How to Choose Porous Media for Enhanced Heat Exchanger Transfer

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Porous Media Heat Transfer Background and Objectives

Heat transfer enhancement through porous media has evolved significantly over the past several decades, transitioning from basic theoretical studies to sophisticated applications across multiple industries. The fundamental concept involves utilizing porous structures to increase surface area, disrupt boundary layers, and enhance mixing, thereby improving overall heat transfer efficiency. Early research in the 1950s and 1960s focused primarily on understanding fluid flow through naturally occurring porous materials, while contemporary studies have expanded to engineered porous media with precisely controlled properties.

The evolution of manufacturing technologies, particularly additive manufacturing and advanced material science, has revolutionized the potential applications of porous media in heat exchangers. These technological advancements have enabled the creation of customized porous structures with tailored properties specific to particular heat transfer requirements, marking a significant departure from the traditional use of generic porous materials.

Current technological trends indicate a growing interest in multi-functional porous media that can simultaneously enhance heat transfer while addressing other challenges such as pressure drop minimization, fouling resistance, and structural integrity under extreme conditions. The integration of nanomaterials and smart materials into porous structures represents another emerging trend, offering potential for responsive heat transfer systems that adapt to changing operational conditions.

The primary objective of porous media selection for enhanced heat exchanger transfer is to identify or design optimal porous structures that maximize heat transfer efficiency while minimizing associated penalties such as increased pressure drop and manufacturing complexity. This involves understanding the complex interplay between various parameters including porosity, pore size distribution, tortuosity, thermal conductivity of the solid phase, and compatibility with working fluids.

Secondary objectives include developing systematic methodologies for porous media selection based on specific application requirements, establishing standardized testing protocols for performance evaluation, and creating predictive models that can accurately simulate heat transfer behavior in complex porous structures. These objectives align with the broader goal of advancing heat exchanger technology to meet increasingly demanding energy efficiency standards and thermal management challenges in various industries.

The ultimate technological goal is to develop a comprehensive framework that enables engineers to precisely match porous media characteristics with specific heat transfer requirements, thereby optimizing system performance across diverse applications ranging from compact electronics cooling to industrial-scale heat recovery systems.

The evolution of manufacturing technologies, particularly additive manufacturing and advanced material science, has revolutionized the potential applications of porous media in heat exchangers. These technological advancements have enabled the creation of customized porous structures with tailored properties specific to particular heat transfer requirements, marking a significant departure from the traditional use of generic porous materials.

Current technological trends indicate a growing interest in multi-functional porous media that can simultaneously enhance heat transfer while addressing other challenges such as pressure drop minimization, fouling resistance, and structural integrity under extreme conditions. The integration of nanomaterials and smart materials into porous structures represents another emerging trend, offering potential for responsive heat transfer systems that adapt to changing operational conditions.

The primary objective of porous media selection for enhanced heat exchanger transfer is to identify or design optimal porous structures that maximize heat transfer efficiency while minimizing associated penalties such as increased pressure drop and manufacturing complexity. This involves understanding the complex interplay between various parameters including porosity, pore size distribution, tortuosity, thermal conductivity of the solid phase, and compatibility with working fluids.

Secondary objectives include developing systematic methodologies for porous media selection based on specific application requirements, establishing standardized testing protocols for performance evaluation, and creating predictive models that can accurately simulate heat transfer behavior in complex porous structures. These objectives align with the broader goal of advancing heat exchanger technology to meet increasingly demanding energy efficiency standards and thermal management challenges in various industries.

The ultimate technological goal is to develop a comprehensive framework that enables engineers to precisely match porous media characteristics with specific heat transfer requirements, thereby optimizing system performance across diverse applications ranging from compact electronics cooling to industrial-scale heat recovery systems.

Market Analysis for Enhanced Heat Exchanger Solutions

The global heat exchanger market is experiencing robust growth, valued at approximately $19.14 billion in 2022 and projected to reach $28.3 billion by 2030, with a compound annual growth rate (CAGR) of 5.1%. This growth is primarily driven by increasing industrialization, stringent energy efficiency regulations, and the rising demand for HVAC systems across residential, commercial, and industrial sectors.

Enhanced heat exchanger solutions utilizing porous media represent a significant segment within this market, with particular strength in high-performance applications where traditional heat exchangers face limitations. Industries including power generation, chemical processing, refrigeration, automotive, and aerospace are showing heightened interest in these advanced solutions due to their superior thermal performance characteristics.

