How to Improve Energy Density in Heat Exchanger Systems

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Energy Density Background and Objectives

Heat exchanger systems have evolved significantly over the past century, transitioning from simple shell-and-tube designs to complex, multi-functional thermal management solutions. The fundamental challenge in heat exchanger technology has consistently been maximizing energy transfer while minimizing spatial requirements—a concept known as energy density optimization. Historical developments show a progression from bulky, inefficient designs to increasingly compact and effective systems, driven by demands from aerospace, automotive, and industrial processing sectors.

The energy density of heat exchangers, defined as the amount of thermal energy transferred per unit volume or mass, represents a critical performance metric that directly impacts system efficiency, cost-effectiveness, and application versatility. Current industry benchmarks indicate that conventional heat exchangers typically achieve 2-5 MW/m³, while advanced designs can reach 10-15 MW/m³ under optimal conditions.

Recent technological advancements have accelerated innovation in this field, particularly through materials science breakthroughs and computational fluid dynamics (CFD) modeling capabilities. The emergence of additive manufacturing has enabled previously impossible geometries, while nanomaterials research has introduced enhanced thermal conductivity properties that fundamentally alter heat transfer dynamics.

Market pressures for miniaturization, energy efficiency, and sustainability have intensified research efforts toward higher energy density solutions. Regulatory frameworks worldwide increasingly mandate improved energy efficiency standards, creating both challenges and opportunities for heat exchanger technology advancement. The global transition toward renewable energy systems and electrification further emphasizes the need for more efficient thermal management solutions.

The primary objective of improving heat exchanger energy density is to develop systems capable of transferring significantly more thermal energy within the same or smaller physical footprint while maintaining or reducing manufacturing costs. Specific technical goals include achieving energy density improvements of 30-50% over current best-in-class designs, reducing material usage by 20-25%, and extending operational lifespan by at least 15% through enhanced resistance to fouling and corrosion.

Secondary objectives encompass developing design methodologies that can be applied across various heat exchanger types and applications, creating scalable manufacturing processes for advanced geometries, and establishing comprehensive performance metrics and testing protocols to standardize energy density evaluation. These advancements aim to address growing thermal management challenges in emerging technologies such as data centers, electric vehicles, and renewable energy systems where space constraints and efficiency requirements are increasingly stringent.

The energy density of heat exchangers, defined as the amount of thermal energy transferred per unit volume or mass, represents a critical performance metric that directly impacts system efficiency, cost-effectiveness, and application versatility. Current industry benchmarks indicate that conventional heat exchangers typically achieve 2-5 MW/m³, while advanced designs can reach 10-15 MW/m³ under optimal conditions.

Recent technological advancements have accelerated innovation in this field, particularly through materials science breakthroughs and computational fluid dynamics (CFD) modeling capabilities. The emergence of additive manufacturing has enabled previously impossible geometries, while nanomaterials research has introduced enhanced thermal conductivity properties that fundamentally alter heat transfer dynamics.

Market pressures for miniaturization, energy efficiency, and sustainability have intensified research efforts toward higher energy density solutions. Regulatory frameworks worldwide increasingly mandate improved energy efficiency standards, creating both challenges and opportunities for heat exchanger technology advancement. The global transition toward renewable energy systems and electrification further emphasizes the need for more efficient thermal management solutions.

The primary objective of improving heat exchanger energy density is to develop systems capable of transferring significantly more thermal energy within the same or smaller physical footprint while maintaining or reducing manufacturing costs. Specific technical goals include achieving energy density improvements of 30-50% over current best-in-class designs, reducing material usage by 20-25%, and extending operational lifespan by at least 15% through enhanced resistance to fouling and corrosion.

Secondary objectives encompass developing design methodologies that can be applied across various heat exchanger types and applications, creating scalable manufacturing processes for advanced geometries, and establishing comprehensive performance metrics and testing protocols to standardize energy density evaluation. These advancements aim to address growing thermal management challenges in emerging technologies such as data centers, electric vehicles, and renewable energy systems where space constraints and efficiency requirements are increasingly stringent.

