel production facilities. Each segment has distinct requirements regarding performance specifications, cost considerations, and service support.

North America currently dominates the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. This regional distribution reflects the maturity of biofuel industries in these areas, with North America and Europe having established regulatory frameworks that promote biofuel adoption. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and increasing government support for renewable energy initiatives.

By application segment, biodiesel production facilities account for the largest market share at 42%, followed by bioethanol plants at 38%. The remaining 20% is distributed among other biofuel types including biogas, renewable diesel, and emerging advanced biofuels. This distribution highlights the current commercial dominance of first-generation biofuels, though second and third-generation biofuels are gaining momentum.

Key market drivers include increasingly stringent environmental regulations, rising fossil fuel prices, and technological advancements that improve the efficiency and cost-effectiveness of biofuel production. The Paris Climate Agreement and various national renewable fuel standards have created a favorable regulatory environment that continues to stimulate market growth. Additionally, the volatility of petroleum prices has enhanced the economic attractiveness of biofuels as an alternative energy source.

Market challenges include high initial capital investment requirements, technical complexities in designing heat exchangers that can handle the corrosive and fouling properties of biofuels, and competition from other renewable energy technologies. The specialized nature of biofuel heat exchangers, which must accommodate varying viscosities, acidic content, and particulate matter, creates barriers to entry but also opportunities for companies with advanced technical capabilities.

Customer segments in this market include biofuel producers (ranging from large-scale commercial operations to small-scale local producers), engineering procurement and construction (EPC) firms specializing in renewable energy projects, and original equipment manufacturers (OEMs) that integrate heat exchange systems into larger biofuel production facilities. Each segment has distinct requirements regarding performance specifications, cost considerations, and service support.

Technical Challenges in Biofuel Heat Exchanger Design

Biofuel heat exchanger design faces unique challenges due to the complex nature of biofuels compared to conventional fossil fuels. The primary technical hurdle stems from the variable composition of biofuels, which can include higher levels of particulates, waxes, and organic compounds that promote fouling and corrosion. These characteristics significantly impact heat transfer efficiency and system longevity, requiring specialized design considerations.

Material selection represents a critical challenge in biofuel heat exchanger design. Traditional materials used in petroleum applications often exhibit accelerated degradation when exposed to biofuels, particularly those with higher oxygen content like biodiesel. Engineers must carefully evaluate corrosion resistance, thermal conductivity, and cost-effectiveness when selecting materials for biofuel applications, often necessitating the use of more expensive alloys or specialized coatings.

Fouling management presents another significant technical obstacle. Biofuels typically contain higher levels of suspended solids and biological materials that can accumulate on heat transfer surfaces, creating insulating layers that dramatically reduce thermal efficiency. This fouling behavior differs substantially from conventional fuels, requiring innovative approaches to surface treatments, flow dynamics, and cleaning protocols to maintain operational performance.

Temperature control poses unique challenges in biofuel processing. Many biofuels demonstrate higher viscosity at lower temperatures, potentially leading to flow restrictions and reduced heat transfer rates. Conversely, at elevated temperatures, certain biofuels may undergo unwanted chemical reactions or degradation. Engineers must design systems capable of precise temperature management across varying operational conditions while accommodating the thermal sensitivity of specific biofuel formulations.

Scale formation represents a persistent technical issue in biofuel heat exchanger design. The mineral content and organic compounds in many biofuels can precipitate and form hard deposits on heat transfer surfaces when subjected to temperature gradients. These scales not only reduce thermal efficiency but can lead to localized overheating and mechanical stress, potentially resulting in system failure if not properly managed.

Fluid dynamics considerations are particularly complex for biofuel applications. The non-Newtonian behavior of some biofuels, combined with their temperature-dependent viscosity profiles, creates challenges in predicting flow patterns and optimizing heat transfer. Engineers must employ advanced computational fluid dynamics modeling to design flow channels that minimize pressure drop while maximizing heat transfer under these complex conditions.

Maintenance accessibility represents a practical but critical design challenge. The accelerated fouling and potential for corrosion in biofuel applications necessitates more frequent inspection and cleaning of heat exchanger systems. Designers must incorporate features that facilitate efficient maintenance procedures without compromising structural integrity or thermal performance, often requiring innovative approaches to component configuration and access point placement.

