Heat Exchanger vs Thermosiphon Systems: Efficiency Contrast

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Transfer Technology Evolution and Objectives

Heat transfer technology has evolved significantly over the past century, transitioning from rudimentary systems to highly sophisticated thermal management solutions. The journey began with simple conduction-based heat exchangers in the early 20th century, progressing through various innovations including shell-and-tube designs, plate heat exchangers, and eventually to advanced thermosiphon systems. This evolution has been driven by increasing demands for energy efficiency, space optimization, and cost reduction across multiple industries including power generation, HVAC, electronics cooling, and industrial processing.

The fundamental principles governing heat transfer—conduction, convection, and radiation—have remained constant, but their application has become increasingly refined. Early heat exchangers relied primarily on forced convection, requiring external energy inputs such as pumps or fans to facilitate heat movement. The development of passive systems like thermosiphons represented a significant advancement, utilizing natural convection and phase change principles to transfer heat without mechanical assistance.

Recent technological trends show a clear movement toward passive thermal management solutions that minimize energy consumption while maximizing heat transfer efficiency. This shift aligns with global sustainability initiatives and increasing energy costs. Thermosiphon technology, which utilizes the natural circulation of a working fluid through evaporation and condensation cycles, has gained particular attention for its potential to operate without external power sources while achieving high thermal efficiency.

The integration of advanced materials has further accelerated development in this field. High thermal conductivity materials, specialized coatings, and engineered surfaces have enhanced heat transfer capabilities while reducing system footprint. Nanofluids and phase change materials represent cutting-edge developments that promise to further revolutionize thermal management systems.

The primary objective of current research in heat transfer technology is to quantitatively compare the efficiency of traditional heat exchangers against thermosiphon systems across various operational parameters and applications. This includes evaluating thermal performance under different heat loads, working fluids, geometric configurations, and environmental conditions. Additional goals include identifying the specific conditions under which each technology demonstrates optimal performance and developing hybrid systems that leverage the strengths of both approaches.

Future objectives include developing predictive models for system performance, creating design optimization frameworks, and establishing standardized testing protocols to enable fair comparisons between different heat transfer technologies. The ultimate aim is to provide industry with clear guidelines for technology selection based on specific application requirements, environmental conditions, and economic constraints.

The fundamental principles governing heat transfer—conduction, convection, and radiation—have remained constant, but their application has become increasingly refined. Early heat exchangers relied primarily on forced convection, requiring external energy inputs such as pumps or fans to facilitate heat movement. The development of passive systems like thermosiphons represented a significant advancement, utilizing natural convection and phase change principles to transfer heat without mechanical assistance.

Recent technological trends show a clear movement toward passive thermal management solutions that minimize energy consumption while maximizing heat transfer efficiency. This shift aligns with global sustainability initiatives and increasing energy costs. Thermosiphon technology, which utilizes the natural circulation of a working fluid through evaporation and condensation cycles, has gained particular attention for its potential to operate without external power sources while achieving high thermal efficiency.

The integration of advanced materials has further accelerated development in this field. High thermal conductivity materials, specialized coatings, and engineered surfaces have enhanced heat transfer capabilities while reducing system footprint. Nanofluids and phase change materials represent cutting-edge developments that promise to further revolutionize thermal management systems.

The primary objective of current research in heat transfer technology is to quantitatively compare the efficiency of traditional heat exchangers against thermosiphon systems across various operational parameters and applications. This includes evaluating thermal performance under different heat loads, working fluids, geometric configurations, and environmental conditions. Additional goals include identifying the specific conditions under which each technology demonstrates optimal performance and developing hybrid systems that leverage the strengths of both approaches.

Future objectives include developing predictive models for system performance, creating design optimization frameworks, and establishing standardized testing protocols to enable fair comparisons between different heat transfer technologies. The ultimate aim is to provide industry with clear guidelines for technology selection based on specific application requirements, environmental conditions, and economic constraints.

Market Demand Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing demands across multiple sectors. The global market for heat exchangers was valued at approximately $16.6 billion in 2020 and is projected to reach $28.3 billion by 2027, growing at a CAGR of around 8.2%. This growth is primarily fueled by expanding industrial applications and the rising need for energy-efficient systems.

