Evaluating Noise Reduction Strategies in Heat Exchanger Operation

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Noise Reduction Background and Objectives

Heat exchangers are critical components in numerous industrial applications, including power generation, chemical processing, HVAC systems, and manufacturing. The evolution of heat exchanger technology spans over a century, with significant advancements in design, materials, and operational efficiency. However, noise generation during operation has emerged as a persistent challenge that impacts both equipment performance and workplace environment.

Historically, noise issues in heat exchangers were often overlooked in favor of thermal efficiency and pressure drop considerations. The growing emphasis on workplace safety standards and environmental regulations since the 1970s has gradually shifted focus toward noise reduction as an essential design parameter. Industry standards such as ISO 14163 and ASHRAE guidelines have established benchmarks for acceptable noise levels in various applications, driving innovation in this field.

Noise in heat exchangers primarily originates from fluid-structure interactions, flow-induced vibrations, cavitation, and mechanical resonance. These phenomena are particularly pronounced in shell-and-tube exchangers, plate heat exchangers, and air-cooled heat exchangers operating at high flow rates or with phase-change processes. The technical evolution has progressed from simple insulation methods to sophisticated computational fluid dynamics (CFD) modeling and advanced material science applications.

Recent technological trends indicate a growing integration of acoustic analysis in the design phase rather than as an afterthought. This proactive approach has been facilitated by advancements in simulation software and measurement techniques that allow for more accurate prediction and quantification of noise generation mechanisms. The industry is witnessing a convergence of thermal-hydraulic optimization with acoustic performance considerations.

The primary objectives of this technical research are multifaceted. First, to comprehensively evaluate existing noise reduction strategies across different heat exchanger types and operational conditions. Second, to identify the correlation between noise reduction measures and their impact on thermal efficiency, pressure drop, and overall system performance. Third, to explore emerging technologies and materials that offer promising noise attenuation properties without compromising heat transfer capabilities.

Additionally, this research aims to develop a systematic framework for noise prediction and mitigation that can be integrated into the design process of next-generation heat exchangers. The ultimate goal is to establish design guidelines that balance acoustic performance with thermal efficiency, enabling engineers to make informed decisions during the specification and selection of heat exchange equipment for noise-sensitive applications.

The findings from this research will contribute to the development of quieter, more efficient heat exchange systems that meet increasingly stringent regulatory requirements while maintaining optimal thermal performance in industrial settings.

Historically, noise issues in heat exchangers were often overlooked in favor of thermal efficiency and pressure drop considerations. The growing emphasis on workplace safety standards and environmental regulations since the 1970s has gradually shifted focus toward noise reduction as an essential design parameter. Industry standards such as ISO 14163 and ASHRAE guidelines have established benchmarks for acceptable noise levels in various applications, driving innovation in this field.

Noise in heat exchangers primarily originates from fluid-structure interactions, flow-induced vibrations, cavitation, and mechanical resonance. These phenomena are particularly pronounced in shell-and-tube exchangers, plate heat exchangers, and air-cooled heat exchangers operating at high flow rates or with phase-change processes. The technical evolution has progressed from simple insulation methods to sophisticated computational fluid dynamics (CFD) modeling and advanced material science applications.

Recent technological trends indicate a growing integration of acoustic analysis in the design phase rather than as an afterthought. This proactive approach has been facilitated by advancements in simulation software and measurement techniques that allow for more accurate prediction and quantification of noise generation mechanisms. The industry is witnessing a convergence of thermal-hydraulic optimization with acoustic performance considerations.

The primary objectives of this technical research are multifaceted. First, to comprehensively evaluate existing noise reduction strategies across different heat exchanger types and operational conditions. Second, to identify the correlation between noise reduction measures and their impact on thermal efficiency, pressure drop, and overall system performance. Third, to explore emerging technologies and materials that offer promising noise attenuation properties without compromising heat transfer capabilities.

Additionally, this research aims to develop a systematic framework for noise prediction and mitigation that can be integrated into the design process of next-generation heat exchangers. The ultimate goal is to establish design guidelines that balance acoustic performance with thermal efficiency, enabling engineers to make informed decisions during the specification and selection of heat exchange equipment for noise-sensitive applications.

The findings from this research will contribute to the development of quieter, more efficient heat exchange systems that meet increasingly stringent regulatory requirements while maintaining optimal thermal performance in industrial settings.

