How to Develop Heat Exchanger Systems for Low-Temperature Operations

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Heat Exchanger Technology Background and Objectives

Cryogenic heat exchanger technology has evolved significantly over the past century, with major advancements occurring during the industrial gas boom of the mid-20th century. The development trajectory has been driven by increasing demands in liquefied natural gas (LNG) processing, aerospace applications, and medical equipment manufacturing. Current technological trends indicate a shift toward more compact, efficient designs with enhanced materials capable of withstanding extreme temperature differentials while maintaining structural integrity.

The evolution of cryogenic heat exchangers has been marked by several breakthrough innovations, including the introduction of plate-fin heat exchangers in the 1950s, spiral-wound exchangers in the 1970s, and more recently, printed circuit heat exchangers that offer unprecedented efficiency in compact designs. These advancements have progressively addressed challenges related to thermal stress management, material brittleness at low temperatures, and heat transfer optimization.

The primary technical objective in developing heat exchanger systems for low-temperature operations is to achieve maximum thermal efficiency while minimizing energy losses in environments below -150°C. This requires overcoming significant engineering challenges related to material selection, thermal expansion management, and prevention of fluid phase changes during operation. Additionally, modern cryogenic systems must address increasing demands for miniaturization, weight reduction, and integration with digital monitoring systems.

Another critical objective is enhancing operational reliability under extreme conditions. Cryogenic heat exchangers must maintain performance consistency despite thermal cycling, which can lead to material fatigue and eventual system failure. The industry is actively pursuing innovations in metallurgy and composite materials that exhibit superior mechanical properties at cryogenic temperatures while resisting embrittlement and stress-induced fractures.

Environmental considerations have also become increasingly important in cryogenic technology development. Modern systems aim to minimize refrigerant losses, reduce energy consumption, and incorporate sustainable manufacturing practices. This aligns with global initiatives to reduce industrial carbon footprints while maintaining technological advancement.

Looking forward, the field is moving toward intelligent cryogenic systems with integrated sensors and predictive maintenance capabilities. These next-generation exchangers will likely incorporate advanced manufacturing techniques such as 3D printing of complex geometries and nano-engineered surfaces to enhance heat transfer coefficients. The convergence of materials science, computational fluid dynamics, and automation technology is expected to drive the next wave of innovation in this specialized field.

The evolution of cryogenic heat exchangers has been marked by several breakthrough innovations, including the introduction of plate-fin heat exchangers in the 1950s, spiral-wound exchangers in the 1970s, and more recently, printed circuit heat exchangers that offer unprecedented efficiency in compact designs. These advancements have progressively addressed challenges related to thermal stress management, material brittleness at low temperatures, and heat transfer optimization.

The primary technical objective in developing heat exchanger systems for low-temperature operations is to achieve maximum thermal efficiency while minimizing energy losses in environments below -150°C. This requires overcoming significant engineering challenges related to material selection, thermal expansion management, and prevention of fluid phase changes during operation. Additionally, modern cryogenic systems must address increasing demands for miniaturization, weight reduction, and integration with digital monitoring systems.

Another critical objective is enhancing operational reliability under extreme conditions. Cryogenic heat exchangers must maintain performance consistency despite thermal cycling, which can lead to material fatigue and eventual system failure. The industry is actively pursuing innovations in metallurgy and composite materials that exhibit superior mechanical properties at cryogenic temperatures while resisting embrittlement and stress-induced fractures.

Environmental considerations have also become increasingly important in cryogenic technology development. Modern systems aim to minimize refrigerant losses, reduce energy consumption, and incorporate sustainable manufacturing practices. This aligns with global initiatives to reduce industrial carbon footprints while maintaining technological advancement.

Looking forward, the field is moving toward intelligent cryogenic systems with integrated sensors and predictive maintenance capabilities. These next-generation exchangers will likely incorporate advanced manufacturing techniques such as 3D printing of complex geometries and nano-engineered surfaces to enhance heat transfer coefficients. The convergence of materials science, computational fluid dynamics, and automation technology is expected to drive the next wave of innovation in this specialized field.

