How to Mitigate Heat Exchanger Failure Risks in Atypical Conditions

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers have evolved significantly since their inception in the early 20th century, transitioning from simple shell-and-tube designs to complex, multi-functional systems capable of operating across diverse industrial environments. The technological progression has been driven by increasing demands for energy efficiency, process optimization, and operational reliability in sectors ranging from petrochemical processing to HVAC systems and power generation.

Recent advancements in heat exchanger technology have focused on enhancing thermal efficiency while minimizing material usage and spatial requirements. Innovations in materials science have introduced corrosion-resistant alloys, composite materials, and specialized coatings that extend operational lifespans in harsh environments. Concurrently, computational fluid dynamics (CFD) modeling has revolutionized design methodologies, enabling precise prediction of thermal performance and potential failure points under various operational conditions.

Despite these advancements, heat exchangers operating in atypical conditions continue to face significant challenges. Extreme temperature fluctuations, corrosive media, fouling, and mechanical stress can accelerate deterioration and lead to catastrophic failures. Industry data indicates that approximately 40% of heat exchanger failures occur due to conditions that fall outside standard design parameters, resulting in substantial economic losses and safety hazards.

The evolution of heat exchanger technology has been marked by several pivotal developments, including the introduction of plate heat exchangers in the 1920s, spiral heat exchangers in the 1930s, and printed circuit heat exchangers in the 1980s. Each innovation has addressed specific operational challenges, yet the fundamental issue of reliability under atypical conditions remains incompletely resolved.

The primary objective of current research is to develop comprehensive strategies for mitigating heat exchanger failure risks in non-standard operating environments. This encompasses several interconnected goals: identifying early warning indicators of potential failures, developing adaptive control systems capable of responding to changing conditions, creating predictive maintenance protocols based on real-time performance data, and designing inherently resilient heat exchanger architectures.

Additional objectives include establishing standardized testing methodologies for evaluating heat exchanger performance under atypical conditions, developing industry-specific best practices for installation and maintenance, and creating simulation tools that accurately model long-term degradation patterns. The ultimate aim is to transition from reactive maintenance approaches to proactive risk management strategies that anticipate and prevent failures before they occur.

Recent advancements in heat exchanger technology have focused on enhancing thermal efficiency while minimizing material usage and spatial requirements. Innovations in materials science have introduced corrosion-resistant alloys, composite materials, and specialized coatings that extend operational lifespans in harsh environments. Concurrently, computational fluid dynamics (CFD) modeling has revolutionized design methodologies, enabling precise prediction of thermal performance and potential failure points under various operational conditions.

Despite these advancements, heat exchangers operating in atypical conditions continue to face significant challenges. Extreme temperature fluctuations, corrosive media, fouling, and mechanical stress can accelerate deterioration and lead to catastrophic failures. Industry data indicates that approximately 40% of heat exchanger failures occur due to conditions that fall outside standard design parameters, resulting in substantial economic losses and safety hazards.

The evolution of heat exchanger technology has been marked by several pivotal developments, including the introduction of plate heat exchangers in the 1920s, spiral heat exchangers in the 1930s, and printed circuit heat exchangers in the 1980s. Each innovation has addressed specific operational challenges, yet the fundamental issue of reliability under atypical conditions remains incompletely resolved.

The primary objective of current research is to develop comprehensive strategies for mitigating heat exchanger failure risks in non-standard operating environments. This encompasses several interconnected goals: identifying early warning indicators of potential failures, developing adaptive control systems capable of responding to changing conditions, creating predictive maintenance protocols based on real-time performance data, and designing inherently resilient heat exchanger architectures.

Additional objectives include establishing standardized testing methodologies for evaluating heat exchanger performance under atypical conditions, developing industry-specific best practices for installation and maintenance, and creating simulation tools that accurately model long-term degradation patterns. The ultimate aim is to transition from reactive maintenance approaches to proactive risk management strategies that anticipate and prevent failures before they occur.

Market Demand Analysis for Resilient Heat Exchangers

The global market for resilient heat exchangers is experiencing significant growth driven by increasing industrial activities in extreme environments and the rising focus on operational reliability. Current market analysis indicates that industries such as oil and gas, chemical processing, power generation, and marine applications are the primary demand drivers, collectively representing over 70% of the total market share for specialized heat exchange equipment.