Market Demand Analysis for Quieter Heat Exchange Systems

The global market for quieter heat exchange systems has been experiencing significant growth, driven primarily by increasing regulatory pressure on noise pollution and growing consumer demand for quieter operational environments. Industry analysis indicates that the heat exchanger market valued at approximately $16.6 billion in 2022 is projected to reach $22.8 billion by 2027, with noise reduction technologies representing an increasingly important segment of this growth.

Residential applications constitute a substantial portion of market demand for quieter heat exchangers, particularly in densely populated urban areas where noise regulations are more stringent. Surveys indicate that 68% of homeowners consider noise levels a critical factor when purchasing HVAC systems, with 42% willing to pay a premium of 15-20% for significantly quieter operation.

The commercial sector presents another major market segment, with hospitals, hotels, and office buildings increasingly specifying low-noise heat exchange systems. Healthcare facilities, in particular, have shown a 23% increase in adoption of noise-optimized systems over the past five years, recognizing the impact of noise pollution on patient recovery and staff performance.

Industrial applications are witnessing a paradigm shift toward worker comfort and regulatory compliance. Manufacturing facilities operating 24/7 are investing in noise reduction technologies to comply with workplace safety regulations that limit continuous noise exposure to 85 dB over an 8-hour period. This has created a specialized market segment estimated at $3.2 billion annually.

Regional analysis reveals that Europe leads in demand for noise-optimized heat exchangers due to stricter environmental regulations, followed by North America and rapidly growing markets in Asia-Pacific. The European market has implemented the Energy-related Products Directive which includes noise emission standards, creating a regulatory-driven demand increase of approximately 18% annually.

Consumer preference studies demonstrate a clear trend toward quieter operational environments, with 76% of respondents indicating noise reduction as a "very important" or "important" factor in purchasing decisions. This trend is particularly pronounced in premium market segments where noise performance has become a key differentiator among competing products.

Market forecasts suggest that demand for noise-optimized heat exchangers will grow at a CAGR of 7.8% through 2028, outpacing the overall heat exchanger market growth of 6.5%. This accelerated growth represents significant opportunities for manufacturers who can deliver effective noise reduction solutions while maintaining thermal efficiency and competitive pricing.

Residential applications constitute a substantial portion of market demand for quieter heat exchangers, particularly in densely populated urban areas where noise regulations are more stringent. Surveys indicate that 68% of homeowners consider noise levels a critical factor when purchasing HVAC systems, with 42% willing to pay a premium of 15-20% for significantly quieter operation.

The commercial sector presents another major market segment, with hospitals, hotels, and office buildings increasingly specifying low-noise heat exchange systems. Healthcare facilities, in particular, have shown a 23% increase in adoption of noise-optimized systems over the past five years, recognizing the impact of noise pollution on patient recovery and staff performance.

Industrial applications are witnessing a paradigm shift toward worker comfort and regulatory compliance. Manufacturing facilities operating 24/7 are investing in noise reduction technologies to comply with workplace safety regulations that limit continuous noise exposure to 85 dB over an 8-hour period. This has created a specialized market segment estimated at $3.2 billion annually.

Regional analysis reveals that Europe leads in demand for noise-optimized heat exchangers due to stricter environmental regulations, followed by North America and rapidly growing markets in Asia-Pacific. The European market has implemented the Energy-related Products Directive which includes noise emission standards, creating a regulatory-driven demand increase of approximately 18% annually.

Consumer preference studies demonstrate a clear trend toward quieter operational environments, with 76% of respondents indicating noise reduction as a "very important" or "important" factor in purchasing decisions. This trend is particularly pronounced in premium market segments where noise performance has become a key differentiator among competing products.

Market forecasts suggest that demand for noise-optimized heat exchangers will grow at a CAGR of 7.8% through 2028, outpacing the overall heat exchanger market growth of 6.5%. This accelerated growth represents significant opportunities for manufacturers who can deliver effective noise reduction solutions while maintaining thermal efficiency and competitive pricing.

Current Noise Reduction Technologies and Challenges

The current landscape of noise reduction technologies in heat exchanger operations presents a complex array of solutions that address various noise sources and mechanisms. Passive noise control methods remain the most widely implemented approach, primarily due to their cost-effectiveness and reliability. These include acoustic insulation materials, vibration damping compounds, and structural modifications such as stiffening ribs and isolation mounts. Recent advancements in composite materials have yielded acoustic insulation with superior performance-to-weight ratios, enabling more efficient noise reduction without significant space or weight penalties.

