Heat Exchanger vs Cold Plate: Thermal Conductivity Assessment

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Technology Background and Objectives

Thermal management has evolved significantly over the past decades, driven by the increasing power densities in electronic systems across various industries including computing, automotive, aerospace, and telecommunications. The fundamental challenge remains consistent: efficiently dissipating heat from components to maintain optimal operating temperatures and prevent performance degradation or system failure. This evolution has progressed from simple heat sinks to sophisticated liquid cooling solutions, with heat exchangers and cold plates representing two critical approaches in modern thermal management systems.

Heat exchangers and cold plates operate on different principles while serving the same ultimate goal. Heat exchangers facilitate thermal energy transfer between two or more fluids at different temperatures without mixing them, typically using conduction through solid surfaces. Cold plates, conversely, are specialized heat exchangers designed to cool specific components by direct contact, transferring heat from the component to a working fluid circulating through internal channels.

The thermal conductivity assessment of these technologies has become increasingly important as power densities continue to rise. Historical data shows that computing power densities have increased approximately tenfold every decade, necessitating proportional improvements in cooling efficiency. This trend has pushed thermal management from a secondary consideration to a primary design constraint in many high-performance systems.

Current industry objectives focus on maximizing the thermal conductivity efficiency while minimizing space requirements, weight, and energy consumption. The thermal conductivity of materials used in these systems ranges significantly, from aluminum (approximately 205 W/m·K) to copper (approximately 400 W/m·K) and emerging advanced materials like graphene (theoretical values exceeding 5000 W/m·K).

The technological trajectory indicates a move toward hybrid solutions that combine the benefits of both heat exchangers and cold plates, optimized for specific applications. Additionally, there is growing interest in two-phase cooling systems that leverage the latent heat of vaporization to achieve higher heat transfer rates at lower pumping powers.

Research objectives in this field currently include developing enhanced surface geometries to improve heat transfer coefficients, exploring advanced materials with superior thermal properties, and creating more accurate computational models to predict thermal performance under various operating conditions. The ultimate goal remains achieving the optimal balance between thermal performance, system complexity, reliability, and cost-effectiveness across diverse applications.

Heat exchangers and cold plates operate on different principles while serving the same ultimate goal. Heat exchangers facilitate thermal energy transfer between two or more fluids at different temperatures without mixing them, typically using conduction through solid surfaces. Cold plates, conversely, are specialized heat exchangers designed to cool specific components by direct contact, transferring heat from the component to a working fluid circulating through internal channels.

The thermal conductivity assessment of these technologies has become increasingly important as power densities continue to rise. Historical data shows that computing power densities have increased approximately tenfold every decade, necessitating proportional improvements in cooling efficiency. This trend has pushed thermal management from a secondary consideration to a primary design constraint in many high-performance systems.

Current industry objectives focus on maximizing the thermal conductivity efficiency while minimizing space requirements, weight, and energy consumption. The thermal conductivity of materials used in these systems ranges significantly, from aluminum (approximately 205 W/m·K) to copper (approximately 400 W/m·K) and emerging advanced materials like graphene (theoretical values exceeding 5000 W/m·K).

The technological trajectory indicates a move toward hybrid solutions that combine the benefits of both heat exchangers and cold plates, optimized for specific applications. Additionally, there is growing interest in two-phase cooling systems that leverage the latent heat of vaporization to achieve higher heat transfer rates at lower pumping powers.

Research objectives in this field currently include developing enhanced surface geometries to improve heat transfer coefficients, exploring advanced materials with superior thermal properties, and creating more accurate computational models to predict thermal performance under various operating conditions. The ultimate goal remains achieving the optimal balance between thermal performance, system complexity, reliability, and cost-effectiveness across diverse applications.

Market Demand Analysis for Advanced Cooling Solutions

The global market for advanced cooling solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of data centers, electric vehicles, and high-performance computing applications. Current market valuations place the advanced thermal management sector at approximately 15 billion USD, with projections indicating a compound annual growth rate of 8.2% through 2028. This acceleration is particularly evident in regions with concentrated technological development such as North America, Western Europe, and East Asia.