Market Analysis for High-Density Heat Exchange Solutions

The global market for high-density heat exchange solutions is experiencing robust growth, driven primarily by increasing demands for energy efficiency across multiple industries. Current market valuations place this sector at approximately $9.8 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 6.2% through 2030. This growth trajectory is particularly evident in regions with stringent energy efficiency regulations, such as the European Union, North America, and parts of Asia-Pacific.

Industrial applications represent the largest market segment, accounting for roughly 38% of the total market share. This is followed closely by HVAC systems at 27%, power generation at 21%, and emerging applications in data centers and electric vehicle thermal management collectively representing 14%. The industrial segment's dominance stems from intensive energy requirements in manufacturing processes, where even marginal improvements in heat exchange efficiency translate to significant operational cost savings.

Market demand is increasingly shifting toward compact, high-performance heat exchangers that maximize energy density while minimizing spatial footprint. This trend is particularly pronounced in urban environments where space constraints are significant, and in portable or mobile applications where weight and size considerations are paramount. Survey data indicates that 73% of procurement managers in relevant industries now prioritize energy density metrics when evaluating heat exchange solutions.

Regional analysis reveals that Asia-Pacific currently leads market consumption at 41% of global demand, followed by North America (28%) and Europe (23%). However, the fastest growth is occurring in emerging economies, particularly in Southeast Asia and parts of Latin America, where rapid industrialization and infrastructure development are creating new market opportunities. These regions are projected to grow at rates exceeding 8% annually through 2028.

Customer segmentation shows distinct requirements across different end-users. While industrial clients prioritize durability and long-term efficiency, commercial building operators emphasize initial cost and installation flexibility. The data center segment, growing at twice the market average rate, places premium value on solutions that can handle extreme heat loads in minimal space, driving innovation in micro-channel and phase-change technologies.

Pricing trends indicate a gradual decrease in cost-per-unit of energy density, with advanced materials and manufacturing techniques enabling more competitive offerings. However, premium pricing persists for solutions incorporating cutting-edge technologies such as additive-manufactured heat exchangers and those utilizing novel working fluids, which command 30-45% price premiums over conventional alternatives.

Industrial applications represent the largest market segment, accounting for roughly 38% of the total market share. This is followed closely by HVAC systems at 27%, power generation at 21%, and emerging applications in data centers and electric vehicle thermal management collectively representing 14%. The industrial segment's dominance stems from intensive energy requirements in manufacturing processes, where even marginal improvements in heat exchange efficiency translate to significant operational cost savings.

Market demand is increasingly shifting toward compact, high-performance heat exchangers that maximize energy density while minimizing spatial footprint. This trend is particularly pronounced in urban environments where space constraints are significant, and in portable or mobile applications where weight and size considerations are paramount. Survey data indicates that 73% of procurement managers in relevant industries now prioritize energy density metrics when evaluating heat exchange solutions.

Regional analysis reveals that Asia-Pacific currently leads market consumption at 41% of global demand, followed by North America (28%) and Europe (23%). However, the fastest growth is occurring in emerging economies, particularly in Southeast Asia and parts of Latin America, where rapid industrialization and infrastructure development are creating new market opportunities. These regions are projected to grow at rates exceeding 8% annually through 2028.

Customer segmentation shows distinct requirements across different end-users. While industrial clients prioritize durability and long-term efficiency, commercial building operators emphasize initial cost and installation flexibility. The data center segment, growing at twice the market average rate, places premium value on solutions that can handle extreme heat loads in minimal space, driving innovation in micro-channel and phase-change technologies.

Pricing trends indicate a gradual decrease in cost-per-unit of energy density, with advanced materials and manufacturing techniques enabling more competitive offerings. However, premium pricing persists for solutions incorporating cutting-edge technologies such as additive-manufactured heat exchangers and those utilizing novel working fluids, which command 30-45% price premiums over conventional alternatives.