The demand for porous media heat exchangers is particularly strong in regions with strict energy efficiency standards and carbon reduction targets. North America and Europe currently lead adoption rates, with the Asia-Pacific region showing the fastest growth trajectory as countries like China and India implement more stringent environmental regulations while expanding their industrial bases.

Market research indicates that end-users are increasingly prioritizing total cost of ownership over initial acquisition costs, creating favorable conditions for premium porous media solutions that offer enhanced efficiency and reduced operational expenses over product lifecycles. Energy savings of 15-30% compared to conventional heat exchangers provide compelling return on investment metrics that are driving market penetration.

Technological advancements in materials science and manufacturing processes are expanding the commercial viability of various porous media options. Metal foams, which held approximately 38% market share in 2022, are facing increasing competition from ceramic matrices and polymer-based porous structures as these alternatives become more cost-effective and their performance characteristics improve.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously accelerated interest in high-efficiency HVAC systems with enhanced filtration capabilities, creating new market opportunities for porous media solutions that can address both thermal management and air quality concerns.

Market segmentation analysis reveals that industrial applications currently dominate revenue generation, accounting for approximately 65% of the enhanced heat exchanger market. However, commercial building applications represent the fastest-growing segment with projected annual growth rates exceeding 7% through 2030, driven by green building initiatives and increasingly stringent building energy codes.

Enhanced heat exchanger solutions utilizing porous media represent a significant segment within this market, with particular strength in high-performance applications where traditional heat exchangers face limitations. Industries including power generation, chemical processing, refrigeration, automotive, and aerospace are showing heightened interest in these advanced solutions due to their superior thermal performance characteristics.

The demand for porous media heat exchangers is particularly strong in regions with strict energy efficiency standards and carbon reduction targets. North America and Europe currently lead adoption rates, with the Asia-Pacific region showing the fastest growth trajectory as countries like China and India implement more stringent environmental regulations while expanding their industrial bases.

Market research indicates that end-users are increasingly prioritizing total cost of ownership over initial acquisition costs, creating favorable conditions for premium porous media solutions that offer enhanced efficiency and reduced operational expenses over product lifecycles. Energy savings of 15-30% compared to conventional heat exchangers provide compelling return on investment metrics that are driving market penetration.

Technological advancements in materials science and manufacturing processes are expanding the commercial viability of various porous media options. Metal foams, which held approximately 38% market share in 2022, are facing increasing competition from ceramic matrices and polymer-based porous structures as these alternatives become more cost-effective and their performance characteristics improve.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously accelerated interest in high-efficiency HVAC systems with enhanced filtration capabilities, creating new market opportunities for porous media solutions that can address both thermal management and air quality concerns.

Market segmentation analysis reveals that industrial applications currently dominate revenue generation, accounting for approximately 65% of the enhanced heat exchanger market. However, commercial building applications represent the fastest-growing segment with projected annual growth rates exceeding 7% through 2030, driven by green building initiatives and increasingly stringent building energy codes.

Current Challenges in Porous Media Heat Transfer Technology

Despite significant advancements in porous media heat transfer technology, several critical challenges continue to impede optimal implementation and performance in heat exchanger applications. One of the primary obstacles remains the accurate characterization of complex porous structures. The inherent irregularity and multi-scale nature of porous media make it difficult to develop standardized models that reliably predict thermal-hydraulic behavior across different operating conditions.

Fouling and clogging represent persistent operational challenges, particularly in applications involving particulate-laden fluids. As porous media enhance surface area for heat transfer, they simultaneously create more opportunities for contaminant deposition, leading to gradual performance degradation and increased maintenance requirements. This issue becomes especially pronounced in industrial settings where regular cleaning cycles significantly impact operational efficiency.

Thermal contact resistance at the interface between porous media and solid walls presents another substantial technical hurdle. Imperfect bonding between these components creates thermal bottlenecks that can severely limit overall heat transfer effectiveness. Current manufacturing techniques struggle to consistently produce interfaces with minimal thermal resistance, resulting in performance variations across supposedly identical heat exchanger units.

Flow maldistribution within porous structures continues to challenge designers, as non-uniform flow patterns can create localized hot spots and reduce overall thermal efficiency. The difficulty in predicting and controlling flow distribution increases with geometric complexity and scale, making optimization particularly challenging for large industrial heat exchangers incorporating porous media.

