CSACs For Defence Applications: Certification And Compliance Paths

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Technology Background and Defense Objectives

Chip-Scale Atomic Clocks (CSACs) represent a revolutionary advancement in precision timing technology, miniaturizing atomic clock capabilities into semiconductor-sized packages. Developed initially through DARPA's Chip-Scale Atomic Clock program in the early 2000s, these devices have evolved from laboratory curiosities to deployable defense technologies. CSACs utilize the quantum properties of atoms, typically cesium or rubidium, to maintain extraordinarily precise time measurements with stability reaching 10^-11 over one hour, far surpassing traditional quartz oscillators.

The evolution of CSAC technology has been driven by the increasing demand for autonomous operation in defense systems where GPS may be unavailable or compromised. From early prototypes consuming several watts of power and occupying substantial volume, modern CSACs have achieved power consumption below 120 mW and volumes under 16 cm³, enabling integration into portable military equipment and small unmanned systems.

For defense applications, CSACs serve critical timing and synchronization functions across multiple domains. In communications, they enable frequency-hopping spread spectrum techniques that enhance security against jamming and interception. For navigation systems, they provide holdover capabilities during GPS denial scenarios, maintaining positional accuracy for extended periods. In electronic warfare, precise timing enables coordinated operations and signal intelligence activities.

The technical objectives for defense-oriented CSACs focus on several key parameters: further size reduction to enable integration in increasingly compact platforms; improved power efficiency to extend operational duration in field conditions; enhanced environmental resilience to withstand extreme temperatures, shock, and vibration encountered in combat environments; and radiation hardening for space-based applications.

Beyond performance metrics, defense objectives include establishing standardized certification pathways that address the unique requirements of military systems. This includes developing testing protocols that verify performance under battlefield conditions and ensuring compliance with military standards such as MIL-STD-810 for environmental engineering considerations and MIL-STD-461 for electromagnetic compatibility.

Strategic defense goals also encompass supply chain security, as CSACs contain components that may be subject to export controls or vulnerable to foreign manipulation. Developing domestic manufacturing capabilities and secure supply chains has become a priority for defense departments globally, particularly as CSACs become integral to critical military systems including secure communications networks, precision-guided munitions, and autonomous platforms.

The convergence of quantum physics, microelectronics, and defense requirements continues to drive CSAC innovation, with research focusing on alternative atomic species, novel interrogation techniques, and integrated photonics to further enhance performance while meeting the stringent demands of defense applications.

The evolution of CSAC technology has been driven by the increasing demand for autonomous operation in defense systems where GPS may be unavailable or compromised. From early prototypes consuming several watts of power and occupying substantial volume, modern CSACs have achieved power consumption below 120 mW and volumes under 16 cm³, enabling integration into portable military equipment and small unmanned systems.

For defense applications, CSACs serve critical timing and synchronization functions across multiple domains. In communications, they enable frequency-hopping spread spectrum techniques that enhance security against jamming and interception. For navigation systems, they provide holdover capabilities during GPS denial scenarios, maintaining positional accuracy for extended periods. In electronic warfare, precise timing enables coordinated operations and signal intelligence activities.

The technical objectives for defense-oriented CSACs focus on several key parameters: further size reduction to enable integration in increasingly compact platforms; improved power efficiency to extend operational duration in field conditions; enhanced environmental resilience to withstand extreme temperatures, shock, and vibration encountered in combat environments; and radiation hardening for space-based applications.

Beyond performance metrics, defense objectives include establishing standardized certification pathways that address the unique requirements of military systems. This includes developing testing protocols that verify performance under battlefield conditions and ensuring compliance with military standards such as MIL-STD-810 for environmental engineering considerations and MIL-STD-461 for electromagnetic compatibility.

Strategic defense goals also encompass supply chain security, as CSACs contain components that may be subject to export controls or vulnerable to foreign manipulation. Developing domestic manufacturing capabilities and secure supply chains has become a priority for defense departments globally, particularly as CSACs become integral to critical military systems including secure communications networks, precision-guided munitions, and autonomous platforms.

The convergence of quantum physics, microelectronics, and defense requirements continues to drive CSAC innovation, with research focusing on alternative atomic species, novel interrogation techniques, and integrated photonics to further enhance performance while meeting the stringent demands of defense applications.