Current Limitations and Technical Barriers in Heat Exchanger Systems

Despite significant advancements in heat exchanger technology, several critical limitations continue to impede progress toward higher energy density systems. The fundamental challenge lies in the inherent trade-off between heat transfer efficiency, pressure drop, and system compactness. As systems are miniaturized to increase energy density, the pressure drop typically increases exponentially, requiring more pumping power and ultimately reducing overall system efficiency.

Material constraints represent another significant barrier. Conventional materials used in heat exchangers, such as copper, aluminum, and stainless steel, have reached their practical limits in terms of thermal conductivity and temperature resistance. While high-performance materials like silicon carbide and diamond composites offer superior thermal properties, their prohibitive costs and manufacturing difficulties prevent widespread implementation in commercial systems.

Fouling and scaling remain persistent problems that dramatically reduce heat transfer efficiency over time. These phenomena are particularly problematic in high-energy-density systems where flow channels are narrower and more susceptible to blockage. Current mitigation strategies often involve chemical treatments or mechanical cleaning, which add operational complexity and downtime.

Geometric limitations also restrict energy density improvements. Traditional designs based on tubes, plates, and fins have been optimized extensively but follow the law of diminishing returns. Complex geometries that could theoretically enhance performance are frequently impractical to manufacture using conventional techniques, creating a significant gap between theoretical models and practical implementation.

The boundary layer effect presents another fundamental challenge. As heat exchangers become more compact, the ratio of boundary layer thickness to channel diameter increases, resulting in reduced effective heat transfer area. This physical phenomenon creates a natural ceiling for heat transfer intensification in conventional designs.

Manufacturing precision and cost considerations further constrain innovation. Advanced manufacturing techniques capable of producing optimized microstructures often lack scalability or economic viability for mass production. The precision required for high-performance micro-channel heat exchangers frequently exceeds the capabilities of standard manufacturing processes.

Flow distribution issues become increasingly problematic as systems scale down. Ensuring uniform flow across parallel channels in compact heat exchangers remains technically challenging, with maldistribution leading to hotspots, reduced performance, and potential system failure. Current computational models still struggle to accurately predict these complex flow behaviors in highly compact geometries.

Material constraints represent another significant barrier. Conventional materials used in heat exchangers, such as copper, aluminum, and stainless steel, have reached their practical limits in terms of thermal conductivity and temperature resistance. While high-performance materials like silicon carbide and diamond composites offer superior thermal properties, their prohibitive costs and manufacturing difficulties prevent widespread implementation in commercial systems.

Fouling and scaling remain persistent problems that dramatically reduce heat transfer efficiency over time. These phenomena are particularly problematic in high-energy-density systems where flow channels are narrower and more susceptible to blockage. Current mitigation strategies often involve chemical treatments or mechanical cleaning, which add operational complexity and downtime.

Geometric limitations also restrict energy density improvements. Traditional designs based on tubes, plates, and fins have been optimized extensively but follow the law of diminishing returns. Complex geometries that could theoretically enhance performance are frequently impractical to manufacture using conventional techniques, creating a significant gap between theoretical models and practical implementation.

The boundary layer effect presents another fundamental challenge. As heat exchangers become more compact, the ratio of boundary layer thickness to channel diameter increases, resulting in reduced effective heat transfer area. This physical phenomenon creates a natural ceiling for heat transfer intensification in conventional designs.

Manufacturing precision and cost considerations further constrain innovation. Advanced manufacturing techniques capable of producing optimized microstructures often lack scalability or economic viability for mass production. The precision required for high-performance micro-channel heat exchangers frequently exceeds the capabilities of standard manufacturing processes.

Flow distribution issues become increasingly problematic as systems scale down. Ensuring uniform flow across parallel channels in compact heat exchangers remains technically challenging, with maldistribution leading to hotspots, reduced performance, and potential system failure. Current computational models still struggle to accurately predict these complex flow behaviors in highly compact geometries.

