How to Assess Environmental Impacts of Heat Exchanger Innovations

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Innovation Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to complex, highly efficient systems incorporating advanced materials and geometries. This technological progression has been driven by increasing demands for energy efficiency, cost reduction, and more recently, environmental sustainability. The current trajectory points toward innovations focused on minimizing ecological footprints while maximizing thermal performance.

The global emphasis on sustainable development has positioned environmental impact assessment as a critical component in heat exchanger innovation. Traditional evaluation metrics primarily centered on thermal efficiency and economic viability are now insufficient. Modern assessment frameworks must incorporate comprehensive environmental considerations, including lifecycle carbon emissions, resource consumption, and end-of-life management strategies.

Heat exchanger technologies span numerous industries, including power generation, chemical processing, HVAC systems, and emerging applications in renewable energy systems. Each sector presents unique environmental challenges and opportunities for innovation. For instance, in power generation, heat exchangers contribute significantly to overall plant efficiency, directly affecting carbon emissions, while in refrigeration systems, working fluid selection impacts global warming potential.

Recent technological advancements have introduced promising developments such as additive manufacturing for complex geometries, novel surface enhancement techniques, and bio-inspired designs. These innovations offer potential pathways to reduced material usage, enhanced heat transfer coefficients, and lower operational energy requirements. However, their environmental benefits must be systematically quantified against traditional technologies.

The primary objective of environmental impact assessment for heat exchanger innovations is to develop standardized, comprehensive methodologies that accurately capture the multifaceted environmental implications across the entire lifecycle. This includes raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life scenarios.

Secondary objectives include identifying key environmental performance indicators specific to heat exchanger technologies, establishing industry benchmarks for different applications, and creating decision-support tools that enable engineers and manufacturers to optimize designs for environmental performance without compromising functional requirements.

The ultimate goal is to facilitate a transition toward environmentally responsible heat exchanger technologies that contribute to global sustainability targets while meeting the increasing thermal management demands of modern industrial and commercial applications. This requires a holistic understanding of how innovations affect not only direct operational impacts but also indirect environmental consequences throughout the value chain.

The global emphasis on sustainable development has positioned environmental impact assessment as a critical component in heat exchanger innovation. Traditional evaluation metrics primarily centered on thermal efficiency and economic viability are now insufficient. Modern assessment frameworks must incorporate comprehensive environmental considerations, including lifecycle carbon emissions, resource consumption, and end-of-life management strategies.

Heat exchanger technologies span numerous industries, including power generation, chemical processing, HVAC systems, and emerging applications in renewable energy systems. Each sector presents unique environmental challenges and opportunities for innovation. For instance, in power generation, heat exchangers contribute significantly to overall plant efficiency, directly affecting carbon emissions, while in refrigeration systems, working fluid selection impacts global warming potential.

Recent technological advancements have introduced promising developments such as additive manufacturing for complex geometries, novel surface enhancement techniques, and bio-inspired designs. These innovations offer potential pathways to reduced material usage, enhanced heat transfer coefficients, and lower operational energy requirements. However, their environmental benefits must be systematically quantified against traditional technologies.

The primary objective of environmental impact assessment for heat exchanger innovations is to develop standardized, comprehensive methodologies that accurately capture the multifaceted environmental implications across the entire lifecycle. This includes raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life scenarios.

Secondary objectives include identifying key environmental performance indicators specific to heat exchanger technologies, establishing industry benchmarks for different applications, and creating decision-support tools that enable engineers and manufacturers to optimize designs for environmental performance without compromising functional requirements.

The ultimate goal is to facilitate a transition toward environmentally responsible heat exchanger technologies that contribute to global sustainability targets while meeting the increasing thermal management demands of modern industrial and commercial applications. This requires a holistic understanding of how innovations affect not only direct operational impacts but also indirect environmental consequences throughout the value chain.

Environmental Impact Assessment Market Needs

The environmental impact assessment market for heat exchanger innovations is experiencing significant growth driven by increasing regulatory pressures and corporate sustainability commitments. Industries worldwide are facing stricter environmental regulations regarding energy efficiency, greenhouse gas emissions, and resource consumption, compelling manufacturers and end-users to thoroughly evaluate the environmental footprint of heat exchange technologies.

