Cutting Edges in Polyurethane: Bridging Tech and Biology

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Tech Evolution

Polyurethane (PU) technology has undergone significant evolution since its inception in the 1930s. Initially developed as a versatile polymer, PU has continuously adapted to meet changing industrial and consumer needs. The early stages of PU development focused primarily on its use as a flexible foam for cushioning and insulation. However, as research progressed, scientists discovered its potential in a wide array of applications, from coatings and adhesives to elastomers and rigid foams.

The 1960s and 1970s marked a period of rapid advancement in PU chemistry, with the introduction of new catalysts and blowing agents that expanded its processing capabilities. This era saw the emergence of PU in automotive applications, particularly in seating and interior components, due to its superior comfort and durability. Concurrently, the construction industry began to leverage PU's excellent insulation properties, leading to its widespread use in building materials.

The 1980s and 1990s witnessed a shift towards environmental consciousness in PU technology. Researchers focused on developing more sustainable production methods and exploring bio-based alternatives to petroleum-derived polyols. This period also saw advancements in PU formulations for specific performance characteristics, such as improved fire resistance and enhanced durability.

The turn of the millennium brought about a new era of innovation in PU technology, with a strong emphasis on nanotechnology and smart materials. Researchers began incorporating nanoparticles into PU matrices to enhance properties such as strength, thermal stability, and electrical conductivity. This period also saw the development of shape-memory PUs and self-healing PU composites, opening up new possibilities in adaptive and responsive materials.

In recent years, the convergence of PU technology with biology has emerged as a cutting-edge research area. This interdisciplinary approach has led to breakthroughs in biocompatible PU materials for medical applications, such as tissue engineering scaffolds and drug delivery systems. Additionally, the integration of biological components, like enzymes or microorganisms, into PU matrices has paved the way for biodegradable and self-repairing materials.

The latest frontier in PU technology involves the development of "smart" PU materials that can respond to external stimuli such as temperature, pH, or light. These advanced materials have potential applications in areas ranging from wearable technology to adaptive building materials. Furthermore, ongoing research in green chemistry and sustainable production methods continues to drive innovation in bio-based PUs, aiming to reduce the environmental impact of PU production and use.

The 1960s and 1970s marked a period of rapid advancement in PU chemistry, with the introduction of new catalysts and blowing agents that expanded its processing capabilities. This era saw the emergence of PU in automotive applications, particularly in seating and interior components, due to its superior comfort and durability. Concurrently, the construction industry began to leverage PU's excellent insulation properties, leading to its widespread use in building materials.

The 1980s and 1990s witnessed a shift towards environmental consciousness in PU technology. Researchers focused on developing more sustainable production methods and exploring bio-based alternatives to petroleum-derived polyols. This period also saw advancements in PU formulations for specific performance characteristics, such as improved fire resistance and enhanced durability.

The turn of the millennium brought about a new era of innovation in PU technology, with a strong emphasis on nanotechnology and smart materials. Researchers began incorporating nanoparticles into PU matrices to enhance properties such as strength, thermal stability, and electrical conductivity. This period also saw the development of shape-memory PUs and self-healing PU composites, opening up new possibilities in adaptive and responsive materials.

In recent years, the convergence of PU technology with biology has emerged as a cutting-edge research area. This interdisciplinary approach has led to breakthroughs in biocompatible PU materials for medical applications, such as tissue engineering scaffolds and drug delivery systems. Additionally, the integration of biological components, like enzymes or microorganisms, into PU matrices has paved the way for biodegradable and self-repairing materials.

The latest frontier in PU technology involves the development of "smart" PU materials that can respond to external stimuli such as temperature, pH, or light. These advanced materials have potential applications in areas ranging from wearable technology to adaptive building materials. Furthermore, ongoing research in green chemistry and sustainable production methods continues to drive innovation in bio-based PUs, aiming to reduce the environmental impact of PU production and use.

Market Demand Analysis

The polyurethane market has been experiencing significant growth, driven by increasing demand across various industries. The global polyurethane market size was valued at USD 77.9 billion in 2021 and is projected to reach USD 105.3 billion by 2028, growing at a CAGR of 4.5% during the forecast period. This growth is primarily attributed to the versatility and adaptability of polyurethane materials in diverse applications.

The construction industry remains a key driver for polyurethane demand, particularly in insulation materials. With the growing emphasis on energy efficiency and sustainable building practices, polyurethane-based insulation products are gaining traction due to their superior thermal properties and lightweight nature. The automotive sector also contributes significantly to market growth, utilizing polyurethane in various components to reduce vehicle weight and improve fuel efficiency.

