Crankshaft vs Supercharger: Boost Efficiency

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Forced Induction Evolution and Objectives

Forced induction systems have evolved significantly since their inception in the early 20th century, transforming from rudimentary mechanical designs to sophisticated electronic-controlled systems that optimize engine performance. The historical trajectory began with aircraft engines during World War I, where superchargers were employed to maintain power at high altitudes. By the 1920s, these technologies migrated to automotive applications, with Mercedes-Benz introducing the first production supercharged car in 1921.

The evolution of forced induction technology accelerated during the 1970s and 1980s, driven by fuel efficiency concerns following global oil crises. This period marked a pivotal shift from superchargers to turbochargers in mainstream automotive applications, as manufacturers sought to balance performance with fuel economy. The 1990s witnessed further refinement with the introduction of variable geometry turbochargers and electronic boost control systems, enabling more precise management of forced induction.

In recent years, the development focus has shifted toward addressing the inherent limitations of both crankshaft-driven superchargers and exhaust-driven turbochargers. Engineers have been working to minimize the parasitic power loss associated with superchargers while reducing the turbo lag characteristic of turbochargers. This has led to innovations such as twin-scroll turbochargers, electric superchargers, and hybrid boosting systems that combine multiple technologies.

The primary objective of modern forced induction research is to optimize the efficiency of power delivery across the entire engine operating range. This includes minimizing energy losses in the conversion process, reducing thermal inefficiencies, and ensuring responsive power delivery without compromising fuel economy. Specifically for crankshaft-driven systems versus superchargers, the goal is to determine which technology provides superior volumetric efficiency under various operating conditions.

Another critical objective is to enhance compatibility with emerging engine technologies, particularly in the context of increasingly stringent emissions regulations. This includes developing forced induction systems that work harmoniously with direct injection, variable valve timing, and cylinder deactivation technologies to maximize both performance and efficiency.

Looking forward, the industry aims to integrate forced induction systems with electrification strategies. This includes developing electrically-assisted turbochargers and superchargers that can provide instant boost without the traditional drawbacks of mechanical systems. The ultimate goal is to create intelligent boosting systems that can adapt in real-time to driving conditions, engine load, and efficiency requirements, representing the next frontier in forced induction technology.

The evolution of forced induction technology accelerated during the 1970s and 1980s, driven by fuel efficiency concerns following global oil crises. This period marked a pivotal shift from superchargers to turbochargers in mainstream automotive applications, as manufacturers sought to balance performance with fuel economy. The 1990s witnessed further refinement with the introduction of variable geometry turbochargers and electronic boost control systems, enabling more precise management of forced induction.

In recent years, the development focus has shifted toward addressing the inherent limitations of both crankshaft-driven superchargers and exhaust-driven turbochargers. Engineers have been working to minimize the parasitic power loss associated with superchargers while reducing the turbo lag characteristic of turbochargers. This has led to innovations such as twin-scroll turbochargers, electric superchargers, and hybrid boosting systems that combine multiple technologies.

The primary objective of modern forced induction research is to optimize the efficiency of power delivery across the entire engine operating range. This includes minimizing energy losses in the conversion process, reducing thermal inefficiencies, and ensuring responsive power delivery without compromising fuel economy. Specifically for crankshaft-driven systems versus superchargers, the goal is to determine which technology provides superior volumetric efficiency under various operating conditions.

Another critical objective is to enhance compatibility with emerging engine technologies, particularly in the context of increasingly stringent emissions regulations. This includes developing forced induction systems that work harmoniously with direct injection, variable valve timing, and cylinder deactivation technologies to maximize both performance and efficiency.

Looking forward, the industry aims to integrate forced induction systems with electrification strategies. This includes developing electrically-assisted turbochargers and superchargers that can provide instant boost without the traditional drawbacks of mechanical systems. The ultimate goal is to create intelligent boosting systems that can adapt in real-time to driving conditions, engine load, and efficiency requirements, representing the next frontier in forced induction technology.

Market Analysis for Performance Enhancement Systems

The performance enhancement systems market has witnessed substantial growth over the past decade, driven primarily by increasing consumer demand for improved vehicle performance without sacrificing fuel efficiency. The global market for automotive performance enhancement systems was valued at approximately $10.1 billion in 2022 and is projected to reach $15.3 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2%.

Within this market, forced induction systems—specifically crankshaft-driven superchargers and exhaust-driven turbochargers—hold a significant share, accounting for nearly 38% of the total market value. The supercharger segment specifically generated revenues of $2.1 billion in 2022, with centrifugal superchargers (a variant of crankshaft-driven systems) showing the fastest growth at 8.5% annually.

Consumer demographics reveal interesting patterns in market demand. Performance enthusiasts aged 25-45 represent the primary consumer base, accounting for 65% of aftermarket performance enhancement purchases. Additionally, OEM integration of factory-installed forced induction systems has increased by 47% since 2018, indicating mainstream acceptance of these technologies beyond just the enthusiast market.

Regional analysis shows North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (21%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by increasing disposable income and growing automotive culture in countries like China, South Korea, and India.

Market segmentation by vehicle type reveals that performance enhancement systems for passenger vehicles dominate with 73% market share, followed by commercial vehicles (18%) and motorsports applications (9%). Within the passenger vehicle segment, mid-range sports cars and performance-oriented SUVs represent the fastest-growing sub-segments.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at 12.4% annually, outpacing traditional dealership and specialty shop channels. This shift reflects changing consumer purchasing behaviors and increased technical knowledge among end-users.

Key market drivers include stricter emission regulations pushing manufacturers toward more efficient forced induction solutions, rising consumer preference for vehicles with higher power-to-weight ratios, and technological advancements enabling better integration of electronic control systems with mechanical components. The growing trend of downsizing engines while maintaining or improving performance metrics has particularly benefited supercharger technologies that can provide immediate boost without turbo lag.

Within this market, forced induction systems—specifically crankshaft-driven superchargers and exhaust-driven turbochargers—hold a significant share, accounting for nearly 38% of the total market value. The supercharger segment specifically generated revenues of $2.1 billion in 2022, with centrifugal superchargers (a variant of crankshaft-driven systems) showing the fastest growth at 8.5% annually.

Consumer demographics reveal interesting patterns in market demand. Performance enthusiasts aged 25-45 represent the primary consumer base, accounting for 65% of aftermarket performance enhancement purchases. Additionally, OEM integration of factory-installed forced induction systems has increased by 47% since 2018, indicating mainstream acceptance of these technologies beyond just the enthusiast market.