Market research indicates that the global environmental impact assessment services market reached approximately $4.7 billion in 2022, with specialized technical assessments for industrial equipment comprising a substantial segment. The heat exchanger sector specifically represents a critical focus area due to its widespread application across energy-intensive industries including power generation, chemical processing, HVAC, and oil and gas.

Key market drivers include the implementation of carbon pricing mechanisms in over 40 countries, mandatory environmental impact reporting requirements, and the growing adoption of ESG (Environmental, Social, and Governance) criteria by investors. Organizations are increasingly seeking comprehensive life cycle assessments (LCA) for heat exchanger technologies to quantify environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal.

The demand for specialized assessment methodologies tailored to heat exchanger innovations has grown by 18% annually since 2019. This trend reflects the industry's recognition that traditional performance metrics focused solely on thermal efficiency are insufficient for modern sustainability requirements. Stakeholders now require multi-dimensional analyses incorporating carbon footprint, water usage, material toxicity, and circular economy principles.

Regional analysis reveals varying market maturity, with Europe leading in demand for sophisticated environmental impact assessments due to stringent EU regulations including the Industrial Emissions Directive and Ecodesign requirements. North America follows with growing interest driven by corporate sustainability initiatives, while Asia-Pacific represents the fastest-growing market segment with 22% annual growth as emerging economies implement environmental standards.

Industry surveys indicate that 76% of heat exchanger manufacturers and 82% of end-users consider environmental impact assessments essential for new technology adoption decisions. This represents a significant shift from just five years ago when only 31% viewed such assessments as critical factors. The willingness to pay premium prices for environmentally superior heat exchange solutions has increased correspondingly, with 68% of procurement specialists now authorized to select options with better environmental performance despite higher initial costs.

Market research indicates that the global environmental impact assessment services market reached approximately $4.7 billion in 2022, with specialized technical assessments for industrial equipment comprising a substantial segment. The heat exchanger sector specifically represents a critical focus area due to its widespread application across energy-intensive industries including power generation, chemical processing, HVAC, and oil and gas.

Key market drivers include the implementation of carbon pricing mechanisms in over 40 countries, mandatory environmental impact reporting requirements, and the growing adoption of ESG (Environmental, Social, and Governance) criteria by investors. Organizations are increasingly seeking comprehensive life cycle assessments (LCA) for heat exchanger technologies to quantify environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal.

The demand for specialized assessment methodologies tailored to heat exchanger innovations has grown by 18% annually since 2019. This trend reflects the industry's recognition that traditional performance metrics focused solely on thermal efficiency are insufficient for modern sustainability requirements. Stakeholders now require multi-dimensional analyses incorporating carbon footprint, water usage, material toxicity, and circular economy principles.

Regional analysis reveals varying market maturity, with Europe leading in demand for sophisticated environmental impact assessments due to stringent EU regulations including the Industrial Emissions Directive and Ecodesign requirements. North America follows with growing interest driven by corporate sustainability initiatives, while Asia-Pacific represents the fastest-growing market segment with 22% annual growth as emerging economies implement environmental standards.

Industry surveys indicate that 76% of heat exchanger manufacturers and 82% of end-users consider environmental impact assessments essential for new technology adoption decisions. This represents a significant shift from just five years ago when only 31% viewed such assessments as critical factors. The willingness to pay premium prices for environmentally superior heat exchange solutions has increased correspondingly, with 68% of procurement specialists now authorized to select options with better environmental performance despite higher initial costs.

Current Environmental Assessment Challenges

The assessment of environmental impacts from heat exchanger innovations faces significant methodological and practical challenges in today's industrial landscape. Traditional life cycle assessment (LCA) approaches often fail to capture the full spectrum of environmental effects specific to heat exchanger technologies, particularly regarding energy efficiency improvements and their cascading environmental benefits.

Current assessment frameworks struggle with quantifying the long-term environmental implications of incremental innovations in heat exchanger design. The complex interplay between material selection, manufacturing processes, operational efficiency, and end-of-life management creates multidimensional environmental footprints that conventional metrics cannot adequately measure. This complexity is further compounded when considering the varied applications of heat exchangers across industries from power generation to food processing.