Defense Market Requirements Analysis for CSACs

The defense market for Chip Scale Atomic Clocks (CSACs) is characterized by stringent requirements that significantly exceed those of commercial applications. This specialized market demands exceptional performance metrics across multiple dimensions, with reliability and precision being paramount concerns for mission-critical military operations.

Timing accuracy requirements in defense applications typically demand performance in the range of 1×10^-10 to 1×10^-12, significantly more precise than commercial standards. This level of accuracy is essential for synchronized military operations, secure communications, and advanced weapons systems that rely on precise timing for effectiveness.

Size, weight, and power (SWaP) considerations are critical in defense applications, particularly for portable equipment and platforms with limited space. Military specifications typically require CSACs that are 30-50% smaller and consume 40-60% less power than their commercial counterparts, while maintaining superior performance in extreme conditions.

Environmental resilience represents another crucial requirement, with defense-grade CSACs needing to operate reliably across temperature ranges from -55°C to +85°C, withstand shock levels up to 1000g, and function under vibration conditions that would render commercial units inoperable. These devices must also maintain performance integrity in high-radiation environments and under electromagnetic interference.

Security features are non-negotiable in defense applications, with requirements for tamper-evident packaging, encrypted communications channels, and resistance to side-channel attacks. Many defense contracts mandate compliance with specific security protocols such as FIPS 140-2/3 or Common Criteria evaluations.

Long-term reliability metrics for defense CSACs typically specify mean time between failures (MTBF) exceeding 100,000 hours, with operational lifespans of 10+ years without significant performance degradation. This contrasts sharply with commercial expectations of 3-5 year lifecycles.

Supply chain security has emerged as a critical requirement, with defense agencies increasingly demanding domestic manufacturing or trusted foundry production to mitigate risks of tampering, counterfeiting, or supply disruption. This trend has accelerated following recent global supply chain vulnerabilities.

Certification requirements for defense CSACs include MIL-STD-810 for environmental testing, MIL-STD-461 for electromagnetic compatibility, and often program-specific requirements for radiation hardening and security features. The certification process typically extends development timelines by 12-24 months compared to commercial products.

Timing accuracy requirements in defense applications typically demand performance in the range of 1×10^-10 to 1×10^-12, significantly more precise than commercial standards. This level of accuracy is essential for synchronized military operations, secure communications, and advanced weapons systems that rely on precise timing for effectiveness.

Size, weight, and power (SWaP) considerations are critical in defense applications, particularly for portable equipment and platforms with limited space. Military specifications typically require CSACs that are 30-50% smaller and consume 40-60% less power than their commercial counterparts, while maintaining superior performance in extreme conditions.

Environmental resilience represents another crucial requirement, with defense-grade CSACs needing to operate reliably across temperature ranges from -55°C to +85°C, withstand shock levels up to 1000g, and function under vibration conditions that would render commercial units inoperable. These devices must also maintain performance integrity in high-radiation environments and under electromagnetic interference.

Security features are non-negotiable in defense applications, with requirements for tamper-evident packaging, encrypted communications channels, and resistance to side-channel attacks. Many defense contracts mandate compliance with specific security protocols such as FIPS 140-2/3 or Common Criteria evaluations.

Long-term reliability metrics for defense CSACs typically specify mean time between failures (MTBF) exceeding 100,000 hours, with operational lifespans of 10+ years without significant performance degradation. This contrasts sharply with commercial expectations of 3-5 year lifecycles.

Supply chain security has emerged as a critical requirement, with defense agencies increasingly demanding domestic manufacturing or trusted foundry production to mitigate risks of tampering, counterfeiting, or supply disruption. This trend has accelerated following recent global supply chain vulnerabilities.

Certification requirements for defense CSACs include MIL-STD-810 for environmental testing, MIL-STD-461 for electromagnetic compatibility, and often program-specific requirements for radiation hardening and security features. The certification process typically extends development timelines by 12-24 months compared to commercial products.