The demand for heat exchangers capable of withstanding atypical conditions has seen a compound annual growth rate of approximately 6.8% over the past five years, outpacing the general heat exchanger market growth of 4.2%. This acceleration is particularly evident in regions with harsh industrial environments such as the Middle East, Northern Europe, and parts of Asia Pacific where extreme temperature fluctuations, corrosive media, or high-pressure operations are common.

Market research reveals that end-users are increasingly prioritizing total cost of ownership over initial acquisition costs when selecting heat exchange equipment. The financial impact of unexpected failures—including production downtime, emergency maintenance, and potential safety incidents—has become a critical consideration in procurement decisions. Case studies from process industries demonstrate that a single critical heat exchanger failure can result in production losses exceeding $100,000 per day, not including repair costs or potential regulatory penalties.

The market segment for corrosion-resistant heat exchangers has shown particularly strong growth, with titanium, high-nickel alloys, and advanced composite materials gaining traction. Similarly, demand for fouling-resistant designs has increased in response to operational challenges in industries processing high-particulate or scaling-prone media.

Geographically, emerging markets are showing the highest growth rates for resilient heat exchanger technologies, with China, India, and Brazil leading in adoption as they expand their industrial infrastructure while simultaneously implementing more stringent reliability and safety standards. These markets are projected to account for nearly 40% of new installations by volume within the next three years.

Customer surveys indicate evolving expectations regarding equipment monitoring capabilities, with over 65% of industrial buyers now specifying some form of integrated condition monitoring or predictive maintenance functionality in new heat exchanger installations. This trend aligns with the broader industrial movement toward digitalization and IoT integration in process equipment.

The aftermarket service segment for heat exchangers in atypical conditions represents a substantial opportunity, with maintenance, retrofitting, and performance optimization services growing at nearly 9% annually—significantly outpacing new equipment sales.

The demand for heat exchangers capable of withstanding atypical conditions has seen a compound annual growth rate of approximately 6.8% over the past five years, outpacing the general heat exchanger market growth of 4.2%. This acceleration is particularly evident in regions with harsh industrial environments such as the Middle East, Northern Europe, and parts of Asia Pacific where extreme temperature fluctuations, corrosive media, or high-pressure operations are common.

Market research reveals that end-users are increasingly prioritizing total cost of ownership over initial acquisition costs when selecting heat exchange equipment. The financial impact of unexpected failures—including production downtime, emergency maintenance, and potential safety incidents—has become a critical consideration in procurement decisions. Case studies from process industries demonstrate that a single critical heat exchanger failure can result in production losses exceeding $100,000 per day, not including repair costs or potential regulatory penalties.

The market segment for corrosion-resistant heat exchangers has shown particularly strong growth, with titanium, high-nickel alloys, and advanced composite materials gaining traction. Similarly, demand for fouling-resistant designs has increased in response to operational challenges in industries processing high-particulate or scaling-prone media.

Geographically, emerging markets are showing the highest growth rates for resilient heat exchanger technologies, with China, India, and Brazil leading in adoption as they expand their industrial infrastructure while simultaneously implementing more stringent reliability and safety standards. These markets are projected to account for nearly 40% of new installations by volume within the next three years.

Customer surveys indicate evolving expectations regarding equipment monitoring capabilities, with over 65% of industrial buyers now specifying some form of integrated condition monitoring or predictive maintenance functionality in new heat exchanger installations. This trend aligns with the broader industrial movement toward digitalization and IoT integration in process equipment.

The aftermarket service segment for heat exchangers in atypical conditions represents a substantial opportunity, with maintenance, retrofitting, and performance optimization services growing at nearly 9% annually—significantly outpacing new equipment sales.

Current Challenges in Atypical Operating Conditions

Heat exchangers operating in atypical conditions face multifaceted challenges that significantly increase failure risks. Temperature extremes represent a primary concern, with both excessively high and unexpectedly low temperatures causing thermal stress, material fatigue, and accelerated degradation of critical components. These thermal fluctuations often exceed design parameters, leading to thermal expansion mismatches between different materials and subsequent mechanical failures.

Corrosive environments present another substantial challenge, particularly in chemical processing, offshore operations, and geothermal applications. Atypical fluid compositions containing unexpected contaminants can trigger localized corrosion, stress corrosion cracking, and erosion-corrosion mechanisms that standard material selections may not adequately address. The unpredictability of these corrosive agents makes prevention particularly difficult.

