Cylinder head innovations in L92 engine design

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Evolution

The L92 engine, a member of the GM Gen IV small-block V8 family, represents a significant evolution in cylinder head design. This engine, introduced in 2006, marked a departure from traditional pushrod V8 designs, incorporating advanced technologies to enhance performance and efficiency.

The L92's cylinder head innovations were driven by the need for increased power output and improved fuel economy in high-performance applications. GM engineers focused on optimizing airflow and combustion efficiency, resulting in a revolutionary design that set new standards for the industry.

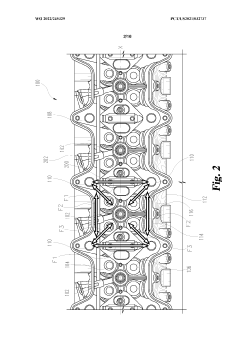

One of the key advancements in the L92 cylinder head was the implementation of a rectangular port design. This departure from the traditional D-shaped ports allowed for improved airflow characteristics, enabling higher volumetric efficiency and better cylinder filling at high engine speeds. The rectangular ports, combined with larger valves, contributed to a significant increase in the engine's breathing capacity.

Another crucial innovation was the adoption of a splayed valve arrangement. This design positioned the valves at optimized angles relative to the cylinder bore, improving mixture distribution and flame propagation within the combustion chamber. The splayed valve layout also allowed for larger valve sizes without interference, further enhancing the engine's ability to flow air and fuel efficiently.

The L92 cylinder head incorporated advanced combustion chamber geometry, featuring a pent-roof design with centrally located spark plugs. This configuration promoted faster and more complete combustion, resulting in improved power output and reduced emissions. The optimized chamber shape also contributed to a higher compression ratio, enhancing thermal efficiency.

GM engineers also focused on weight reduction and thermal management in the L92 cylinder head design. The use of cast aluminum alloys with optimized wall thicknesses allowed for a lightweight yet robust structure. Additionally, improved cooling passages were integrated into the head design, ensuring consistent performance under high-load conditions and prolonging engine life.

The evolution of the L92 engine design also saw the integration of variable valve timing (VVT) technology. This innovation allowed for dynamic adjustment of valve timing based on engine speed and load, optimizing performance across a wide operating range. The VVT system contributed to improved low-end torque, enhanced high-rpm power, and better fuel efficiency.

These cylinder head innovations in the L92 engine design set a new benchmark for performance and efficiency in the automotive industry. The advancements made in airflow management, combustion efficiency, and thermal control laid the foundation for future developments in engine technology, influencing subsequent generations of high-performance engines.

The L92's cylinder head innovations were driven by the need for increased power output and improved fuel economy in high-performance applications. GM engineers focused on optimizing airflow and combustion efficiency, resulting in a revolutionary design that set new standards for the industry.

One of the key advancements in the L92 cylinder head was the implementation of a rectangular port design. This departure from the traditional D-shaped ports allowed for improved airflow characteristics, enabling higher volumetric efficiency and better cylinder filling at high engine speeds. The rectangular ports, combined with larger valves, contributed to a significant increase in the engine's breathing capacity.

Another crucial innovation was the adoption of a splayed valve arrangement. This design positioned the valves at optimized angles relative to the cylinder bore, improving mixture distribution and flame propagation within the combustion chamber. The splayed valve layout also allowed for larger valve sizes without interference, further enhancing the engine's ability to flow air and fuel efficiently.

The L92 cylinder head incorporated advanced combustion chamber geometry, featuring a pent-roof design with centrally located spark plugs. This configuration promoted faster and more complete combustion, resulting in improved power output and reduced emissions. The optimized chamber shape also contributed to a higher compression ratio, enhancing thermal efficiency.

GM engineers also focused on weight reduction and thermal management in the L92 cylinder head design. The use of cast aluminum alloys with optimized wall thicknesses allowed for a lightweight yet robust structure. Additionally, improved cooling passages were integrated into the head design, ensuring consistent performance under high-load conditions and prolonging engine life.