In recent years, there has been a notable shift towards bio-based and sustainable polyurethane products. This trend is driven by increasing environmental concerns and stringent regulations on petrochemical-based materials. The bio-based polyurethane market is expected to grow at a CAGR of 6.5% from 2021 to 2028, outpacing the growth of conventional polyurethanes.

The healthcare and medical device industry presents a promising growth avenue for polyurethane materials. The demand for biocompatible polyurethanes in medical implants, wound dressings, and drug delivery systems is rising. This sector's growth is fueled by an aging population and advancements in medical technologies.

Geographically, Asia-Pacific dominates the polyurethane market, accounting for over 40% of global consumption. China and India are the major contributors, driven by rapid industrialization and urbanization. North America and Europe follow, with steady demand from established industries and increasing focus on sustainable polyurethane solutions.

The COVID-19 pandemic initially disrupted the polyurethane market but also created new opportunities. The surge in demand for personal protective equipment (PPE) and medical devices boosted the consumption of specialized polyurethane materials. As economies recover, the market is expected to rebound strongly, with innovations in bio-based and recyclable polyurethanes leading the way.

In conclusion, the polyurethane market shows robust growth potential, driven by diverse applications and technological advancements. The industry's focus on sustainability and biocompatibility aligns well with global trends, positioning polyurethane as a critical material in the transition towards more environmentally friendly and technologically advanced products across various sectors.

The construction industry remains a key driver for polyurethane demand, particularly in insulation materials. With the growing emphasis on energy efficiency and sustainable building practices, polyurethane-based insulation products are gaining traction due to their superior thermal properties and lightweight nature. The automotive sector also contributes significantly to market growth, utilizing polyurethane in various components to reduce vehicle weight and improve fuel efficiency.

In recent years, there has been a notable shift towards bio-based and sustainable polyurethane products. This trend is driven by increasing environmental concerns and stringent regulations on petrochemical-based materials. The bio-based polyurethane market is expected to grow at a CAGR of 6.5% from 2021 to 2028, outpacing the growth of conventional polyurethanes.

The healthcare and medical device industry presents a promising growth avenue for polyurethane materials. The demand for biocompatible polyurethanes in medical implants, wound dressings, and drug delivery systems is rising. This sector's growth is fueled by an aging population and advancements in medical technologies.

Geographically, Asia-Pacific dominates the polyurethane market, accounting for over 40% of global consumption. China and India are the major contributors, driven by rapid industrialization and urbanization. North America and Europe follow, with steady demand from established industries and increasing focus on sustainable polyurethane solutions.

The COVID-19 pandemic initially disrupted the polyurethane market but also created new opportunities. The surge in demand for personal protective equipment (PPE) and medical devices boosted the consumption of specialized polyurethane materials. As economies recover, the market is expected to rebound strongly, with innovations in bio-based and recyclable polyurethanes leading the way.

In conclusion, the polyurethane market shows robust growth potential, driven by diverse applications and technological advancements. The industry's focus on sustainability and biocompatibility aligns well with global trends, positioning polyurethane as a critical material in the transition towards more environmentally friendly and technologically advanced products across various sectors.

PU Challenges

Polyurethane (PU) technology faces several significant challenges in its quest to bridge the gap between traditional materials science and biological applications. One of the primary obstacles is achieving biocompatibility without compromising the material's mechanical properties. While PU has excellent durability and flexibility, its interaction with living tissues can sometimes lead to inflammation or rejection, limiting its use in medical implants and devices.

Another major challenge lies in developing biodegradable PU formulations that maintain the desired performance characteristics. As environmental concerns grow, there is an increasing demand for materials that can decompose naturally without leaving harmful residues. However, creating PU that degrades predictably while retaining its functional properties throughout its intended lifespan remains a complex task.

The customization of PU properties at the molecular level presents another hurdle. Researchers are striving to fine-tune the material's structure to mimic specific biological tissues or to respond to physiological stimuli. This requires precise control over the polymerization process and the incorporation of bioactive molecules, which can be technically challenging and may affect the overall stability of the material.

Antimicrobial resistance is a critical issue in medical applications of PU. While efforts have been made to incorporate antimicrobial agents into PU formulations, maintaining long-term effectiveness without promoting bacterial resistance or compromising the material's properties is an ongoing challenge.

The development of self-healing PU materials is another frontier that researchers are exploring. Creating PU that can autonomously repair damage, similar to biological tissues, could significantly extend the lifespan of products and reduce maintenance needs. However, achieving this while maintaining other essential properties remains a complex engineering problem.