Pressure excursions beyond normal operating ranges frequently occur in atypical conditions, causing mechanical stress that can lead to deformation, rupture, or catastrophic failure. These pressure anomalies may result from process upsets, control system failures, or external factors such as extreme weather events, creating conditions that testing protocols rarely simulate during equipment qualification.

Fouling and scaling mechanisms become more aggressive and unpredictable in atypical environments. Unusual contaminants can accelerate deposit formation, while irregular flow patterns may create dead zones where particulates accumulate. These deposits not only reduce heat transfer efficiency but also create localized hot spots that accelerate material degradation and increase the risk of mechanical failure.

Vibration-induced damage represents a significant challenge in non-standard operating conditions. Atypical flow rates, fluid compositions, or external mechanical factors can generate resonant frequencies that standard design calculations do not anticipate. The resulting vibration can lead to fatigue failure, tube-to-tubesheet joint deterioration, and accelerated wear of supporting structures.

Monitoring limitations compound these challenges, as conventional instrumentation often proves inadequate for detecting early failure indicators in extreme environments. Sensors may themselves fail under harsh conditions, creating blind spots in critical monitoring systems. This limitation is particularly problematic for remote installations or equipment operating in hazardous zones where regular physical inspection is impractical.

Maintenance complexity increases substantially in atypical conditions, with standard procedures often proving insufficient or impractical. Access restrictions, environmental hazards, and the need for specialized equipment can delay necessary interventions, allowing incipient failures to progress to critical stages before remediation can occur.

Corrosive environments present another substantial challenge, particularly in chemical processing, offshore operations, and geothermal applications. Atypical fluid compositions containing unexpected contaminants can trigger localized corrosion, stress corrosion cracking, and erosion-corrosion mechanisms that standard material selections may not adequately address. The unpredictability of these corrosive agents makes prevention particularly difficult.

Pressure excursions beyond normal operating ranges frequently occur in atypical conditions, causing mechanical stress that can lead to deformation, rupture, or catastrophic failure. These pressure anomalies may result from process upsets, control system failures, or external factors such as extreme weather events, creating conditions that testing protocols rarely simulate during equipment qualification.

Fouling and scaling mechanisms become more aggressive and unpredictable in atypical environments. Unusual contaminants can accelerate deposit formation, while irregular flow patterns may create dead zones where particulates accumulate. These deposits not only reduce heat transfer efficiency but also create localized hot spots that accelerate material degradation and increase the risk of mechanical failure.

Vibration-induced damage represents a significant challenge in non-standard operating conditions. Atypical flow rates, fluid compositions, or external mechanical factors can generate resonant frequencies that standard design calculations do not anticipate. The resulting vibration can lead to fatigue failure, tube-to-tubesheet joint deterioration, and accelerated wear of supporting structures.

Monitoring limitations compound these challenges, as conventional instrumentation often proves inadequate for detecting early failure indicators in extreme environments. Sensors may themselves fail under harsh conditions, creating blind spots in critical monitoring systems. This limitation is particularly problematic for remote installations or equipment operating in hazardous zones where regular physical inspection is impractical.

Maintenance complexity increases substantially in atypical conditions, with standard procedures often proving insufficient or impractical. Access restrictions, environmental hazards, and the need for specialized equipment can delay necessary interventions, allowing incipient failures to progress to critical stages before remediation can occur.

Existing Failure Mitigation Strategies

01 Corrosion and material degradation risks

Heat exchangers are susceptible to various forms of corrosion and material degradation that can lead to failure. These include galvanic corrosion between dissimilar metals, erosion from high-velocity fluids, stress corrosion cracking, and chemical attack from process fluids. Over time, these degradation mechanisms can thin walls, create leakage paths, and ultimately cause catastrophic failure. Proper material selection, protective coatings, and regular inspection are essential to mitigate these risks.- Corrosion and material degradation risks: Heat exchangers are susceptible to various forms of corrosion and material degradation that can lead to failure. These include galvanic corrosion between dissimilar metals, erosion from high-velocity fluids, and chemical attack from process fluids. Over time, these mechanisms can thin walls, create pinholes, or weaken critical components, ultimately leading to leaks or catastrophic failures. Proper material selection, protective coatings, and regular inspection protocols are essential to mitigate these risks.