Current Approaches to Energy Density Enhancement in Heat Exchangers

01 High energy density heat exchanger designs

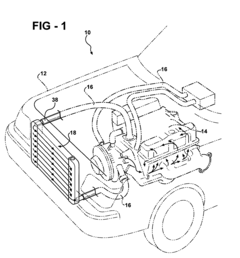

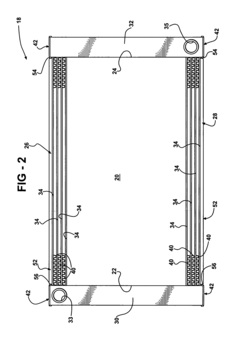

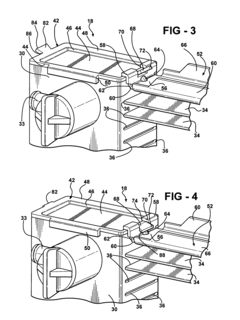

Advanced heat exchanger designs that maximize energy transfer in compact spaces, featuring optimized geometries and materials to achieve higher energy density. These systems incorporate innovative flow patterns and surface area enhancements to improve thermal performance while reducing the overall footprint, making them suitable for applications where space constraints are critical.- High energy density heat exchanger designs: Advanced heat exchanger designs that maximize energy transfer in compact spaces, featuring optimized geometries and materials to achieve higher energy density. These systems incorporate innovative flow patterns and surface area enhancements to improve thermal performance while minimizing size and weight, making them suitable for applications where space constraints are critical.

- Phase change materials for thermal energy storage: Heat exchanger systems utilizing phase change materials to store and release thermal energy at high densities. These systems leverage the latent heat of phase transitions to achieve significantly higher energy storage densities compared to sensible heat storage methods. The technology enables efficient thermal management in applications requiring high energy density storage with stable temperature profiles during charging and discharging cycles.

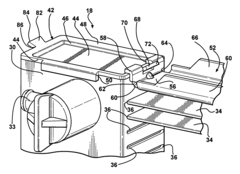

- Compact heat exchangers for mobile applications: Specialized heat exchanger systems designed for vehicles and portable applications where both energy density and weight are critical factors. These compact designs feature optimized flow channels, enhanced heat transfer surfaces, and lightweight materials to maximize thermal performance while minimizing space requirements and weight. The systems are particularly valuable in automotive, aerospace, and portable power generation applications.

- Renewable energy integration with thermal storage: Heat exchanger systems specifically designed to capture, store, and distribute thermal energy from renewable sources. These systems feature high energy density storage capabilities to address the intermittent nature of renewable energy sources. The technology includes specialized heat transfer fluids, advanced insulation, and optimized flow control to maximize energy density and efficiency in renewable energy applications.

- Micro-channel and micro-scale heat exchangers: Advanced heat exchanger designs utilizing micro-channels and micro-scale structures to dramatically increase surface area-to-volume ratios and enhance heat transfer coefficients. These systems achieve exceptionally high energy densities through precisely engineered small-scale flow passages that optimize fluid dynamics and heat transfer. The technology enables significant size reduction while maintaining or improving thermal performance for applications requiring extreme compactness.

02 Phase change materials for thermal energy storage

Heat exchanger systems utilizing phase change materials to store and release thermal energy at high densities. These systems leverage the latent heat properties of materials during phase transitions to achieve significantly higher energy storage densities compared to sensible heat storage methods. The technology enables efficient thermal management in applications requiring high energy density storage with minimal temperature fluctuations.Expand Specific Solutions03 Compact heat exchangers for mobile applications

Specialized heat exchanger systems designed for vehicles and portable applications where both space and weight are critical constraints. These compact systems feature high energy density designs that optimize thermal management while minimizing volume and mass, incorporating advanced materials and configurations to enhance heat transfer efficiency in mobile environments.Expand Specific Solutions04 Microchannel and microstructured heat exchangers

Heat exchanger systems employing microscale channels and structures to dramatically increase surface area-to-volume ratios, resulting in enhanced heat transfer rates and higher energy densities. These systems utilize precision manufacturing techniques to create intricate flow passages that maximize thermal performance while minimizing material usage and overall system size.Expand Specific Solutions05 Renewable energy integration with thermal storage