Regional analysis shows North America leading with 42% market share, followed by Europe (31%) and Asia-Pacific (21%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by increasing disposable income and growing automotive culture in countries like China, South Korea, and India.

Market segmentation by vehicle type reveals that performance enhancement systems for passenger vehicles dominate with 73% market share, followed by commercial vehicles (18%) and motorsports applications (9%). Within the passenger vehicle segment, mid-range sports cars and performance-oriented SUVs represent the fastest-growing sub-segments.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at 12.4% annually, outpacing traditional dealership and specialty shop channels. This shift reflects changing consumer purchasing behaviors and increased technical knowledge among end-users.

Key market drivers include stricter emission regulations pushing manufacturers toward more efficient forced induction solutions, rising consumer preference for vehicles with higher power-to-weight ratios, and technological advancements enabling better integration of electronic control systems with mechanical components. The growing trend of downsizing engines while maintaining or improving performance metrics has particularly benefited supercharger technologies that can provide immediate boost without turbo lag.

Current Supercharging Technologies and Limitations

Supercharging technology has evolved significantly over the past decades, with several distinct types dominating the market today. Mechanical superchargers, including Roots-type, twin-screw, and centrifugal designs, each offer unique performance characteristics. Roots-type superchargers, the oldest design, provide immediate boost but suffer from lower thermal efficiency due to internal compression. Twin-screw superchargers offer improved efficiency through internal compression but come with higher manufacturing costs and complexity. Centrifugal superchargers deliver excellent high-RPM performance but lag at lower engine speeds, creating a noticeable boost threshold.

Electric superchargers have emerged as a promising alternative, eliminating parasitic power loss from the crankshaft by utilizing electric motors powered by the vehicle's electrical system. This technology offers instantaneous boost and improved low-end torque without the traditional mechanical drawbacks, though it requires robust electrical architecture to support high power demands.

Despite technological advancements, superchargers face several inherent limitations. The most significant challenge remains parasitic power loss, with mechanical superchargers typically consuming 15-30% of the power they generate. This inefficiency directly impacts fuel economy, creating a performance-efficiency tradeoff that manufacturers must carefully balance. Additionally, heat generation presents another major limitation, as compressed air temperatures can exceed 200°F, reducing air density and limiting power potential without effective intercooling systems.

Packaging constraints also pose significant challenges for supercharger implementation. The bulky nature of supercharger systems, particularly when including necessary intercoolers and associated plumbing, creates design complications in modern engine compartments where space is increasingly limited. This often necessitates compromises in component placement or hood design modifications.

Noise, vibration, and harshness (NVH) characteristics remain problematic for certain supercharger designs. While some enthusiasts appreciate the distinctive whine of Roots-type superchargers, this noise can be undesirable in luxury or mainstream applications where refinement is prioritized. Twin-screw designs offer quieter operation but still generate more noise than naturally aspirated engines.

Cost considerations represent another significant limitation, with supercharger systems adding substantial manufacturing expense. This cost premium must be justified through performance benefits or market positioning, limiting widespread adoption across vehicle segments. The complexity of these systems also increases maintenance requirements and potential reliability concerns over the vehicle's lifetime.

Recent technological innovations have begun addressing these limitations through advanced materials, improved manufacturing techniques, and hybrid electric-mechanical designs. Variable-ratio superchargers and electronically controlled bypass systems are emerging as solutions to improve part-load efficiency, though these add further complexity and cost to already sophisticated systems.

Electric superchargers have emerged as a promising alternative, eliminating parasitic power loss from the crankshaft by utilizing electric motors powered by the vehicle's electrical system. This technology offers instantaneous boost and improved low-end torque without the traditional mechanical drawbacks, though it requires robust electrical architecture to support high power demands.

Despite technological advancements, superchargers face several inherent limitations. The most significant challenge remains parasitic power loss, with mechanical superchargers typically consuming 15-30% of the power they generate. This inefficiency directly impacts fuel economy, creating a performance-efficiency tradeoff that manufacturers must carefully balance. Additionally, heat generation presents another major limitation, as compressed air temperatures can exceed 200°F, reducing air density and limiting power potential without effective intercooling systems.

Packaging constraints also pose significant challenges for supercharger implementation. The bulky nature of supercharger systems, particularly when including necessary intercoolers and associated plumbing, creates design complications in modern engine compartments where space is increasingly limited. This often necessitates compromises in component placement or hood design modifications.

Noise, vibration, and harshness (NVH) characteristics remain problematic for certain supercharger designs. While some enthusiasts appreciate the distinctive whine of Roots-type superchargers, this noise can be undesirable in luxury or mainstream applications where refinement is prioritized. Twin-screw designs offer quieter operation but still generate more noise than naturally aspirated engines.

Cost considerations represent another significant limitation, with supercharger systems adding substantial manufacturing expense. This cost premium must be justified through performance benefits or market positioning, limiting widespread adoption across vehicle segments. The complexity of these systems also increases maintenance requirements and potential reliability concerns over the vehicle's lifetime.

Recent technological innovations have begun addressing these limitations through advanced materials, improved manufacturing techniques, and hybrid electric-mechanical designs. Variable-ratio superchargers and electronically controlled bypass systems are emerging as solutions to improve part-load efficiency, though these add further complexity and cost to already sophisticated systems.

Technical Comparison of Crankshaft and Supercharger Systems

01 Crankshaft design optimization for supercharged engines

Specialized crankshaft designs can significantly improve the efficiency of supercharged engines. These designs include modified counterweights, optimized journal configurations, and improved bearing surfaces that can better handle the increased loads from supercharging. By reducing rotational mass and friction, these crankshafts allow engines to accelerate more quickly and operate more efficiently under boost conditions, ultimately improving fuel economy and power output.- Crankshaft design optimization for supercharged engines: Specialized crankshaft designs can significantly improve the efficiency of supercharged engines. These designs include modified counterweights, optimized journal bearings, and crankshaft geometry that reduces rotational mass while maintaining structural integrity. Such modifications help manage the increased loads from supercharging while minimizing parasitic losses, resulting in improved power delivery and fuel efficiency.

- Supercharger drive mechanisms and integration: Various drive mechanisms can be employed to optimize the connection between the crankshaft and supercharger. These include direct drive systems, gear-driven arrangements, belt drives with optimized ratios, and electronically controlled variable-speed drives. Proper integration of these systems reduces parasitic losses and ensures the supercharger operates at optimal speeds across different engine operating conditions.