The evolution of the L92 engine design also saw the integration of variable valve timing (VVT) technology. This innovation allowed for dynamic adjustment of valve timing based on engine speed and load, optimizing performance across a wide operating range. The VVT system contributed to improved low-end torque, enhanced high-rpm power, and better fuel efficiency.

These cylinder head innovations in the L92 engine design set a new benchmark for performance and efficiency in the automotive industry. The advancements made in airflow management, combustion efficiency, and thermal control laid the foundation for future developments in engine technology, influencing subsequent generations of high-performance engines.

Market Demand Analysis

The market demand for cylinder head innovations in L92 engine design has been steadily increasing, driven by the automotive industry's pursuit of improved engine performance, fuel efficiency, and emissions reduction. As environmental regulations become more stringent worldwide, manufacturers are seeking advanced cylinder head designs to meet these challenges while maintaining or enhancing engine power output.

The L92 engine, primarily used in high-performance vehicles, has garnered significant attention from both manufacturers and consumers. Its cylinder head design plays a crucial role in optimizing combustion efficiency and overall engine performance. Market research indicates a growing demand for L92 engines with enhanced cylinder heads, particularly in the luxury and sports car segments.

Consumer preferences are shifting towards vehicles that offer a balance of power and fuel economy. This trend has created a substantial market opportunity for L92 engines with innovative cylinder head designs that can deliver improved horsepower and torque while reducing fuel consumption. The aftermarket sector has also shown increased interest in upgraded cylinder heads for L92 engines, catering to enthusiasts seeking to enhance their vehicle's performance.

The commercial vehicle sector presents another significant market for L92 engine cylinder head innovations. Fleet operators are increasingly focused on reducing operational costs through improved fuel efficiency and extended engine life. Advanced cylinder head designs that offer better heat management and reduced wear can provide substantial long-term cost savings for these operators.

Geographically, North America and Europe remain the primary markets for L92 engine applications, with Asia-Pacific showing rapid growth potential. The expanding automotive industries in countries like China and India are expected to drive further demand for high-performance engines, including those with advanced L92 cylinder head designs.

Market analysts project a compound annual growth rate (CAGR) of 4.5% for the high-performance engine market over the next five years, with cylinder head innovations playing a significant role in this growth. The increasing adoption of electric vehicles poses a potential challenge to this market segment. However, experts believe that there will be a sustained demand for high-performance internal combustion engines in specific vehicle categories and regions for the foreseeable future.

In conclusion, the market demand for cylinder head innovations in L92 engine design remains robust, driven by the need for improved performance, efficiency, and compliance with environmental regulations. Manufacturers who can successfully develop and implement advanced cylinder head technologies are likely to gain a competitive edge in this evolving market landscape.

The L92 engine, primarily used in high-performance vehicles, has garnered significant attention from both manufacturers and consumers. Its cylinder head design plays a crucial role in optimizing combustion efficiency and overall engine performance. Market research indicates a growing demand for L92 engines with enhanced cylinder heads, particularly in the luxury and sports car segments.

Consumer preferences are shifting towards vehicles that offer a balance of power and fuel economy. This trend has created a substantial market opportunity for L92 engines with innovative cylinder head designs that can deliver improved horsepower and torque while reducing fuel consumption. The aftermarket sector has also shown increased interest in upgraded cylinder heads for L92 engines, catering to enthusiasts seeking to enhance their vehicle's performance.

The commercial vehicle sector presents another significant market for L92 engine cylinder head innovations. Fleet operators are increasingly focused on reducing operational costs through improved fuel efficiency and extended engine life. Advanced cylinder head designs that offer better heat management and reduced wear can provide substantial long-term cost savings for these operators.

Geographically, North America and Europe remain the primary markets for L92 engine applications, with Asia-Pacific showing rapid growth potential. The expanding automotive industries in countries like China and India are expected to drive further demand for high-performance engines, including those with advanced L92 cylinder head designs.