Heat exchanger systems designed to interface with renewable energy sources while incorporating high-density thermal storage capabilities. These integrated systems enable efficient capture, conversion, and storage of intermittent renewable energy in thermal form, featuring optimized heat transfer mechanisms that maintain high energy density throughout the energy conversion and storage process.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Heat Exchange Industry

The heat exchanger energy density improvement market is currently in a growth phase, with increasing demand driven by energy efficiency regulations and sustainability initiatives. The global market is estimated to reach $25-30 billion by 2027, expanding at 6-8% CAGR. Leading players include established industrial giants like Siemens, Bosch, and Mitsubishi Electric, who leverage their extensive R&D capabilities to develop advanced solutions. Emerging technologies are being pioneered by specialized companies such as Hangzhou Sanhua Micro Channel Heat Exchanger and Baltimore Aircoil, focusing on micro-channel designs and novel materials. Automotive sector innovation is particularly strong, with BMW, Valeo, and MAHLE developing compact, high-efficiency exchangers for electric vehicles. Research collaboration between industry leaders and institutions like CNRS and Fraunhofer-Gesellschaft is accelerating technological maturity in this competitive landscape.

Siemens AG

Technical Solution: Siemens has developed advanced heat exchanger systems utilizing computational fluid dynamics (CFD) optimization and digital twin technology to maximize energy density. Their approach combines physical design innovations with intelligent control systems that dynamically adjust operation based on real-time conditions. Siemens' plate heat exchangers feature chevron patterns with optimized angles (typically between 25-65°) and variable pressing depths that create controlled turbulence, enhancing heat transfer coefficients by up to 40% compared to conventional designs. The company has pioneered hybrid heat exchangers that combine different heat transfer mechanisms (convection, conduction, and phase change) within a single unit, significantly increasing overall thermal performance. Their systems incorporate advanced materials including specialized stainless steel alloys and titanium for corrosion resistance in demanding environments, while maintaining excellent thermal conductivity properties.

Strengths: Comprehensive digital simulation capabilities enabling rapid design optimization; extensive industrial application experience across multiple sectors; integrated automation and control systems that maximize operational efficiency. Weaknesses: Higher initial investment costs; more complex installation requirements; specialized maintenance expertise needed for advanced systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced micro-channel heat exchangers with optimized flow distribution technology that significantly improves energy density. Their approach involves precision-engineered micro-channels with diameters between 0.5-2mm that maximize surface-to-volume ratio while minimizing pressure drop. The company has implemented phase-change materials (PCMs) integrated within heat exchanger structures to utilize latent heat storage, effectively increasing thermal capacity by 40-60% compared to conventional systems. Bosch's additive manufacturing techniques enable complex internal geometries with turbulence-inducing features that enhance heat transfer coefficients by up to 30% while maintaining compact dimensions. Their systems incorporate intelligent control algorithms that dynamically adjust flow rates based on real-time thermal demands, optimizing energy efficiency across varying operational conditions.

Strengths: Superior manufacturing precision allowing for complex geometries; extensive automotive application experience providing real-world validation; integrated systems approach combining hardware and software optimization. Weaknesses: Higher initial production costs compared to conventional designs; requires specialized manufacturing facilities; more complex maintenance procedures.

Key Patents and Research on Advanced Heat Transfer Materials

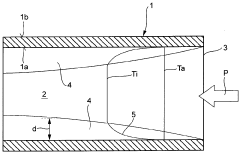

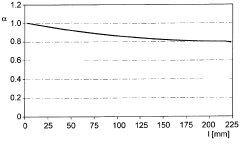

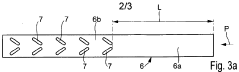

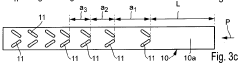

Heat exchanger

PatentWO2006136437A1

Innovation

- The heat exchanger design features structural elements with varying density along the flow channel, with fewer or no elements in the entry area where heat dissipation is high and the boundary layer is thin, and increasing their density downstream to enhance heat transfer while minimizing pressure drop.