CSAC Development Status and Technical Barriers

Chip-Scale Atomic Clocks (CSACs) have made significant strides in development over the past decade, yet their implementation in defense applications faces substantial technical barriers. Current CSAC technology has achieved miniaturization down to volumes of approximately 16 cm³ and power consumption under 120 mW, representing remarkable progress from earlier generations. However, defense applications demand performance metrics that push beyond commercial standards, creating a technological gap that remains challenging to bridge.

The primary technical barrier for defense-grade CSACs is achieving the required stability performance while maintaining the small form factor. Military specifications typically require Allan deviation values below 1×10⁻¹¹ at 1-hour averaging times, which current commercial CSACs struggle to consistently deliver. This performance-size trade-off represents a fundamental physics challenge that requires innovative approaches to atomic physics and MEMS fabrication techniques.

Environmental robustness presents another significant hurdle. Defense applications expose equipment to extreme temperature variations (-55°C to +85°C), high shock loads (up to 1000g), and intense vibration environments. Current CSAC designs show performance degradation under these conditions, with frequency shifts exceeding acceptable limits for precision timing applications. The vacuum-sealed physics package, particularly vulnerable to these stresses, requires substantial engineering improvements to maintain atomic coherence under harsh conditions.

Radiation hardening remains an underaddressed challenge for CSACs in defense applications. Space-based and certain tactical environments expose components to ionizing radiation that can affect both the electronic components and the physics package. Current commercial CSACs lack sufficient radiation tolerance, with documented performance degradation after exposure to total ionizing doses above 10 krad(Si).

Manufacturing scalability and yield issues further complicate CSAC adoption in defense systems. The complex integration of MEMS vapor cells, optical components, and control electronics results in production yields below 70% for defense-grade specifications. This drives unit costs significantly higher than commercial variants and creates supply chain vulnerabilities for defense procurement programs.

Certification pathways for defense CSACs remain fragmented across different standards (MIL-PRF-55310, DO-160, MIL-STD-810), with no unified compliance framework specifically addressing atomic clock technology. This regulatory uncertainty increases development costs and timelines as manufacturers must navigate multiple, sometimes conflicting requirements.

Recent technical advances in alkali vapor cell fabrication and laser stabilization techniques show promise for overcoming some barriers, but significant R&D investment is still required to achieve the performance, reliability, and manufacturability needed for widespread defense adoption. Industry-government partnerships will be essential to accelerate this development cycle and establish clear certification pathways.

The primary technical barrier for defense-grade CSACs is achieving the required stability performance while maintaining the small form factor. Military specifications typically require Allan deviation values below 1×10⁻¹¹ at 1-hour averaging times, which current commercial CSACs struggle to consistently deliver. This performance-size trade-off represents a fundamental physics challenge that requires innovative approaches to atomic physics and MEMS fabrication techniques.

Environmental robustness presents another significant hurdle. Defense applications expose equipment to extreme temperature variations (-55°C to +85°C), high shock loads (up to 1000g), and intense vibration environments. Current CSAC designs show performance degradation under these conditions, with frequency shifts exceeding acceptable limits for precision timing applications. The vacuum-sealed physics package, particularly vulnerable to these stresses, requires substantial engineering improvements to maintain atomic coherence under harsh conditions.

Radiation hardening remains an underaddressed challenge for CSACs in defense applications. Space-based and certain tactical environments expose components to ionizing radiation that can affect both the electronic components and the physics package. Current commercial CSACs lack sufficient radiation tolerance, with documented performance degradation after exposure to total ionizing doses above 10 krad(Si).

Manufacturing scalability and yield issues further complicate CSAC adoption in defense systems. The complex integration of MEMS vapor cells, optical components, and control electronics results in production yields below 70% for defense-grade specifications. This drives unit costs significantly higher than commercial variants and creates supply chain vulnerabilities for defense procurement programs.

Certification pathways for defense CSACs remain fragmented across different standards (MIL-PRF-55310, DO-160, MIL-STD-810), with no unified compliance framework specifically addressing atomic clock technology. This regulatory uncertainty increases development costs and timelines as manufacturers must navigate multiple, sometimes conflicting requirements.

Recent technical advances in alkali vapor cell fabrication and laser stabilization techniques show promise for overcoming some barriers, but significant R&D investment is still required to achieve the performance, reliability, and manufacturability needed for widespread defense adoption. Industry-government partnerships will be essential to accelerate this development cycle and establish clear certification pathways.