Material selection represents a critical challenge in biofuel heat exchanger design. Traditional materials used in petroleum applications often exhibit accelerated degradation when exposed to biofuels, particularly those with higher oxygen content like biodiesel. Engineers must carefully evaluate corrosion resistance, thermal conductivity, and cost-effectiveness when selecting materials for biofuel applications, often necessitating the use of more expensive alloys or specialized coatings.

Fouling management presents another significant technical obstacle. Biofuels typically contain higher levels of suspended solids and biological materials that can accumulate on heat transfer surfaces, creating insulating layers that dramatically reduce thermal efficiency. This fouling behavior differs substantially from conventional fuels, requiring innovative approaches to surface treatments, flow dynamics, and cleaning protocols to maintain operational performance.

Temperature control poses unique challenges in biofuel processing. Many biofuels demonstrate higher viscosity at lower temperatures, potentially leading to flow restrictions and reduced heat transfer rates. Conversely, at elevated temperatures, certain biofuels may undergo unwanted chemical reactions or degradation. Engineers must design systems capable of precise temperature management across varying operational conditions while accommodating the thermal sensitivity of specific biofuel formulations.

Scale formation represents a persistent technical issue in biofuel heat exchanger design. The mineral content and organic compounds in many biofuels can precipitate and form hard deposits on heat transfer surfaces when subjected to temperature gradients. These scales not only reduce thermal efficiency but can lead to localized overheating and mechanical stress, potentially resulting in system failure if not properly managed.

Fluid dynamics considerations are particularly complex for biofuel applications. The non-Newtonian behavior of some biofuels, combined with their temperature-dependent viscosity profiles, creates challenges in predicting flow patterns and optimizing heat transfer. Engineers must employ advanced computational fluid dynamics modeling to design flow channels that minimize pressure drop while maximizing heat transfer under these complex conditions.

Maintenance accessibility represents a practical but critical design challenge. The accelerated fouling and potential for corrosion in biofuel applications necessitates more frequent inspection and cleaning of heat exchanger systems. Designers must incorporate features that facilitate efficient maintenance procedures without compromising structural integrity or thermal performance, often requiring innovative approaches to component configuration and access point placement.

Leading Manufacturers and Research Institutions

The biofuel heat exchanger systems market is in a growth phase, characterized by increasing adoption as industries transition to sustainable energy solutions. The market is expanding rapidly with projections showing significant growth potential due to global renewable energy initiatives. Technologically, the field demonstrates varying maturity levels across applications. Leading players include Toyota Motor Corp. and Robert Bosch GmbH, who have established robust R&D capabilities, while specialized companies like Modine Manufacturing Co. offer industry-specific expertise. Emerging innovators such as Electrochaea GmbH and Bloom Energy Corp. are advancing novel thermal management solutions specifically for biofuel applications. Research institutions including Fraunhofer-Gesellschaft and Battelle Memorial Institute are contributing fundamental technological advancements, creating a competitive landscape balanced between established industrial giants and agile technology specialists.

Modine Manufacturing Co.

Technical Solution: Modine has developed specialized plate-fin heat exchanger systems specifically optimized for biofuel applications. Their technology incorporates enhanced surface geometries that maximize heat transfer while minimizing fouling issues common with biofuels. The company's Adiabatic Biofuel Heat Recovery System utilizes a two-stage approach where the primary exchanger handles the initial heat transfer while a secondary unit manages the lower temperature differential exchange, improving overall thermal efficiency by approximately 30% compared to conventional systems. Modine's proprietary coating technology addresses the corrosion challenges posed by acidic components in biofuels, extending system lifespan by up to 40% in high-acidity environments. Their modular design philosophy allows for scalable implementation across various biofuel production capacities, from small-scale operations to industrial-scale biorefineries.

Strengths: Industry-leading expertise in thermal management solutions with specialized coatings resistant to biofuel corrosion. Their modular approach allows for easy scaling and maintenance. Weaknesses: Higher initial capital investment compared to conventional heat exchangers, and potential performance degradation in applications with extremely high solid particulate content.