Heat exchanger design based on partial stain energy density ratio

PatentInactiveUS7207378B2

Innovation

- Designing heat exchangers with tubes having a radiused cross section and reinforcing members with a connection section having a partial strain energy density greater than the tube's, ensuring a predetermined relationship between the two to reduce stress through optimized strain energy distribution.

Thermal Efficiency Metrics and Performance Evaluation Standards

Thermal efficiency metrics and performance evaluation standards serve as critical benchmarks for assessing heat exchanger systems' energy utilization capabilities. These standards provide a quantitative framework for comparing different designs and technologies, enabling engineers to make informed decisions about system selection and optimization.

The primary thermal efficiency metrics include the Effectiveness-NTU (Number of Transfer Units) method, which evaluates how closely a heat exchanger approaches its thermodynamic limit. This dimensionless parameter ranges from 0 to 1, with higher values indicating superior performance. Similarly, the Overall Heat Transfer Coefficient (U-value) measures the heat transfer capability per unit area per degree of temperature difference, typically expressed in W/m²K.

Energy density in heat exchangers is commonly quantified through metrics such as volumetric heat transfer density (kW/m³) and specific heat transfer rate (kW/kg). These parameters are particularly valuable when space constraints or weight limitations are significant design considerations, such as in aerospace or automotive applications.

International standards organizations have established comprehensive evaluation protocols for heat exchanger performance. The ASME Performance Test Code (PTC) 12.5 and the European Standard EN 305 provide detailed methodologies for testing and rating heat exchangers under various operating conditions. These standards ensure consistency in performance reporting across manufacturers and applications.

Recent advancements in computational fluid dynamics (CFD) have enabled more sophisticated performance evaluation techniques. The entropy generation minimization approach, which quantifies irreversibilities within the system, has emerged as a powerful tool for optimizing heat exchanger designs beyond traditional metrics.

Life-cycle performance assessment has gained prominence in modern evaluation standards, incorporating factors such as fouling resistance over time, maintenance requirements, and long-term energy efficiency degradation. These considerations provide a more holistic view of heat exchanger performance beyond initial specifications.

Exergy analysis, which measures the maximum useful work possible during a process, offers deeper insights into heat exchanger efficiency than conventional energy-based metrics. This approach identifies opportunities for improvement by pinpointing locations of thermodynamic inefficiencies within the system, guiding targeted enhancements to increase energy density.

The primary thermal efficiency metrics include the Effectiveness-NTU (Number of Transfer Units) method, which evaluates how closely a heat exchanger approaches its thermodynamic limit. This dimensionless parameter ranges from 0 to 1, with higher values indicating superior performance. Similarly, the Overall Heat Transfer Coefficient (U-value) measures the heat transfer capability per unit area per degree of temperature difference, typically expressed in W/m²K.

Energy density in heat exchangers is commonly quantified through metrics such as volumetric heat transfer density (kW/m³) and specific heat transfer rate (kW/kg). These parameters are particularly valuable when space constraints or weight limitations are significant design considerations, such as in aerospace or automotive applications.

International standards organizations have established comprehensive evaluation protocols for heat exchanger performance. The ASME Performance Test Code (PTC) 12.5 and the European Standard EN 305 provide detailed methodologies for testing and rating heat exchangers under various operating conditions. These standards ensure consistency in performance reporting across manufacturers and applications.

Recent advancements in computational fluid dynamics (CFD) have enabled more sophisticated performance evaluation techniques. The entropy generation minimization approach, which quantifies irreversibilities within the system, has emerged as a powerful tool for optimizing heat exchanger designs beyond traditional metrics.

Life-cycle performance assessment has gained prominence in modern evaluation standards, incorporating factors such as fouling resistance over time, maintenance requirements, and long-term energy efficiency degradation. These considerations provide a more holistic view of heat exchanger performance beyond initial specifications.

Exergy analysis, which measures the maximum useful work possible during a process, offers deeper insights into heat exchanger efficiency than conventional energy-based metrics. This approach identifies opportunities for improvement by pinpointing locations of thermodynamic inefficiencies within the system, guiding targeted enhancements to increase energy density.