Market Analysis for Low-Temperature Heat Exchange Systems

The global market for low-temperature heat exchange systems is experiencing robust growth, driven primarily by increasing demand across cryogenic applications, liquefied natural gas (LNG) processing, and cold climate operations. Current market valuation stands at approximately 5.2 billion USD with projections indicating a compound annual growth rate of 6.8% through 2028, significantly outpacing the broader industrial equipment sector.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for advanced low-temperature heat exchangers. The European Union's Energy Efficiency Directive and similar policies in North America and Asia have established stringent performance requirements, effectively expanding the addressable market for high-efficiency systems. This regulatory landscape has transformed from a constraint into a market driver, with companies increasingly viewing compliance as a competitive advantage rather than merely a requirement.

Industry segmentation reveals distinct market dynamics across different applications. The LNG sector represents the largest market share at 38%, followed by petrochemical processing (24%), food preservation (17%), pharmaceutical manufacturing (12%), and other applications (9%). Geographic distribution shows North America and Europe as mature markets with steady growth rates of 4-5%, while Asia-Pacific demonstrates accelerated adoption with growth exceeding 9% annually, particularly in China and India where industrial expansion coincides with stricter environmental regulations.

Customer requirements analysis indicates a clear shift toward total cost of ownership considerations rather than initial acquisition costs. End-users increasingly prioritize energy efficiency, operational reliability in extreme conditions, and reduced maintenance requirements. Market research shows willingness to pay premium prices of 15-20% for systems demonstrating superior performance in low-temperature environments, particularly those offering enhanced resistance to thermal cycling fatigue and improved thermal transfer coefficients.

Competitive landscape assessment reveals market consolidation among traditional players while specialized technology providers gain market share through innovation. The top five manufacturers control approximately 62% of global market share, though this concentration is being challenged by emerging companies offering specialized solutions for ultra-low temperature applications. Chinese manufacturers have significantly increased their global presence, growing from 8% market share in 2018 to 17% currently, primarily competing on cost advantages while rapidly closing the technology gap.

Distribution channels are evolving with direct-to-customer models gaining prominence, particularly for customized industrial applications. Traditional distributor networks remain dominant in standardized product segments, though e-commerce platforms are disrupting this model in the replacement parts and smaller system segments.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for advanced low-temperature heat exchangers. The European Union's Energy Efficiency Directive and similar policies in North America and Asia have established stringent performance requirements, effectively expanding the addressable market for high-efficiency systems. This regulatory landscape has transformed from a constraint into a market driver, with companies increasingly viewing compliance as a competitive advantage rather than merely a requirement.

Industry segmentation reveals distinct market dynamics across different applications. The LNG sector represents the largest market share at 38%, followed by petrochemical processing (24%), food preservation (17%), pharmaceutical manufacturing (12%), and other applications (9%). Geographic distribution shows North America and Europe as mature markets with steady growth rates of 4-5%, while Asia-Pacific demonstrates accelerated adoption with growth exceeding 9% annually, particularly in China and India where industrial expansion coincides with stricter environmental regulations.

Customer requirements analysis indicates a clear shift toward total cost of ownership considerations rather than initial acquisition costs. End-users increasingly prioritize energy efficiency, operational reliability in extreme conditions, and reduced maintenance requirements. Market research shows willingness to pay premium prices of 15-20% for systems demonstrating superior performance in low-temperature environments, particularly those offering enhanced resistance to thermal cycling fatigue and improved thermal transfer coefficients.

Competitive landscape assessment reveals market consolidation among traditional players while specialized technology providers gain market share through innovation. The top five manufacturers control approximately 62% of global market share, though this concentration is being challenged by emerging companies offering specialized solutions for ultra-low temperature applications. Chinese manufacturers have significantly increased their global presence, growing from 8% market share in 2018 to 17% currently, primarily competing on cost advantages while rapidly closing the technology gap.

Distribution channels are evolving with direct-to-customer models gaining prominence, particularly for customized industrial applications. Traditional distributor networks remain dominant in standardized product segments, though e-commerce platforms are disrupting this model in the replacement parts and smaller system segments.

Current Challenges in Cryogenic Heat Transfer Technology

Cryogenic heat transfer technology faces significant challenges that impede the development of efficient heat exchanger systems for low-temperature operations. The primary obstacle remains material selection, as conventional materials become brittle and lose thermal conductivity at extremely low temperatures. Materials such as stainless steel, aluminum alloys, and specialized copper alloys exhibit varying degrees of performance degradation, necessitating careful engineering compromises between thermal efficiency, mechanical integrity, and cost considerations.