Active noise control technologies have seen substantial development in the past decade, though their application in heat exchanger systems remains limited to specialized high-value installations. These systems employ sensors to detect noise patterns and generate counter-phase sound waves to cancel unwanted noise. The primary challenges for active systems include high implementation costs, complexity in controlling broadband noise, and reliability concerns in harsh industrial environments where heat exchangers typically operate.

Flow-induced noise, a predominant issue in heat exchangers, has been addressed through various hydrodynamic design improvements. These include optimized tube arrangements, modified baffle designs, and flow distributors that minimize turbulence. Computational Fluid Dynamics (CFD) modeling has significantly enhanced the ability to predict and mitigate flow-induced noise during the design phase, though the accuracy of these models remains a challenge when dealing with complex multiphase flows and thermal gradients.

Mechanical noise reduction strategies focus on addressing vibration transmission pathways. Flexible connections, precision balancing of rotating components, and enhanced bearing designs have shown effectiveness in reducing mechanical noise sources. However, these solutions often require trade-offs between thermal efficiency, pressure drop, and noise performance, presenting ongoing engineering challenges.

A significant limitation in current noise reduction technologies is the lack of integrated approaches that address multiple noise mechanisms simultaneously. Most existing solutions target specific noise sources in isolation, potentially creating unintended consequences for other performance parameters or even introducing new noise sources. Additionally, the long-term performance degradation of noise reduction systems in the harsh operating environments typical of heat exchangers remains poorly understood.

Emerging technologies showing promise include smart materials that adapt their acoustic properties based on operating conditions, nanomaterial-based acoustic treatments with exceptional absorption characteristics, and machine learning algorithms that optimize system operation for minimal noise generation while maintaining thermal performance. However, these technologies face significant barriers to widespread adoption, including high costs, limited field validation, and integration challenges with existing systems.

Active noise control technologies have seen substantial development in the past decade, though their application in heat exchanger systems remains limited to specialized high-value installations. These systems employ sensors to detect noise patterns and generate counter-phase sound waves to cancel unwanted noise. The primary challenges for active systems include high implementation costs, complexity in controlling broadband noise, and reliability concerns in harsh industrial environments where heat exchangers typically operate.

Flow-induced noise, a predominant issue in heat exchangers, has been addressed through various hydrodynamic design improvements. These include optimized tube arrangements, modified baffle designs, and flow distributors that minimize turbulence. Computational Fluid Dynamics (CFD) modeling has significantly enhanced the ability to predict and mitigate flow-induced noise during the design phase, though the accuracy of these models remains a challenge when dealing with complex multiphase flows and thermal gradients.

Mechanical noise reduction strategies focus on addressing vibration transmission pathways. Flexible connections, precision balancing of rotating components, and enhanced bearing designs have shown effectiveness in reducing mechanical noise sources. However, these solutions often require trade-offs between thermal efficiency, pressure drop, and noise performance, presenting ongoing engineering challenges.

A significant limitation in current noise reduction technologies is the lack of integrated approaches that address multiple noise mechanisms simultaneously. Most existing solutions target specific noise sources in isolation, potentially creating unintended consequences for other performance parameters or even introducing new noise sources. Additionally, the long-term performance degradation of noise reduction systems in the harsh operating environments typical of heat exchangers remains poorly understood.

Emerging technologies showing promise include smart materials that adapt their acoustic properties based on operating conditions, nanomaterial-based acoustic treatments with exceptional absorption characteristics, and machine learning algorithms that optimize system operation for minimal noise generation while maintaining thermal performance. However, these technologies face significant barriers to widespread adoption, including high costs, limited field validation, and integration challenges with existing systems.

Mainstream Noise Reduction Solutions and Implementation

01 Vibration isolation and damping systems

Vibration isolation and damping systems can be incorporated into heat exchangers to reduce noise transmission. These systems typically include vibration absorbers, damping materials, or isolation mounts that prevent the propagation of vibrations from the heat exchanger to surrounding structures. By isolating the heat exchanger from its mounting surface, mechanical vibrations that contribute to noise are significantly reduced.- Vibration isolation and damping systems: Vibration isolation and damping systems are used to reduce noise in heat exchangers by preventing the transmission of vibrations from the heat exchanger to surrounding structures. These systems typically include vibration isolators, damping materials, or shock absorbers that are strategically placed to absorb vibrations. By reducing vibrations, these systems effectively minimize noise generation and transmission, resulting in quieter heat exchanger operation.