Material stability under thermal cycling and harsh operating environments remains problematic. Many high-performance porous materials exhibit degradation when subjected to repeated thermal expansion and contraction, while others may be unsuitable for corrosive or high-temperature applications. This limitation restricts the deployment of porous media heat exchangers in certain industrial sectors where extreme conditions prevail.

Computational modeling challenges persist due to the multi-physics nature of heat transfer in porous media. Current simulation tools often struggle to accurately capture the coupled effects of conduction, convection, and sometimes radiation across different scales within reasonable computational timeframes. This hampers the ability to perform rapid design iterations and optimization.

Manufacturing constraints and cost considerations further complicate widespread adoption. Advanced porous structures with optimized geometries often require sophisticated fabrication techniques that are expensive or difficult to scale. The trade-off between enhanced thermal performance and increased manufacturing complexity represents a significant barrier to commercial implementation.

Fouling and clogging represent persistent operational challenges, particularly in applications involving particulate-laden fluids. As porous media enhance surface area for heat transfer, they simultaneously create more opportunities for contaminant deposition, leading to gradual performance degradation and increased maintenance requirements. This issue becomes especially pronounced in industrial settings where regular cleaning cycles significantly impact operational efficiency.

Thermal contact resistance at the interface between porous media and solid walls presents another substantial technical hurdle. Imperfect bonding between these components creates thermal bottlenecks that can severely limit overall heat transfer effectiveness. Current manufacturing techniques struggle to consistently produce interfaces with minimal thermal resistance, resulting in performance variations across supposedly identical heat exchanger units.

Flow maldistribution within porous structures continues to challenge designers, as non-uniform flow patterns can create localized hot spots and reduce overall thermal efficiency. The difficulty in predicting and controlling flow distribution increases with geometric complexity and scale, making optimization particularly challenging for large industrial heat exchangers incorporating porous media.

Material stability under thermal cycling and harsh operating environments remains problematic. Many high-performance porous materials exhibit degradation when subjected to repeated thermal expansion and contraction, while others may be unsuitable for corrosive or high-temperature applications. This limitation restricts the deployment of porous media heat exchangers in certain industrial sectors where extreme conditions prevail.

Computational modeling challenges persist due to the multi-physics nature of heat transfer in porous media. Current simulation tools often struggle to accurately capture the coupled effects of conduction, convection, and sometimes radiation across different scales within reasonable computational timeframes. This hampers the ability to perform rapid design iterations and optimization.

Manufacturing constraints and cost considerations further complicate widespread adoption. Advanced porous structures with optimized geometries often require sophisticated fabrication techniques that are expensive or difficult to scale. The trade-off between enhanced thermal performance and increased manufacturing complexity represents a significant barrier to commercial implementation.

Current Porous Media Selection Methodologies for Heat Exchangers

01 Heat transfer enhancement in porous media systems

Various techniques can be employed to enhance heat transfer in porous media systems. These include optimizing the porosity and permeability of the media, incorporating high thermal conductivity materials, and designing specific flow patterns. Enhanced heat transfer in porous media is crucial for applications requiring efficient thermal management, such as heat exchangers and thermal energy storage systems.- Heat exchanger designs for porous media: Various heat exchanger designs utilize porous media to enhance heat transfer efficiency. These designs incorporate specific structural elements such as microchannels, fins, and specialized geometries that maximize surface area and optimize fluid flow through the porous material. The porous structure creates turbulence and increases contact between the heat transfer fluid and the solid matrix, resulting in improved thermal conductivity and heat exchange rates in applications ranging from industrial cooling systems to electronic device thermal management.

- Thermal energy storage in porous materials: Porous materials serve as effective media for thermal energy storage systems due to their large surface area and ability to retain heat. These systems utilize the porous structure to store thermal energy through sensible heat, latent heat, or thermochemical reactions. The porous matrix enhances heat transfer between the storage medium and the heat transfer fluid, improving charging and discharging rates. Applications include solar thermal storage, waste heat recovery, and building heating/cooling systems where the porous media provides efficient energy storage and release capabilities.