Heat transfer coefficient reduction presents another substantial challenge. As temperatures approach cryogenic levels, the heat transfer coefficients of most working fluids decrease dramatically, requiring larger heat exchange surfaces and consequently bulkier equipment. This contradicts the industry trend toward miniaturization and efficiency, particularly in space applications and compact laboratory systems where size and weight constraints are critical.

Phase change phenomena at cryogenic temperatures introduce complex thermodynamic behaviors that are difficult to model accurately. Two-phase flow patterns, nucleate boiling, and film boiling mechanisms differ significantly from their room-temperature counterparts. These differences create substantial uncertainties in design calculations, often leading to conservative over-engineering or unexpected performance shortfalls in practical applications.

Thermal insulation represents a persistent challenge, as even minimal heat leakage can cause significant operational inefficiencies in cryogenic systems. Vacuum-jacketed designs, multi-layer insulation (MLI), and aerogel-based solutions all present their own implementation difficulties, including manufacturing complexity, long-term performance degradation, and high costs.

Flow instabilities and maldistribution issues become more pronounced at cryogenic temperatures. Density variations in the working fluid can trigger flow oscillations and uneven distribution across parallel channels, leading to localized hotspots, reduced overall efficiency, and potential system failure. These phenomena are particularly problematic in micro-channel heat exchangers where precise flow control is essential.

Measurement and control systems face unique challenges in cryogenic environments. Sensor accuracy, response time, and longevity are all compromised at extremely low temperatures. This complicates both research efforts to understand fundamental heat transfer mechanisms and the implementation of reliable control systems for operational equipment.

Manufacturing limitations further constrain innovation in this field. Specialized joining techniques, precise dimensional control, and surface finish requirements for cryogenic heat exchangers often push the boundaries of current manufacturing capabilities. Advanced techniques such as additive manufacturing show promise but remain limited in material options and structural integrity for critical cryogenic applications.

Heat transfer coefficient reduction presents another substantial challenge. As temperatures approach cryogenic levels, the heat transfer coefficients of most working fluids decrease dramatically, requiring larger heat exchange surfaces and consequently bulkier equipment. This contradicts the industry trend toward miniaturization and efficiency, particularly in space applications and compact laboratory systems where size and weight constraints are critical.

Phase change phenomena at cryogenic temperatures introduce complex thermodynamic behaviors that are difficult to model accurately. Two-phase flow patterns, nucleate boiling, and film boiling mechanisms differ significantly from their room-temperature counterparts. These differences create substantial uncertainties in design calculations, often leading to conservative over-engineering or unexpected performance shortfalls in practical applications.

Thermal insulation represents a persistent challenge, as even minimal heat leakage can cause significant operational inefficiencies in cryogenic systems. Vacuum-jacketed designs, multi-layer insulation (MLI), and aerogel-based solutions all present their own implementation difficulties, including manufacturing complexity, long-term performance degradation, and high costs.

Flow instabilities and maldistribution issues become more pronounced at cryogenic temperatures. Density variations in the working fluid can trigger flow oscillations and uneven distribution across parallel channels, leading to localized hotspots, reduced overall efficiency, and potential system failure. These phenomena are particularly problematic in micro-channel heat exchangers where precise flow control is essential.

Measurement and control systems face unique challenges in cryogenic environments. Sensor accuracy, response time, and longevity are all compromised at extremely low temperatures. This complicates both research efforts to understand fundamental heat transfer mechanisms and the implementation of reliable control systems for operational equipment.

Manufacturing limitations further constrain innovation in this field. Specialized joining techniques, precise dimensional control, and surface finish requirements for cryogenic heat exchangers often push the boundaries of current manufacturing capabilities. Advanced techniques such as additive manufacturing show promise but remain limited in material options and structural integrity for critical cryogenic applications.

Current Engineering Solutions for Sub-Zero Heat Exchange

01 Temperature control systems in heat exchangers

Heat exchanger systems incorporate various temperature control mechanisms to maintain optimal operating conditions. These systems utilize sensors, controllers, and feedback loops to monitor and adjust temperature parameters in real-time. Advanced control algorithms enable precise temperature regulation across different zones of the heat exchanger, improving overall efficiency and preventing thermal stress. These temperature control systems are essential for applications requiring strict thermal management.- Temperature control systems in heat exchangers: Heat exchanger systems often incorporate sophisticated temperature control mechanisms to maintain optimal operating conditions. These systems typically include sensors, controllers, and feedback loops that continuously monitor and adjust the temperature parameters. Advanced control algorithms can be implemented to ensure precise temperature regulation across various operating conditions, improving overall efficiency and preventing thermal stress on components.