Market analysts project a compound annual growth rate (CAGR) of 4.5% for the high-performance engine market over the next five years, with cylinder head innovations playing a significant role in this growth. The increasing adoption of electric vehicles poses a potential challenge to this market segment. However, experts believe that there will be a sustained demand for high-performance internal combustion engines in specific vehicle categories and regions for the foreseeable future.

In conclusion, the market demand for cylinder head innovations in L92 engine design remains robust, driven by the need for improved performance, efficiency, and compliance with environmental regulations. Manufacturers who can successfully develop and implement advanced cylinder head technologies are likely to gain a competitive edge in this evolving market landscape.

Cylinder Head Challenges

The L92 engine design, while innovative, faces several significant challenges in its cylinder head configuration. One of the primary issues is the optimization of airflow dynamics within the combustion chamber. The complex geometry of the cylinder head, including the intake and exhaust ports, valve positioning, and combustion chamber shape, must be carefully engineered to maximize efficiency and power output.

Heat management presents another critical challenge in the L92 cylinder head design. The high-performance nature of this engine generates substantial thermal loads, requiring advanced cooling strategies to maintain optimal operating temperatures. This includes the design of coolant passages, the selection of materials with appropriate thermal properties, and the integration of efficient heat dissipation mechanisms.

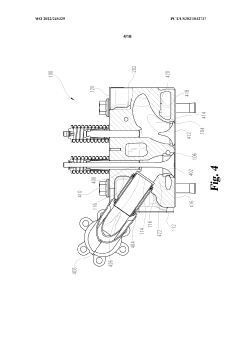

The valve train system in the L92 engine poses unique challenges due to its high-revving capabilities. The cylinder head must accommodate a robust and precise valve actuation mechanism, capable of withstanding high RPMs while maintaining accurate valve timing and lift. This often necessitates the use of advanced materials and manufacturing techniques to ensure durability and performance.

Fuel injection and mixture preparation are also areas of significant concern in the L92 cylinder head design. The placement and design of fuel injectors, as well as the overall port geometry, must be optimized to ensure proper fuel atomization and distribution within the combustion chamber. This directly impacts engine efficiency, power output, and emissions performance.

Weight reduction while maintaining structural integrity is another key challenge. The cylinder head, being a substantial component of the engine, contributes significantly to overall engine weight. Engineers must balance the need for a robust structure capable of withstanding high combustion pressures with the desire for lightweight design to improve overall vehicle performance.

Manufacturing complexity is an additional hurdle in the L92 cylinder head design. The intricate internal passages, precise tolerances, and complex surface geometries required for optimal performance can be challenging to produce consistently and cost-effectively. This often necessitates advanced manufacturing techniques and quality control processes.

Lastly, meeting increasingly stringent emissions regulations while maintaining high performance is a significant challenge. The cylinder head design plays a crucial role in combustion efficiency and exhaust gas management, directly impacting the engine's emissions profile. Engineers must innovate to find solutions that balance performance with environmental compliance, often requiring advanced combustion strategies and exhaust aftertreatment integration.

Heat management presents another critical challenge in the L92 cylinder head design. The high-performance nature of this engine generates substantial thermal loads, requiring advanced cooling strategies to maintain optimal operating temperatures. This includes the design of coolant passages, the selection of materials with appropriate thermal properties, and the integration of efficient heat dissipation mechanisms.

The valve train system in the L92 engine poses unique challenges due to its high-revving capabilities. The cylinder head must accommodate a robust and precise valve actuation mechanism, capable of withstanding high RPMs while maintaining accurate valve timing and lift. This often necessitates the use of advanced materials and manufacturing techniques to ensure durability and performance.

Fuel injection and mixture preparation are also areas of significant concern in the L92 cylinder head design. The placement and design of fuel injectors, as well as the overall port geometry, must be optimized to ensure proper fuel atomization and distribution within the combustion chamber. This directly impacts engine efficiency, power output, and emissions performance.