- Variable boost control systems: Advanced control systems can dynamically adjust supercharger boost levels based on engine load, speed, and environmental conditions. These systems incorporate electronic controllers, bypass valves, variable geometry components, and sensors to optimize boost pressure. By providing precisely the right amount of boost at the right time, these systems maximize efficiency while preventing engine damage from excessive boost.

- Thermal management for supercharged systems: Effective thermal management is crucial for maintaining efficiency in supercharged engines. This includes intercooling systems to reduce charge air temperature, oil cooling systems for the supercharger bearings, and integrated cooling passages in the supercharger housing. These thermal management solutions help maintain optimal operating temperatures, improving volumetric efficiency and reducing the risk of detonation.

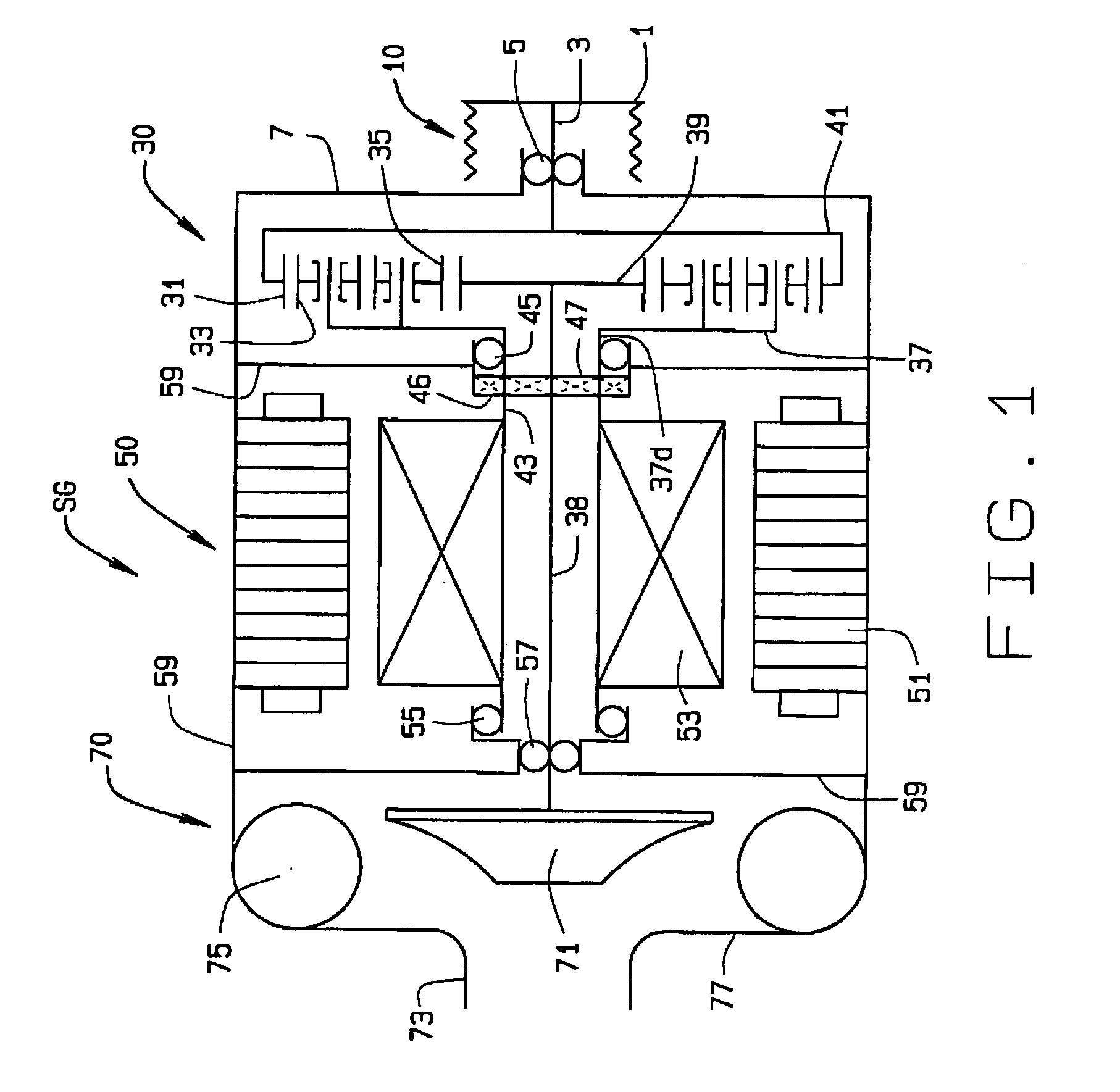

- Hybrid supercharging configurations: Innovative hybrid supercharging systems combine different boosting technologies to maximize efficiency across the entire operating range. These include twin-charging setups (supercharger plus turbocharger), electrically assisted superchargers, and multi-stage boosting arrangements. Such configurations help eliminate lag, provide immediate throttle response at low RPM, and maintain efficient boost at higher engine speeds.