Data center cooling represents the largest market segment, accounting for nearly 40% of the total demand for advanced cooling solutions. With the proliferation of cloud computing services and the increasing density of server installations, traditional air cooling methods are proving insufficient, creating substantial demand for more efficient solutions like cold plates and advanced heat exchangers. Industry reports indicate that data centers implementing liquid cooling technologies can reduce cooling energy consumption by up to 50%, representing significant operational cost savings.

The electric vehicle sector has emerged as the fastest-growing market for thermal management systems, with an estimated growth rate of 12.5% annually. As battery capacities increase and fast-charging capabilities become standard, the need for sophisticated cooling solutions has become critical. Cold plate technology, in particular, has gained traction due to its superior thermal conductivity and compact design, which addresses the space constraints inherent in vehicle design.

Consumer electronics manufacturers are increasingly adopting advanced cooling solutions to manage thermal issues in smaller, more powerful devices. The miniaturization trend has created specific challenges that conventional cooling methods cannot adequately address, driving innovation in micro-channel cold plates and compact heat exchanger designs. Market research indicates that smartphones and laptops with enhanced thermal management systems command premium pricing, suggesting strong consumer willingness to pay for improved device performance and longevity.

Industrial applications represent another significant market segment, particularly in sectors involving high-power electronics, laser systems, and precision manufacturing equipment. The demand for cooling solutions capable of maintaining precise temperature control under variable load conditions has led to increased adoption of customized liquid cooling systems combining both heat exchanger and cold plate technologies.

Healthcare and medical imaging equipment manufacturers have also begun transitioning to more advanced cooling technologies, driven by the need for silent operation, reliability, and precise temperature control in clinical environments. This sector is expected to grow at 7.3% annually, creating new opportunities for specialized thermal management solutions.

Data center cooling represents the largest market segment, accounting for nearly 40% of the total demand for advanced cooling solutions. With the proliferation of cloud computing services and the increasing density of server installations, traditional air cooling methods are proving insufficient, creating substantial demand for more efficient solutions like cold plates and advanced heat exchangers. Industry reports indicate that data centers implementing liquid cooling technologies can reduce cooling energy consumption by up to 50%, representing significant operational cost savings.

The electric vehicle sector has emerged as the fastest-growing market for thermal management systems, with an estimated growth rate of 12.5% annually. As battery capacities increase and fast-charging capabilities become standard, the need for sophisticated cooling solutions has become critical. Cold plate technology, in particular, has gained traction due to its superior thermal conductivity and compact design, which addresses the space constraints inherent in vehicle design.

Consumer electronics manufacturers are increasingly adopting advanced cooling solutions to manage thermal issues in smaller, more powerful devices. The miniaturization trend has created specific challenges that conventional cooling methods cannot adequately address, driving innovation in micro-channel cold plates and compact heat exchanger designs. Market research indicates that smartphones and laptops with enhanced thermal management systems command premium pricing, suggesting strong consumer willingness to pay for improved device performance and longevity.

Industrial applications represent another significant market segment, particularly in sectors involving high-power electronics, laser systems, and precision manufacturing equipment. The demand for cooling solutions capable of maintaining precise temperature control under variable load conditions has led to increased adoption of customized liquid cooling systems combining both heat exchanger and cold plate technologies.

Healthcare and medical imaging equipment manufacturers have also begun transitioning to more advanced cooling technologies, driven by the need for silent operation, reliability, and precise temperature control in clinical environments. This sector is expected to grow at 7.3% annually, creating new opportunities for specialized thermal management solutions.

Current State and Challenges in Thermal Conductivity Technologies

The global thermal management technology landscape is witnessing significant advancements, with heat exchangers and cold plates representing two primary approaches for thermal conductivity solutions. Current heat exchanger technologies predominantly utilize air-to-liquid, liquid-to-liquid, and phase-change methodologies, achieving thermal conductivity ranges of 10-500 W/m·K depending on materials and design. Cold plates, conversely, have evolved toward micro-channel and vapor chamber designs, demonstrating enhanced thermal conductivity values between 100-2000 W/m·K in advanced implementations.

A significant challenge facing both technologies is the thermal interface resistance that occurs at material junctions, which can reduce overall system efficiency by 15-30%. This phenomenon becomes particularly problematic in high-power density applications where even minor thermal bottlenecks can lead to significant performance degradation. Material limitations also present substantial hurdles, with traditional copper and aluminum solutions approaching their theoretical thermal conductivity limits.