Data availability presents another substantial challenge. Comprehensive environmental impact data for novel materials and manufacturing techniques used in advanced heat exchangers remains scarce. This data gap impedes accurate comparative analyses between conventional and innovative designs, often leading to conservative adoption of new technologies despite their potential environmental advantages.

Standardization issues further complicate assessment efforts. The heat exchanger industry lacks universally accepted environmental performance indicators specifically tailored to thermal exchange technologies. This absence of standardized metrics makes cross-comparison between different innovations difficult and creates barriers to objective environmental performance evaluation.

The dynamic nature of environmental impacts throughout a heat exchanger's operational lifetime presents additional assessment challenges. Performance degradation, maintenance requirements, and changing operational conditions significantly affect environmental footprints over time, yet these temporal dimensions are rarely incorporated into current assessment methodologies.

Boundary definition represents another critical challenge. Determining appropriate system boundaries for environmental assessment of heat exchangers remains contentious, particularly regarding how far upstream (raw material extraction) and downstream (end-use efficiency gains) effects should be considered. Narrow boundary definitions may undervalue innovations that deliver environmental benefits across broader industrial systems.

Finally, current assessment approaches struggle to balance trade-offs between different environmental impact categories. Innovations that reduce greenhouse gas emissions might simultaneously increase water consumption or material intensity. Without robust multi-criteria decision frameworks, evaluators lack systematic methods to weigh these competing environmental considerations when assessing heat exchanger innovations.

Current assessment frameworks struggle with quantifying the long-term environmental implications of incremental innovations in heat exchanger design. The complex interplay between material selection, manufacturing processes, operational efficiency, and end-of-life management creates multidimensional environmental footprints that conventional metrics cannot adequately measure. This complexity is further compounded when considering the varied applications of heat exchangers across industries from power generation to food processing.

Data availability presents another substantial challenge. Comprehensive environmental impact data for novel materials and manufacturing techniques used in advanced heat exchangers remains scarce. This data gap impedes accurate comparative analyses between conventional and innovative designs, often leading to conservative adoption of new technologies despite their potential environmental advantages.

Standardization issues further complicate assessment efforts. The heat exchanger industry lacks universally accepted environmental performance indicators specifically tailored to thermal exchange technologies. This absence of standardized metrics makes cross-comparison between different innovations difficult and creates barriers to objective environmental performance evaluation.

The dynamic nature of environmental impacts throughout a heat exchanger's operational lifetime presents additional assessment challenges. Performance degradation, maintenance requirements, and changing operational conditions significantly affect environmental footprints over time, yet these temporal dimensions are rarely incorporated into current assessment methodologies.

Boundary definition represents another critical challenge. Determining appropriate system boundaries for environmental assessment of heat exchangers remains contentious, particularly regarding how far upstream (raw material extraction) and downstream (end-use efficiency gains) effects should be considered. Narrow boundary definitions may undervalue innovations that deliver environmental benefits across broader industrial systems.

Finally, current assessment approaches struggle to balance trade-offs between different environmental impact categories. Innovations that reduce greenhouse gas emissions might simultaneously increase water consumption or material intensity. Without robust multi-criteria decision frameworks, evaluators lack systematic methods to weigh these competing environmental considerations when assessing heat exchanger innovations.

Current Environmental Impact Assessment Methodologies

01 Energy-efficient heat exchanger designs

Innovative heat exchanger designs focus on improving energy efficiency, thereby reducing environmental impact. These designs incorporate advanced materials and configurations that enhance heat transfer while minimizing energy consumption. Features include optimized flow patterns, improved surface area utilization, and reduced pressure drops. These innovations contribute to lower greenhouse gas emissions and reduced operational costs in various industrial applications.- Energy-efficient heat exchanger designs: Innovative heat exchanger designs focus on improving energy efficiency, thereby reducing environmental impact. These designs incorporate advanced materials and configurations that enhance heat transfer while minimizing energy consumption. Features include optimized flow patterns, improved surface geometries, and novel structural arrangements that maximize thermal efficiency while reducing the carbon footprint of heating and cooling systems.