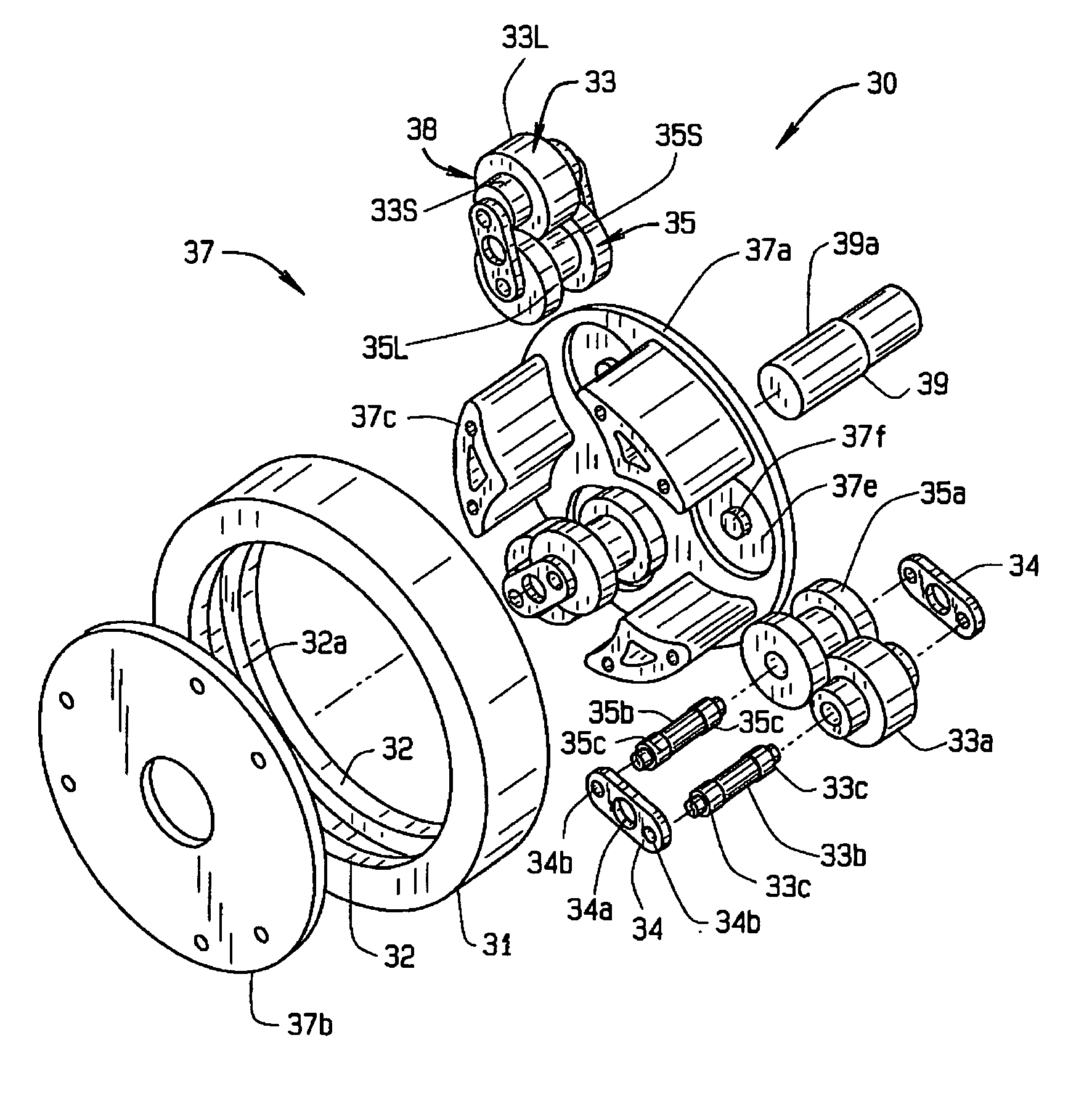

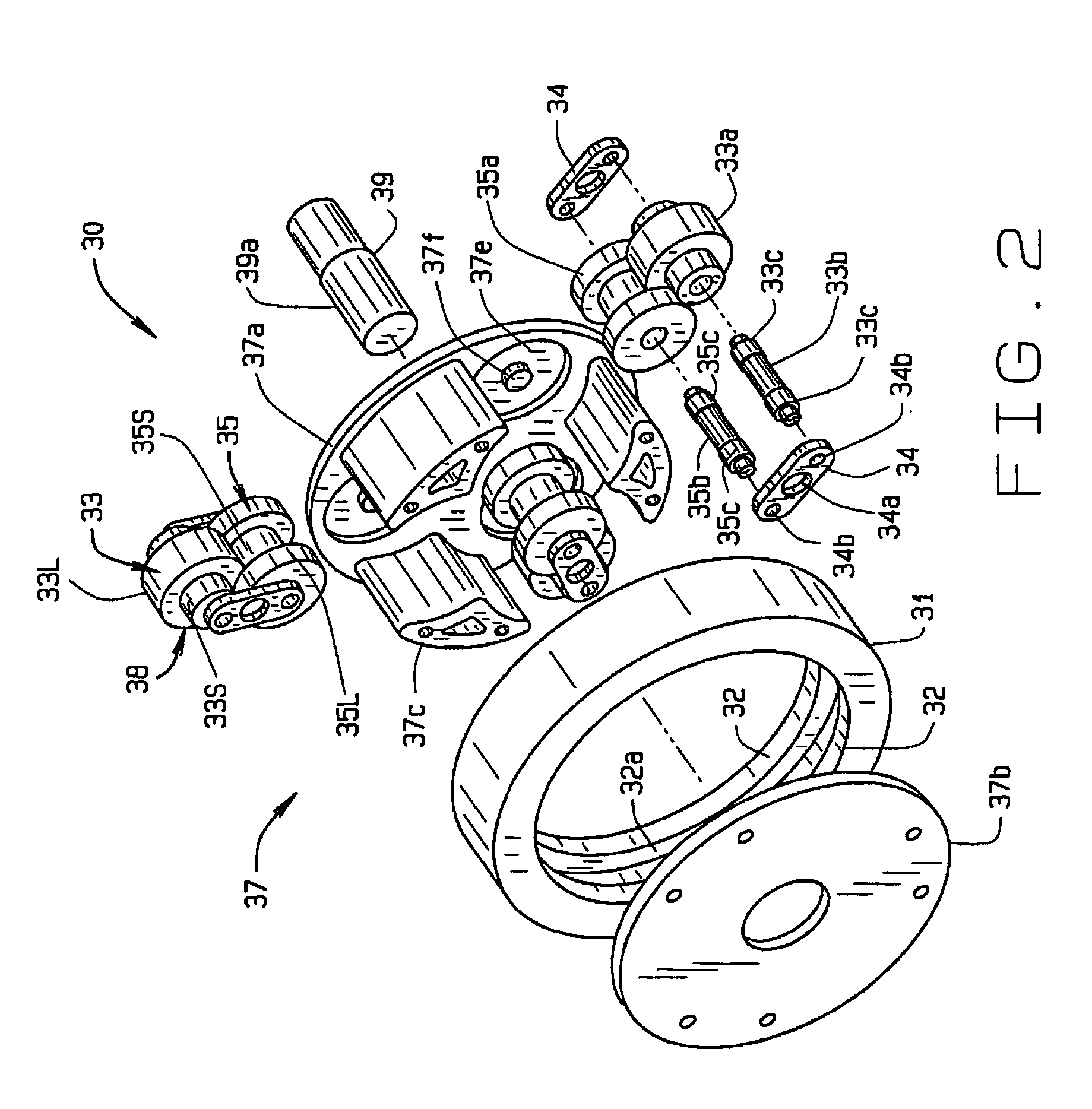

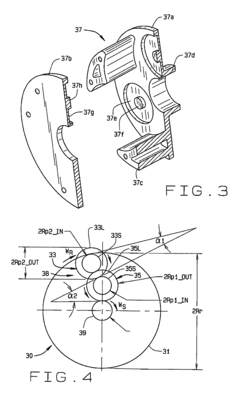

02 Supercharger drive mechanisms and pulley systems

Advanced drive mechanisms connecting the crankshaft to the supercharger can significantly enhance boost efficiency. These systems include variable-ratio pulleys, clutch mechanisms, and gear-driven setups that optimize the relationship between engine RPM and supercharger speed. By ensuring the supercharger operates at its most efficient speed across the engine's power band, these systems maximize boost pressure while minimizing parasitic power losses, resulting in improved overall engine efficiency.Expand Specific Solutions03 Electronic control systems for boost management