- Energy efficiency improvements in heat exchange systems: Various innovations focus on enhancing the energy efficiency of heat exchanger systems through improved temperature management. These include optimized flow patterns, advanced materials with superior thermal conductivity, and innovative surface designs that maximize heat transfer while minimizing energy consumption. Some systems incorporate waste heat recovery mechanisms to capture and repurpose thermal energy that would otherwise be lost, significantly improving overall system efficiency.

- Thermal management in industrial heat exchangers: Industrial applications often require specialized heat exchanger designs to handle extreme temperature conditions. These systems may incorporate multiple stages of heat exchange, specialized cooling or heating circuits, and robust materials capable of withstanding thermal cycling. Advanced thermal management techniques can include phase-change materials, dynamic flow control, and strategic insulation to maintain optimal temperature gradients across the system.

- Temperature monitoring and safety features: Modern heat exchanger systems incorporate comprehensive temperature monitoring and safety features to prevent overheating, freezing, or other temperature-related failures. These may include redundant temperature sensors, automatic shutdown mechanisms, pressure relief systems, and alarm notifications. Advanced systems might employ predictive analytics to anticipate potential temperature-related issues before they occur, allowing for preventative maintenance and reducing system downtime.

- Innovative heat transfer technologies for temperature optimization: Emerging technologies are revolutionizing temperature management in heat exchanger systems. These include microchannels for enhanced surface area, nanofluids with improved thermal properties, and hybrid systems that combine multiple heat transfer mechanisms. Some innovations focus on adaptive heat exchange surfaces that can modify their characteristics based on temperature conditions, while others explore novel geometries that minimize thermal resistance and improve temperature uniformity across the exchange interface.

02 Thermal efficiency enhancement techniques

Various design innovations focus on enhancing the thermal efficiency of heat exchanger systems. These include optimized flow path configurations, improved surface geometries, and advanced material selection to maximize heat transfer rates while minimizing temperature gradients. Some systems incorporate turbulence generators or extended surfaces to increase heat transfer coefficients. These enhancements allow heat exchangers to operate at lower temperature differentials while achieving the same thermal performance, resulting in energy savings.Expand Specific Solutions03 Temperature monitoring and sensing technologies

Modern heat exchanger systems employ sophisticated temperature monitoring technologies to ensure optimal performance. These include distributed temperature sensors, thermal imaging systems, and wireless monitoring networks that provide comprehensive temperature mapping across the exchanger. Real-time temperature data collection enables predictive maintenance, early fault detection, and performance optimization. Advanced sensing technologies allow for more precise temperature control and improved system reliability under varying operating conditions.Expand Specific Solutions04 High-temperature heat exchanger designs

Specialized heat exchanger designs are developed for high-temperature applications in industries such as power generation, chemical processing, and metallurgy. These designs incorporate temperature-resistant materials, specialized coatings, and thermal barrier systems to withstand extreme operating conditions. Some high-temperature exchangers utilize ceramic components, refractory metals, or advanced alloys to maintain structural integrity and performance at elevated temperatures. These systems often include additional thermal management features to protect surrounding components and infrastructure.Expand Specific Solutions05 Low-temperature and cryogenic heat exchange systems

Heat exchanger systems designed for low-temperature and cryogenic applications incorporate specialized features to maintain efficiency at reduced temperatures. These systems often utilize multi-stage cooling arrangements, specialized insulation, and materials with favorable thermal properties at low temperatures. Design considerations include preventing thermal stress, managing differential contraction, and minimizing heat leakage. These exchangers are critical in applications such as gas liquefaction, superconducting systems, and cold storage facilities where precise low-temperature control is essential.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Cryogenic Systems

The heat exchanger systems for low-temperature operations market is in a growth phase, driven by increasing demand for energy efficiency and sustainable solutions. The market size is expanding significantly, particularly in industrial, renewable energy, and cryogenic applications. From a technological maturity perspective, established players like Siemens, Linde GmbH, and ABB Group offer conventional solutions, while companies such as Climeon AB and ECOP Technologies are pioneering innovative approaches for waste heat recovery at lower temperatures. CIMC's multiple subsidiaries indicate strong Chinese market presence, while specialized players like Nooter/Eriksen and O-Flexx Technologies are developing niche solutions. The competitive landscape shows a mix of diversified industrial conglomerates (Bosch, Siemens) and specialized thermal management firms, with increasing focus on sustainability and energy efficiency driving technological advancement.