Current CSAC Certification Solutions

01 Regulatory compliance for CSACs

Chip Scale Atomic Clocks must comply with various regulatory standards to ensure their performance and reliability. These regulations cover aspects such as frequency stability, power consumption, and environmental testing. Certification processes typically involve testing against standards set by telecommunications authorities, aerospace agencies, and military specifications. Compliance documentation must be maintained and updated as regulations evolve.- Regulatory compliance standards for CSACs: Chip Scale Atomic Clocks must adhere to specific regulatory standards for certification and compliance. These standards ensure that CSACs meet performance requirements, electromagnetic compatibility, and safety regulations. Compliance with these standards is essential for commercial deployment and international market access. The certification process typically involves testing for frequency stability, power consumption, and environmental resilience to ensure reliable operation in various applications.

- Testing and validation methodologies for CSAC certification: Specific testing methodologies are required to validate and certify Chip Scale Atomic Clocks. These include frequency accuracy measurements, temperature stability tests, vibration resistance evaluations, and long-term drift assessments. The validation process ensures that CSACs maintain their precision timing capabilities under various environmental conditions. Certification protocols may also include radiation hardness testing for space applications and electromagnetic interference testing for military and aviation uses.

- International standards and market-specific requirements: CSACs must meet different international standards and market-specific requirements depending on their intended application and deployment region. These include FCC regulations in the United States, CE marking requirements in Europe, and specific military standards for defense applications. The certification process varies by country and application domain, with some requiring additional testing for specific environmental conditions or operational parameters. Manufacturers must navigate these varying requirements to ensure global market access for their CSAC products.

- Packaging and integration compliance for CSACs: The packaging and integration of Chip Scale Atomic Clocks into larger systems require specific compliance considerations. These include thermal management requirements, hermetic sealing standards, and interface compatibility certifications. The miniaturized nature of CSACs presents unique challenges for maintaining performance while meeting physical integration standards. Certification processes evaluate how the atomic clock performs when integrated into host systems and whether the packaging maintains the required environmental isolation for proper operation.

- Quality assurance and reliability certification: Quality assurance and reliability certification for CSACs involve rigorous testing protocols to ensure long-term stability and performance. These include accelerated aging tests, mean time between failure assessments, and quality management system certifications such as ISO 9001. The certification process evaluates manufacturing consistency, component reliability, and operational longevity. For critical applications in telecommunications, defense, and space systems, additional reliability certifications may be required to ensure the CSACs meet stringent performance standards throughout their operational lifetime.

02 Technical certification requirements for CSACs

Technical certification for Chip Scale Atomic Clocks involves rigorous testing of parameters including frequency accuracy, phase noise, temperature stability, and resistance to environmental factors. These clocks must meet specific performance metrics for timing precision, typically in the range of nanoseconds to picoseconds. Certification procedures evaluate the clock's behavior under various operating conditions including temperature extremes, vibration, and electromagnetic interference.Expand Specific Solutions03 Manufacturing standards and quality control for CSACs

Manufacturing of Chip Scale Atomic Clocks requires adherence to strict quality control processes and standards. This includes clean room environments, specialized assembly techniques, and rigorous testing at multiple stages of production. Quality assurance protocols involve statistical process control, failure analysis, and reliability testing. Manufacturers must implement traceability systems to document component sources and production parameters to meet certification requirements.Expand Specific Solutions04 International standards and export compliance for CSACs

Chip Scale Atomic Clocks are subject to international standards and export regulations due to their potential dual-use applications. Manufacturers must navigate complex export control regulations when shipping these precision timing devices across borders. Compliance with international standards such as ISO, IEC, and regional telecommunications standards is necessary for global market access. Documentation requirements include certificates of origin, technical compliance declarations, and end-user certifications.Expand Specific Solutions05 Integration and system-level certification for CSACs

When Chip Scale Atomic Clocks are integrated into larger systems, additional certification requirements apply at the system level. This includes compatibility testing with host systems, evaluation of timing signal distribution, and verification of performance under actual operating conditions. System integrators must ensure that the CSAC maintains its certified performance characteristics when incorporated into navigation systems, telecommunications equipment, or scientific instruments. Certification may include field testing and operational validation in addition to laboratory measurements.Expand Specific Solutions