Sophisticated electronic control systems can dynamically manage supercharger operation based on engine conditions. These systems monitor parameters such as throttle position, engine load, and temperature to adjust boost pressure accordingly. By incorporating sensors on both the crankshaft and supercharger, these control systems can optimize boost timing and pressure, prevent over-boosting, and ensure efficient power delivery across all operating conditions, resulting in improved fuel economy and engine longevity.Expand Specific Solutions04 Integrated cooling and lubrication systems

Enhanced cooling and lubrication systems specifically designed for supercharged engines can significantly improve efficiency. These systems include dedicated oil circuits, improved heat exchangers, and specialized coolant routing that address the increased thermal loads generated by supercharging. By maintaining optimal operating temperatures for both the crankshaft bearings and supercharger components, these systems reduce friction, prevent heat-related power losses, and extend component life under high-boost conditions.Expand Specific Solutions05 Hybrid supercharging systems with multiple boost sources

Innovative hybrid supercharging systems combine multiple boost sources to maximize efficiency across the entire RPM range. These systems may integrate a mechanically-driven supercharger with an electrically-assisted component or turbocharger to provide immediate low-end torque while maintaining high-end power. By reducing the load on the crankshaft at specific operating points and optimizing boost delivery, these hybrid systems minimize parasitic losses while maximizing power output and responsiveness throughout the engine's operating range.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The crankshaft vs supercharger efficiency competition is evolving in a maturing market with significant growth potential, driven by increasing demand for fuel-efficient and high-performance engines. The technology landscape shows varying levels of maturity, with established automotive giants like Ford, Mazda, and Honda leveraging traditional expertise while specialized players such as SuperTurbo Technologies and BRP-Rotax focus on innovation. Component manufacturers including Eaton, Bosch, and Timken provide critical supporting technologies. The competitive dynamics are further shaped by regional players from Asia, particularly Chinese manufacturers like BYD and Chery, who are rapidly advancing their capabilities. Market differentiation occurs through proprietary designs, materials science advancements, and integration with emerging powertrain technologies.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced EcoBoost technology that combines turbocharging with direct injection to deliver significant performance improvements from smaller displacement engines. Their crankshaft design incorporates specialized counterweights and bearing surfaces to handle increased loads from forced induction. Ford's PowerBoost hybrid system integrates with their turbocharging technology to provide enhanced efficiency. Their latest patents show innovations in variable geometry turbochargers that adjust boost pressure based on engine load conditions, optimizing power delivery across the RPM range. Ford has also developed advanced electronic control systems that precisely manage boost pressure to maximize efficiency while minimizing turbo lag, a common issue with traditional turbocharging systems.

Strengths: Ford's EcoBoost technology delivers excellent power-to-efficiency ratio, with smaller engines producing power comparable to larger naturally aspirated engines while consuming less fuel. Their integrated electronic control systems minimize turbo lag. Weaknesses: Their systems typically require premium fuel for optimal performance, and the complex turbocharging systems can add maintenance costs over the vehicle lifetime.

Eaton Corp.

Technical Solution: Eaton has pioneered the development of Twin Vortices Series (TVS) supercharger technology, representing a significant advancement in Roots-type positive displacement superchargers. Their TVS superchargers feature twisted four-lobe rotors with 160-degree twists that provide greater thermal efficiency, higher volumetric capacity, and reduced noise compared to traditional designs. Eaton's supercharger technology delivers immediate throttle response with boost available from very low RPM, eliminating the lag associated with turbochargers. Their latest generation TVS R2650 supercharger can support over 700 horsepower in aftermarket applications while maintaining excellent low-end torque. Eaton has also developed integrated bypass valve systems that reduce parasitic losses during cruising conditions, addressing one of the traditional efficiency drawbacks of superchargers.

Strengths: Eaton's superchargers provide instant throttle response with no lag, consistent power delivery across the RPM range, and simpler installation compared to turbocharging systems. Their designs are highly reliable with minimal maintenance requirements. Weaknesses: Despite improvements, superchargers still create some parasitic drag on the engine, reducing efficiency during normal driving conditions, and they generally provide less maximum boost than turbocharging systems at high RPMs.