Geographically, thermal management technology development shows distinct regional characteristics. North American research emphasizes innovative materials and liquid cooling systems, while European efforts focus on energy-efficient designs and sustainability. Asian markets, particularly Japan and South Korea, lead in miniaturization technologies for compact electronic applications, with China rapidly expanding manufacturing capabilities for thermal management components.

Manufacturing scalability represents another critical challenge, especially for advanced cold plate designs requiring precision micro-channel fabrication. Current production methods struggle to maintain consistent quality at high volumes, with defect rates increasing exponentially beyond certain production thresholds. This manufacturing constraint directly impacts cost structures, with high-performance cold plates typically commanding a 30-50% premium over comparable heat exchanger solutions.

Energy efficiency considerations are increasingly shaping technology development, with regulatory frameworks in multiple regions mandating improved thermal performance metrics. The industry faces pressure to reduce pumping power requirements while maintaining or enhancing thermal transfer capabilities, creating a complex optimization challenge that has yet to be fully resolved.

Integration complexity presents additional hurdles, particularly in applications requiring retrofit solutions or systems with space constraints. Heat exchangers generally offer more flexible implementation options but sacrifice performance density, while cold plates deliver superior thermal conductivity but demand more precise system integration and often require specialized coolants that introduce maintenance and reliability concerns.

A significant challenge facing both technologies is the thermal interface resistance that occurs at material junctions, which can reduce overall system efficiency by 15-30%. This phenomenon becomes particularly problematic in high-power density applications where even minor thermal bottlenecks can lead to significant performance degradation. Material limitations also present substantial hurdles, with traditional copper and aluminum solutions approaching their theoretical thermal conductivity limits.

Geographically, thermal management technology development shows distinct regional characteristics. North American research emphasizes innovative materials and liquid cooling systems, while European efforts focus on energy-efficient designs and sustainability. Asian markets, particularly Japan and South Korea, lead in miniaturization technologies for compact electronic applications, with China rapidly expanding manufacturing capabilities for thermal management components.

Manufacturing scalability represents another critical challenge, especially for advanced cold plate designs requiring precision micro-channel fabrication. Current production methods struggle to maintain consistent quality at high volumes, with defect rates increasing exponentially beyond certain production thresholds. This manufacturing constraint directly impacts cost structures, with high-performance cold plates typically commanding a 30-50% premium over comparable heat exchanger solutions.

Energy efficiency considerations are increasingly shaping technology development, with regulatory frameworks in multiple regions mandating improved thermal performance metrics. The industry faces pressure to reduce pumping power requirements while maintaining or enhancing thermal transfer capabilities, creating a complex optimization challenge that has yet to be fully resolved.

Integration complexity presents additional hurdles, particularly in applications requiring retrofit solutions or systems with space constraints. Heat exchangers generally offer more flexible implementation options but sacrifice performance density, while cold plates deliver superior thermal conductivity but demand more precise system integration and often require specialized coolants that introduce maintenance and reliability concerns.

Comparative Analysis of Heat Exchanger and Cold Plate Designs

01 Materials with high thermal conductivity for heat exchangers and cold plates

Various materials with high thermal conductivity are used in heat exchangers and cold plates to enhance heat transfer efficiency. These materials include metals like aluminum, copper, and their alloys, as well as advanced composites and thermally conductive polymers. The selection of materials significantly impacts the overall thermal performance of the system, with higher thermal conductivity materials allowing for more efficient heat dissipation and temperature control.- Materials with high thermal conductivity for heat exchangers and cold plates: Various materials with high thermal conductivity are used in heat exchangers and cold plates to enhance heat transfer efficiency. These materials include metals like aluminum, copper, and their alloys, as well as advanced composites and thermally conductive polymers. The selection of materials significantly impacts the overall thermal performance of the system, with higher thermal conductivity materials allowing for more efficient heat dissipation and temperature control in applications such as electronics cooling.