- Numerical modeling and simulation of heat transfer in porous media: Advanced computational methods are employed to model and simulate heat transfer phenomena in porous media. These numerical approaches include finite element analysis, computational fluid dynamics, and machine learning techniques to predict thermal behavior in complex porous structures. The models account for factors such as porosity, permeability, tortuosity, and phase changes, enabling accurate prediction of temperature distributions, heat flux, and fluid flow patterns. These simulation tools are essential for optimizing design parameters and understanding heat transfer mechanisms in porous media applications.

- Enhanced heat transfer through engineered porous structures: Engineered porous structures with tailored properties significantly improve heat transfer performance. These structures feature controlled porosity, pore size distribution, and interconnectivity designed specifically for thermal applications. Advanced manufacturing techniques such as 3D printing, sintering, and template-based fabrication enable the creation of optimized porous geometries. The engineered structures can incorporate multiple materials, hierarchical designs, and functional gradients to enhance thermal conductivity, reduce thermal resistance, and improve overall heat transfer efficiency in various industrial and technological applications.

- Phase change and multiphase flow heat transfer in porous media: Heat transfer processes involving phase changes and multiphase flows in porous media present unique characteristics and applications. These systems utilize the porous structure to facilitate evaporation, condensation, boiling, or freezing processes while managing the flow of multiple fluid phases. The porous matrix enhances phase change heat transfer by providing nucleation sites, increasing interfacial area, and improving fluid distribution. Applications include heat pipes, vapor chambers, distillation systems, and thermal management solutions where the porous media optimizes the phase change process and associated heat transfer rates.

02 Numerical modeling and simulation of porous media heat transfer

Computational methods are used to model and simulate heat transfer phenomena in porous media. These models account for complex interactions between fluid flow and solid matrix, considering factors such as thermal dispersion, interfacial heat transfer, and phase change processes. Advanced numerical techniques help predict thermal behavior in porous systems, enabling optimization of design parameters for various applications.Expand Specific Solutions03 Porous media in thermal energy storage applications

Porous materials are utilized in thermal energy storage systems to enhance heat transfer and storage capacity. The high surface area of porous media facilitates efficient heat exchange between the storage medium and heat transfer fluid. Various materials with different thermal properties can be incorporated into porous structures to optimize energy storage performance for specific temperature ranges and applications.Expand Specific Solutions04 Phase change heat transfer in porous media

Heat transfer involving phase change (melting, solidification, evaporation, condensation) in porous media is studied for various applications. The porous structure affects phase change dynamics by providing nucleation sites and modifying heat transfer rates. Understanding these phenomena is important for designing efficient cooling systems, heat pipes, and thermal management solutions where phase change materials are embedded in porous structures.Expand Specific Solutions05 Porous media in heat exchangers and cooling systems

Porous media are incorporated into heat exchangers and cooling systems to improve thermal performance. The enhanced surface area and mixing effects provided by porous structures lead to higher heat transfer coefficients compared to conventional designs. Applications include electronics cooling, HVAC systems, and industrial heat exchangers where porous materials can be tailored to meet specific thermal management requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Porous Media

The enhanced heat exchanger transfer market is currently in a growth phase, driven by increasing energy efficiency demands across industries. The market size is expanding significantly, with projections indicating robust growth due to applications in HVAC, automotive, and power generation sectors. Technologically, the field shows varying maturity levels, with established players like General Electric, Mitsubishi Electric, and LG Electronics offering commercial solutions, while academic institutions such as MIT, Xi'an Jiaotong University, and University of Washington lead fundamental research. Research institutes including Shanghai Research Institute of Chemical Industry and Korea Institute of Machinery & Materials bridge the gap between theoretical advances and industrial applications. The competitive landscape features both specialized manufacturers focusing on porous media innovations and diversified conglomerates integrating these technologies into broader thermal management solutions.

FuelCell Energy, Inc.

Technical Solution: FuelCell Energy has developed specialized porous media heat exchangers optimized for electrochemical systems, particularly fuel cells and electrolyzers. Their technology focuses on multi-functional porous structures that simultaneously facilitate heat transfer, fluid distribution, and electrochemical reactions. FCE's approach utilizes gradient porosity materials with tailored wettability characteristics, featuring hydrophilic regions for water management and hydrophobic regions for gas transport. Their proprietary manufacturing process creates interconnected pore networks with precisely controlled tortuosity (1.2-1.8) and pore size distributions (5-100μm) to balance pressure drop against heat transfer performance. Recent innovations include carbon-ceramic composite porous media with enhanced electrical conductivity and corrosion resistance for high-temperature applications. Testing has demonstrated these materials can improve overall system efficiency by 15-20% compared to conventional designs by reducing thermal gradients and improving reactant distribution.