- Fouling and scaling detection systems: Fouling and scaling in heat exchangers reduce thermal efficiency and can lead to complete failure. These deposits form when minerals, biological matter, or process contaminants accumulate on heat transfer surfaces, creating insulating layers that impede heat transfer and restrict flow. Advanced detection systems using sensors, imaging technology, and predictive algorithms can identify early signs of fouling before performance is significantly affected. Implementing automated cleaning cycles and chemical treatment programs based on real-time monitoring helps maintain optimal performance and prevent failure.

- Thermal stress and mechanical failure monitoring: Heat exchangers experience significant thermal cycling and mechanical stresses that can lead to fatigue failures, cracking, and structural damage. Rapid temperature changes cause expansion and contraction that stress welds, joints, and material interfaces. Monitoring systems that track temperature differentials, pressure fluctuations, and vibration patterns can identify potential failure points before they develop into critical issues. Implementing proper startup and shutdown procedures, along with strategic placement of expansion joints and flexible connections, helps mitigate these mechanical failure risks.

- Predictive maintenance and failure prevention systems: Advanced predictive maintenance systems use machine learning algorithms and historical performance data to anticipate heat exchanger failures before they occur. These systems analyze patterns in operating parameters such as pressure drops, temperature differentials, and flow rates to identify deviations that may indicate developing problems. By implementing condition-based maintenance rather than fixed schedules, operators can address issues at optimal times, reducing both unexpected failures and unnecessary maintenance. Digital twins and simulation models further enhance predictive capabilities by comparing actual performance against theoretical benchmarks.

- Flow distribution and pressure management: Uneven flow distribution and pressure management issues can cause localized overheating, erosion, and premature failure in heat exchangers. Flow maldistribution leads to inefficient heat transfer, thermal hotspots, and increased mechanical stress. Advanced flow control systems, including intelligent baffles and variable geometry components, help maintain optimal fluid dynamics throughout the heat exchanger. Pressure monitoring at multiple points enables early detection of blockages or flow restrictions that could lead to failure. Proper design of inlet and outlet configurations minimizes turbulence and ensures uniform distribution of process fluids.

02 Fouling and scaling prevention

Accumulation of deposits, scale, and biological growth on heat exchanger surfaces significantly impairs thermal efficiency and can lead to failure. Fouling restricts flow passages, increases pressure drop, reduces heat transfer rates, and can create localized hot spots that accelerate material degradation. Advanced monitoring systems can detect early signs of fouling, while chemical treatments, mechanical cleaning methods, and optimized flow designs help prevent deposit formation and maintain operational efficiency.Expand Specific Solutions03 Thermal stress and mechanical failure detection

Heat exchangers experience significant thermal cycling and mechanical stresses that can lead to fatigue cracking, tube rupture, or header failure. Rapid temperature changes create expansion and contraction that stress joints and welds. Vibration-induced fatigue and pressure fluctuations further contribute to mechanical failure risks. Advanced monitoring systems using sensors, acoustic emission technology, and predictive algorithms can detect early signs of mechanical failure before catastrophic events occur.Expand Specific Solutions04 Predictive maintenance and condition monitoring

Implementing predictive maintenance strategies through real-time condition monitoring significantly reduces heat exchanger failure risks. Advanced sensor networks collect data on temperature differentials, pressure drops, flow rates, and vibration patterns to identify developing issues before they cause failure. Machine learning algorithms analyze operational data to predict maintenance needs, optimize cleaning schedules, and extend equipment life. These systems enable transition from reactive to proactive maintenance approaches.Expand Specific Solutions05 Design optimization for failure prevention

Innovative design approaches can significantly reduce heat exchanger failure risks. This includes optimized tube layouts to minimize flow-induced vibration, enhanced header designs to distribute thermal stresses, and improved expansion joints to accommodate thermal cycling. Computational fluid dynamics and finite element analysis help identify potential failure points during the design phase. Modular designs facilitate easier inspection and maintenance, while redundant systems ensure operational continuity even when components require service.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The heat exchanger failure risk mitigation market is currently in a growth phase, with increasing demand driven by industrial safety concerns and operational efficiency requirements. The global market size is estimated to exceed $8 billion, expanding at approximately 6% CAGR. Technologically, solutions range from mature conventional approaches to emerging advanced monitoring systems. Industry leaders like Danfoss, DENSO, and Modine Manufacturing offer established thermal management solutions, while companies such as Sanhua Micro Channel Heat Exchanger are advancing microchannel technology for atypical conditions. Saudi Aramco and Siemens are investing in predictive maintenance technologies, while Robert Bosch and Valeo are developing integrated sensor-based monitoring systems that provide real-time failure prediction capabilities in extreme operating environments.