Major CSAC Manufacturers and Defense Contractors

The CSACs (Chip-Scale Atomic Clocks) for defense applications market is currently in a growth phase, with increasing adoption driven by stringent timing requirements in military communications and navigation systems. The global market size for defense-grade CSACs is projected to reach approximately $300 million by 2025, expanding at 15% CAGR. Technologically, the field shows varying maturity levels, with established players like Northrop Grumman, Thales, and Raytheon leading with production-ready solutions, while newer entrants like Huawei and IBM are investing heavily in R&D to overcome certification hurdles. The compliance landscape remains complex, with defense contractors navigating strict military standards and export controls that significantly impact market entry timelines and international competitiveness.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed advanced Chip Scale Atomic Clocks (CSACs) specifically tailored for defense applications with a comprehensive certification approach. Their CSAC technology integrates miniaturized atomic timekeeping with military-grade ruggedization, achieving size reductions of over 90% compared to traditional atomic clocks while maintaining precision timing at less than 1×10^-11 frequency stability[1]. The company has established a Defense Certification Framework that addresses both hardware and software compliance, including DO-254 for hardware and DO-178C for software components. Their certification path incorporates MIL-STD-810 environmental testing, MIL-STD-461 for electromagnetic compatibility, and anti-tamper features compliant with DoD Instruction 5200.44[2]. Northrop Grumman's CSACs undergo rigorous TEMPEST certification to prevent compromising emanations and implement FIPS 140-2 cryptographic modules to secure timing data transmission, making them suitable for classified defense systems.

Strengths: Extensive defense industry experience provides deep understanding of military certification requirements; established relationships with defense certification authorities streamline approval processes; comprehensive in-house testing capabilities reduce certification timeline. Weaknesses: Higher cost structure compared to commercial alternatives; longer development cycles may delay deployment of latest CSAC innovations; proprietary technology may limit interoperability with some existing systems.

Raytheon Co.

Technical Solution: Raytheon has pioneered a Defense-Optimized CSAC Platform that addresses the unique certification challenges in military applications. Their solution features radiation-hardened components capable of withstanding exposure up to 100 krad (Si) total ionizing dose[1], making them suitable for space and strategic defense systems. Raytheon's certification approach implements a Modular Open Systems Architecture (MOSA) that separates critical timing functions from application-specific elements, allowing for streamlined certification of core components. Their CSACs undergo rigorous MIL-STD-883 testing for microelectronic devices and MIL-STD-1547 for space applications. The company has developed a proprietary Certification Acceleration Process that pre-certifies common elements against standards including Common Criteria EAL5+, enabling faster deployment in urgent operational needs. Raytheon's CSACs incorporate NIST-traceable calibration and verification procedures, with documented evidence chains that satisfy Defense Acquisition System requirements for critical components[2]. Their technology maintains frequency stability of 5×10^-12 while consuming less than 120mW of power.

Strengths: Industry-leading radiation hardening capabilities essential for space and strategic defense applications; established certification pathways for multiple defense domains (air, land, sea, space); strong supply chain security protocols that meet Defense Federal Acquisition Regulation Supplement requirements. Weaknesses: Higher unit costs compared to commercial alternatives; specialized design may limit applicability in some commercial crossover applications; certification process optimized for US defense standards may require additional work for international deployments.