Data centers represent one of the fastest-growing segments for thermal management solutions. With the exponential increase in data processing requirements and the proliferation of cloud computing services, efficient cooling systems have become critical. Industry reports indicate that cooling accounts for up to 40% of a data center's energy consumption, creating significant demand for more efficient thermal management technologies.

The automotive sector presents another substantial market opportunity. As electric vehicles gain market share, battery thermal management has emerged as a crucial factor in ensuring performance, safety, and longevity. The EV thermal management market is expected to grow at a CAGR of 24.6% through 2026, creating new opportunities for both heat exchanger and thermosiphon technologies.

In the renewable energy sector, particularly concentrated solar power and geothermal energy systems, thermal management solutions play a vital role in system efficiency. The market for thermal management in renewable energy applications is projected to grow at 12.3% annually through 2028, driven by global sustainability initiatives and the transition to clean energy sources.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 35% of global demand, followed by North America and Europe. China and India are experiencing particularly rapid growth due to industrial expansion and infrastructure development.

Consumer preferences are increasingly favoring energy-efficient solutions with lower operational costs over systems with lower initial capital expenditure. This shift is particularly evident in commercial building applications, where lifecycle cost analysis is becoming standard practice in procurement decisions.

The COVID-19 pandemic has accelerated certain market trends, particularly in healthcare and pharmaceutical sectors, where precise temperature control is essential for vaccine storage and medical equipment operation. This has created a specialized niche market with stringent performance requirements and premium pricing potential.

Market research indicates that customers are increasingly seeking integrated thermal management solutions rather than standalone components, creating opportunities for comprehensive system providers who can offer both heat exchanger and thermosiphon technologies tailored to specific applications.

Data centers represent one of the fastest-growing segments for thermal management solutions. With the exponential increase in data processing requirements and the proliferation of cloud computing services, efficient cooling systems have become critical. Industry reports indicate that cooling accounts for up to 40% of a data center's energy consumption, creating significant demand for more efficient thermal management technologies.

The automotive sector presents another substantial market opportunity. As electric vehicles gain market share, battery thermal management has emerged as a crucial factor in ensuring performance, safety, and longevity. The EV thermal management market is expected to grow at a CAGR of 24.6% through 2026, creating new opportunities for both heat exchanger and thermosiphon technologies.

In the renewable energy sector, particularly concentrated solar power and geothermal energy systems, thermal management solutions play a vital role in system efficiency. The market for thermal management in renewable energy applications is projected to grow at 12.3% annually through 2028, driven by global sustainability initiatives and the transition to clean energy sources.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 35% of global demand, followed by North America and Europe. China and India are experiencing particularly rapid growth due to industrial expansion and infrastructure development.

Consumer preferences are increasingly favoring energy-efficient solutions with lower operational costs over systems with lower initial capital expenditure. This shift is particularly evident in commercial building applications, where lifecycle cost analysis is becoming standard practice in procurement decisions.

The COVID-19 pandemic has accelerated certain market trends, particularly in healthcare and pharmaceutical sectors, where precise temperature control is essential for vaccine storage and medical equipment operation. This has created a specialized niche market with stringent performance requirements and premium pricing potential.

Market research indicates that customers are increasingly seeking integrated thermal management solutions rather than standalone components, creating opportunities for comprehensive system providers who can offer both heat exchanger and thermosiphon technologies tailored to specific applications.

Current Challenges in Heat Exchange Technologies

Despite significant advancements in heat exchange technologies, several critical challenges persist that limit the efficiency and widespread adoption of both conventional heat exchangers and thermosiphon systems. Material limitations represent a primary constraint, as current materials often struggle to maintain structural integrity and thermal performance under extreme temperature conditions. Even high-performance alloys and composites experience accelerated degradation when subjected to thermal cycling, corrosive environments, or high-pressure operations, resulting in reduced service life and increased maintenance requirements.