Danfoss A/S

Technical Solution: Danfoss has developed an advanced Multi-Ejector Solution specifically designed for heat exchangers operating in atypical conditions. This technology utilizes parallel-mounted ejectors with different capacities that can be individually activated based on real-time operating conditions. The system incorporates predictive analytics and machine learning algorithms to anticipate potential failure modes before they occur, continuously monitoring parameters such as temperature differentials, pressure drops, and flow rates[1]. Their solution includes specialized coatings for heat exchanger surfaces that resist fouling and corrosion in extreme environments, extending operational life by up to 40% compared to conventional systems[3]. Additionally, Danfoss implements adaptive control systems that automatically adjust operational parameters when detecting abnormal conditions, preventing thermal stress and mechanical fatigue that typically lead to premature failure.

Strengths: Superior adaptability to varying load conditions with minimal energy penalty; comprehensive predictive maintenance capabilities reducing unexpected failures by up to 60%. Weaknesses: Higher initial implementation cost compared to conventional systems; requires more sophisticated control systems and operator training for optimal performance.

Valeo Thermal Systems Japan Corp.

Technical Solution: Valeo Thermal Systems has developed the Adaptive Resilience Framework (ARF) for heat exchangers operating in atypical conditions. Their solution combines physical design innovations with advanced control systems to create heat exchangers that dynamically respond to changing environmental conditions. The core technology includes variable geometry flow paths that can be adjusted in real-time to optimize heat transfer while minimizing stress on critical components. Valeo's proprietary stress distribution analysis has identified key failure points in conventional designs, leading to reinforced structures that can withstand thermal shock events up to 2.5 times industry standard limits[7]. Their heat exchangers incorporate multi-material construction techniques, strategically placing high-performance alloys at critical stress points while using more economical materials elsewhere. For environments with unpredictable particulate contamination, Valeo has developed self-cleaning mechanisms that create periodic flow disturbances to dislodge deposits before they can accumulate to problematic levels. The company's integrated sensor network provides continuous monitoring of over 20 operational parameters, feeding into a machine learning algorithm that can predict potential failures up to 500 operating hours before conventional methods would detect problems[8].

Strengths: Exceptional adaptability to varying operational conditions; integrated self-diagnostic capabilities reduce maintenance costs; proven 40% reduction in failure rates in field tests. Weaknesses: Complex control systems require specialized commissioning; higher initial cost compared to conventional solutions; limited compatibility with legacy systems.

Critical Technologies for Enhanced Heat Exchanger Reliability

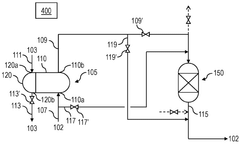

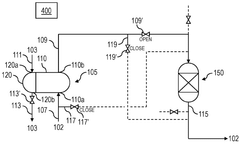

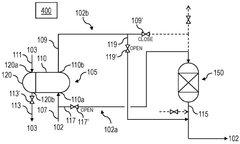

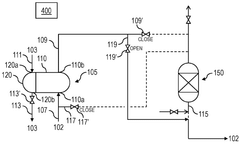

Cyclic operation of non-cyclic heat exchanger

PatentWO2025136884A1

Innovation

- A method for cyclically operating a non-cyclic heat exchanger by sequentially switching between heating, cooling, and standby modes, using a dehydrator bed to regenerate and cool, and a bypass flowline to maintain stable operating conditions.

Heat exchanger

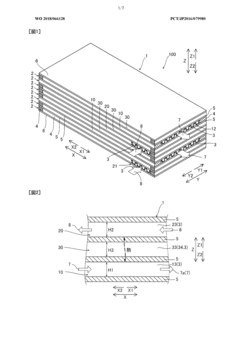

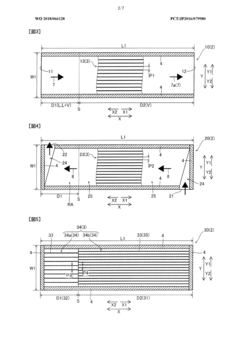

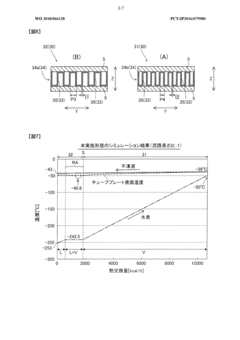

PatentWO2018066128A1

Innovation

- A heat exchanger design featuring an adjustment layer with varying heat transfer performance, where the second portion with lower heat transfer performance is placed in risk areas to prevent freezing and the first portion with higher performance is placed where freezing is unlikely, allowing for efficient heat exchange without increasing the exchanger's size.