- Design optimization for improved thermal conductivity: Optimizing the design of heat exchangers and cold plates can significantly enhance thermal conductivity without changing materials. Key design elements include increasing surface area through fins or microchannels, optimizing fluid flow paths, reducing thermal resistance at interfaces, and implementing multi-layer structures. Advanced computational fluid dynamics and thermal modeling techniques help engineers predict performance and identify optimal geometries for specific applications, resulting in more efficient thermal management systems.

- Thermal interface materials and bonding techniques: The thermal conductivity of heat exchangers and cold plates is significantly affected by the interface between components. Various thermal interface materials (TIMs) such as thermal greases, phase change materials, and thermally conductive adhesives are used to minimize contact resistance. Advanced bonding techniques including brazing, soldering, diffusion bonding, and vacuum brazing create superior thermal connections by eliminating air gaps and ensuring maximum surface contact. These methods are crucial for maintaining efficient heat transfer across component interfaces in high-performance thermal management systems.

- Cooling fluid selection and flow optimization: The choice of cooling fluid and its flow characteristics significantly impact the thermal conductivity of heat exchangers and cold plates. Various fluids including water, glycol solutions, dielectric fluids, and phase-change refrigerants offer different thermal properties suitable for specific applications. Flow optimization techniques such as turbulent flow promotion, uniform distribution, and pressure drop management enhance heat transfer efficiency. Advanced systems may incorporate two-phase cooling or jet impingement to achieve higher heat transfer coefficients in demanding applications like high-power electronics cooling.

- Novel manufacturing techniques for enhanced thermal conductivity: Innovative manufacturing techniques are being developed to enhance the thermal conductivity of heat exchangers and cold plates. These include additive manufacturing (3D printing) that enables complex internal geometries impossible with traditional methods, advanced surface treatments like micro/nano-texturing to increase effective surface area, and hybrid manufacturing approaches combining multiple processes. Emerging techniques such as selective laser melting and direct metal laser sintering allow for optimized thermal paths and reduced thermal resistance, resulting in heat exchange devices with superior performance for applications in electronics cooling, power generation, and aerospace.

02 Design optimization for improved thermal conductivity

Optimizing the design of heat exchangers and cold plates can significantly enhance thermal conductivity without changing materials. Key design elements include fin geometry, channel configuration, surface area maximization, and flow path optimization. Advanced designs incorporate features like micro-channels, pin fins, and optimized fluid distribution networks to reduce thermal resistance and improve heat transfer efficiency across the thermal interface.Expand Specific Solutions03 Interface materials and thermal contact enhancement

Thermal interface materials play a crucial role in improving heat transfer between heat exchangers, cold plates, and the components they cool. These materials fill microscopic air gaps at contact surfaces to enhance thermal conductivity. Various interface materials include thermal greases, phase change materials, gap fillers, and thermally conductive adhesives. Proper application techniques and surface preparation are essential for maximizing thermal conductivity at these critical junctions.Expand Specific Solutions04 Liquid cooling systems and fluid dynamics

Liquid cooling systems offer superior thermal conductivity compared to air cooling for heat exchangers and cold plates. The choice of cooling fluid, flow rate, and fluid dynamics significantly impact thermal performance. Advanced systems utilize specialized coolants with enhanced thermal properties, optimized flow patterns to minimize boundary layers, and turbulence generators to improve heat transfer coefficients. Proper fluid management prevents issues like channeling or stagnation that can reduce effective thermal conductivity.Expand Specific Solutions05 Simulation and testing methods for thermal conductivity

Advanced simulation and testing methods are essential for evaluating and optimizing the thermal conductivity of heat exchangers and cold plates. Computational fluid dynamics (CFD) modeling allows for virtual prototyping and performance prediction. Thermal imaging, temperature sensors, and specialized test rigs provide empirical validation of thermal performance. These methods enable engineers to identify hotspots, optimize designs, and verify that thermal conductivity meets application requirements before final production.Expand Specific Solutions