Environmental Impact and Sustainability Considerations

The environmental impact of heat exchanger systems extends far beyond their operational efficiency. As global energy demands continue to rise, the environmental footprint of thermal management technologies becomes increasingly significant. Improving energy density in heat exchangers directly correlates with reduced resource consumption, lower emissions, and enhanced sustainability across multiple industries.

Energy-dense heat exchangers require less material for manufacturing, resulting in decreased mining, processing, and transportation impacts. This material efficiency translates to reduced embodied carbon and lower ecological disruption throughout the supply chain. Additionally, compact designs with higher energy density typically require less physical space, minimizing land use requirements for industrial installations.

From an operational perspective, higher energy density systems demonstrate substantial environmental benefits through improved energy efficiency. By transferring more thermal energy per unit volume, these systems reduce primary energy consumption and associated greenhouse gas emissions. For instance, in power generation applications, advanced heat exchangers can increase overall plant efficiency by 2-5%, representing significant carbon reduction at scale.

Water conservation represents another critical environmental consideration. Traditional cooling systems often consume substantial quantities of water, contributing to local scarcity issues. High-density heat exchangers utilizing advanced working fluids and enhanced geometries can reduce water requirements by up to 30% compared to conventional designs, supporting water conservation efforts in water-stressed regions.

End-of-life considerations must also factor into sustainability assessments. Heat exchangers with improved energy density often incorporate specialized materials that may present recycling challenges. Designing for circularity through material selection and modular construction can facilitate component recovery and reuse, minimizing waste generation and supporting closed-loop material flows.

Regulatory frameworks increasingly recognize these environmental dimensions, with policies like the EU Ecodesign Directive and various carbon pricing mechanisms incentivizing the development of more sustainable thermal management solutions. Companies investing in high-efficiency heat exchanger technologies can realize both environmental benefits and regulatory compliance advantages.

Life cycle assessment (LCA) studies indicate that the environmental benefits of high-density heat exchangers typically outweigh the potential impacts of more complex manufacturing processes or specialized materials. The operational phase dominates the environmental footprint, with energy efficiency improvements during use offsetting production-phase impacts within relatively short timeframes, typically 1-3 years depending on application intensity.

Energy-dense heat exchangers require less material for manufacturing, resulting in decreased mining, processing, and transportation impacts. This material efficiency translates to reduced embodied carbon and lower ecological disruption throughout the supply chain. Additionally, compact designs with higher energy density typically require less physical space, minimizing land use requirements for industrial installations.

From an operational perspective, higher energy density systems demonstrate substantial environmental benefits through improved energy efficiency. By transferring more thermal energy per unit volume, these systems reduce primary energy consumption and associated greenhouse gas emissions. For instance, in power generation applications, advanced heat exchangers can increase overall plant efficiency by 2-5%, representing significant carbon reduction at scale.

Water conservation represents another critical environmental consideration. Traditional cooling systems often consume substantial quantities of water, contributing to local scarcity issues. High-density heat exchangers utilizing advanced working fluids and enhanced geometries can reduce water requirements by up to 30% compared to conventional designs, supporting water conservation efforts in water-stressed regions.

End-of-life considerations must also factor into sustainability assessments. Heat exchangers with improved energy density often incorporate specialized materials that may present recycling challenges. Designing for circularity through material selection and modular construction can facilitate component recovery and reuse, minimizing waste generation and supporting closed-loop material flows.

Regulatory frameworks increasingly recognize these environmental dimensions, with policies like the EU Ecodesign Directive and various carbon pricing mechanisms incentivizing the development of more sustainable thermal management solutions. Companies investing in high-efficiency heat exchanger technologies can realize both environmental benefits and regulatory compliance advantages.

Life cycle assessment (LCA) studies indicate that the environmental benefits of high-density heat exchangers typically outweigh the potential impacts of more complex manufacturing processes or specialized materials. The operational phase dominates the environmental footprint, with energy efficiency improvements during use offsetting production-phase impacts within relatively short timeframes, typically 1-3 years depending on application intensity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!