Strengths: Highly specialized for electrochemical applications; excellent multifunctional performance; superior corrosion resistance in aggressive environments. Weaknesses: Limited application outside electrochemical systems; higher manufacturing complexity requiring specialized production facilities.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive approach to porous media heat exchangers focusing on ceramic-metal composite materials. Their technology utilizes sintered metal powders with controlled porosity gradients (ranging from 30-70%) and pore sizes optimized for specific applications. Mitsubishi's innovation lies in their manufacturing process that creates anisotropic porous structures with directionally-oriented pores that enhance fluid flow in preferred directions while maintaining structural integrity. Their heat exchangers incorporate computational optimization algorithms that determine ideal pore morphology based on operating conditions. For high-temperature applications, Mitsubishi has pioneered ceramic-infiltrated porous metals that maintain performance at temperatures exceeding 800°C. Field testing has demonstrated these exchangers achieve 25-35% higher heat transfer rates compared to conventional designs while exhibiting superior corrosion resistance in harsh environments.

Strengths: Advanced manufacturing capabilities for complex porous structures; excellent high-temperature performance; strong integration with other Mitsubishi industrial systems. Weaknesses: Higher initial cost compared to conventional designs; limited flexibility for retrofitting existing systems.

Key Technical Parameters and Material Properties Analysis

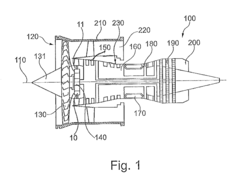

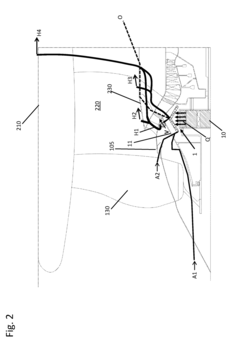

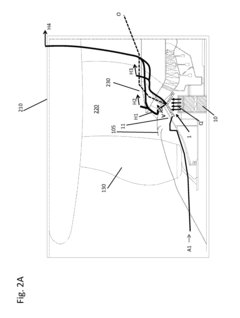

Heat exchange system for a power gear box, a power gear box and a turbo engine with a power gear box

PatentActiveUS20170175630A1

Innovation

- A heat exchange system with an enclosed, embedded, or attached heat transfer device is integrated within the power gear box casing, utilizing airflow from the aircraft engine to manage thermal loads, which can switch between cooling and heating modes based on operational needs, and features a porous medium and high thermal conductivity materials for enhanced heat transfer.

Enhanced heat exchanger

PatentInactiveUS6958912B2

Innovation

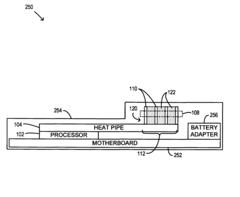

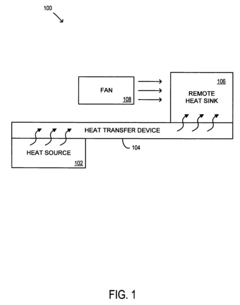

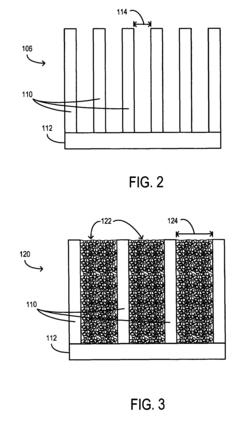

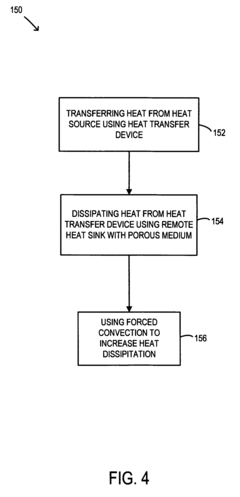

- The use of a heat transfer device, like a heat pipe, to relocate heat to a remote location where a smaller, enhanced heat exchanger with a porous medium between fins can efficiently dissipate heat, utilizing forced convection with a blower fan to optimize heat transfer and reduce manufacturing complexities and costs.