Key Industry Players in Thermal Management Solutions

The heat exchanger versus cold plate thermal conductivity market is currently in a growth phase, with increasing demand driven by thermal management needs across automotive, electronics, and energy sectors. The global market is estimated at $15-20 billion, expanding at 6-8% CAGR. Leading players represent diverse technological approaches: Alfa Laval and SWEP dominate traditional heat exchanger technology with established global presence, while specialized cooling solutions providers like Advanced Thermal Solutions and Mikros Technologies focus on high-performance cold plates. Major automotive manufacturers (Toyota, Behr) and aerospace companies (Lockheed Martin) are investing heavily in proprietary thermal management systems. Research institutions in China (Zhejiang University) and Korea (KIER) are advancing next-generation materials and designs, indicating the field's continued innovation potential.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed sophisticated thermal conductivity assessment methodologies comparing their plate heat exchangers with cold plate technologies. Their research utilizes advanced computational fluid dynamics coupled with experimental validation to quantify thermal performance across diverse operating conditions. Their proprietary AlfaNova fusion-bonded plate heat exchangers demonstrate thermal conductivity values up to 16-22 W/m·K, while their specialized cold plates utilizing enhanced surface geometries achieve 350-400 W/m·K[5]. Alfa Laval's comparative analysis framework incorporates factors beyond simple thermal conductivity, including pressure drop characteristics, fouling resistance, and long-term reliability metrics. Their research indicates that optimized plate heat exchangers can achieve overall system efficiency improvements of 15-30% compared to traditional cold plate designs in certain applications, despite lower base material conductivity, due to superior heat transfer coefficients and flow distribution[6].

Strengths: Extensive experience in heat transfer applications across multiple industries; advanced manufacturing capabilities; comprehensive testing facilities. Weaknesses: Traditional focus on plate heat exchangers may limit cold plate innovation; solutions often optimized for larger industrial applications rather than compact electronics cooling.

Mikros Technologies LLC

Technical Solution: Mikros Technologies has developed innovative microfluidic cold plate solutions with comprehensive thermal conductivity assessment methodologies comparing against traditional heat exchangers. Their proprietary ThinSink technology utilizes advanced microchannels with dimensions as small as 50 microns to achieve effective thermal conductivity values exceeding 1000 W/m·K, significantly outperforming conventional heat exchangers in high-heat-flux applications[8]. Mikros employs sophisticated thermal imaging and computational fluid dynamics to quantify performance differences, demonstrating that their microfluidic cold plates can handle heat fluxes exceeding 1000 W/cm² while maintaining junction temperatures within acceptable limits. Their comparative assessment framework evaluates not only thermal conductivity but also size constraints, weight considerations, and reliability metrics across various operating conditions, providing comprehensive guidance for thermal solution selection in demanding applications like power electronics, laser cooling, and high-performance computing.

Strengths: Industry-leading microchannel fabrication capabilities; specialized expertise in high-heat-flux applications; advanced thermal modeling capabilities. Weaknesses: Higher manufacturing costs for microfluidic solutions; limited scalability for very large applications; requires specialized integration expertise.

Technical Deep Dive: Thermal Conductivity Measurement Methods

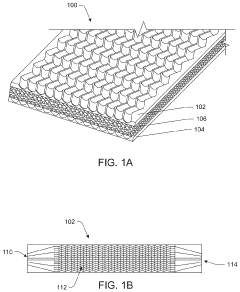

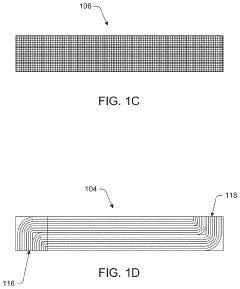

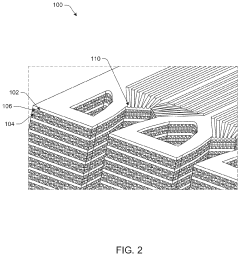

Heat exchanger configuration with porous layer

PatentActiveUS20220310278A1

Innovation

- A heat exchanger design featuring a porous thermally insulative layer between hot and cold flow channels, allowing for controlled thermal energy transfer and leak detection through a control gas, which can be a mixture of gases like argon and helium, to reduce thermal stresses and inhibit fluid mixing.