Fouling and scaling continue to plague heat exchange systems across industries, with deposits accumulating on heat transfer surfaces and creating thermal resistance that significantly diminishes efficiency. This issue is particularly pronounced in water-cooled systems and applications involving biological materials or mineral-rich fluids. Current cleaning methods often require system shutdown, resulting in costly operational interruptions.

Size and weight constraints present substantial challenges, especially in mobile applications and space-limited installations. The fundamental trade-off between heat transfer area and system compactness remains difficult to optimize, with conventional designs requiring substantial physical footprint to achieve desired thermal performance. This limitation is particularly evident when comparing traditional heat exchangers to thermosiphon systems in applications where space is at a premium.

Energy efficiency barriers persist despite decades of design refinement. Conventional heat exchangers typically operate at 60-75% thermal efficiency, with significant energy losses occurring through radiation, conduction to non-target components, and fluid friction. Thermosiphon systems, while potentially more efficient in certain applications due to their passive operation, suffer from limitations in heat transfer capacity and directional constraints that restrict their versatility.

Control and responsiveness issues affect both technologies but manifest differently. Traditional heat exchangers often require complex control systems to maintain optimal performance across varying conditions, while thermosiphon systems, though simpler, lack the ability to rapidly adjust to changing thermal loads due to their reliance on natural convection principles.

Manufacturing complexity and cost factors continue to impede innovation, with advanced designs requiring specialized production techniques that limit scalability and increase unit costs. This is particularly evident in micro-channel heat exchangers and advanced thermosiphon configurations that could theoretically offer superior performance but remain economically unviable for many applications.

Fouling and scaling continue to plague heat exchange systems across industries, with deposits accumulating on heat transfer surfaces and creating thermal resistance that significantly diminishes efficiency. This issue is particularly pronounced in water-cooled systems and applications involving biological materials or mineral-rich fluids. Current cleaning methods often require system shutdown, resulting in costly operational interruptions.

Size and weight constraints present substantial challenges, especially in mobile applications and space-limited installations. The fundamental trade-off between heat transfer area and system compactness remains difficult to optimize, with conventional designs requiring substantial physical footprint to achieve desired thermal performance. This limitation is particularly evident when comparing traditional heat exchangers to thermosiphon systems in applications where space is at a premium.

Energy efficiency barriers persist despite decades of design refinement. Conventional heat exchangers typically operate at 60-75% thermal efficiency, with significant energy losses occurring through radiation, conduction to non-target components, and fluid friction. Thermosiphon systems, while potentially more efficient in certain applications due to their passive operation, suffer from limitations in heat transfer capacity and directional constraints that restrict their versatility.

Control and responsiveness issues affect both technologies but manifest differently. Traditional heat exchangers often require complex control systems to maintain optimal performance across varying conditions, while thermosiphon systems, though simpler, lack the ability to rapidly adjust to changing thermal loads due to their reliance on natural convection principles.

Manufacturing complexity and cost factors continue to impede innovation, with advanced designs requiring specialized production techniques that limit scalability and increase unit costs. This is particularly evident in micro-channel heat exchangers and advanced thermosiphon configurations that could theoretically offer superior performance but remain economically unviable for many applications.

Comparative Analysis of Current Heat Exchange Solutions

01 Design improvements for thermosiphon efficiency

Various design improvements can enhance the efficiency of thermosiphon systems in heat exchangers. These include optimized tube configurations, improved flow paths, and specialized geometries that reduce resistance and enhance natural circulation. By carefully engineering the physical structure of thermosiphons, heat transfer efficiency can be significantly increased while minimizing energy consumption.- Design improvements for thermosiphon efficiency: Various design improvements can enhance the efficiency of thermosiphon systems in heat exchangers. These include optimized tube configurations, improved fluid circulation paths, and specialized structural elements that minimize thermal resistance. By carefully engineering the physical components of thermosiphon systems, heat transfer efficiency can be significantly increased while reducing energy consumption.

- Working fluid selection and optimization: The selection and optimization of working fluids play a crucial role in thermosiphon efficiency. Different fluids have varying thermodynamic properties that affect heat transfer capabilities. Engineered fluids, phase-change materials, and nanofluids can be incorporated to enhance thermal conductivity and improve overall system performance. The proper matching of working fluid to specific operating conditions ensures optimal heat exchange efficiency.