Key Patents and Innovations in Boost Technology

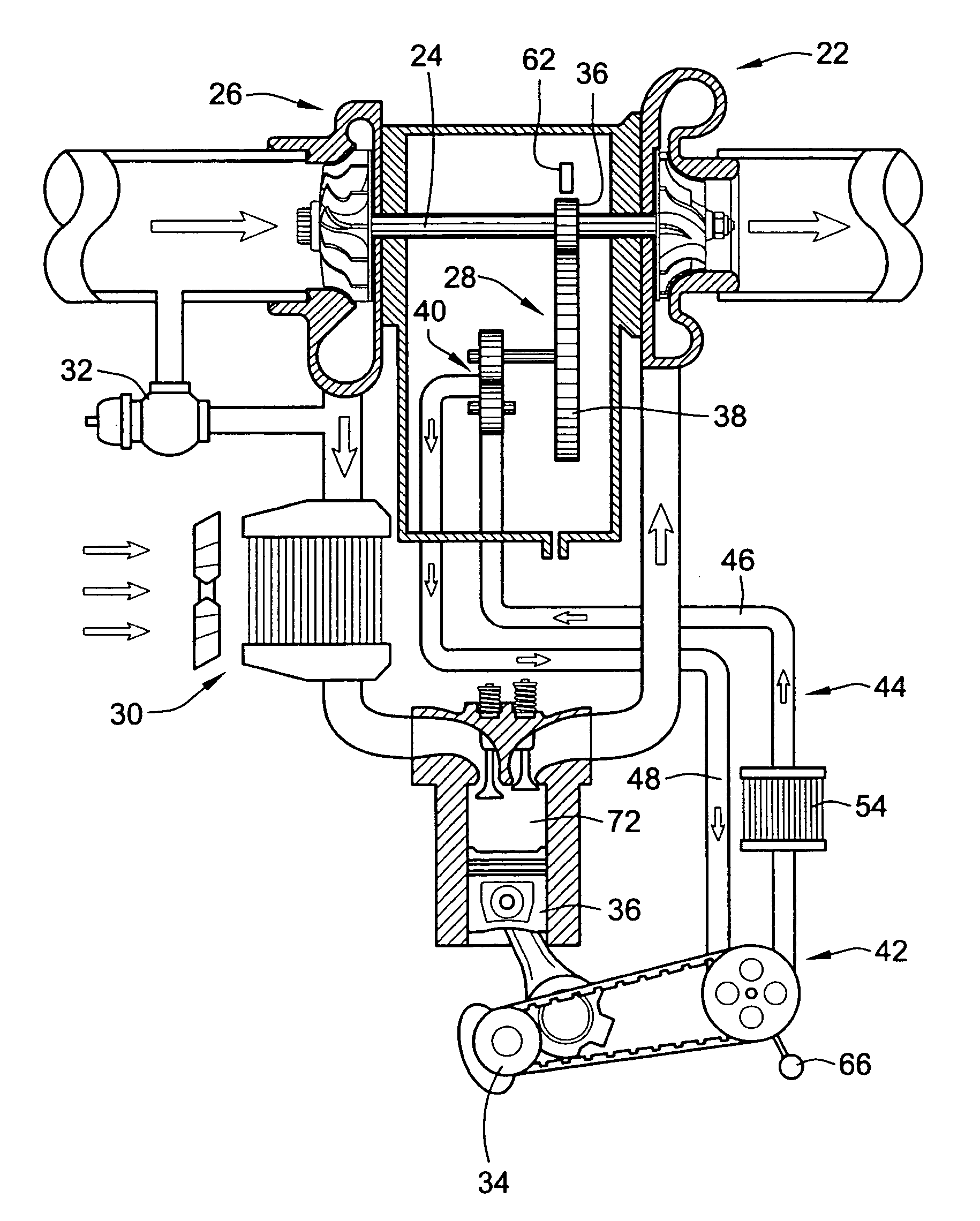

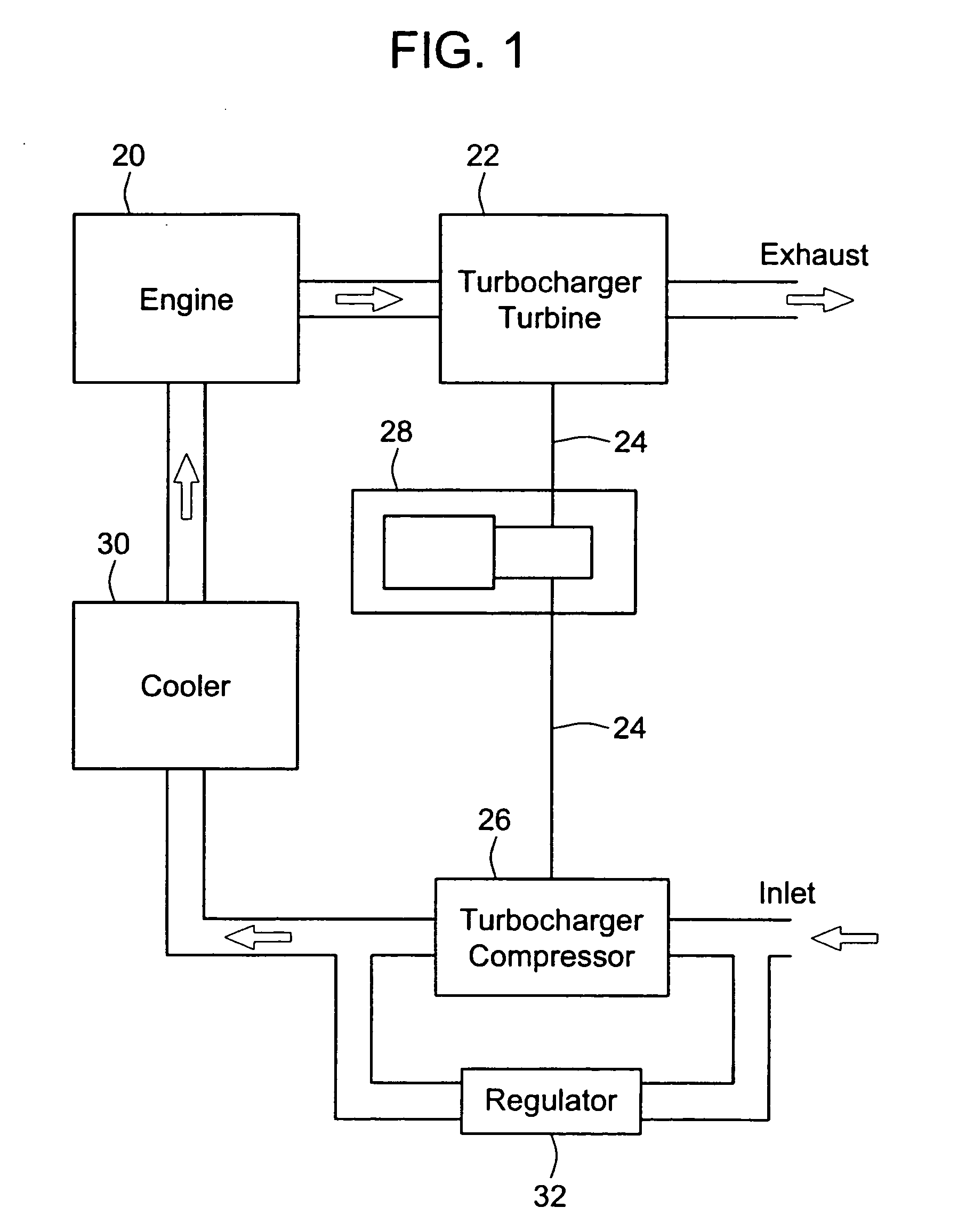

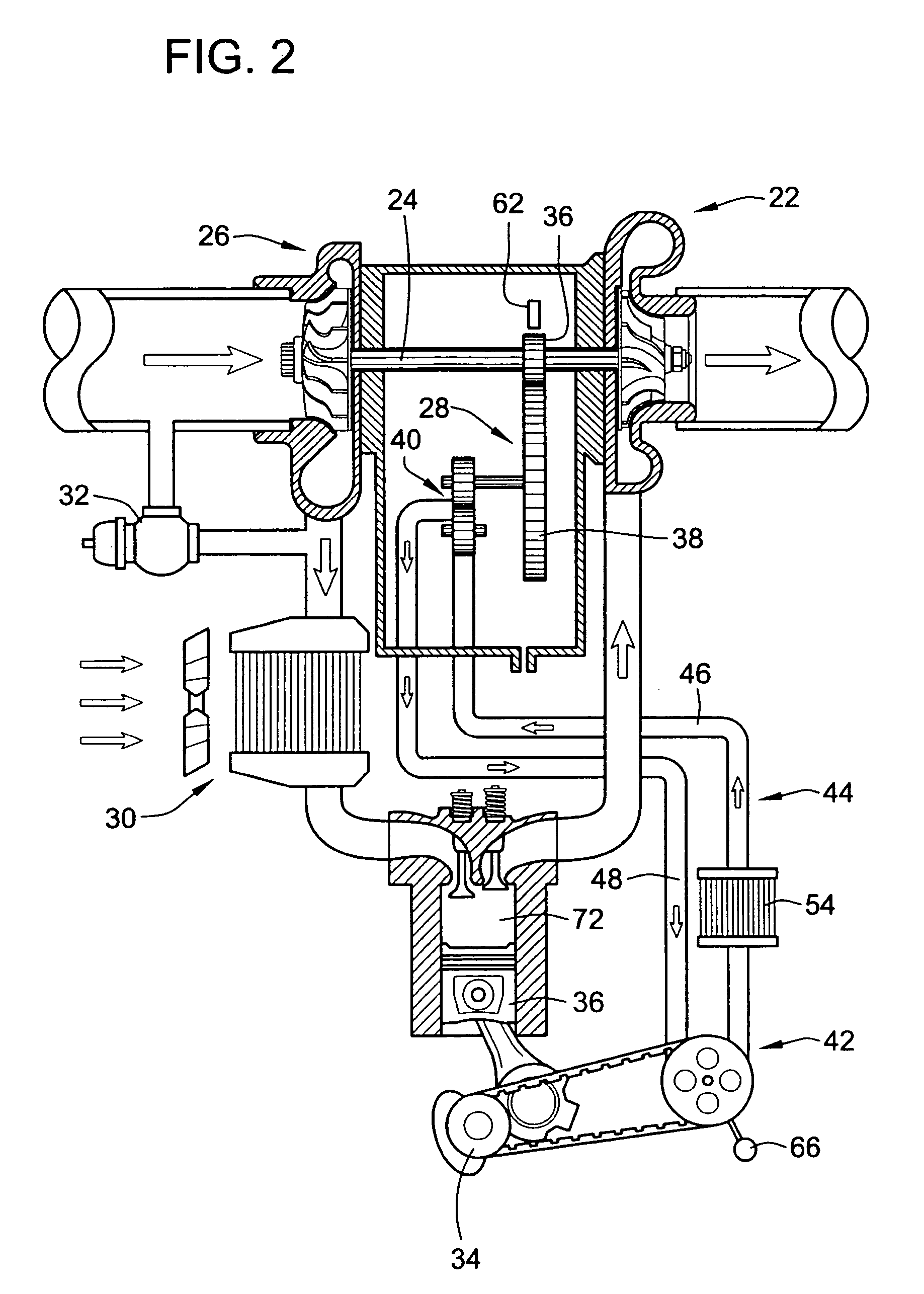

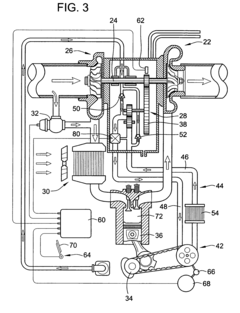

Super-turbocharger

PatentInactiveUS20060032225A1

Innovation

- A super-turbocharger system that combines a turbocharger and supercharger using a hydraulic pump to drive the turbocharger to specific speeds, recovering excess energy to turn the crankshaft and maintaining optimal speed, eliminating the need for wastegates and incorporating a power take-off mechanism with a variable speed transmission and planetary gear system.

Variable Speed Supercharger With Electric Power Generation

PatentActiveUS20100050998A1

Innovation

- An electro-mechanical variable speed supercharger that combines a supercharger and an alternator, utilizing a three-branch planetary friction drive with an electric machine to provide controllable boost-on-demand operation and intelligent electric power generation, allowing for three operating modes to optimize engine performance across all speed ranges.

Environmental Impact and Emissions Considerations

The environmental implications of engine boosting technologies have become increasingly significant in the automotive industry's pursuit of sustainability. When comparing crankshaft-driven systems versus superchargers, emissions considerations play a crucial role in determining overall efficiency beyond mere performance metrics.

Superchargers, particularly the mechanical variants directly driven by the crankshaft, introduce additional load on the engine, potentially increasing fuel consumption during normal driving conditions. This translates to higher carbon dioxide (CO2) emissions per kilometer traveled compared to naturally aspirated engines operating under similar conditions. However, modern electronic clutch systems that disengage the supercharger during cruising have significantly mitigated this disadvantage.

Conversely, crankshaft optimization technologies focus on reducing internal friction and improving combustion efficiency, which inherently produces fewer emissions across the operating range. The reduced parasitic losses in advanced crankshaft designs contribute to lower fuel consumption and consequently decreased greenhouse gas emissions, particularly in urban driving cycles where stop-start conditions prevail.