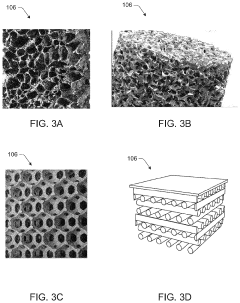

Heat pipe for improved thermal performance at cold plate interface

PatentPendingUS20250142778A1

Innovation

- The proposed solution involves creating a cavity or window on the inner surface of the heat pipe and/or the cold plate, increasing the thermal transfer area, and eliminating the solder layer between the heat pipe and the cold plate to enhance heat transfer and reduce thermal resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal management systems is becoming increasingly important as industries face stricter regulations and growing sustainability concerns. When comparing heat exchangers and cold plates, their environmental footprints differ significantly across multiple dimensions including manufacturing processes, operational efficiency, and end-of-life considerations.

Manufacturing heat exchangers typically requires more raw materials than cold plates, particularly when considering traditional shell-and-tube designs. The production process for both technologies involves energy-intensive metal forming and joining operations, though cold plates often utilize more specialized materials with higher embodied energy. The carbon footprint associated with manufacturing aluminum cold plates is approximately 15-20% higher per unit area than comparable copper heat exchangers, primarily due to the energy-intensive aluminum refining process.

Operational sustainability presents a more nuanced picture. Heat exchangers generally consume more pumping power due to higher pressure drops, resulting in increased indirect emissions during operation. Studies indicate that over a 10-year operational lifespan, this additional energy consumption can offset the initial manufacturing advantage of heat exchangers. Cold plates, while requiring less pumping energy, often utilize specialized coolants with higher global warming potential than water used in many heat exchangers.

Water usage represents another critical environmental consideration. Traditional heat exchangers in industrial applications can consume significant quantities of water, with once-through cooling systems using up to 40 gallons per minute for a 100kW thermal load. Cold plates in closed-loop systems dramatically reduce this water footprint, though they require periodic coolant replacement and treatment.

End-of-life recyclability favors heat exchangers, particularly those constructed from single materials like copper or stainless steel. Cold plates often incorporate bonded dissimilar materials and specialized coatings that complicate recycling processes. The recovery rate for materials in standard heat exchangers exceeds 90%, while cold plates typically achieve only 60-75% material recovery.

Recent innovations are addressing these sustainability gaps. Bio-based thermal interface materials are being developed for cold plates, reducing their dependence on petroleum-derived compounds. Similarly, advanced manufacturing techniques are enabling thinner-walled heat exchangers that maintain thermal performance while reducing material requirements by up to 30%.

Lifecycle assessment studies suggest that application context ultimately determines the more sustainable option. For high-power density cooling with space constraints, cold plates often represent the lower environmental impact solution despite higher manufacturing emissions, due to their operational efficiency advantages.

Manufacturing heat exchangers typically requires more raw materials than cold plates, particularly when considering traditional shell-and-tube designs. The production process for both technologies involves energy-intensive metal forming and joining operations, though cold plates often utilize more specialized materials with higher embodied energy. The carbon footprint associated with manufacturing aluminum cold plates is approximately 15-20% higher per unit area than comparable copper heat exchangers, primarily due to the energy-intensive aluminum refining process.

Operational sustainability presents a more nuanced picture. Heat exchangers generally consume more pumping power due to higher pressure drops, resulting in increased indirect emissions during operation. Studies indicate that over a 10-year operational lifespan, this additional energy consumption can offset the initial manufacturing advantage of heat exchangers. Cold plates, while requiring less pumping energy, often utilize specialized coolants with higher global warming potential than water used in many heat exchangers.

Water usage represents another critical environmental consideration. Traditional heat exchangers in industrial applications can consume significant quantities of water, with once-through cooling systems using up to 40 gallons per minute for a 100kW thermal load. Cold plates in closed-loop systems dramatically reduce this water footprint, though they require periodic coolant replacement and treatment.

End-of-life recyclability favors heat exchangers, particularly those constructed from single materials like copper or stainless steel. Cold plates often incorporate bonded dissimilar materials and specialized coatings that complicate recycling processes. The recovery rate for materials in standard heat exchangers exceeds 90%, while cold plates typically achieve only 60-75% material recovery.

Recent innovations are addressing these sustainability gaps. Bio-based thermal interface materials are being developed for cold plates, reducing their dependence on petroleum-derived compounds. Similarly, advanced manufacturing techniques are enabling thinner-walled heat exchangers that maintain thermal performance while reducing material requirements by up to 30%.