Scaling up production of biologically-inspired PU materials from laboratory to industrial levels presents additional challenges. Ensuring consistency in properties, cost-effectiveness, and compliance with regulatory standards for biological applications are crucial considerations that require extensive research and development efforts.

Lastly, the integration of smart functionalities into PU materials, such as shape memory or stimuli-responsiveness, while maintaining biocompatibility and safety, represents a significant challenge. These advanced properties could revolutionize applications in fields like tissue engineering and drug delivery, but their development requires overcoming complex technical and biological barriers.

Another major challenge lies in developing biodegradable PU formulations that maintain the desired performance characteristics. As environmental concerns grow, there is an increasing demand for materials that can decompose naturally without leaving harmful residues. However, creating PU that degrades predictably while retaining its functional properties throughout its intended lifespan remains a complex task.

The customization of PU properties at the molecular level presents another hurdle. Researchers are striving to fine-tune the material's structure to mimic specific biological tissues or to respond to physiological stimuli. This requires precise control over the polymerization process and the incorporation of bioactive molecules, which can be technically challenging and may affect the overall stability of the material.

Antimicrobial resistance is a critical issue in medical applications of PU. While efforts have been made to incorporate antimicrobial agents into PU formulations, maintaining long-term effectiveness without promoting bacterial resistance or compromising the material's properties is an ongoing challenge.

The development of self-healing PU materials is another frontier that researchers are exploring. Creating PU that can autonomously repair damage, similar to biological tissues, could significantly extend the lifespan of products and reduce maintenance needs. However, achieving this while maintaining other essential properties remains a complex engineering problem.

Scaling up production of biologically-inspired PU materials from laboratory to industrial levels presents additional challenges. Ensuring consistency in properties, cost-effectiveness, and compliance with regulatory standards for biological applications are crucial considerations that require extensive research and development efforts.

Lastly, the integration of smart functionalities into PU materials, such as shape memory or stimuli-responsiveness, while maintaining biocompatibility and safety, represents a significant challenge. These advanced properties could revolutionize applications in fields like tissue engineering and drug delivery, but their development requires overcoming complex technical and biological barriers.

Current PU Solutions

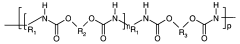

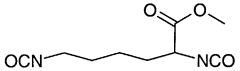

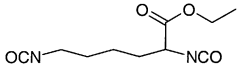

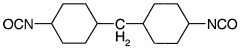

01 Polyurethane synthesis and composition

This category focuses on the development of new polyurethane compositions and synthesis methods. It includes innovations in the formulation of polyurethane materials, such as the use of novel monomers, catalysts, or additives to enhance specific properties. The research in this area aims to improve the performance, durability, and versatility of polyurethane products.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.

- Polyurethane applications in coatings and films: This point covers the use of polyurethane in various coating and film applications. It includes formulations for protective coatings, adhesive films, and specialty surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.

- Polyurethane foam technology: This category encompasses innovations in polyurethane foam production and properties. It includes advancements in foam formulations, processing techniques, and the development of specialized foam products. The foams may have applications in insulation, cushioning, packaging, and other industries requiring lightweight, durable materials.

- Polyurethane in textile and fiber applications: This point focuses on the use of polyurethane in textile and fiber-related applications. It includes the development of polyurethane-based fibers, coatings for fabrics, and treatments for improving textile properties. Applications may range from waterproof and breathable fabrics to high-performance sportswear and technical textiles.

- Environmentally friendly polyurethane innovations: This category covers advancements in making polyurethane more environmentally friendly. It includes the development of bio-based polyurethanes, recyclable formulations, and production methods with reduced environmental impact. These innovations aim to address sustainability concerns while maintaining or improving the performance of polyurethane materials.

02 Polyurethane applications in coatings and adhesives

This point covers the use of polyurethanes in coating and adhesive applications. It includes developments in polyurethane-based paints, varnishes, and adhesives for various industries. The research focuses on improving properties such as adhesion strength, chemical resistance, and durability for specific end-use applications.Expand Specific Solutions03 Polyurethane foams and insulation materials

This category encompasses innovations in polyurethane foam technology, including rigid and flexible foams used for insulation and cushioning applications. It covers advancements in foam formulations, processing techniques, and the development of eco-friendly alternatives to traditional blowing agents.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This point focuses on the use of polyurethanes in textile and fiber applications. It includes developments in polyurethane-based fibers, coatings for fabrics, and other textile treatments. The research aims to enhance properties such as elasticity, moisture management, and durability in textile products.Expand Specific Solutions05 Sustainable and bio-based polyurethanes

This category covers the development of sustainable and bio-based polyurethane materials. It includes research on using renewable resources, such as plant-based polyols, to replace petroleum-based components in polyurethane production. The focus is on creating more environmentally friendly alternatives while maintaining or improving performance characteristics.Expand Specific Solutions