Nitrogen oxide (NOx) emissions present another critical environmental consideration. Supercharged engines typically operate at higher temperatures, potentially increasing NOx formation during combustion. Manufacturers have addressed this challenge through advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technologies, though these add complexity and cost to the overall system.

Particulate matter emissions also differ between these technologies. Supercharged direct-injection engines may produce higher particulate emissions under certain load conditions due to increased fuel pressure and altered air-fuel mixing dynamics. This has prompted the development of gasoline particulate filters (GPFs) similar to those used in diesel applications.

From a lifecycle assessment perspective, manufacturing impacts must also be considered. Supercharger systems require additional components including the compressor unit, intercooler, and associated plumbing, representing increased material usage and manufacturing energy. Advanced crankshaft technologies, while requiring precision manufacturing, generally involve fewer additional components and associated environmental impacts.

Regulatory frameworks worldwide are increasingly stringent regarding emissions standards, with Euro 7, China 6b, and California LEV III pushing manufacturers toward cleaner solutions. This regulatory landscape favors technologies that can deliver performance while minimizing environmental impact, creating a complex optimization challenge for engineers balancing boost efficiency against emissions compliance.

The recyclability of components presents another environmental dimension, with aluminum supercharger housings offering better end-of-life recovery potential compared to composite materials sometimes used in modern engine components. This circular economy consideration is becoming increasingly important as automotive sustainability metrics expand beyond tailpipe emissions to encompass the entire product lifecycle.