- Acoustic insulation and noise barriers: Acoustic insulation materials and noise barriers can be incorporated into heat exchanger designs to contain and absorb sound waves. These solutions typically involve surrounding the heat exchanger with sound-absorbing materials or enclosures that prevent noise from propagating to the surrounding environment. The insulation may be made of various materials such as foam, fiberglass, or composite materials specifically designed for sound attenuation in industrial equipment.

- Optimized flow path design: Redesigning the internal flow paths of heat exchangers can significantly reduce turbulence and fluid-induced vibrations that cause noise. This approach involves modifying the geometry of channels, tubes, or fins to create smoother fluid flow patterns. By reducing sudden changes in flow direction or velocity, these designs minimize the formation of vortices and pressure fluctuations that generate noise, resulting in quieter operation without compromising thermal performance.

- Structural reinforcement and stiffening: Reinforcing and stiffening the heat exchanger structure can reduce noise by minimizing vibrations caused by fluid flow or mechanical forces. This approach involves adding support elements, braces, or increasing the thickness of certain components to enhance structural rigidity. By making the heat exchanger less prone to vibration and resonance, these modifications effectively reduce noise generation during operation.

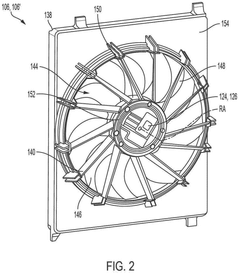

- Advanced fan and pump designs: Incorporating advanced fan and pump designs in heat exchanger systems can significantly reduce noise generation. These designs focus on optimizing blade shapes, reducing rotational speeds, and improving flow characteristics to minimize turbulence and pressure fluctuations. Low-noise fans often feature specially designed impellers, diffusers, or variable speed controls that allow for quieter operation while maintaining adequate heat transfer performance.

02 Acoustic insulation and noise barriers

Acoustic insulation materials and noise barriers can be applied to heat exchanger surfaces to absorb sound waves and prevent noise propagation. These solutions typically involve wrapping or enclosing the heat exchanger with sound-absorbing materials, installing acoustic panels, or creating noise-blocking enclosures. These methods effectively reduce the transmission of operational noise to the surrounding environment.Expand Specific Solutions03 Optimized fluid flow design

Redesigning the fluid flow paths within heat exchangers can significantly reduce turbulence and associated noise. This approach includes modifying the geometry of flow channels, optimizing the arrangement of tubes and fins, and incorporating flow straighteners or diffusers. By creating more laminar flow conditions and reducing pressure fluctuations, these design improvements minimize the generation of flow-induced noise.Expand Specific Solutions04 Structural modifications for noise reduction

Structural modifications to heat exchanger components can reduce resonance and mechanical noise. These modifications include reinforcing vibration-prone parts, changing the natural frequency of components to avoid resonance, and using alternative materials with better noise-damping properties. By addressing the structural sources of noise generation, these approaches provide effective noise reduction without compromising thermal performance.Expand Specific Solutions05 Fan and compressor noise reduction

Many heat exchanger systems incorporate fans or compressors that contribute significantly to overall noise levels. Techniques for reducing this noise include using low-noise fan designs, variable speed drives to operate at quieter speeds, fan blade optimization, and acoustic treatments specifically targeting fan-generated noise. By addressing these auxiliary components, the overall noise signature of the heat exchanger system can be substantially reduced.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The noise reduction market in heat exchanger operations is currently in a growth phase, with increasing demand driven by energy efficiency regulations and sustainability initiatives. The competitive landscape features established industrial giants like General Electric, Denso, and Mercedes-Benz Group alongside specialized thermal management companies such as Hanon Systems, Behr, and Daikin Industries. Market maturity varies across applications, with automotive thermal systems showing higher technological advancement than industrial implementations. Leading companies like LG Electronics, Gree, and Qualcomm are investing in smart noise reduction technologies that integrate IoT capabilities. The competitive dynamics are shifting as traditional manufacturers face pressure from technology-focused entrants developing advanced acoustic dampening solutions and computational fluid dynamics models for noise prediction and mitigation.