Key PU Industry Players

The field of cutting-edge polyurethane technology bridging tech and biology is in a dynamic growth phase, characterized by rapid innovation and expanding applications. The market size is substantial and growing, driven by increasing demand in medical, industrial, and consumer sectors. Technological maturity varies across applications, with some areas highly advanced while others are still emerging. Companies like Medtronic, Inc., DePuy Synthes Products, Inc., and PolyNovo Biomaterials Pty Ltd. are at the forefront, pushing boundaries in biomedical applications. Wanhua Chemical Group Co., Ltd. and Covestro Deutschland AG lead in industrial innovations, while research institutions like Sichuan University and Commonwealth Scientific & Industrial Research Organisation contribute significantly to fundamental advancements in this interdisciplinary field.

PolyNovo Biomaterials Pty Ltd.

Technical Solution: PolyNovo has developed a revolutionary Biodegradable Temporising Matrix (BTM) for wound healing and tissue reconstruction. This polyurethane-based technology creates a scaffold that supports tissue ingrowth and vascularization. The BTM is designed to be gradually absorbed by the body as new tissue forms, providing a temporary extracellular matrix for cellular infiltration and capillary growth. This approach bridges the gap between synthetic materials and biological processes, offering a unique solution for complex wound management.

Strengths: Biocompatibility, customizable degradation rates, and ability to support tissue regeneration. Weaknesses: Potential variability in degradation rates depending on patient factors, and the need for careful monitoring during the healing process.

Medtronic, Inc.

Technical Solution: Medtronic has developed advanced polyurethane-based materials for medical devices, particularly in the field of cardiovascular implants. Their technology focuses on creating biocompatible polyurethane coatings and components that can withstand the harsh environment of the human body. These materials are engineered to reduce thrombogenicity and improve the long-term performance of implantable devices such as pacemakers and cardiac leads. Medtronic's approach involves modifying the surface properties of polyurethanes to enhance their interaction with biological tissues, thereby improving device integration and reducing the risk of complications.

Strengths: Extensive clinical experience, strong focus on long-term biocompatibility, and integration with electronic components. Weaknesses: Potential for oxidative degradation in long-term implants and challenges in achieving complete biological integration.