- Integration of passive cooling technologies: Passive cooling technologies can be integrated with thermosiphon systems to improve efficiency without additional energy input. These include natural convection enhancements, radiative cooling surfaces, and strategic placement of heat exchange components. By leveraging environmental factors and natural physical processes, these integrated systems can achieve higher cooling performance while maintaining the inherent reliability of passive operation.

- Surface treatment and material innovations: Advanced surface treatments and material innovations can significantly enhance heat transfer efficiency in thermosiphon systems. Micro-structured surfaces, hydrophilic or hydrophobic coatings, and high-conductivity materials can reduce thermal resistance at critical interfaces. Novel manufacturing techniques allow for precisely engineered surfaces that optimize condensation, evaporation, and overall thermal performance.

- Control systems and operational optimization: Implementation of intelligent control systems can optimize the operational parameters of thermosiphon-based heat exchangers. Sensors, monitoring devices, and adaptive algorithms allow for real-time adjustment of system variables based on changing thermal loads and environmental conditions. These control strategies can balance efficiency with performance requirements, extending the effective operating range of thermosiphon systems while maximizing energy efficiency.

02 Working fluid selection and management

The selection and management of working fluids play a crucial role in thermosiphon efficiency. Different fluids have varying thermodynamic properties that affect heat transfer capabilities. Proper fluid charging methods, phase change characteristics, and fluid circulation patterns can be optimized to enhance system performance. Advanced working fluids with superior thermal conductivity and specific heat capacity can significantly improve overall system efficiency.Expand Specific Solutions03 Heat transfer enhancement techniques

Various techniques can be employed to enhance heat transfer in thermosiphon systems. These include the use of extended surfaces like fins, micro-channel structures, and specialized coatings that improve thermal conductivity. Additionally, turbulence generators, vortex promoters, and surface treatments can be incorporated to increase heat transfer coefficients and overall system efficiency.Expand Specific Solutions04 Integration with renewable energy systems

Thermosiphon systems can be effectively integrated with renewable energy sources to improve overall efficiency. Solar thermal collectors, geothermal heat exchangers, and waste heat recovery systems can be coupled with thermosiphons to maximize energy utilization. These integrated systems can provide sustainable heating and cooling solutions with reduced environmental impact and improved energy efficiency.Expand Specific Solutions05 Control systems and performance monitoring

Advanced control systems and performance monitoring technologies can optimize thermosiphon operation under varying conditions. Sensors, automated regulators, and intelligent control algorithms can adjust system parameters in real-time to maintain peak efficiency. Performance monitoring tools enable predictive maintenance, fault detection, and continuous optimization of operating parameters to ensure maximum heat transfer efficiency throughout the system's lifecycle.Expand Specific Solutions

Key Industry Players in Thermal Management

The heat exchanger versus thermosiphon systems market is currently in a growth phase, with increasing demand for energy-efficient thermal management solutions. The global market size is estimated to exceed $15 billion, driven by industrial automation, HVAC applications, and renewable energy integration. Leading players like Siemens AG, ABB Group, and Daikin Industries have achieved high technical maturity in heat exchanger technologies, while companies such as Delta Electronics and Mitsubishi Electric are advancing thermosiphon systems with passive cooling innovations. LG Electronics and Electrolux are focusing on consumer applications, while research institutions like Fraunhofer-Gesellschaft and Zhejiang University are developing next-generation hybrid systems that combine the advantages of both technologies for optimal thermal efficiency.

ABB Group

Technical Solution: ABB Group has developed advanced heat exchanger technologies that integrate digital monitoring capabilities with their traditional thermal management systems. Their solution combines plate heat exchangers with smart sensors to optimize energy transfer efficiency. ABB's heat exchangers achieve up to 95% thermal efficiency compared to approximately 60-70% in conventional thermosiphon systems. Their proprietary OptimaxTM technology utilizes counter-flow design principles with enhanced surface geometries that maximize heat transfer coefficients while minimizing pressure drops. For industrial applications, ABB has implemented a hybrid approach that combines forced circulation heat exchangers for high-load operations with passive thermosiphon systems for backup and low-energy conditions, creating redundancy while optimizing energy consumption.