General Electric Company

Technical Solution: GE has pioneered a multi-faceted approach to noise reduction in industrial heat exchangers through their "Quiet-Tech" program. Their strategy incorporates advanced materials science with computational modeling to address noise at its source. GE utilizes composite materials with superior vibration damping properties for critical components, reducing structure-borne noise transmission. Their proprietary flow distribution technology ensures uniform fluid distribution across heat exchanger tubes, minimizing turbulence-induced noise. GE's acoustic modeling capabilities allow them to predict and mitigate noise generation through design optimization before manufacturing. Additionally, they've developed specialized tube-to-header joints that reduce thermal expansion noise and implemented micro-perforated acoustic panels that absorb sound energy without impeding thermal performance. For large industrial applications, GE employs active noise cancellation systems that continuously monitor and counteract low-frequency noise components that are difficult to address through passive means.

Strengths: Comprehensive integration of materials science and computational modeling; solutions applicable across various scales from residential to industrial applications; proven track record in noise reduction while maintaining thermal efficiency. Weaknesses: Premium pricing structure limits accessibility for smaller operations; some solutions require specialized maintenance expertise; retrofit applications can be challenging in space-constrained environments.

Hanon Systems

Technical Solution: Hanon Systems has developed a comprehensive noise reduction framework specifically for automotive thermal management systems. Their approach begins with advanced computational fluid dynamics (CFD) simulations to identify and mitigate noise sources during the design phase. Hanon's proprietary "Acoustic Mapping" technology creates detailed noise profiles of heat exchanger operations across various operating conditions, allowing engineers to target specific frequency ranges for mitigation. Their heat exchangers incorporate specially designed turbulators that maintain thermal efficiency while reducing flow-induced vibration and noise. For refrigerant-based systems, Hanon has pioneered pulsation dampening technologies that minimize the noise generated by pressure fluctuations in the refrigerant circuit. Their latest innovation includes micro-perforated baffle systems integrated directly into heat exchanger headers, which provide acoustic absorption without compromising flow characteristics. Hanon also utilizes advanced composite materials with superior damping properties for mounting brackets and support structures, effectively isolating heat exchanger vibrations from the vehicle structure.

Strengths: Specialized expertise in automotive thermal management systems; comprehensive approach addressing both airborne and structure-borne noise pathways; solutions designed for manufacturing scalability. Weaknesses: Limited application outside automotive sector; some solutions add complexity to manufacturing processes; noise reduction technologies may add cost that is challenging to justify in lower-price vehicle segments.

Key Patents and Technical Literature on Acoustic Dampening

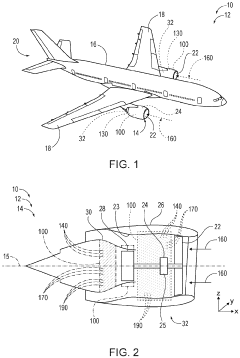

Heat exchanger system

PatentPendingEP4571065A1

Innovation

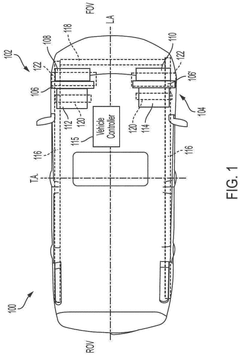

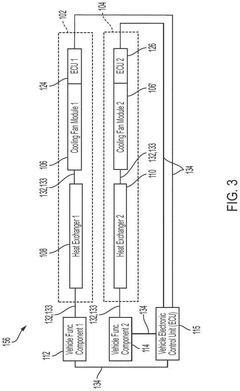

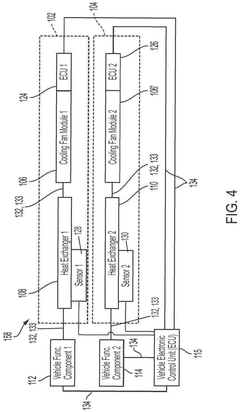

- A heat exchanger system comprising two cooling fan modules with a controller that adjusts their rotational speeds to maintain a speed differential, thereby mitigating objectionable acoustic properties. The system receives demanded heat rejection rates for each heat exchanger and adjusts the fan speeds accordingly to ensure acoustic properties remain below a predetermined threshold.