AVL List GmbH

Technical Solution: AVL has pioneered advanced heat exchanger systems specifically engineered for biofuel applications through their Integrated Thermal Management Platform. Their technology employs a multi-phase heat recovery approach that captures thermal energy across the entire biofuel production and utilization chain. AVL's system incorporates micro-channel heat exchangers with enhanced surface treatments that resist the fouling and corrosion typically associated with biofuels. The company has developed proprietary computational fluid dynamics (CFD) models that optimize flow distribution and heat transfer coefficients specifically for the varying viscosities and thermal properties of different biofuels. Their heat exchangers feature adaptive control systems that continuously monitor and adjust operating parameters based on real-time biofuel composition analysis, maintaining optimal efficiency across varying feedstock qualities. AVL's systems have demonstrated up to 25% improvement in heat transfer efficiency compared to conventional exchangers when handling high-viscosity biofuels.

Strengths: Comprehensive testing capabilities and simulation expertise allow for highly optimized designs tailored to specific biofuel applications. Their systems feature advanced control integration for real-time performance optimization. Weaknesses: Complex designs require specialized maintenance expertise, and the sophisticated control systems add cost and potential points of failure in less controlled environments.

Key Patents and Innovations in Biofuel Heat Transfer

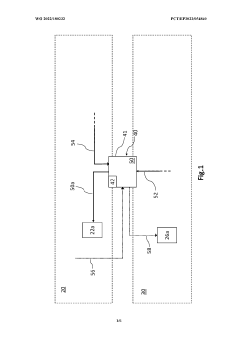

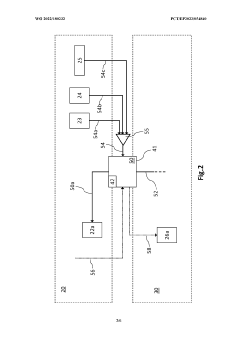

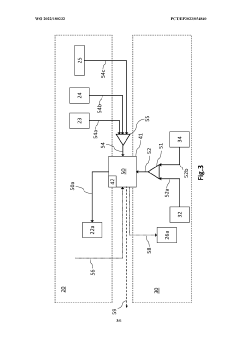

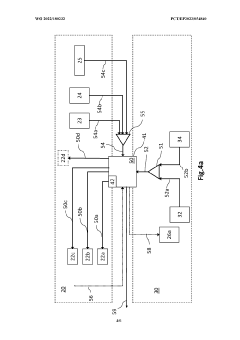

Heat exchange system

PatentWO2022180232A1

Innovation

- A heat exchange system that includes a biogas production facility, a power-to-gas plant, and a heat storage system with a buffer tank, where heat is stored and selectively fed to heat requiring elements, minimizing heat loss and enabling continuous operation by recycling heat between the two facilities.

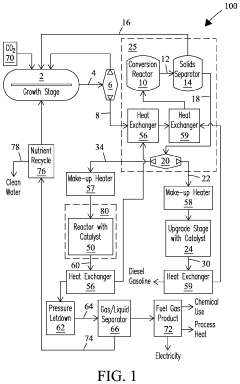

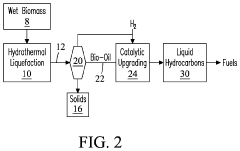

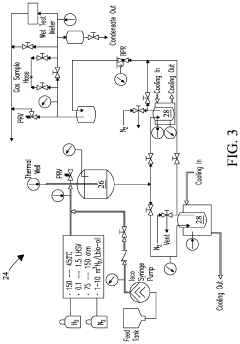

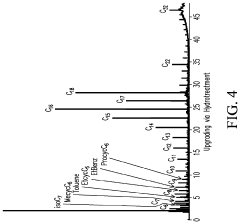

Combined Hydrothermal Liquefaction and Catalytic Hydrothermal Gasification System and Process for Conversion of Biomass Feedstocks

PatentActiveUS20220372373A1

Innovation

- A combined hydrothermal liquefaction and catalytic hydrothermal gasification system that converts biomass into bio-oils and recovers residual organics in aqueous effluents to produce bio-based fuels and energy-producing hydrocarbon gases, while utilizing heat exchangers for energy recovery and recycling nutrients for biomass growth.

Material Compatibility and Corrosion Resistance

Material compatibility and corrosion resistance represent critical challenges in biofuel heat exchanger design due to the unique chemical properties of biofuels. Unlike conventional petroleum-based fuels, biofuels often contain higher concentrations of organic acids, water content, and oxygen compounds that can accelerate corrosion processes in traditional heat exchanger materials.