Weight reduction while maintaining structural integrity is another key challenge. The cylinder head, being a substantial component of the engine, contributes significantly to overall engine weight. Engineers must balance the need for a robust structure capable of withstanding high combustion pressures with the desire for lightweight design to improve overall vehicle performance.

Manufacturing complexity is an additional hurdle in the L92 cylinder head design. The intricate internal passages, precise tolerances, and complex surface geometries required for optimal performance can be challenging to produce consistently and cost-effectively. This often necessitates advanced manufacturing techniques and quality control processes.

Lastly, meeting increasingly stringent emissions regulations while maintaining high performance is a significant challenge. The cylinder head design plays a crucial role in combustion efficiency and exhaust gas management, directly impacting the engine's emissions profile. Engineers must innovate to find solutions that balance performance with environmental compliance, often requiring advanced combustion strategies and exhaust aftertreatment integration.

Current L92 Solutions

01 Improved cooling system design

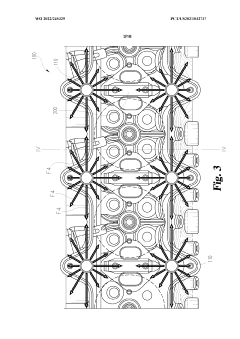

Innovations in the L92 engine cylinder head cooling system include enhanced coolant flow paths and optimized cooling jacket designs. These improvements help to maintain optimal operating temperatures, increase engine efficiency, and extend the lifespan of critical components.- Improved combustion chamber design: Innovations in the L92 engine cylinder head focus on optimizing the combustion chamber geometry. This includes modifications to the shape and contours of the chamber to enhance fuel mixture distribution, improve flame propagation, and increase overall combustion efficiency. These design changes can lead to better performance, fuel economy, and reduced emissions.

- Enhanced cooling system: The cylinder head design incorporates advanced cooling techniques to manage heat more effectively. This may include improved coolant passages, strategic placement of cooling channels, and the use of materials with better thermal conductivity. These enhancements help maintain optimal operating temperatures, prevent overheating, and contribute to increased engine longevity and performance.

- Optimized intake and exhaust port configuration: Innovations in the intake and exhaust port design aim to improve airflow characteristics. This includes refining the shape, size, and orientation of the ports to reduce flow restrictions, enhance volumetric efficiency, and promote better scavenging. These improvements contribute to increased engine power output and improved overall performance.

- Integration of variable valve timing technology: The L92 engine cylinder head design incorporates advanced variable valve timing mechanisms. This technology allows for dynamic adjustment of valve timing and lift, optimizing engine performance across different operating conditions. The integration of this system can lead to improved power output, fuel efficiency, and reduced emissions.

- Lightweight and durable materials: Innovations in material selection and manufacturing processes for the L92 engine cylinder head focus on reducing weight while maintaining or improving durability. This may include the use of advanced alloys, composite materials, or novel casting techniques. The resulting lightweight design contributes to improved fuel efficiency and overall engine performance without compromising structural integrity.

02 Advanced valve train configuration

The L92 engine cylinder head features innovative valve train designs, including variable valve timing systems and optimized valve positioning. These advancements contribute to improved engine performance, fuel efficiency, and reduced emissions across a wide range of operating conditions.Expand Specific Solutions03 Lightweight materials and construction

Design innovations in the L92 engine cylinder head incorporate lightweight materials and advanced manufacturing techniques. These improvements result in reduced overall engine weight, improved power-to-weight ratio, and enhanced fuel efficiency without compromising structural integrity.Expand Specific Solutions04 Optimized combustion chamber geometry

The L92 engine cylinder head features innovative combustion chamber designs, including optimized shapes and contours. These improvements enhance fuel mixture distribution, combustion efficiency, and overall engine performance while reducing emissions.Expand Specific Solutions05 Integrated exhaust manifold design

Design innovations in the L92 engine cylinder head include an integrated exhaust manifold. This feature improves exhaust gas flow, reduces overall engine size, and enhances thermal management, resulting in improved performance and emissions control.Expand Specific Solutions

Key Industry Players

The cylinder head innovations in L92 engine design represent a competitive landscape in the mature automotive engine sector. The market is characterized by established players like Honda, Ford, and Caterpillar, alongside emerging companies focusing on specialized technologies. The industry is in a phase of incremental innovation, with companies striving to improve engine efficiency and performance. Market size is substantial, given the widespread application of L92 engines in various vehicles. Technological maturity is high, with companies like AVL List GmbH and Southwest Research Institute leading in research and development, while manufacturers such as Cummins and Weichai Power focus on practical implementations and large-scale production.