- Eco-friendly refrigerants and working fluids: Environmental concerns have driven the development of heat exchangers using eco-friendly refrigerants and working fluids. These innovations focus on replacing traditional refrigerants with alternatives having lower global warming potential and zero ozone depletion potential. The new formulations maintain or improve thermal performance while significantly reducing negative environmental impacts associated with refrigerant leakage or disposal.

- Waste heat recovery systems: Advanced heat exchanger technologies enable effective waste heat recovery from industrial processes and power generation. These systems capture thermal energy that would otherwise be lost to the environment and repurpose it for heating, cooling, or electricity generation. By reclaiming waste heat, these innovations reduce primary energy consumption, decrease greenhouse gas emissions, and improve overall system efficiency across various industrial applications.

- Sustainable materials and manufacturing processes: Environmental impact reduction in heat exchanger technology includes the use of sustainable materials and manufacturing processes. Innovations focus on biodegradable or recyclable materials, reduced use of rare or toxic elements, and manufacturing techniques that minimize waste and energy consumption. These approaches consider the entire lifecycle environmental impact from production through operation to end-of-life disposal or recycling.

- Smart control systems for environmental optimization: Integration of intelligent control systems with heat exchangers enables real-time optimization for environmental performance. These smart systems use sensors, data analytics, and adaptive algorithms to continuously adjust operating parameters based on changing conditions. By optimizing performance under varying loads and ambient conditions, these systems minimize energy consumption, reduce emissions, and extend equipment lifespan while maintaining desired thermal management capabilities.

02 Eco-friendly refrigerants and working fluids

Heat exchangers utilizing environmentally friendly refrigerants and working fluids represent a significant advancement in reducing environmental impact. These systems employ low global warming potential (GWP) and zero ozone depletion potential (ODP) substances as alternatives to traditional refrigerants. The innovations include natural refrigerants, hydrofluoroolefins (HFOs), and other sustainable working fluids that maintain or improve thermal efficiency while minimizing harm to the atmosphere.Expand Specific Solutions03 Waste heat recovery systems

Advanced waste heat recovery systems capture and repurpose thermal energy that would otherwise be lost to the environment. These innovations include heat exchangers specifically designed to extract energy from industrial processes, exhaust gases, and cooling systems. By reclaiming this waste heat for productive use, these systems significantly improve overall energy efficiency, reduce fossil fuel consumption, and decrease carbon emissions across various industries including manufacturing, power generation, and HVAC applications.Expand Specific Solutions04 Sustainable materials and manufacturing processes

Innovations in heat exchanger technology include the use of sustainable materials and environmentally responsible manufacturing processes. These advancements focus on reducing the carbon footprint of heat exchanger production through the use of recycled materials, biodegradable components, and manufacturing techniques that minimize waste and energy consumption. Additionally, these innovations extend the operational lifespan of heat exchangers, reducing the environmental impact associated with replacement and disposal.Expand Specific Solutions05 Smart monitoring and control systems

Integration of intelligent monitoring and control systems in heat exchangers enables real-time optimization of performance and environmental impact. These systems utilize sensors, data analytics, and automated controls to maintain optimal operating conditions, detect inefficiencies, and prevent failures. By continuously adjusting parameters based on actual conditions, these smart systems minimize energy consumption, reduce emissions, and extend equipment life, contributing to overall environmental sustainability in heating and cooling applications.Expand Specific Solutions

Leading Organizations in Green Heat Exchange

The environmental impact assessment of heat exchanger innovations is currently in a growth phase, with an expanding market driven by increasing sustainability regulations and corporate ESG commitments. Key players represent diverse sectors, with research institutions like CEA, Xi'an Jiaotong University, and École Polytechnique Fédérale de Lausanne advancing fundamental research, while industrial leaders such as Honeywell, Rolls-Royce, Carrier, and Air Liquide focus on commercial applications. Energy companies including China General Nuclear Power, Saudi Aramco, and Shell are investing in heat exchanger efficiency improvements to reduce environmental footprints. The technology shows moderate maturity with established methodologies for lifecycle assessment, but innovations in materials, design optimization, and integration with renewable energy systems represent emerging frontiers requiring more sophisticated impact evaluation frameworks.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed a comprehensive Life Cycle Assessment (LCA) methodology specifically tailored for heat exchanger technologies. Their approach integrates thermal-hydraulic performance evaluation with environmental impact metrics across the entire product lifecycle. CEA's framework quantifies impacts through multiple categories including Global Warming Potential (GWP), resource depletion, water usage, and toxicity indicators. Their methodology incorporates advanced computational fluid dynamics (CFD) modeling to optimize heat exchanger designs while minimizing environmental footprint. The CEA has pioneered the use of eco-design principles in heat exchanger development, creating a standardized protocol that evaluates both direct impacts (materials, manufacturing) and indirect impacts (operational efficiency, end-of-life disposal). Their assessment tools enable comparison between conventional and innovative heat exchanger technologies based on environmental performance indicators normalized to functional thermal units.