PU-Bio Integration

Biodegradable polyurethane and polyurethane ureas

PatentWO2005089778A1

Innovation

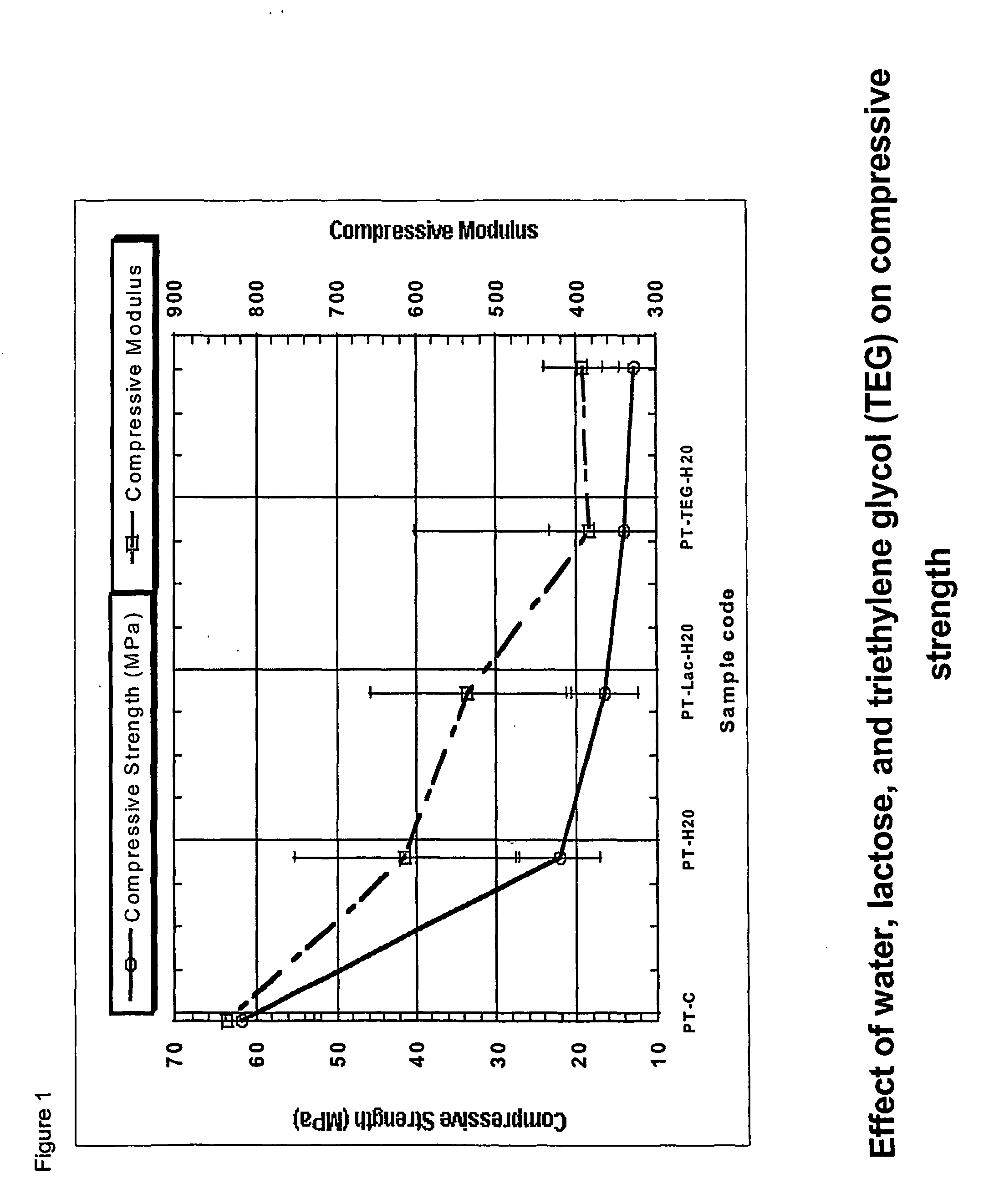

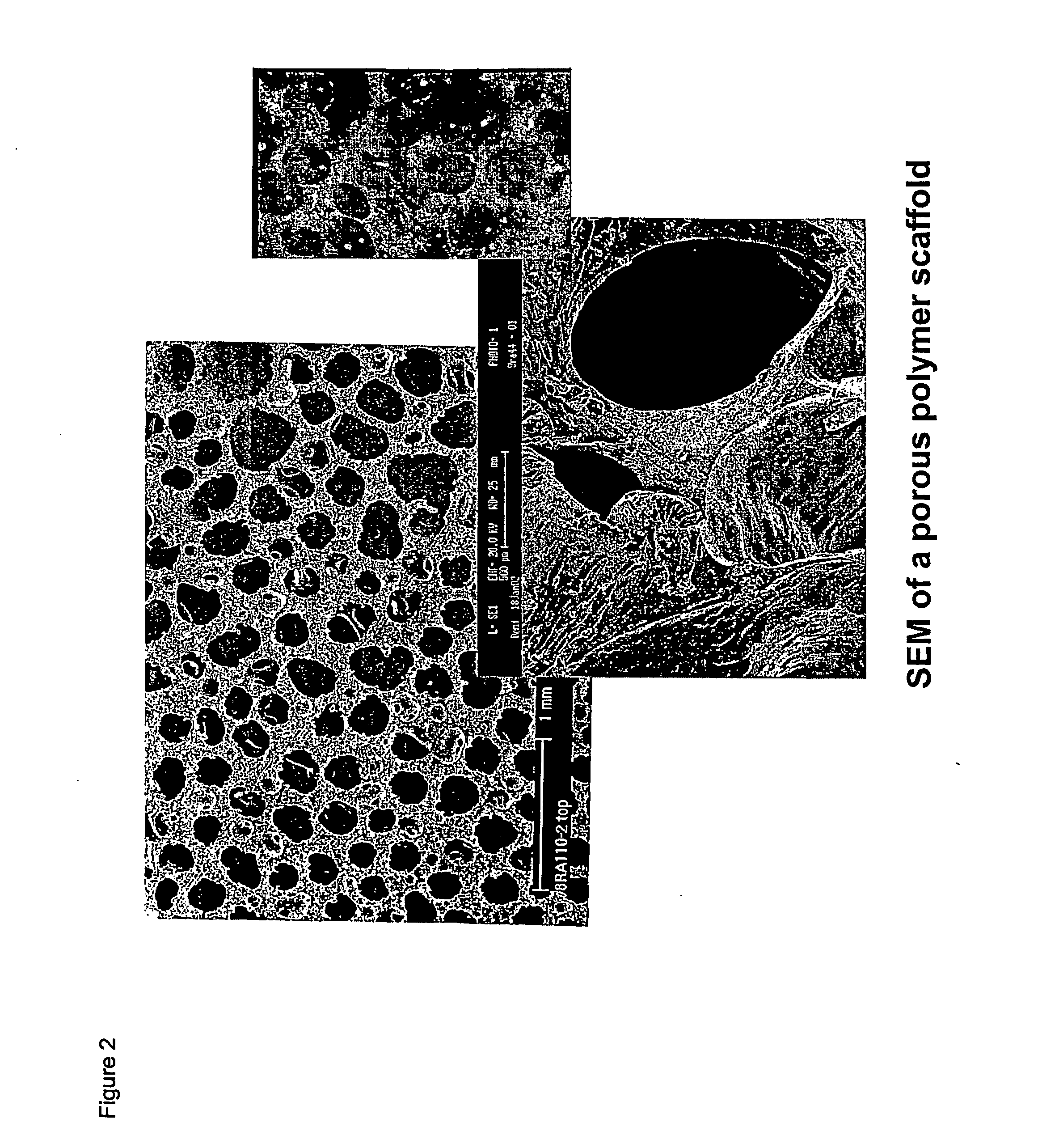

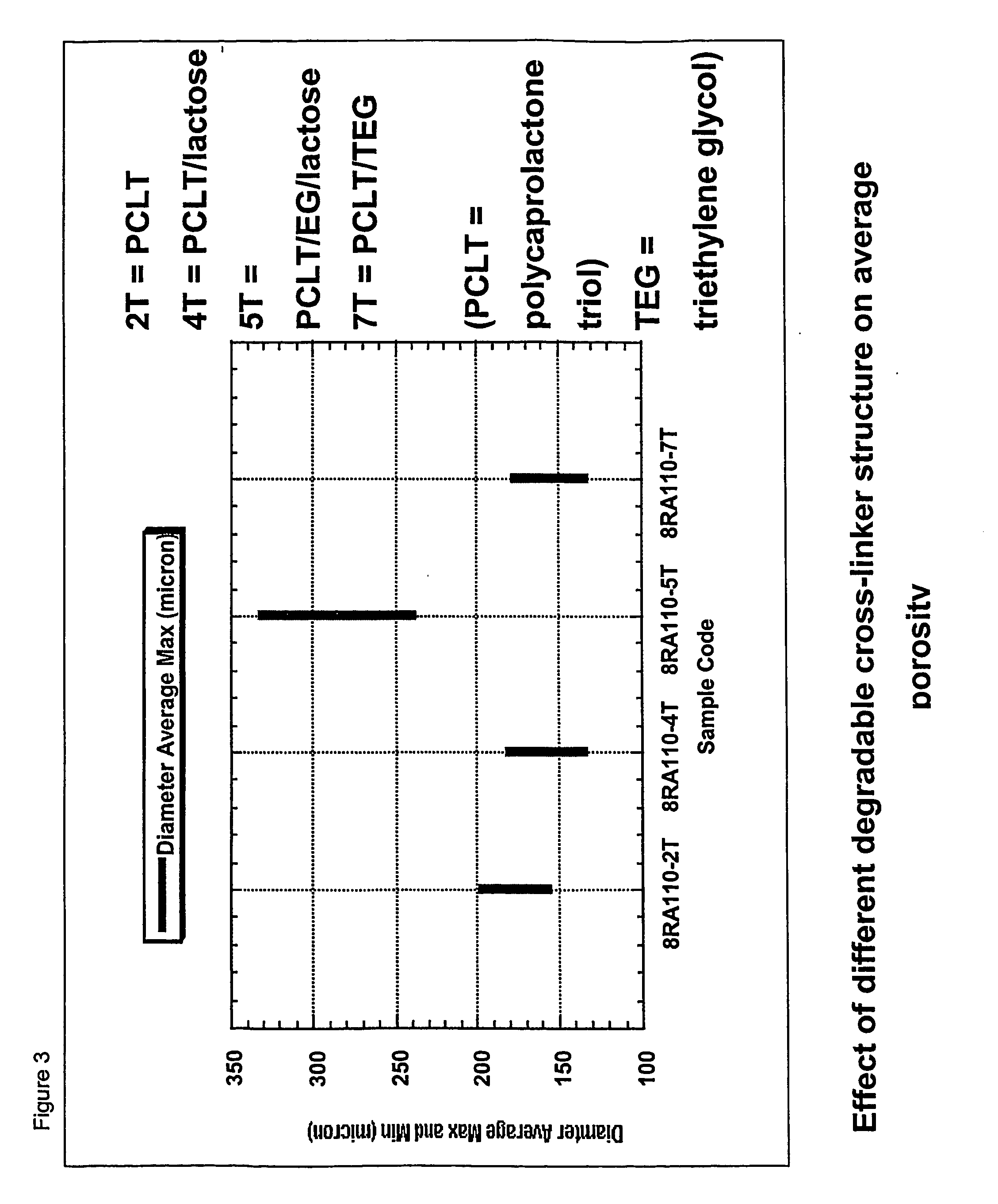

- Development of biocompatible and biodegradable polyurethanes or polyurethane/ureas comprising isocyanates, polyols, and chain extenders with hydrolysable linking groups, which can be processed using rapid prototyping techniques like FDM, allowing for the creation of scaffolds with controlled porosity and mechanical properties suitable for tissue engineering applications.