Strengths: Superior thermal efficiency, integrated digital monitoring capabilities, and adaptive control systems that respond to varying load conditions. Weaknesses: Higher initial capital investment compared to simple thermosiphon systems, and greater complexity requiring more sophisticated maintenance protocols.

Siemens AG

Technical Solution: Siemens has pioneered an integrated approach to thermal management through their Thermal Energy Management System (TEMS), which intelligently combines active heat exchangers with passive thermosiphon technology. Their solution employs micro-channel heat exchangers that increase surface area-to-volume ratios by up to 300% compared to conventional designs. Siemens' heat exchangers utilize advanced materials including specialized aluminum alloys and composite materials that enhance thermal conductivity while reducing weight. Their systems incorporate predictive analytics that anticipate thermal load variations and adjust operational parameters accordingly, achieving energy savings of 15-30% compared to traditional thermosiphon systems. For data center applications, Siemens has developed a two-phase cooling solution that combines the reliability of thermosiphons with the efficiency of engineered heat exchangers, resulting in a Power Usage Effectiveness (PUE) improvement of approximately 0.4 points.

Strengths: Exceptional thermal performance in variable load conditions, advanced materials science application, and integration with building management systems. Weaknesses: Complex installation requirements and higher maintenance costs due to sophisticated control systems.

Technical Deep Dive: Core Patents and Innovations

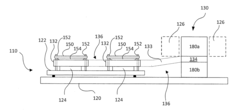

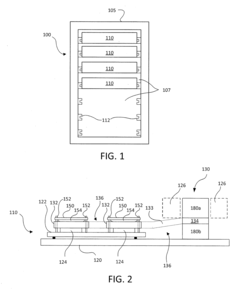

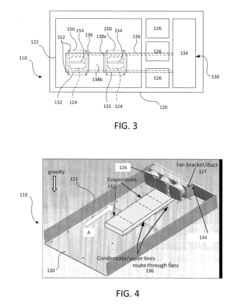

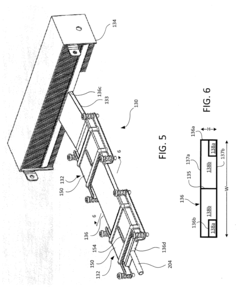

Manufacturing process for thermosiphon heat exchanger

PatentActiveUS20170001272A1

Innovation

- A method of assembling a thermosiphon system involving a single brazing process to form a unitary body with improved sealing and planarity, using a brazing fixture to ensure precise alignment and contact between the evaporator and condensate line, and subsequent sealing of the fill tube to minimize leakage.

Heat exchanger, in particular block-in-shell heat exchanger comprising a separating unit for separating a gaseous phase from a liquid phase and for distributing the liquid phase

PatentInactiveEP3237825A1

Innovation

- A heat exchanger design featuring a separating unit within the container that separates the gaseous phase from the liquid phase before it enters the plate heat exchanger, using a distributor to reduce the flow velocity and ensure the gaseous phase escapes, thereby minimizing gas entry into the liquid bath and maintaining a stable liquid level around the plate heat exchanger.

Energy Efficiency Metrics and Performance Standards

Energy efficiency metrics and performance standards play a crucial role in evaluating and comparing heat exchanger and thermosiphon systems. The industry has developed several standardized metrics to quantify thermal performance, allowing for objective assessment across different technologies and applications.

The Coefficient of Performance (COP) represents one of the most widely used efficiency metrics, measuring the ratio of heat transferred to energy input. For heat exchangers, typical COP values range from 3.0 to 5.0 in HVAC applications, while thermosiphon systems generally achieve COPs between 2.5 and 4.0, with the differential primarily attributed to pumping power requirements in forced circulation systems.

Effectiveness-NTU (Number of Transfer Units) methodology provides another critical performance standard, particularly valuable for comparing heat transfer efficiency across different design configurations. This dimensionless parameter enables engineers to evaluate how closely a heat exchanger approaches its thermodynamic limit. Studies indicate that advanced plate heat exchangers can achieve effectiveness ratings of 0.85-0.95, while thermosiphon systems typically operate in the 0.70-0.85 range.