Strengths: Comprehensive methodology that integrates technical performance with environmental metrics; strong scientific foundation with validated assessment protocols; ability to compare diverse heat exchanger technologies on standardized environmental criteria. Weaknesses: Complex implementation requiring specialized expertise; primarily focused on industrial and nuclear applications with less emphasis on consumer applications.

Modine Manufacturing Co.

Technical Solution: Modine has implemented an Environmental Impact Assessment (EIA) framework specifically designed for their heat exchanger innovations. Their approach centers on a "Design for Environment" methodology that evaluates environmental impacts across the entire product lifecycle. Modine's assessment protocol quantifies impacts in key categories including carbon footprint, material efficiency, energy consumption, and end-of-life recyclability. Their proprietary software tools integrate thermal performance modeling with environmental impact calculations to optimize designs for both efficiency and sustainability. Modine has developed specific metrics for evaluating refrigerant selection in heat exchangers, considering Global Warming Potential (GWP), Ozone Depletion Potential (ODP), and atmospheric lifetime. Their assessment methodology includes a comparative analysis component that benchmarks new designs against industry standards and previous generations of heat exchangers. Modine's approach also incorporates supply chain environmental assessments, evaluating the upstream impacts of raw material sourcing and manufacturing processes used in heat exchanger production.

Strengths: Industry-specific metrics tailored to heat exchanger applications; integrated approach that balances thermal performance with environmental considerations; practical implementation in commercial product development. Weaknesses: Primarily focused on automotive and HVAC applications; proprietary methodology that may limit broader industry adoption and standardization.

Key Environmental Metrics and Measurement Techniques

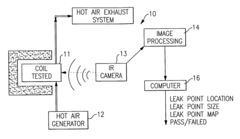

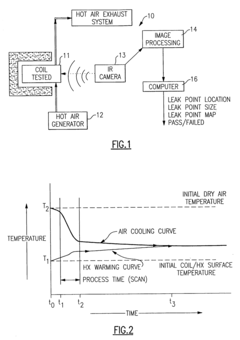

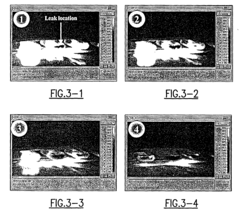

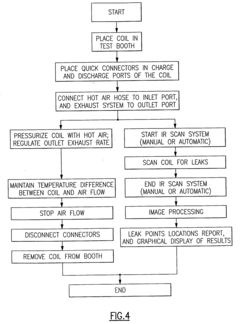

Leak detection with thermal imaging

PatentInactiveUS20040003914A1

Innovation

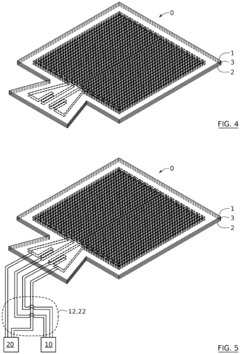

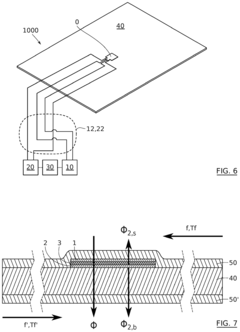

- The method involves pressurizing a heat exchanger with ambient air and using an infrared camera to detect temperature gradients between the heat exchanger and the pressurized vapor, eliminating the need for trace gases and allowing for efficient leak detection by analyzing temperature differences.