Linde GmbH

Technical Solution: Linde has developed advanced cryogenic heat exchanger systems for low-temperature operations, particularly focusing on plate-fin heat exchangers (PFHE) and coil-wound heat exchangers (CWHE) technologies. Their systems utilize aluminum brazed plate-fin design for temperatures down to -269°C, featuring multiple stream capabilities and high thermal efficiency. Linde's proprietary CWHE technology employs helically wound tube bundles around a central mandrel, allowing for high-pressure applications up to 200 bar. Their systems incorporate specialized materials selection protocols that account for thermal expansion coefficients and brittleness at cryogenic temperatures. Linde's heat exchangers feature advanced defrosting mechanisms and specialized insulation systems to minimize heat leakage. For LNG applications, they've developed Main Cryogenic Heat Exchangers (MCHE) that can process up to 5 MTPA of natural gas in a single unit, with proprietary distribution systems ensuring uniform flow across all passages.

Strengths: Industry-leading expertise in cryogenic applications with proven reliability in extreme conditions; proprietary manufacturing techniques allowing for custom solutions; extensive material science knowledge for low-temperature applications. Weaknesses: Higher initial capital costs compared to conventional systems; requires specialized maintenance expertise; longer lead times for custom-engineered solutions.

Praxair Technology, Inc.

Technical Solution: Praxair has pioneered brazed aluminum heat exchangers (BAHX) specifically designed for low-temperature operations in industrial gas separation and liquefaction processes. Their systems feature multi-stream capability with up to 12 separate fluid streams in a single unit, operating efficiently at temperatures as low as -196°C. Praxair's proprietary fin designs optimize heat transfer while minimizing pressure drop, achieving thermal effectiveness exceeding 98% in many applications. Their manufacturing process includes specialized aluminum brazing techniques that ensure leak-tight construction capable of withstanding thermal cycling. For ultra-low temperature applications, Praxair employs vacuum-insulated designs with multi-layer insulation systems that reduce heat leak to less than 0.1 W/m². Their heat exchangers incorporate advanced distributors and headers that ensure uniform flow distribution, critical for preventing temperature pinch points and local freezing. Praxair's systems also feature integrated frost management technologies that extend operational periods between defrosting cycles.

Strengths: Exceptional thermal efficiency in cryogenic applications; compact design with high surface area density (up to 1500 m²/m³); proven reliability in industrial gas production with millions of operating hours. Weaknesses: Limited pressure capabilities compared to stainless steel alternatives; susceptibility to fouling in certain process streams; higher sensitivity to thermal shock during startup and shutdown procedures.

Key Innovations in Materials and Insulation for Cryogenic Applications

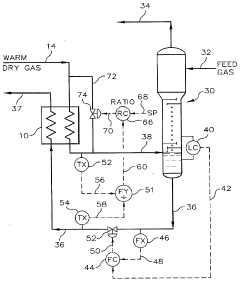

Heat exchanger controls for low temperature fluids

PatentInactiveUS5669238A

Innovation

- A control system with a by-pass conduit and a control valve that adjusts the warm fluid flow based on the temperature ratio of the heat exchange fluids, along with a high selector for automatic start-up, ensures safe temperature management and reduces initial equipment temperature requirements.

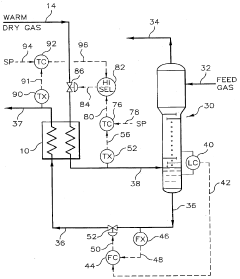

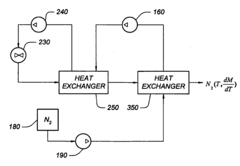

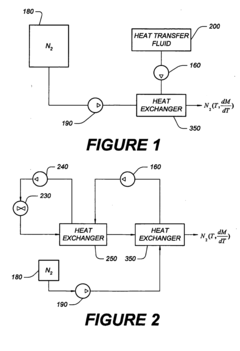

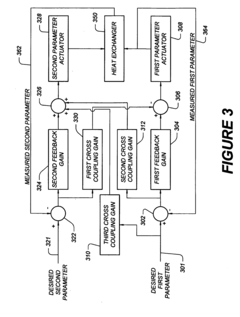

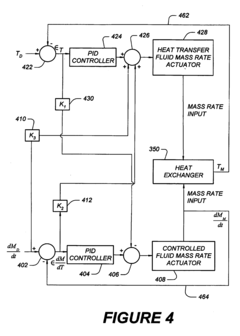

Methods and systems for controlling rate and output of heat exchanger fluids

PatentInactiveUS20060112701A1

Innovation

- The method involves measuring parameters of the controlled fluid, adjusting inputs to actuators based on feedback loops with cross-coupling gains to minimize errors between desired and measured values, allowing for precise control of temperature and mass flow rate through a heat exchanger system.