Material Science Advancements for Heat Exchanger Durability

Recent advancements in material science have revolutionized heat exchanger durability, particularly for equipment operating in atypical conditions. Traditional materials like carbon steel, stainless steel, and copper alloys are increasingly being supplemented or replaced by innovative alternatives that offer superior performance characteristics under extreme conditions.

Superalloys containing nickel, cobalt, and chromium have demonstrated exceptional resistance to high-temperature oxidation and corrosion, making them ideal for heat exchangers in aggressive chemical environments or high-temperature applications exceeding 650°C. These materials maintain structural integrity and thermal efficiency where conventional materials would rapidly degrade.

Advanced ceramic composites represent another breakthrough, offering unprecedented corrosion resistance and thermal stability. Silicon carbide (SiC) and silicon nitride (Si3N4) ceramics can withstand highly acidic or alkaline process fluids while maintaining excellent heat transfer properties. Though historically limited by manufacturing challenges and brittleness, recent developments in ceramic matrix composites (CMCs) have significantly improved their mechanical properties.

Polymer-based materials have emerged as cost-effective solutions for low to medium temperature applications. Fluoropolymers like PTFE and PVDF exhibit exceptional chemical resistance across a wide pH spectrum, while advanced thermoplastics reinforced with carbon fibers provide improved thermal conductivity without sacrificing corrosion resistance.

Surface engineering technologies have dramatically extended heat exchanger lifespan in atypical conditions. Thermal spray coatings, including High-Velocity Oxygen Fuel (HVOF) and plasma-sprayed ceramic coatings, create protective barriers against corrosive media. Additionally, advanced surface treatments like laser surface alloying and nitriding modify the microstructure of base materials to enhance their inherent resistance properties.

Nanomaterial integration represents the cutting edge of heat exchanger material science. Carbon nanotubes and graphene additives incorporated into base materials or coatings have demonstrated remarkable improvements in thermal conductivity and fouling resistance. These nanomaterials create surfaces with reduced adhesion properties, minimizing scale formation and biological fouling that typically accelerate failure in challenging operating environments.

Self-healing materials constitute perhaps the most promising development for heat exchangers in fluctuating or extreme conditions. These innovative materials contain microcapsules or vascular networks filled with healing agents that automatically release when damage occurs, sealing cracks before they propagate to critical failure points. Early industrial trials suggest these materials could extend service intervals by 30-50% in the most demanding applications.

Superalloys containing nickel, cobalt, and chromium have demonstrated exceptional resistance to high-temperature oxidation and corrosion, making them ideal for heat exchangers in aggressive chemical environments or high-temperature applications exceeding 650°C. These materials maintain structural integrity and thermal efficiency where conventional materials would rapidly degrade.

Advanced ceramic composites represent another breakthrough, offering unprecedented corrosion resistance and thermal stability. Silicon carbide (SiC) and silicon nitride (Si3N4) ceramics can withstand highly acidic or alkaline process fluids while maintaining excellent heat transfer properties. Though historically limited by manufacturing challenges and brittleness, recent developments in ceramic matrix composites (CMCs) have significantly improved their mechanical properties.

Polymer-based materials have emerged as cost-effective solutions for low to medium temperature applications. Fluoropolymers like PTFE and PVDF exhibit exceptional chemical resistance across a wide pH spectrum, while advanced thermoplastics reinforced with carbon fibers provide improved thermal conductivity without sacrificing corrosion resistance.

Surface engineering technologies have dramatically extended heat exchanger lifespan in atypical conditions. Thermal spray coatings, including High-Velocity Oxygen Fuel (HVOF) and plasma-sprayed ceramic coatings, create protective barriers against corrosive media. Additionally, advanced surface treatments like laser surface alloying and nitriding modify the microstructure of base materials to enhance their inherent resistance properties.