Device and method for evaluating at least one operating condition of a heat exchanger

PatentActiveEP3339828A1

Innovation

- A dual temperature probe system comprising two single temperature probes with resistive circuits and a thermally insulating layer, allowing for independent temperature measurements and heat flux association, enabling the calculation of thermal resistances and fluid temperatures on both sides of the heat exchanger wall, thereby identifying fouling location and contribution.

Regulatory Compliance and Standards

The regulatory landscape governing heat exchanger innovations has become increasingly complex as environmental concerns gain prominence globally. Heat exchanger manufacturers and operators must navigate a multifaceted framework of international, national, and local regulations designed to minimize environmental impacts. The ISO 14000 series, particularly ISO 14001 for Environmental Management Systems, provides a foundational framework for organizations to systematically address environmental responsibilities. Additionally, industry-specific standards such as ASME Boiler and Pressure Vessel Code Section VIII and TEMA (Tubular Exchanger Manufacturers Association) standards incorporate environmental considerations alongside safety and performance requirements.

Emissions regulations represent a critical compliance area for heat exchanger operations. The Clean Air Act in the United States and similar legislation worldwide establish limits on air pollutants associated with heat exchange processes, including nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. The European Union's Industrial Emissions Directive (IED) implements a more integrated approach, requiring the application of Best Available Techniques (BAT) for pollution prevention across industrial activities involving heat exchangers.

Water-related regulations constitute another significant compliance domain, as many heat exchangers utilize water for cooling purposes. Discharge permits under frameworks like the Clean Water Act regulate temperature differentials, chemical additives, and potential contaminants in cooling water returned to natural water bodies. The EU Water Framework Directive similarly establishes comprehensive protection for water resources potentially affected by industrial heat exchange processes.

Energy efficiency standards have emerged as a powerful regulatory tool for driving environmental improvements in heat exchanger design. The EU Ecodesign Directive establishes minimum efficiency requirements for energy-related products, while programs like ENERGY STAR in the United States provide voluntary benchmarks that often become de facto industry standards. These frameworks increasingly incorporate lifecycle assessment methodologies to evaluate comprehensive environmental impacts beyond operational efficiency.

Chemical regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and similar programs worldwide affect material selection for heat exchangers, particularly regarding corrosion inhibitors, cleaning agents, and materials used in manufacturing. Compliance requires detailed documentation of chemical inventories and substitution of hazardous substances with safer alternatives when technically and economically feasible.

Emerging regulatory trends indicate a shift toward more holistic environmental assessment frameworks. Carbon pricing mechanisms, extended producer responsibility regulations, and circular economy directives are expanding the scope of environmental compliance for heat exchanger innovations. Forward-looking manufacturers are adopting voluntary certification programs like Cradle to Cradle and Environmental Product Declarations to demonstrate environmental performance beyond minimum regulatory requirements, anticipating future regulatory developments and gaining competitive advantages in environmentally conscious markets.

Emissions regulations represent a critical compliance area for heat exchanger operations. The Clean Air Act in the United States and similar legislation worldwide establish limits on air pollutants associated with heat exchange processes, including nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. The European Union's Industrial Emissions Directive (IED) implements a more integrated approach, requiring the application of Best Available Techniques (BAT) for pollution prevention across industrial activities involving heat exchangers.

Water-related regulations constitute another significant compliance domain, as many heat exchangers utilize water for cooling purposes. Discharge permits under frameworks like the Clean Water Act regulate temperature differentials, chemical additives, and potential contaminants in cooling water returned to natural water bodies. The EU Water Framework Directive similarly establishes comprehensive protection for water resources potentially affected by industrial heat exchange processes.

Energy efficiency standards have emerged as a powerful regulatory tool for driving environmental improvements in heat exchanger design. The EU Ecodesign Directive establishes minimum efficiency requirements for energy-related products, while programs like ENERGY STAR in the United States provide voluntary benchmarks that often become de facto industry standards. These frameworks increasingly incorporate lifecycle assessment methodologies to evaluate comprehensive environmental impacts beyond operational efficiency.

Chemical regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and similar programs worldwide affect material selection for heat exchangers, particularly regarding corrosion inhibitors, cleaning agents, and materials used in manufacturing. Compliance requires detailed documentation of chemical inventories and substitution of hazardous substances with safer alternatives when technically and economically feasible.