Energy Efficiency Considerations in Cryogenic Systems

Energy efficiency in cryogenic systems represents a critical factor when developing heat exchanger systems for low-temperature operations. The fundamental challenge lies in the inherently high energy consumption required to achieve and maintain cryogenic temperatures, typically defined as below -150°C (-238°F). This energy intensity makes efficiency optimization not merely desirable but economically essential for sustainable operation.

Cryogenic systems face unique thermodynamic constraints that directly impact energy efficiency. The Carnot efficiency principle indicates that as operating temperatures decrease, the theoretical maximum efficiency of cooling systems diminishes significantly. For instance, cooling from ambient temperature (293K) to liquid nitrogen temperature (77K) requires at least 2.8 units of input energy per unit of cooling effect, even in an ideal system.

Heat leak minimization emerges as the primary efficiency consideration in cryogenic heat exchangers. Advanced multi-layer insulation (MLI) technologies, consisting of alternating layers of reflective material and low-conductivity spacers, can reduce radiative heat transfer by up to 97% compared to conventional insulation. Vacuum-jacketed designs further minimize conductive and convective heat transfer, though they introduce manufacturing complexity and cost implications.

Regenerative heat exchange represents another crucial efficiency strategy. By recovering cooling energy from return streams to pre-cool incoming process fluids, regenerative systems can reduce external cooling requirements by 60-85%. Modern plate-fin and spiral-wound heat exchangers achieve remarkable temperature approaches of less than 1K, maximizing this regenerative effect while maintaining compact dimensions suitable for cryogenic applications.

Material selection significantly impacts energy performance in low-temperature operations. Advanced materials like aluminum-lithium alloys and certain composites maintain favorable thermal conductivity at cryogenic temperatures while reducing thermal mass, decreasing cooldown energy requirements by up to 30% compared to traditional materials. These materials must simultaneously address thermal cycling fatigue and brittleness concerns inherent to cryogenic applications.

Process integration techniques further enhance system-wide efficiency. Pinch analysis and exergy-based optimization methods identify opportunities to cascade cooling effects across multiple process streams, potentially reducing overall energy consumption by 15-25%. Additionally, the integration of mixed refrigerant cycles can provide better temperature matching to process requirements than single-component refrigerants, improving coefficient of performance by 20-40% in appropriate applications.

Cryogenic systems face unique thermodynamic constraints that directly impact energy efficiency. The Carnot efficiency principle indicates that as operating temperatures decrease, the theoretical maximum efficiency of cooling systems diminishes significantly. For instance, cooling from ambient temperature (293K) to liquid nitrogen temperature (77K) requires at least 2.8 units of input energy per unit of cooling effect, even in an ideal system.

Heat leak minimization emerges as the primary efficiency consideration in cryogenic heat exchangers. Advanced multi-layer insulation (MLI) technologies, consisting of alternating layers of reflective material and low-conductivity spacers, can reduce radiative heat transfer by up to 97% compared to conventional insulation. Vacuum-jacketed designs further minimize conductive and convective heat transfer, though they introduce manufacturing complexity and cost implications.

Regenerative heat exchange represents another crucial efficiency strategy. By recovering cooling energy from return streams to pre-cool incoming process fluids, regenerative systems can reduce external cooling requirements by 60-85%. Modern plate-fin and spiral-wound heat exchangers achieve remarkable temperature approaches of less than 1K, maximizing this regenerative effect while maintaining compact dimensions suitable for cryogenic applications.

Material selection significantly impacts energy performance in low-temperature operations. Advanced materials like aluminum-lithium alloys and certain composites maintain favorable thermal conductivity at cryogenic temperatures while reducing thermal mass, decreasing cooldown energy requirements by up to 30% compared to traditional materials. These materials must simultaneously address thermal cycling fatigue and brittleness concerns inherent to cryogenic applications.