Biodegradable polyurethane/urea compositions

PatentActiveUS20050238683A1

Innovation

- Development of biodegradable, biocompatible polyurethane/urea compositions formed from star, dendrimer, or hyper-branched prepolymers reacting with isocyanates and low molecular weight multifunctional core molecules, which can be cured in vivo or ex vivo to create porous scaffolds with incorporated biological components, minimizing heat generation and ensuring cell compatibility.

Environmental Impact

The environmental impact of polyurethane has been a growing concern in recent years, prompting researchers and industry leaders to explore innovative solutions at the intersection of technology and biology. As polyurethane production and usage continue to increase globally, it is crucial to address its environmental footprint throughout its lifecycle.

One of the primary environmental challenges associated with polyurethane is its persistence in ecosystems. Traditional polyurethanes are not biodegradable, leading to long-term accumulation in landfills and natural environments. This accumulation contributes to pollution and poses risks to wildlife. Additionally, the production of polyurethane involves the use of fossil fuel-based raw materials, contributing to greenhouse gas emissions and resource depletion.

To mitigate these environmental impacts, cutting-edge research is focusing on developing bio-based and biodegradable polyurethanes. These innovative materials utilize renewable resources such as plant-derived polyols, reducing reliance on petrochemicals. For instance, researchers have successfully synthesized polyurethanes from soybean oil, castor oil, and other vegetable oils, demonstrating promising mechanical properties comparable to conventional polyurethanes.

Furthermore, advancements in enzyme technology are paving the way for enhanced biodegradability of polyurethane materials. Scientists have identified specific enzymes capable of breaking down polyurethane chains, offering potential solutions for more efficient recycling and waste management. This approach not only addresses end-of-life concerns but also opens up possibilities for circular economy models in the polyurethane industry.

Another significant environmental consideration is the reduction of volatile organic compounds (VOCs) emissions during polyurethane production and application. Cutting-edge technologies are being developed to minimize VOC release, including water-based polyurethane systems and novel curing methods that reduce the need for solvent-based processes. These advancements not only improve air quality but also enhance workplace safety in manufacturing environments.

The integration of nanotechnology in polyurethane research is also yielding promising results for environmental sustainability. Nanocomposites and nanostructured polyurethanes exhibit improved durability and performance, potentially extending product lifespans and reducing waste generation. Additionally, nanomaterials can enhance the flame-retardant properties of polyurethanes without the need for environmentally harmful halogenated additives.

As the field of polyurethane technology continues to evolve, the focus on environmental impact remains paramount. The convergence of biological principles and advanced materials science is driving innovation towards more sustainable polyurethane solutions. These developments not only address current environmental challenges but also pave the way for a new generation of eco-friendly materials that balance performance with ecological responsibility.

One of the primary environmental challenges associated with polyurethane is its persistence in ecosystems. Traditional polyurethanes are not biodegradable, leading to long-term accumulation in landfills and natural environments. This accumulation contributes to pollution and poses risks to wildlife. Additionally, the production of polyurethane involves the use of fossil fuel-based raw materials, contributing to greenhouse gas emissions and resource depletion.

To mitigate these environmental impacts, cutting-edge research is focusing on developing bio-based and biodegradable polyurethanes. These innovative materials utilize renewable resources such as plant-derived polyols, reducing reliance on petrochemicals. For instance, researchers have successfully synthesized polyurethanes from soybean oil, castor oil, and other vegetable oils, demonstrating promising mechanical properties comparable to conventional polyurethanes.

Furthermore, advancements in enzyme technology are paving the way for enhanced biodegradability of polyurethane materials. Scientists have identified specific enzymes capable of breaking down polyurethane chains, offering potential solutions for more efficient recycling and waste management. This approach not only addresses end-of-life concerns but also opens up possibilities for circular economy models in the polyurethane industry.

Another significant environmental consideration is the reduction of volatile organic compounds (VOCs) emissions during polyurethane production and application. Cutting-edge technologies are being developed to minimize VOC release, including water-based polyurethane systems and novel curing methods that reduce the need for solvent-based processes. These advancements not only improve air quality but also enhance workplace safety in manufacturing environments.