Nanomaterial integration represents the cutting edge of heat exchanger material science. Carbon nanotubes and graphene additives incorporated into base materials or coatings have demonstrated remarkable improvements in thermal conductivity and fouling resistance. These nanomaterials create surfaces with reduced adhesion properties, minimizing scale formation and biological fouling that typically accelerate failure in challenging operating environments.

Self-healing materials constitute perhaps the most promising development for heat exchangers in fluctuating or extreme conditions. These innovative materials contain microcapsules or vascular networks filled with healing agents that automatically release when damage occurs, sealing cracks before they propagate to critical failure points. Early industrial trials suggest these materials could extend service intervals by 30-50% in the most demanding applications.

Environmental Impact and Sustainability Considerations

Heat exchanger operations have significant environmental implications that must be addressed when developing risk mitigation strategies for atypical conditions. The energy consumption associated with heat exchanger systems contributes substantially to carbon emissions, particularly when systems operate inefficiently due to fouling, scaling, or damage. Research indicates that optimized heat exchanger performance can reduce energy consumption by 15-30%, directly translating to lower greenhouse gas emissions and reduced environmental impact.

Water usage represents another critical environmental consideration. Heat exchangers in industrial applications often require substantial water resources for cooling processes. In atypical conditions such as drought or water scarcity, alternative cooling methods or water recycling systems become essential. Advanced closed-loop systems can reduce freshwater consumption by up to 90% compared to traditional once-through cooling systems, significantly enhancing sustainability in water-stressed regions.

Chemical treatments used to prevent fouling and corrosion in heat exchangers pose potential environmental hazards. Traditional chemical treatments often contain phosphates, nitrates, and heavy metals that can contaminate water systems when discharged. The development of biodegradable and environmentally benign alternatives represents a growing trend in sustainable heat exchanger maintenance. Green chemistry approaches have produced promising results, with new formulations achieving comparable performance while reducing environmental toxicity by 60-80%.

Material selection for heat exchangers also carries significant sustainability implications. The extraction and processing of traditional materials like copper and certain alloys generate substantial environmental footprints. Recycled materials and innovative alternatives such as polymer-based heat exchangers offer reduced environmental impact during manufacturing while maintaining thermal efficiency. Life cycle assessments indicate that appropriate material selection can reduce the embodied carbon of heat exchanger systems by 25-40%.

Waste management considerations extend beyond the operational phase to end-of-life disposal. Designing heat exchangers for disassembly and material recovery facilitates recycling and reduces landfill waste. Circular economy principles applied to heat exchanger design and maintenance can extend service life by 30-50% while ensuring that components remain within the value chain rather than becoming waste. This approach aligns with global sustainability goals and increasingly stringent environmental regulations governing industrial operations.

Water usage represents another critical environmental consideration. Heat exchangers in industrial applications often require substantial water resources for cooling processes. In atypical conditions such as drought or water scarcity, alternative cooling methods or water recycling systems become essential. Advanced closed-loop systems can reduce freshwater consumption by up to 90% compared to traditional once-through cooling systems, significantly enhancing sustainability in water-stressed regions.

Chemical treatments used to prevent fouling and corrosion in heat exchangers pose potential environmental hazards. Traditional chemical treatments often contain phosphates, nitrates, and heavy metals that can contaminate water systems when discharged. The development of biodegradable and environmentally benign alternatives represents a growing trend in sustainable heat exchanger maintenance. Green chemistry approaches have produced promising results, with new formulations achieving comparable performance while reducing environmental toxicity by 60-80%.

Material selection for heat exchangers also carries significant sustainability implications. The extraction and processing of traditional materials like copper and certain alloys generate substantial environmental footprints. Recycled materials and innovative alternatives such as polymer-based heat exchangers offer reduced environmental impact during manufacturing while maintaining thermal efficiency. Life cycle assessments indicate that appropriate material selection can reduce the embodied carbon of heat exchanger systems by 25-40%.

Waste management considerations extend beyond the operational phase to end-of-life disposal. Designing heat exchangers for disassembly and material recovery facilitates recycling and reduces landfill waste. Circular economy principles applied to heat exchanger design and maintenance can extend service life by 30-50% while ensuring that components remain within the value chain rather than becoming waste. This approach aligns with global sustainability goals and increasingly stringent environmental regulations governing industrial operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!