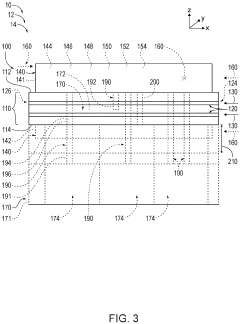

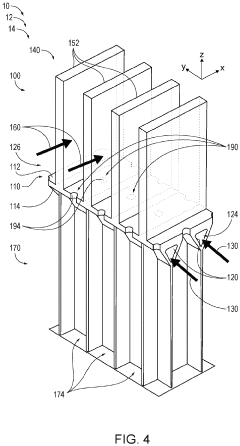

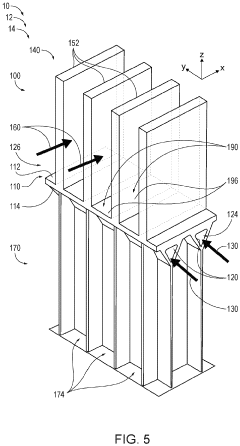

Sound-attenuating heat exchangers and methods of exchanging heat and attenuating sound within sound-attenuating heat exchangers

PatentPendingEP4293213A1

Innovation

- The sound-attenuating heat exchangers incorporate a base region with elongate fluid conduits and heat transfer-enhancing structures that extend from one base side, and a sound-attenuating region with resonator cells and openings on the other side, allowing for the attenuation of sound waves within the cooling fluid stream while maintaining fluid separation between the cooling and cooled fluid streams.

Environmental Impact and Energy Efficiency Considerations

Noise reduction strategies in heat exchanger operations must be evaluated not only for their technical efficacy but also for their environmental impact and energy efficiency implications. The implementation of noise reduction technologies often creates a complex interplay between acoustic performance, environmental sustainability, and operational efficiency.

Heat exchangers are significant energy consumers in industrial settings, with noise reduction modifications potentially affecting their energy consumption profiles. Research indicates that certain acoustic treatments, such as insulation materials and vibration dampeners, can simultaneously provide thermal insulation benefits, reducing heat loss and improving overall system efficiency by 5-15% depending on the application environment.

Conversely, some noise reduction strategies may introduce additional flow restrictions or increase system complexity, potentially leading to higher pumping power requirements or pressure drops. These trade-offs must be carefully balanced through comprehensive life cycle assessments that consider both immediate operational impacts and long-term environmental consequences.

From an environmental perspective, reduced noise pollution represents a significant ecological benefit, particularly in urban industrial zones or environmentally sensitive areas. Studies have documented the adverse effects of industrial noise on local wildlife populations and ecosystem dynamics, with noise reduction strategies offering measurable improvements in biodiversity indicators around industrial facilities.

Material selection for acoustic treatments presents another critical environmental consideration. Traditional sound-absorbing materials often contain synthetic compounds with substantial carbon footprints or end-of-life disposal challenges. The emerging trend toward bio-based acoustic materials derived from agricultural waste or sustainable forestry products offers promising alternatives with reduced environmental impact.

Energy recovery systems integrated with noise reduction technologies represent a particularly promising development path. Advanced designs now incorporate regenerative features that capture acoustic energy and convert it to usable forms, though these technologies remain in early commercial development stages with efficiency rates typically below 5%.

Regulatory frameworks increasingly recognize this interconnection between noise control and energy efficiency. The European Union's Ecodesign Directive and similar regulations worldwide now incorporate acoustic performance as a component of overall energy efficiency ratings for industrial equipment, creating market incentives for integrated solutions that address both concerns simultaneously.

Heat exchangers are significant energy consumers in industrial settings, with noise reduction modifications potentially affecting their energy consumption profiles. Research indicates that certain acoustic treatments, such as insulation materials and vibration dampeners, can simultaneously provide thermal insulation benefits, reducing heat loss and improving overall system efficiency by 5-15% depending on the application environment.

Conversely, some noise reduction strategies may introduce additional flow restrictions or increase system complexity, potentially leading to higher pumping power requirements or pressure drops. These trade-offs must be carefully balanced through comprehensive life cycle assessments that consider both immediate operational impacts and long-term environmental consequences.

From an environmental perspective, reduced noise pollution represents a significant ecological benefit, particularly in urban industrial zones or environmentally sensitive areas. Studies have documented the adverse effects of industrial noise on local wildlife populations and ecosystem dynamics, with noise reduction strategies offering measurable improvements in biodiversity indicators around industrial facilities.

Material selection for acoustic treatments presents another critical environmental consideration. Traditional sound-absorbing materials often contain synthetic compounds with substantial carbon footprints or end-of-life disposal challenges. The emerging trend toward bio-based acoustic materials derived from agricultural waste or sustainable forestry products offers promising alternatives with reduced environmental impact.