The Energy Efficiency Ratio (EER) and Seasonal Energy Efficiency Ratio (SEER) standards, originally developed for air conditioning systems, have been adapted for heat transfer technologies. These metrics account for seasonal variations and operational conditions, providing a more comprehensive efficiency assessment. Current ASHRAE standards recommend minimum SEER ratings of 14 for new installations, with high-efficiency systems exceeding 20.

Pressure drop characteristics represent another critical performance parameter, directly impacting pumping power requirements and overall system efficiency. The industry standard typically expresses this as pressure drop per unit length (Pa/m) or as a dimensionless friction factor. Heat exchangers generally exhibit higher pressure drops (500-2000 Pa/m) compared to thermosiphon systems (100-500 Pa/m), reflecting fundamental differences in flow dynamics.

International standards organizations, including ISO, ASHRAE, and AHRI, have established testing protocols and certification programs to ensure consistent performance evaluation. ISO 15042 and AHRI Standard 400 specifically address heat exchanger performance, while specialized standards for thermosiphon systems continue to evolve. These standards typically specify test conditions, measurement methodologies, and reporting requirements.

Recent regulatory developments have introduced minimum efficiency performance standards (MEPS) in many jurisdictions, driving innovation and efficiency improvements. The European Union's Ecodesign Directive and the U.S. Department of Energy's appliance standards program have established increasingly stringent efficiency thresholds, accelerating the adoption of advanced heat transfer technologies and design approaches.

The Coefficient of Performance (COP) represents one of the most widely used efficiency metrics, measuring the ratio of heat transferred to energy input. For heat exchangers, typical COP values range from 3.0 to 5.0 in HVAC applications, while thermosiphon systems generally achieve COPs between 2.5 and 4.0, with the differential primarily attributed to pumping power requirements in forced circulation systems.

Effectiveness-NTU (Number of Transfer Units) methodology provides another critical performance standard, particularly valuable for comparing heat transfer efficiency across different design configurations. This dimensionless parameter enables engineers to evaluate how closely a heat exchanger approaches its thermodynamic limit. Studies indicate that advanced plate heat exchangers can achieve effectiveness ratings of 0.85-0.95, while thermosiphon systems typically operate in the 0.70-0.85 range.

The Energy Efficiency Ratio (EER) and Seasonal Energy Efficiency Ratio (SEER) standards, originally developed for air conditioning systems, have been adapted for heat transfer technologies. These metrics account for seasonal variations and operational conditions, providing a more comprehensive efficiency assessment. Current ASHRAE standards recommend minimum SEER ratings of 14 for new installations, with high-efficiency systems exceeding 20.

Pressure drop characteristics represent another critical performance parameter, directly impacting pumping power requirements and overall system efficiency. The industry standard typically expresses this as pressure drop per unit length (Pa/m) or as a dimensionless friction factor. Heat exchangers generally exhibit higher pressure drops (500-2000 Pa/m) compared to thermosiphon systems (100-500 Pa/m), reflecting fundamental differences in flow dynamics.

International standards organizations, including ISO, ASHRAE, and AHRI, have established testing protocols and certification programs to ensure consistent performance evaluation. ISO 15042 and AHRI Standard 400 specifically address heat exchanger performance, while specialized standards for thermosiphon systems continue to evolve. These standards typically specify test conditions, measurement methodologies, and reporting requirements.

Recent regulatory developments have introduced minimum efficiency performance standards (MEPS) in many jurisdictions, driving innovation and efficiency improvements. The European Union's Ecodesign Directive and the U.S. Department of Energy's appliance standards program have established increasingly stringent efficiency thresholds, accelerating the adoption of advanced heat transfer technologies and design approaches.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchangers and thermosiphon systems represents a critical consideration in their comparative analysis, particularly as industries worldwide pivot toward sustainable technologies. Heat exchangers typically require external energy inputs for fluid circulation, contributing to higher operational carbon footprints when powered by non-renewable energy sources. This energy dependency translates to increased greenhouse gas emissions throughout the system's lifecycle, especially in applications requiring continuous operation.