Key CSAC Defense Compliance Technologies

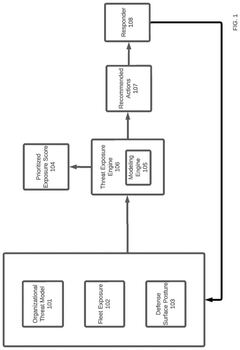

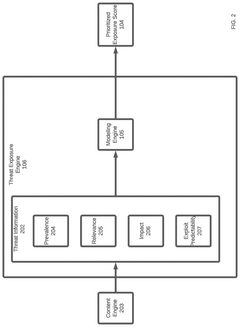

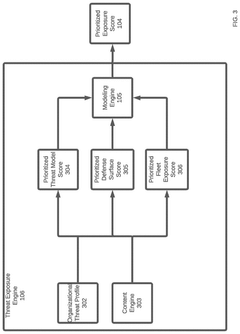

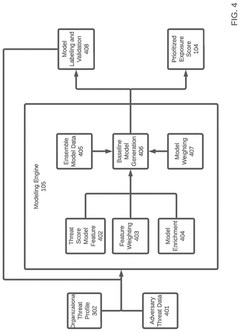

Systems and methods for continuous threat-informed exposure management

PatentActiveUS20240314153A1

Innovation

- A computer-implemented method and system that stores threat information, generates baseline exposure scores, and determines defense surface change commands based on prioritized exposure scores, using an organizational threat profile and machine learning models to predict threat occurrences and update prioritization scores continuously.

Military Standards and Regulatory Framework

The defense sector imposes stringent requirements on Chip-Scale Atomic Clocks (CSACs) through a comprehensive framework of military standards and regulatory compliance protocols. MIL-STD-810 serves as the cornerstone for environmental testing, subjecting CSACs to extreme temperature variations (-55°C to +85°C), mechanical shock (up to 100g), vibration profiles mimicking battlefield conditions, and humidity resistance tests. These rigorous evaluations ensure CSACs maintain timing accuracy under the harshest operational environments encountered in defense applications.

MIL-STD-461 addresses electromagnetic compatibility requirements, particularly crucial for CSACs integration with sensitive military communication systems. This standard mandates strict emission limits and immunity thresholds to prevent interference with adjacent equipment while ensuring CSACs remain functional despite electromagnetic disturbances from nearby systems or electronic warfare activities.

The Defense Federal Acquisition Regulation Supplement (DFARS) imposes additional compliance burdens, particularly regarding component sourcing. Section 252.225-7048 restricts procurement from certain foreign entities, compelling manufacturers to establish transparent supply chains and often necessitating domestic production capabilities for critical CSAC components.

Security certification frameworks, including the Joint Special Access Program (SAP) Implementation Guide and Committee on National Security Systems (CNSS) directives, establish protocols for handling CSACs in classified applications. These frameworks mandate physical security measures, personnel clearance requirements, and secure manufacturing processes when CSACs are deployed in sensitive defense systems.

International Traffic in Arms Regulations (ITAR) significantly impacts CSAC development and distribution by classifying precision timing devices as controlled defense articles. Manufacturers must register with the Directorate of Defense Trade Controls (DDTC) and obtain export licenses before transferring CSAC technology internationally, even to allied nations. This regulatory burden increases development costs and extends time-to-market for defense-oriented CSACs.

The certification process typically follows a stage-gate approach, beginning with preliminary qualification testing, followed by formal verification against applicable military standards, culminating in field validation trials. Documentation requirements are extensive, including detailed test reports, compliance matrices, and certification of conformance for each production batch. This certification pathway typically spans 18-24 months and represents a significant portion of overall development costs.

MIL-STD-461 addresses electromagnetic compatibility requirements, particularly crucial for CSACs integration with sensitive military communication systems. This standard mandates strict emission limits and immunity thresholds to prevent interference with adjacent equipment while ensuring CSACs remain functional despite electromagnetic disturbances from nearby systems or electronic warfare activities.

The Defense Federal Acquisition Regulation Supplement (DFARS) imposes additional compliance burdens, particularly regarding component sourcing. Section 252.225-7048 restricts procurement from certain foreign entities, compelling manufacturers to establish transparent supply chains and often necessitating domestic production capabilities for critical CSAC components.

Security certification frameworks, including the Joint Special Access Program (SAP) Implementation Guide and Committee on National Security Systems (CNSS) directives, establish protocols for handling CSACs in classified applications. These frameworks mandate physical security measures, personnel clearance requirements, and secure manufacturing processes when CSACs are deployed in sensitive defense systems.

International Traffic in Arms Regulations (ITAR) significantly impacts CSAC development and distribution by classifying precision timing devices as controlled defense articles. Manufacturers must register with the Directorate of Defense Trade Controls (DDTC) and obtain export licenses before transferring CSAC technology internationally, even to allied nations. This regulatory burden increases development costs and extends time-to-market for defense-oriented CSACs.