Energy recovery systems integrated with noise reduction technologies represent a particularly promising development path. Advanced designs now incorporate regenerative features that capture acoustic energy and convert it to usable forms, though these technologies remain in early commercial development stages with efficiency rates typically below 5%.

Regulatory frameworks increasingly recognize this interconnection between noise control and energy efficiency. The European Union's Ecodesign Directive and similar regulations worldwide now incorporate acoustic performance as a component of overall energy efficiency ratings for industrial equipment, creating market incentives for integrated solutions that address both concerns simultaneously.

Regulatory Standards for Industrial Noise Control

Industrial noise control is governed by a complex framework of regulations that vary significantly across regions and jurisdictions. In the United States, the Occupational Safety and Health Administration (OSHA) establishes permissible noise exposure limits, typically setting the threshold at 85-90 dBA for an 8-hour time-weighted average. The Environmental Protection Agency (EPA) further regulates environmental noise pollution through the Noise Control Act, which impacts heat exchanger operations in industrial settings.

The European Union implements more stringent standards through the EU Noise Directive (2002/49/EC), requiring member states to map noise pollution and develop action plans when levels exceed 55 dB during daytime and 50 dB at night. These regulations directly influence heat exchanger design and operational parameters, particularly in densely populated areas where industrial facilities operate in proximity to residential zones.

International Organization for Standardization (ISO) provides globally recognized standards, with ISO 11690 specifically addressing the design of low-noise workplaces containing machinery. For heat exchanger operations, ISO 15665 offers guidance on acoustic insulation for pipes, valves, and flanges, which are critical components in heat exchange systems.

Compliance verification methodologies vary by jurisdiction but typically involve sound pressure level measurements using calibrated sound level meters. These measurements must follow standardized protocols such as those outlined in IEC 61672 for sound level meters and ISO 3744 for determination of sound power levels. Documentation requirements generally include noise assessment reports, mitigation plans, and periodic monitoring data.

Penalties for non-compliance can be severe, ranging from substantial fines to operational restrictions or facility closures. In the United States, OSHA violations related to noise exposure can result in penalties exceeding $13,000 per violation, with repeat offenders facing significantly higher fines. The European Union's enforcement mechanisms typically involve graduated response systems, beginning with improvement notices and escalating to financial penalties.

Recent regulatory trends indicate a movement toward more comprehensive noise management approaches, incorporating not just maximum thresholds but also considerations of tonal characteristics, impulsiveness, and low-frequency components. This evolution in regulatory frameworks necessitates more sophisticated noise reduction strategies for heat exchanger operations, moving beyond simple sound pressure level compliance to address the qualitative aspects of industrial noise.

The European Union implements more stringent standards through the EU Noise Directive (2002/49/EC), requiring member states to map noise pollution and develop action plans when levels exceed 55 dB during daytime and 50 dB at night. These regulations directly influence heat exchanger design and operational parameters, particularly in densely populated areas where industrial facilities operate in proximity to residential zones.

International Organization for Standardization (ISO) provides globally recognized standards, with ISO 11690 specifically addressing the design of low-noise workplaces containing machinery. For heat exchanger operations, ISO 15665 offers guidance on acoustic insulation for pipes, valves, and flanges, which are critical components in heat exchange systems.

Compliance verification methodologies vary by jurisdiction but typically involve sound pressure level measurements using calibrated sound level meters. These measurements must follow standardized protocols such as those outlined in IEC 61672 for sound level meters and ISO 3744 for determination of sound power levels. Documentation requirements generally include noise assessment reports, mitigation plans, and periodic monitoring data.

Penalties for non-compliance can be severe, ranging from substantial fines to operational restrictions or facility closures. In the United States, OSHA violations related to noise exposure can result in penalties exceeding $13,000 per violation, with repeat offenders facing significantly higher fines. The European Union's enforcement mechanisms typically involve graduated response systems, beginning with improvement notices and escalating to financial penalties.

Recent regulatory trends indicate a movement toward more comprehensive noise management approaches, incorporating not just maximum thresholds but also considerations of tonal characteristics, impulsiveness, and low-frequency components. This evolution in regulatory frameworks necessitates more sophisticated noise reduction strategies for heat exchanger operations, moving beyond simple sound pressure level compliance to address the qualitative aspects of industrial noise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!