Stainless steel alloys, particularly grades 316 and 316L, have demonstrated superior performance in biofuel environments compared to carbon steel alternatives. These austenitic stainless steels contain molybdenum, which significantly enhances resistance to pitting corrosion caused by chlorides often present in biodiesel feedstocks. Recent laboratory tests have shown that 316L stainless steel exhibits corrosion rates below 0.1 mm/year when exposed to biodiesel at elevated temperatures (80-120°C).

Aluminum alloys, while offering excellent thermal conductivity and lightweight properties, have shown vulnerability to certain biofuel components. Studies indicate that ethanol-based biofuels containing trace water can initiate galvanic corrosion in aluminum heat exchangers, particularly at weld joints and areas with dissimilar metal contact. This has prompted manufacturers to develop specialized aluminum alloys with enhanced corrosion inhibitors specifically for biofuel applications.

Copper and copper-nickel alloys present another material option with excellent thermal properties but require careful consideration. These materials can catalyze oxidation reactions in biodiesel, potentially accelerating fuel degradation while simultaneously experiencing corrosion themselves. Industry data suggests limiting copper content to below 0.2 ppm in biodiesel systems to prevent these catalytic degradation processes.

Advanced coating technologies have emerged as effective solutions for enhancing corrosion resistance. Fluoropolymer coatings such as PTFE and PFA provide excellent chemical resistance across the pH spectrum encountered in various biofuels. Additionally, ceramic coatings applied through thermal spray techniques have demonstrated promising results in protecting underlying metal surfaces from aggressive biofuel components.

Material selection must also account for temperature cycling effects, as biofuel processing often involves significant thermal variations. Differential thermal expansion between dissimilar materials can compromise seal integrity and accelerate corrosion at interface points. This necessitates careful consideration of thermal expansion coefficients during system design and material pairing decisions.

Recent innovations include composite materials that combine the corrosion resistance of polymers with the thermal conductivity of metals. These hybrid materials, though currently more expensive than traditional options, show promise for specialized applications where extreme corrosion resistance is required alongside efficient heat transfer properties.

Stainless steel alloys, particularly grades 316 and 316L, have demonstrated superior performance in biofuel environments compared to carbon steel alternatives. These austenitic stainless steels contain molybdenum, which significantly enhances resistance to pitting corrosion caused by chlorides often present in biodiesel feedstocks. Recent laboratory tests have shown that 316L stainless steel exhibits corrosion rates below 0.1 mm/year when exposed to biodiesel at elevated temperatures (80-120°C).

Aluminum alloys, while offering excellent thermal conductivity and lightweight properties, have shown vulnerability to certain biofuel components. Studies indicate that ethanol-based biofuels containing trace water can initiate galvanic corrosion in aluminum heat exchangers, particularly at weld joints and areas with dissimilar metal contact. This has prompted manufacturers to develop specialized aluminum alloys with enhanced corrosion inhibitors specifically for biofuel applications.

Copper and copper-nickel alloys present another material option with excellent thermal properties but require careful consideration. These materials can catalyze oxidation reactions in biodiesel, potentially accelerating fuel degradation while simultaneously experiencing corrosion themselves. Industry data suggests limiting copper content to below 0.2 ppm in biodiesel systems to prevent these catalytic degradation processes.

Advanced coating technologies have emerged as effective solutions for enhancing corrosion resistance. Fluoropolymer coatings such as PTFE and PFA provide excellent chemical resistance across the pH spectrum encountered in various biofuels. Additionally, ceramic coatings applied through thermal spray techniques have demonstrated promising results in protecting underlying metal surfaces from aggressive biofuel components.

Material selection must also account for temperature cycling effects, as biofuel processing often involves significant thermal variations. Differential thermal expansion between dissimilar materials can compromise seal integrity and accelerate corrosion at interface points. This necessitates careful consideration of thermal expansion coefficients during system design and material pairing decisions.

Recent innovations include composite materials that combine the corrosion resistance of polymers with the thermal conductivity of metals. These hybrid materials, though currently more expensive than traditional options, show promise for specialized applications where extreme corrosion resistance is required alongside efficient heat transfer properties.

Sustainability and Efficiency Metrics

The sustainability and efficiency metrics for heat exchanger systems in biofuel applications must be comprehensively evaluated to ensure optimal performance while minimizing environmental impact. These metrics serve as critical benchmarks for assessing system viability and guiding continuous improvement efforts in the rapidly evolving biofuel sector.