Honda Motor Co., Ltd.

Technical Solution: Honda has made significant strides in cylinder head innovations for their engine designs, including those applicable to L92-type engines. The company has developed a compact combustion chamber design that promotes faster flame propagation and more complete combustion[4]. Honda's cylinder head innovations include the implementation of a tumble port design, which creates a strong vertical air motion in the combustion chamber, enhancing fuel-air mixing and combustion efficiency[5]. The company has also integrated its i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system into the cylinder head, allowing for optimized valve timing and lift across different engine speeds and loads. Honda's cylinder heads often feature integrated exhaust manifolds, reducing weight and improving thermal efficiency[6].

Strengths: Enhanced combustion efficiency, improved fuel economy, and reduced emissions. The i-VTEC system provides excellent performance across a wide range of engine speeds. Weaknesses: Potential increased manufacturing complexity and cost due to advanced technologies integrated into the cylinder head.

Ford Global Technologies LLC

Technical Solution: Ford's L92 engine design incorporates several cylinder head innovations to enhance performance and efficiency. The company has developed a unique dual overhead camshaft (DOHC) configuration with variable valve timing (VVT) for improved combustion control[1]. The cylinder head features an advanced port design that optimizes airflow and fuel mixture, resulting in better combustion efficiency. Ford has also implemented a high-flow intake manifold and larger valves to increase the engine's breathing capacity[2]. Additionally, the L92 cylinder head utilizes a direct injection system, allowing for precise fuel delivery and improved fuel atomization. The company has incorporated advanced cooling channels within the cylinder head to manage thermal loads more effectively, enhancing durability and performance[3].

Strengths: Improved combustion efficiency, enhanced power output, and better fuel economy. The VVT system allows for optimized engine performance across various operating conditions. Weaknesses: Increased complexity and potential higher manufacturing costs compared to simpler cylinder head designs.

Core L92 Innovations

Cylinder head for internal combustion engine

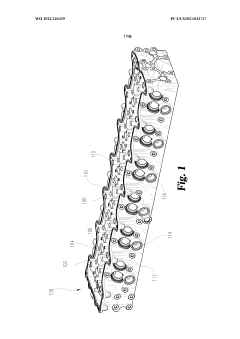

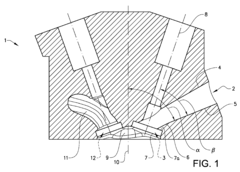

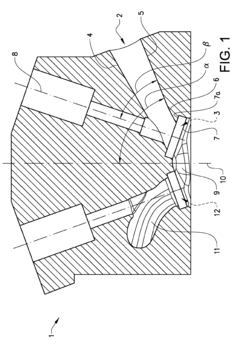

PatentWO2022245329A1

Innovation

- The cylinder head design incorporates novel features such as undercuts, contours of the outer enclosure, coolant jackets, and cavities within the outer enclosure, along with an exhaust jumper tube to enhance heat transfer and temperature control, reducing unwanted heat transfer and weight while maintaining structural integrity.

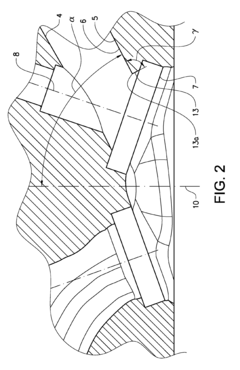

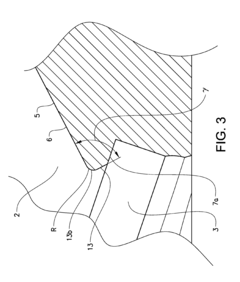

Cylinder head for a combustion engine

PatentActiveEP2933466A1

Innovation

- A cylinder head design featuring an intake channel with a straight lower wall positioned at specific angles relative to the cylinder bore and intake valve axis, combined with a conically expanding end zone, which enhances the tumble motion and mixing of air and fuel without significant pressure losses.