Thermal-Hydraulic Performance Optimization Strategies

Optimizing thermal-hydraulic performance in porous media heat exchangers requires a systematic approach that balances heat transfer enhancement with acceptable pressure drop penalties. The selection of appropriate optimization strategies depends on specific application requirements, operating conditions, and design constraints.

Material selection represents a primary optimization pathway, with metals like aluminum, copper, and nickel foams offering excellent thermal conductivity. Advanced ceramic foams provide superior performance in high-temperature or corrosive environments, while polymer-based porous media may be suitable for low-temperature applications where cost and weight are critical factors. Hybrid materials combining multiple base materials can achieve synergistic performance improvements that exceed the capabilities of single-material solutions.

Structural optimization involves manipulating pore size distribution, porosity gradients, and tortuosity to enhance heat transfer while minimizing pressure drop. Non-uniform porosity distributions can be strategically implemented to concentrate flow in regions requiring enhanced heat transfer. Anisotropic porous structures with directionally-oriented pores can channel flow more effectively than isotropic structures, particularly in applications with predominant flow directions.

Surface modification techniques offer significant performance enhancements through increased surface area and improved fluid-solid interactions. Nano-coatings can alter wettability characteristics, while micro-structured surfaces promote turbulence at the pore level. Chemical treatments may be employed to create catalytic surfaces that enhance heat transfer through exothermic or endothermic reactions in appropriate applications.

Flow arrangement optimization involves strategic placement of inlet/outlet configurations and flow distributors to ensure uniform fluid distribution throughout the porous medium. Counter-flow, cross-flow, and multi-pass arrangements can be implemented based on specific performance requirements. Pulsating or oscillating flows have demonstrated enhanced heat transfer coefficients in certain porous media configurations by disrupting boundary layers and promoting mixing.

Hybrid approaches combining multiple optimization strategies often yield the most significant performance improvements. For instance, gradient porosity structures with surface-modified pores and optimized flow arrangements can achieve thermal performance enhancements of 200-300% compared to conventional heat exchangers, albeit with corresponding pressure drop increases that must be carefully managed through system-level optimization.

Computational fluid dynamics (CFD) modeling and experimental validation are essential tools in the optimization process, enabling rapid iteration and performance prediction before physical prototyping. Machine learning algorithms are increasingly being applied to navigate the complex multi-parameter optimization space of porous media heat exchangers, identifying non-intuitive design solutions that human engineers might overlook.

Material selection represents a primary optimization pathway, with metals like aluminum, copper, and nickel foams offering excellent thermal conductivity. Advanced ceramic foams provide superior performance in high-temperature or corrosive environments, while polymer-based porous media may be suitable for low-temperature applications where cost and weight are critical factors. Hybrid materials combining multiple base materials can achieve synergistic performance improvements that exceed the capabilities of single-material solutions.

Structural optimization involves manipulating pore size distribution, porosity gradients, and tortuosity to enhance heat transfer while minimizing pressure drop. Non-uniform porosity distributions can be strategically implemented to concentrate flow in regions requiring enhanced heat transfer. Anisotropic porous structures with directionally-oriented pores can channel flow more effectively than isotropic structures, particularly in applications with predominant flow directions.

Surface modification techniques offer significant performance enhancements through increased surface area and improved fluid-solid interactions. Nano-coatings can alter wettability characteristics, while micro-structured surfaces promote turbulence at the pore level. Chemical treatments may be employed to create catalytic surfaces that enhance heat transfer through exothermic or endothermic reactions in appropriate applications.

Flow arrangement optimization involves strategic placement of inlet/outlet configurations and flow distributors to ensure uniform fluid distribution throughout the porous medium. Counter-flow, cross-flow, and multi-pass arrangements can be implemented based on specific performance requirements. Pulsating or oscillating flows have demonstrated enhanced heat transfer coefficients in certain porous media configurations by disrupting boundary layers and promoting mixing.

Hybrid approaches combining multiple optimization strategies often yield the most significant performance improvements. For instance, gradient porosity structures with surface-modified pores and optimized flow arrangements can achieve thermal performance enhancements of 200-300% compared to conventional heat exchangers, albeit with corresponding pressure drop increases that must be carefully managed through system-level optimization.

Computational fluid dynamics (CFD) modeling and experimental validation are essential tools in the optimization process, enabling rapid iteration and performance prediction before physical prototyping. Machine learning algorithms are increasingly being applied to navigate the complex multi-parameter optimization space of porous media heat exchangers, identifying non-intuitive design solutions that human engineers might overlook.