The integration of nanotechnology in polyurethane research is also yielding promising results for environmental sustainability. Nanocomposites and nanostructured polyurethanes exhibit improved durability and performance, potentially extending product lifespans and reducing waste generation. Additionally, nanomaterials can enhance the flame-retardant properties of polyurethanes without the need for environmentally harmful halogenated additives.

As the field of polyurethane technology continues to evolve, the focus on environmental impact remains paramount. The convergence of biological principles and advanced materials science is driving innovation towards more sustainable polyurethane solutions. These developments not only address current environmental challenges but also pave the way for a new generation of eco-friendly materials that balance performance with ecological responsibility.

Regulatory Landscape

The regulatory landscape surrounding polyurethane technology, particularly in the context of bridging technology and biology, is complex and evolving. Governments and international bodies have implemented various regulations to ensure the safety, quality, and environmental sustainability of polyurethane products and their production processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polyurethane manufacturing and usage. The Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemical substances, including those used in polyurethane production. The EPA has also established guidelines for the disposal and recycling of polyurethane products to minimize environmental impact.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects polyurethane manufacturers and users. REACH requires companies to register chemical substances and provide safety information, ensuring that potentially harmful substances are identified and managed appropriately.

As polyurethane technology increasingly intersects with biological applications, regulatory bodies are adapting their frameworks to address new challenges. The FDA in the United States and the European Medicines Agency (EMA) in the EU are developing guidelines for biocompatible polyurethane materials used in medical devices and implants. These regulations focus on ensuring the safety and efficacy of polyurethane-based products in biological environments.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, address worker protection in polyurethane manufacturing facilities. These regulations cover exposure limits to isocyanates and other chemicals used in polyurethane production, as well as safety protocols for handling and processing.

Environmental regulations are becoming increasingly stringent, with a focus on reducing volatile organic compound (VOC) emissions from polyurethane production and products. Many countries have implemented restrictions on certain flame retardants and other additives used in polyurethane formulations due to their potential environmental and health impacts.

As the field of bio-based polyurethanes expands, regulatory bodies are developing new frameworks to assess and certify these materials. The USDA BioPreferred program in the United States, for example, provides certification for bio-based products, including polyurethanes derived from renewable resources.

International standards organizations, such as ISO and ASTM, play a crucial role in establishing testing methods and performance criteria for polyurethane materials. These standards help ensure consistency and quality across different applications and facilitate global trade in polyurethane products.

The regulatory landscape for polyurethane technology is expected to continue evolving as new applications emerge, particularly at the intersection of technology and biology. Manufacturers and researchers must stay informed about regulatory changes and actively engage with regulatory bodies to ensure compliance and drive innovation in this dynamic field.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polyurethane manufacturing and usage. The Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemical substances, including those used in polyurethane production. The EPA has also established guidelines for the disposal and recycling of polyurethane products to minimize environmental impact.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects polyurethane manufacturers and users. REACH requires companies to register chemical substances and provide safety information, ensuring that potentially harmful substances are identified and managed appropriately.

As polyurethane technology increasingly intersects with biological applications, regulatory bodies are adapting their frameworks to address new challenges. The FDA in the United States and the European Medicines Agency (EMA) in the EU are developing guidelines for biocompatible polyurethane materials used in medical devices and implants. These regulations focus on ensuring the safety and efficacy of polyurethane-based products in biological environments.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, address worker protection in polyurethane manufacturing facilities. These regulations cover exposure limits to isocyanates and other chemicals used in polyurethane production, as well as safety protocols for handling and processing.

Environmental regulations are becoming increasingly stringent, with a focus on reducing volatile organic compound (VOC) emissions from polyurethane production and products. Many countries have implemented restrictions on certain flame retardants and other additives used in polyurethane formulations due to their potential environmental and health impacts.

As the field of bio-based polyurethanes expands, regulatory bodies are developing new frameworks to assess and certify these materials. The USDA BioPreferred program in the United States, for example, provides certification for bio-based products, including polyurethanes derived from renewable resources.

International standards organizations, such as ISO and ASTM, play a crucial role in establishing testing methods and performance criteria for polyurethane materials. These standards help ensure consistency and quality across different applications and facilitate global trade in polyurethane products.

The regulatory landscape for polyurethane technology is expected to continue evolving as new applications emerge, particularly at the intersection of technology and biology. Manufacturers and researchers must stay informed about regulatory changes and actively engage with regulatory bodies to ensure compliance and drive innovation in this dynamic field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!