Superchargers, particularly the mechanical variants directly driven by the crankshaft, introduce additional load on the engine, potentially increasing fuel consumption during normal driving conditions. This translates to higher carbon dioxide (CO2) emissions per kilometer traveled compared to naturally aspirated engines operating under similar conditions. However, modern electronic clutch systems that disengage the supercharger during cruising have significantly mitigated this disadvantage.

Conversely, crankshaft optimization technologies focus on reducing internal friction and improving combustion efficiency, which inherently produces fewer emissions across the operating range. The reduced parasitic losses in advanced crankshaft designs contribute to lower fuel consumption and consequently decreased greenhouse gas emissions, particularly in urban driving cycles where stop-start conditions prevail.

Nitrogen oxide (NOx) emissions present another critical environmental consideration. Supercharged engines typically operate at higher temperatures, potentially increasing NOx formation during combustion. Manufacturers have addressed this challenge through advanced exhaust gas recirculation (EGR) systems and selective catalytic reduction (SCR) technologies, though these add complexity and cost to the overall system.

Particulate matter emissions also differ between these technologies. Supercharged direct-injection engines may produce higher particulate emissions under certain load conditions due to increased fuel pressure and altered air-fuel mixing dynamics. This has prompted the development of gasoline particulate filters (GPFs) similar to those used in diesel applications.

From a lifecycle assessment perspective, manufacturing impacts must also be considered. Supercharger systems require additional components including the compressor unit, intercooler, and associated plumbing, representing increased material usage and manufacturing energy. Advanced crankshaft technologies, while requiring precision manufacturing, generally involve fewer additional components and associated environmental impacts.

Regulatory frameworks worldwide are increasingly stringent regarding emissions standards, with Euro 7, China 6b, and California LEV III pushing manufacturers toward cleaner solutions. This regulatory landscape favors technologies that can deliver performance while minimizing environmental impact, creating a complex optimization challenge for engineers balancing boost efficiency against emissions compliance.

The recyclability of components presents another environmental dimension, with aluminum supercharger housings offering better end-of-life recovery potential compared to composite materials sometimes used in modern engine components. This circular economy consideration is becoming increasingly important as automotive sustainability metrics expand beyond tailpipe emissions to encompass the entire product lifecycle.

Cost-Benefit Analysis of Implementation Options

When evaluating implementation options for crankshaft versus supercharger technologies, financial considerations play a crucial role in decision-making processes. Initial investment costs for supercharger systems typically range from $2,000 to $7,500, depending on system complexity and brand reputation. This represents a significant premium over traditional crankshaft modifications, which generally cost between $800 and $3,000. However, this analysis must extend beyond purchase price to include installation expenses, which average 8-12 labor hours for supercharger systems compared to 5-7 hours for crankshaft upgrades.

Operational efficiency creates notable long-term financial implications. Superchargers consume approximately 15-20% of engine power to operate, resulting in a fuel economy reduction of 2-3 MPG under normal driving conditions. This translates to approximately $400-600 in additional fuel costs annually for average drivers. Conversely, optimized crankshaft designs can improve engine efficiency by 3-5% in specific RPM ranges, potentially offsetting their implementation costs within 2-3 years through fuel savings.

Maintenance requirements further differentiate these technologies economically. Supercharger systems require specialized maintenance every 50,000-75,000 miles, including oil changes and belt replacements, averaging $300-500 per service interval. Crankshafts, being passive mechanical components, typically require minimal maintenance beyond standard engine care, representing significant lifetime savings.

Performance benefits must be quantified against costs. Superchargers deliver immediate power increases of 30-50% across the RPM range, enhancing vehicle marketability and user experience. This performance premium commands approximately 15-25% higher resale values for supercharged vehicles compared to naturally aspirated counterparts. Crankshaft optimizations offer more modest 5-15% performance improvements, primarily in specific operating ranges, with correspondingly smaller impacts on resale value.

Reliability factors significantly impact total ownership costs. Supercharger systems introduce additional failure points, with repair costs averaging $1,200-2,500 for major component failures. These systems carry typical warranty periods of 1-3 years. Properly engineered crankshafts demonstrate excellent durability, with failure rates below 2% within 100,000 miles when professionally installed, resulting in lower warranty claim expenses and reduced downtime costs for fleet operators.

Environmental compliance considerations increasingly influence implementation decisions. Supercharger systems may require additional emissions equipment costing $500-1,200 to maintain regulatory compliance in stringent markets. Crankshaft optimizations typically maintain original emissions profiles, avoiding these supplementary expenses while potentially qualifying for efficiency incentives in certain jurisdictions.

Operational efficiency creates notable long-term financial implications. Superchargers consume approximately 15-20% of engine power to operate, resulting in a fuel economy reduction of 2-3 MPG under normal driving conditions. This translates to approximately $400-600 in additional fuel costs annually for average drivers. Conversely, optimized crankshaft designs can improve engine efficiency by 3-5% in specific RPM ranges, potentially offsetting their implementation costs within 2-3 years through fuel savings.

Maintenance requirements further differentiate these technologies economically. Supercharger systems require specialized maintenance every 50,000-75,000 miles, including oil changes and belt replacements, averaging $300-500 per service interval. Crankshafts, being passive mechanical components, typically require minimal maintenance beyond standard engine care, representing significant lifetime savings.

Performance benefits must be quantified against costs. Superchargers deliver immediate power increases of 30-50% across the RPM range, enhancing vehicle marketability and user experience. This performance premium commands approximately 15-25% higher resale values for supercharged vehicles compared to naturally aspirated counterparts. Crankshaft optimizations offer more modest 5-15% performance improvements, primarily in specific operating ranges, with correspondingly smaller impacts on resale value.

Reliability factors significantly impact total ownership costs. Supercharger systems introduce additional failure points, with repair costs averaging $1,200-2,500 for major component failures. These systems carry typical warranty periods of 1-3 years. Properly engineered crankshafts demonstrate excellent durability, with failure rates below 2% within 100,000 miles when professionally installed, resulting in lower warranty claim expenses and reduced downtime costs for fleet operators.

Environmental compliance considerations increasingly influence implementation decisions. Supercharger systems may require additional emissions equipment costing $500-1,200 to maintain regulatory compliance in stringent markets. Crankshaft optimizations typically maintain original emissions profiles, avoiding these supplementary expenses while potentially qualifying for efficiency incentives in certain jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!