Sustainability and Energy Efficiency Considerations

The integration of porous media in heat exchangers represents a significant opportunity for enhancing sustainability and energy efficiency in thermal management systems. When selecting porous materials for heat exchange applications, environmental impact considerations must be prioritized throughout the entire lifecycle - from raw material extraction to manufacturing, operation, and eventual disposal or recycling.

Material sustainability plays a crucial role in selection criteria. Environmentally friendly options such as recycled metal foams, biodegradable polymeric structures, and naturally occurring porous materials offer reduced carbon footprints compared to conventional alternatives. The embodied energy in manufacturing these materials varies significantly, with some advanced ceramic foams requiring energy-intensive sintering processes while metal foams produced through investment casting may present more energy-efficient pathways.

Energy efficiency during operation constitutes perhaps the most compelling advantage of porous media heat exchangers. The enhanced surface area-to-volume ratio can reduce pumping power requirements by 15-30% compared to traditional designs while maintaining equivalent heat transfer performance. This translates directly to lower operational energy consumption and reduced greenhouse gas emissions over the system lifetime.

Water conservation represents another critical sustainability dimension. Porous media designs can facilitate closed-loop cooling systems that minimize water consumption - particularly valuable in water-stressed regions. Some hydrophilic porous structures have demonstrated water usage reductions of up to 40% in evaporative cooling applications while maintaining thermal performance targets.

Longevity and durability of porous media directly impact sustainability metrics. Materials resistant to fouling, corrosion, and mechanical degradation extend operational lifespans, reducing replacement frequency and associated resource consumption. Advanced ceramic foams, while initially more energy-intensive to produce, may offer superior lifecycle benefits through extended service periods of 15+ years compared to 5-7 years for conventional alternatives.

End-of-life considerations must factor into selection decisions. Recyclability varies dramatically across porous media types - aluminum foams can be recycled with approximately 95% energy savings compared to virgin material production, while composite polymer foams may present significant recycling challenges. Designing for disassembly and material recovery should be incorporated into initial material selection criteria.

Regulatory compliance and emerging sustainability standards increasingly influence material selection. Many jurisdictions have implemented restrictions on certain manufacturing processes and materials with adverse environmental impacts. Forward-looking selection strategies should anticipate regulatory evolution and prioritize materials aligned with circular economy principles.

Material sustainability plays a crucial role in selection criteria. Environmentally friendly options such as recycled metal foams, biodegradable polymeric structures, and naturally occurring porous materials offer reduced carbon footprints compared to conventional alternatives. The embodied energy in manufacturing these materials varies significantly, with some advanced ceramic foams requiring energy-intensive sintering processes while metal foams produced through investment casting may present more energy-efficient pathways.

Energy efficiency during operation constitutes perhaps the most compelling advantage of porous media heat exchangers. The enhanced surface area-to-volume ratio can reduce pumping power requirements by 15-30% compared to traditional designs while maintaining equivalent heat transfer performance. This translates directly to lower operational energy consumption and reduced greenhouse gas emissions over the system lifetime.

Water conservation represents another critical sustainability dimension. Porous media designs can facilitate closed-loop cooling systems that minimize water consumption - particularly valuable in water-stressed regions. Some hydrophilic porous structures have demonstrated water usage reductions of up to 40% in evaporative cooling applications while maintaining thermal performance targets.

Longevity and durability of porous media directly impact sustainability metrics. Materials resistant to fouling, corrosion, and mechanical degradation extend operational lifespans, reducing replacement frequency and associated resource consumption. Advanced ceramic foams, while initially more energy-intensive to produce, may offer superior lifecycle benefits through extended service periods of 15+ years compared to 5-7 years for conventional alternatives.

End-of-life considerations must factor into selection decisions. Recyclability varies dramatically across porous media types - aluminum foams can be recycled with approximately 95% energy savings compared to virgin material production, while composite polymer foams may present significant recycling challenges. Designing for disassembly and material recovery should be incorporated into initial material selection criteria.

Regulatory compliance and emerging sustainability standards increasingly influence material selection. Many jurisdictions have implemented restrictions on certain manufacturing processes and materials with adverse environmental impacts. Forward-looking selection strategies should anticipate regulatory evolution and prioritize materials aligned with circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!