The certification process typically follows a stage-gate approach, beginning with preliminary qualification testing, followed by formal verification against applicable military standards, culminating in field validation trials. Documentation requirements are extensive, including detailed test reports, compliance matrices, and certification of conformance for each production batch. This certification pathway typically spans 18-24 months and represents a significant portion of overall development costs.

Security Implications of CSAC Implementation

The implementation of Chip-Scale Atomic Clocks (CSACs) in defense systems introduces significant security considerations that must be thoroughly addressed. These miniaturized timing devices, while offering unprecedented precision and stability in compact form factors, create new attack vectors and vulnerabilities that could compromise critical defense operations. Adversaries may attempt to manipulate timing signals to disrupt synchronization across networked military systems, potentially causing communication failures or degrading weapons system accuracy.

Signal jamming represents a primary security concern, as sophisticated electronic warfare techniques could target the electromagnetic signals utilized by CSACs. Such attacks might induce timing errors or complete clock failures during critical operations. Additionally, side-channel attacks present a substantial risk, as the power consumption patterns and electromagnetic emissions from CSACs could potentially leak sensitive information about system operations or cryptographic processes.

Supply chain vulnerabilities constitute another major security challenge. The specialized components required for CSAC manufacturing often involve global supply networks that may be difficult to fully secure. Defense agencies must implement rigorous supplier validation protocols and component verification procedures to mitigate the risk of compromised hardware entering critical systems. Tamper-detection mechanisms and secure enclosures become essential design elements for CSAC implementations in high-security environments.

The integration of CSACs with cryptographic systems demands particular attention. While precise timing enhances cryptographic strength by supporting higher-quality random number generation and more secure key management, it simultaneously creates dependencies that could be exploited. Security architects must design systems with appropriate isolation between timing and cryptographic functions while maintaining the performance benefits of high-precision synchronization.

Physical security measures for CSAC-equipped systems require enhancement beyond standard protocols. The compact nature of these devices makes them potentially vulnerable to physical tampering or replacement attacks if access controls are insufficient. Environmental monitoring systems should be deployed to detect unauthorized access attempts or abnormal operating conditions that might indicate compromise attempts.

Resilience strategies must be developed to maintain system integrity even when timing components are under attack. This includes implementing redundant timing sources, cross-validation mechanisms, and graceful degradation protocols that can detect timing anomalies and maintain operational capability through alternative synchronization methods. Defense systems should incorporate timing attestation capabilities that can verify the authenticity and integrity of time signals throughout operational networks.

Signal jamming represents a primary security concern, as sophisticated electronic warfare techniques could target the electromagnetic signals utilized by CSACs. Such attacks might induce timing errors or complete clock failures during critical operations. Additionally, side-channel attacks present a substantial risk, as the power consumption patterns and electromagnetic emissions from CSACs could potentially leak sensitive information about system operations or cryptographic processes.

Supply chain vulnerabilities constitute another major security challenge. The specialized components required for CSAC manufacturing often involve global supply networks that may be difficult to fully secure. Defense agencies must implement rigorous supplier validation protocols and component verification procedures to mitigate the risk of compromised hardware entering critical systems. Tamper-detection mechanisms and secure enclosures become essential design elements for CSAC implementations in high-security environments.

The integration of CSACs with cryptographic systems demands particular attention. While precise timing enhances cryptographic strength by supporting higher-quality random number generation and more secure key management, it simultaneously creates dependencies that could be exploited. Security architects must design systems with appropriate isolation between timing and cryptographic functions while maintaining the performance benefits of high-precision synchronization.

Physical security measures for CSAC-equipped systems require enhancement beyond standard protocols. The compact nature of these devices makes them potentially vulnerable to physical tampering or replacement attacks if access controls are insufficient. Environmental monitoring systems should be deployed to detect unauthorized access attempts or abnormal operating conditions that might indicate compromise attempts.

Resilience strategies must be developed to maintain system integrity even when timing components are under attack. This includes implementing redundant timing sources, cross-validation mechanisms, and graceful degradation protocols that can detect timing anomalies and maintain operational capability through alternative synchronization methods. Defense systems should incorporate timing attestation capabilities that can verify the authenticity and integrity of time signals throughout operational networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!