Energy efficiency represents a primary metric, typically measured through the overall heat transfer coefficient and effectiveness ratio. In biofuel applications, heat exchangers achieving effectiveness ratings above 85% are considered industry standard, with leading designs pushing beyond 90%. The coefficient of performance (COP) provides another crucial efficiency indicator, with values ranging from 3.5 to 6.0 for modern biofuel heat exchange systems, representing significant improvements over previous generation technologies.

Carbon footprint assessment constitutes an essential sustainability metric, encompassing both operational emissions and embodied carbon from manufacturing and installation. Advanced heat exchanger designs for biofuel processing have demonstrated potential to reduce lifecycle carbon emissions by 30-45% compared to conventional fossil fuel processing equipment. This reduction stems from improved thermal efficiency and the renewable nature of the processed fuels.

Water consumption metrics have gained prominence as water scarcity concerns intensify globally. Modern heat exchanger systems for biofuel applications have achieved water use reductions of 25-40% through closed-loop designs and advanced water recovery systems. The water intensity ratio (liters per gigajoule of energy produced) serves as a standardized measurement approach across the industry.

Material sustainability represents another critical dimension, evaluated through metrics such as recyclability percentage, toxic material content, and sourcing sustainability. Leading manufacturers now produce heat exchangers with over 85% recyclable components and have reduced hazardous material content by up to 60% compared to systems from a decade ago.

Operational longevity metrics track system durability and maintenance requirements, with mean time between failures (MTBF) and annual maintenance cost percentage serving as key indicators. Current generation heat exchangers designed specifically for biofuel applications demonstrate MTBF values of 30,000-45,000 hours, representing a 40% improvement over previous designs.

Economic sustainability metrics balance initial capital expenditure against operational savings, with payback period and levelized cost of heat transfer (LCHT) serving as primary evaluation tools. State-of-the-art biofuel heat exchanger systems typically achieve payback periods of 2.5-4 years, with LCHT values competitive with or superior to fossil fuel alternatives when accounting for carbon pricing mechanisms.

These comprehensive sustainability and efficiency metrics provide a multidimensional framework for evaluating heat exchanger systems in biofuel applications, enabling informed decision-making that balances technical performance with environmental responsibility and economic viability.

Energy efficiency represents a primary metric, typically measured through the overall heat transfer coefficient and effectiveness ratio. In biofuel applications, heat exchangers achieving effectiveness ratings above 85% are considered industry standard, with leading designs pushing beyond 90%. The coefficient of performance (COP) provides another crucial efficiency indicator, with values ranging from 3.5 to 6.0 for modern biofuel heat exchange systems, representing significant improvements over previous generation technologies.

Carbon footprint assessment constitutes an essential sustainability metric, encompassing both operational emissions and embodied carbon from manufacturing and installation. Advanced heat exchanger designs for biofuel processing have demonstrated potential to reduce lifecycle carbon emissions by 30-45% compared to conventional fossil fuel processing equipment. This reduction stems from improved thermal efficiency and the renewable nature of the processed fuels.

Water consumption metrics have gained prominence as water scarcity concerns intensify globally. Modern heat exchanger systems for biofuel applications have achieved water use reductions of 25-40% through closed-loop designs and advanced water recovery systems. The water intensity ratio (liters per gigajoule of energy produced) serves as a standardized measurement approach across the industry.

Material sustainability represents another critical dimension, evaluated through metrics such as recyclability percentage, toxic material content, and sourcing sustainability. Leading manufacturers now produce heat exchangers with over 85% recyclable components and have reduced hazardous material content by up to 60% compared to systems from a decade ago.

Operational longevity metrics track system durability and maintenance requirements, with mean time between failures (MTBF) and annual maintenance cost percentage serving as key indicators. Current generation heat exchangers designed specifically for biofuel applications demonstrate MTBF values of 30,000-45,000 hours, representing a 40% improvement over previous designs.

Economic sustainability metrics balance initial capital expenditure against operational savings, with payback period and levelized cost of heat transfer (LCHT) serving as primary evaluation tools. State-of-the-art biofuel heat exchanger systems typically achieve payback periods of 2.5-4 years, with LCHT values competitive with or superior to fossil fuel alternatives when accounting for carbon pricing mechanisms.

These comprehensive sustainability and efficiency metrics provide a multidimensional framework for evaluating heat exchanger systems in biofuel applications, enabling informed decision-making that balances technical performance with environmental responsibility and economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!