Lifecycle assessment studies suggest that application context ultimately determines the more sustainable option. For high-power density cooling with space constraints, cold plates often represent the lower environmental impact solution despite higher manufacturing emissions, due to their operational efficiency advantages.

Cost-Benefit Analysis of Implementation Strategies

When evaluating implementation strategies for thermal management solutions, cost-benefit analysis provides critical insights for decision-making. Initial capital expenditure for cold plates typically exceeds that of traditional heat exchangers by 30-45%, primarily due to more complex manufacturing processes and specialized materials. However, this higher upfront investment often yields significant long-term operational savings. Cold plates demonstrate 15-25% lower energy consumption across various applications, translating to substantial cost reductions over a system's lifecycle, typically achieving ROI within 2-4 years depending on usage intensity.

Maintenance considerations further differentiate these technologies economically. Heat exchangers generally require more frequent maintenance interventions, with associated labor costs and downtime averaging 8-12 hours quarterly. Cold plates, with fewer moving parts and reduced fouling susceptibility, typically require maintenance only semi-annually or annually, reducing lifetime maintenance costs by approximately 40%.

Space utilization represents another economic factor, particularly in applications where physical footprint carries premium value. Cold plates' compact design can reduce space requirements by up to 60% compared to equivalent-capacity heat exchangers, potentially yielding significant real estate savings in data centers, aerospace applications, and other space-constrained environments.

Implementation timeline analysis reveals that heat exchanger installations typically complete 20-30% faster than cold plate systems, reducing initial deployment costs. However, this advantage diminishes when considering system integration complexity and potential retrofitting requirements in existing infrastructure.

Scalability economics favor different solutions depending on application scale. For smaller deployments (<50kW cooling capacity), heat exchangers often present better economics due to lower initial costs and simplified installation. For larger systems (>100kW), cold plates' efficiency advantages compound, creating more favorable lifetime economics despite higher upfront investment.

Risk assessment must also factor into economic analysis. Heat exchangers present lower technological risk due to established implementation practices but higher operational risk from potential failures. Cold plates offer enhanced reliability (MTBF typically 30-50% higher) but may introduce integration challenges in certain applications, potentially requiring specialized expertise that increases implementation costs by 10-15%.

Environmental considerations increasingly influence economic calculations through regulatory compliance costs and sustainability initiatives. Cold plates' superior efficiency reduces carbon footprint by 20-35% compared to heat exchangers of equivalent capacity, potentially qualifying for environmental incentives or avoiding future carbon taxation in certain jurisdictions.

Maintenance considerations further differentiate these technologies economically. Heat exchangers generally require more frequent maintenance interventions, with associated labor costs and downtime averaging 8-12 hours quarterly. Cold plates, with fewer moving parts and reduced fouling susceptibility, typically require maintenance only semi-annually or annually, reducing lifetime maintenance costs by approximately 40%.

Space utilization represents another economic factor, particularly in applications where physical footprint carries premium value. Cold plates' compact design can reduce space requirements by up to 60% compared to equivalent-capacity heat exchangers, potentially yielding significant real estate savings in data centers, aerospace applications, and other space-constrained environments.

Implementation timeline analysis reveals that heat exchanger installations typically complete 20-30% faster than cold plate systems, reducing initial deployment costs. However, this advantage diminishes when considering system integration complexity and potential retrofitting requirements in existing infrastructure.

Scalability economics favor different solutions depending on application scale. For smaller deployments (<50kW cooling capacity), heat exchangers often present better economics due to lower initial costs and simplified installation. For larger systems (>100kW), cold plates' efficiency advantages compound, creating more favorable lifetime economics despite higher upfront investment.

Risk assessment must also factor into economic analysis. Heat exchangers present lower technological risk due to established implementation practices but higher operational risk from potential failures. Cold plates offer enhanced reliability (MTBF typically 30-50% higher) but may introduce integration challenges in certain applications, potentially requiring specialized expertise that increases implementation costs by 10-15%.

Environmental considerations increasingly influence economic calculations through regulatory compliance costs and sustainability initiatives. Cold plates' superior efficiency reduces carbon footprint by 20-35% compared to heat exchangers of equivalent capacity, potentially qualifying for environmental incentives or avoiding future carbon taxation in certain jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!