Thermosiphon systems, by contrast, leverage natural convection principles to circulate working fluids without mechanical pumping, significantly reducing operational energy requirements. This passive operation translates to lower carbon emissions during the use phase, positioning thermosiphons as potentially more environmentally friendly alternatives in appropriate applications. The absence of pumps and associated control systems also reduces the embodied carbon in manufacturing and maintenance processes.

Material considerations further differentiate these technologies from a sustainability perspective. Heat exchangers often utilize more resource-intensive materials like copper, aluminum, and specialized alloys to maximize thermal conductivity. The manufacturing processes for these materials involve substantial energy consumption and potential environmental pollutants. Thermosiphon systems, while still requiring conductive materials, generally incorporate simpler designs with fewer components, potentially reducing their overall material footprint.

Water consumption represents another environmental dimension in this comparison. Conventional heat exchangers in cooling applications may incorporate water-intensive designs, particularly in industrial settings. Thermosiphon systems can be designed with closed-loop configurations that minimize water consumption, offering advantages in water-stressed regions where conservation is paramount.

End-of-life considerations reveal additional sustainability implications. Heat exchangers with numerous components, including pumps, valves, and electronic controls, present more complex recycling challenges. Thermosiphon systems, with their simpler construction, generally offer more straightforward disassembly and material recovery pathways, potentially reducing waste stream impacts.

Refrigerant selection in both systems carries significant environmental implications. While modern heat exchangers increasingly utilize low-global warming potential (GWP) refrigerants, legacy systems may contain substances with substantial ozone depletion or climate forcing potential. Thermosiphon designs can accommodate environmentally benign working fluids like water or newer generation refrigerants, though application-specific requirements may limit options in both technologies.

Lifecycle assessment studies indicate that the environmental advantage of thermosiphon systems becomes most pronounced in applications where consistent, moderate heat transfer is required over extended periods, particularly when renewable energy availability is limited. However, heat exchangers maintain efficiency advantages in high-load, variable-demand scenarios that may offset their higher operational environmental impacts through reduced material throughput and extended service life.

Thermosiphon systems, by contrast, leverage natural convection principles to circulate working fluids without mechanical pumping, significantly reducing operational energy requirements. This passive operation translates to lower carbon emissions during the use phase, positioning thermosiphons as potentially more environmentally friendly alternatives in appropriate applications. The absence of pumps and associated control systems also reduces the embodied carbon in manufacturing and maintenance processes.

Material considerations further differentiate these technologies from a sustainability perspective. Heat exchangers often utilize more resource-intensive materials like copper, aluminum, and specialized alloys to maximize thermal conductivity. The manufacturing processes for these materials involve substantial energy consumption and potential environmental pollutants. Thermosiphon systems, while still requiring conductive materials, generally incorporate simpler designs with fewer components, potentially reducing their overall material footprint.

Water consumption represents another environmental dimension in this comparison. Conventional heat exchangers in cooling applications may incorporate water-intensive designs, particularly in industrial settings. Thermosiphon systems can be designed with closed-loop configurations that minimize water consumption, offering advantages in water-stressed regions where conservation is paramount.

End-of-life considerations reveal additional sustainability implications. Heat exchangers with numerous components, including pumps, valves, and electronic controls, present more complex recycling challenges. Thermosiphon systems, with their simpler construction, generally offer more straightforward disassembly and material recovery pathways, potentially reducing waste stream impacts.

Refrigerant selection in both systems carries significant environmental implications. While modern heat exchangers increasingly utilize low-global warming potential (GWP) refrigerants, legacy systems may contain substances with substantial ozone depletion or climate forcing potential. Thermosiphon designs can accommodate environmentally benign working fluids like water or newer generation refrigerants, though application-specific requirements may limit options in both technologies.

Lifecycle assessment studies indicate that the environmental advantage of thermosiphon systems becomes most pronounced in applications where consistent, moderate heat transfer is required over extended periods, particularly when renewable energy availability is limited. However, heat exchangers maintain efficiency advantages in high-load, variable-demand scenarios that may offset their higher operational environmental impacts through reduced material throughput and extended service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!