Process integration techniques further enhance system-wide efficiency. Pinch analysis and exergy-based optimization methods identify opportunities to cascade cooling effects across multiple process streams, potentially reducing overall energy consumption by 15-25%. Additionally, the integration of mixed refrigerant cycles can provide better temperature matching to process requirements than single-component refrigerants, improving coefficient of performance by 20-40% in appropriate applications.

Safety Standards and Compliance for Low-Temperature Operations

Low-temperature heat exchanger operations present unique safety challenges that require strict adherence to established standards and regulations. The primary international standards governing these systems include ISO 16890 for filtration requirements, ASME Boiler and Pressure Vessel Code Section VIII for pressure vessels, and ASHRAE Standard 15 specifically addressing refrigeration system safety. These standards establish minimum requirements for materials, design methodologies, fabrication techniques, and testing protocols essential for cryogenic applications.

Regulatory compliance frameworks vary significantly across regions, with the European Union enforcing the Pressure Equipment Directive (PED) 2014/68/EU, while North America follows ASME B31.5 for refrigeration piping and CGA G-4.1 for handling liquid oxygen systems. Organizations must navigate these complex regulatory landscapes to ensure legal operation while maintaining optimal system performance.

Material selection standards are particularly critical in low-temperature environments. ASTM A333 specifies requirements for low-temperature carbon and alloy steel pipes, while ASTM A240 covers stainless steel plate requirements. These standards ensure materials maintain structural integrity and prevent brittle fracture under extreme temperature conditions, a phenomenon that can lead to catastrophic system failures.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) have become mandatory components of safety compliance for cryogenic heat exchanger systems. These systematic approaches identify potential failure points and establish mitigation strategies before system deployment, significantly reducing operational risks.

Personal protective equipment requirements are extensively detailed in standards like EN 511 for cold-protective gloves and NFPA 70E for electrical safety in potentially explosive atmospheres created by cryogenic fluids. Training certification requirements for personnel operating low-temperature systems are governed by standards such as OSHA 1910.119 Process Safety Management, which mandates comprehensive operator qualification programs.

Emerging safety technologies, including advanced leak detection systems and remote monitoring capabilities, are increasingly being incorporated into compliance frameworks. The International Cryogenic Safety Standard (ICSS) is currently developing next-generation guidelines that integrate these technologies with traditional safety approaches, creating more comprehensive protection systems.

Companies developing heat exchanger systems for low-temperature operations must establish robust compliance documentation systems that track design specifications, material certifications, testing results, and maintenance records throughout the system lifecycle. This documentation serves both as evidence of regulatory compliance and as critical reference material for system optimization and troubleshooting.

Regulatory compliance frameworks vary significantly across regions, with the European Union enforcing the Pressure Equipment Directive (PED) 2014/68/EU, while North America follows ASME B31.5 for refrigeration piping and CGA G-4.1 for handling liquid oxygen systems. Organizations must navigate these complex regulatory landscapes to ensure legal operation while maintaining optimal system performance.

Material selection standards are particularly critical in low-temperature environments. ASTM A333 specifies requirements for low-temperature carbon and alloy steel pipes, while ASTM A240 covers stainless steel plate requirements. These standards ensure materials maintain structural integrity and prevent brittle fracture under extreme temperature conditions, a phenomenon that can lead to catastrophic system failures.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) have become mandatory components of safety compliance for cryogenic heat exchanger systems. These systematic approaches identify potential failure points and establish mitigation strategies before system deployment, significantly reducing operational risks.

Personal protective equipment requirements are extensively detailed in standards like EN 511 for cold-protective gloves and NFPA 70E for electrical safety in potentially explosive atmospheres created by cryogenic fluids. Training certification requirements for personnel operating low-temperature systems are governed by standards such as OSHA 1910.119 Process Safety Management, which mandates comprehensive operator qualification programs.

Emerging safety technologies, including advanced leak detection systems and remote monitoring capabilities, are increasingly being incorporated into compliance frameworks. The International Cryogenic Safety Standard (ICSS) is currently developing next-generation guidelines that integrate these technologies with traditional safety approaches, creating more comprehensive protection systems.

Companies developing heat exchanger systems for low-temperature operations must establish robust compliance documentation systems that track design specifications, material certifications, testing results, and maintenance records throughout the system lifecycle. This documentation serves both as evidence of regulatory compliance and as critical reference material for system optimization and troubleshooting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!