Emerging regulatory trends indicate a shift toward more holistic environmental assessment frameworks. Carbon pricing mechanisms, extended producer responsibility regulations, and circular economy directives are expanding the scope of environmental compliance for heat exchanger innovations. Forward-looking manufacturers are adopting voluntary certification programs like Cradle to Cradle and Environmental Product Declarations to demonstrate environmental performance beyond minimum regulatory requirements, anticipating future regulatory developments and gaining competitive advantages in environmentally conscious markets.

Life Cycle Analysis Framework

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of heat exchanger innovations throughout their entire life cycle. This systematic approach begins with raw material extraction and continues through manufacturing, transportation, use phase, and end-of-life disposal or recycling. For heat exchanger technologies, the framework typically divides the assessment into four distinct phases: goal and scope definition, inventory analysis, impact assessment, and interpretation.

The goal and scope definition phase establishes the purpose of the assessment, system boundaries, functional unit, and assumptions. For heat exchangers, the functional unit might be defined as the transfer of a specific amount of thermal energy under standardized conditions over a predetermined operational lifetime. System boundaries must clearly delineate which processes are included and excluded from the analysis.

Inventory analysis involves quantifying all inputs (raw materials, energy, water) and outputs (emissions, waste) associated with each life cycle stage of the heat exchanger. This phase requires detailed data collection regarding material composition, manufacturing processes, operational energy requirements, maintenance needs, and end-of-life scenarios. For innovative heat exchanger designs, this may include novel materials like advanced alloys, composites, or nanomaterials.

Impact assessment translates the inventory data into potential environmental impacts across multiple categories. These typically include global warming potential, acidification, eutrophication, ozone depletion, human toxicity, and resource depletion. For heat exchangers, particular attention should be paid to energy efficiency during operation, as this often represents the most significant environmental impact over the product lifecycle.

The interpretation phase synthesizes findings to identify environmental hotspots and improvement opportunities. This involves sensitivity analysis to test assumptions and uncertainty assessment to validate conclusions. For heat exchanger innovations, this phase often reveals trade-offs between material intensity, manufacturing complexity, operational efficiency, and end-of-life management.

Advanced LCA methodologies for heat exchangers may incorporate dynamic modeling to account for changing operational conditions, consequential approaches to capture market effects of widespread adoption, and integration with economic assessments through Life Cycle Costing (LCC). These enhancements provide a more nuanced understanding of environmental performance beyond traditional attributional LCA approaches.

The goal and scope definition phase establishes the purpose of the assessment, system boundaries, functional unit, and assumptions. For heat exchangers, the functional unit might be defined as the transfer of a specific amount of thermal energy under standardized conditions over a predetermined operational lifetime. System boundaries must clearly delineate which processes are included and excluded from the analysis.

Inventory analysis involves quantifying all inputs (raw materials, energy, water) and outputs (emissions, waste) associated with each life cycle stage of the heat exchanger. This phase requires detailed data collection regarding material composition, manufacturing processes, operational energy requirements, maintenance needs, and end-of-life scenarios. For innovative heat exchanger designs, this may include novel materials like advanced alloys, composites, or nanomaterials.

Impact assessment translates the inventory data into potential environmental impacts across multiple categories. These typically include global warming potential, acidification, eutrophication, ozone depletion, human toxicity, and resource depletion. For heat exchangers, particular attention should be paid to energy efficiency during operation, as this often represents the most significant environmental impact over the product lifecycle.

The interpretation phase synthesizes findings to identify environmental hotspots and improvement opportunities. This involves sensitivity analysis to test assumptions and uncertainty assessment to validate conclusions. For heat exchanger innovations, this phase often reveals trade-offs between material intensity, manufacturing complexity, operational efficiency, and end-of-life management.

Advanced LCA methodologies for heat exchangers may incorporate dynamic modeling to account for changing operational conditions, consequential approaches to capture market effects of widespread adoption, and integration with economic assessments through Life Cycle Costing (LCC). These enhancements provide a more nuanced understanding of environmental performance beyond traditional attributional LCA approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!