Emissions Regulations

Emissions regulations have played a significant role in shaping cylinder head innovations for the L92 engine design. As environmental concerns continue to grow, governments worldwide have implemented increasingly stringent emissions standards, forcing automotive manufacturers to adapt their engine designs to meet these requirements.

The L92 engine, a member of General Motors' Gen IV small-block V8 family, has been subject to these regulatory pressures. In response, engineers have focused on developing cylinder head innovations that improve combustion efficiency and reduce harmful emissions. One key area of improvement has been the optimization of intake and exhaust port designs to enhance airflow and fuel mixture distribution.

Advanced computational fluid dynamics (CFD) simulations have been employed to refine the shape and size of intake runners, resulting in more uniform air distribution across all cylinders. This improved airflow contributes to more complete combustion, reducing unburned hydrocarbons and carbon monoxide emissions.

The L92's cylinder heads also incorporate variable valve timing (VVT) technology, which allows for precise control of valve opening and closing events. This feature enables the engine to optimize its performance across different operating conditions, leading to reduced emissions during cold starts and improved fuel efficiency during normal operation.

Furthermore, the integration of direct fuel injection technology in the L92 engine design has had a significant impact on emissions reduction. By precisely controlling the fuel delivery timing and quantity, direct injection allows for a more complete burn of the air-fuel mixture, resulting in lower emissions of particulate matter and nitrogen oxides.

The cylinder head design also incorporates advanced cooling strategies to maintain optimal operating temperatures. Improved coolant flow paths and strategic placement of cooling jackets help prevent hot spots that could lead to pre-ignition or increased NOx formation. This thermal management contributes to more consistent combustion and lower emissions across various engine load conditions.

To address the challenge of cold-start emissions, which are typically higher due to incomplete combustion, the L92 engine's cylinder heads feature rapid warm-up technologies. These include isolated coolant passages that allow for quicker heating of critical components, reducing the time required for the engine to reach its optimal operating temperature and minimizing cold-start emissions.

In conclusion, the cylinder head innovations in the L92 engine design reflect a concerted effort to meet increasingly stringent emissions regulations. Through a combination of advanced port designs, variable valve timing, direct injection, and thermal management strategies, engineers have successfully reduced emissions while maintaining performance and efficiency. As regulations continue to evolve, further innovations in cylinder head design will likely be necessary to ensure compliance and environmental sustainability.

The L92 engine, a member of General Motors' Gen IV small-block V8 family, has been subject to these regulatory pressures. In response, engineers have focused on developing cylinder head innovations that improve combustion efficiency and reduce harmful emissions. One key area of improvement has been the optimization of intake and exhaust port designs to enhance airflow and fuel mixture distribution.

Advanced computational fluid dynamics (CFD) simulations have been employed to refine the shape and size of intake runners, resulting in more uniform air distribution across all cylinders. This improved airflow contributes to more complete combustion, reducing unburned hydrocarbons and carbon monoxide emissions.

The L92's cylinder heads also incorporate variable valve timing (VVT) technology, which allows for precise control of valve opening and closing events. This feature enables the engine to optimize its performance across different operating conditions, leading to reduced emissions during cold starts and improved fuel efficiency during normal operation.

Furthermore, the integration of direct fuel injection technology in the L92 engine design has had a significant impact on emissions reduction. By precisely controlling the fuel delivery timing and quantity, direct injection allows for a more complete burn of the air-fuel mixture, resulting in lower emissions of particulate matter and nitrogen oxides.

The cylinder head design also incorporates advanced cooling strategies to maintain optimal operating temperatures. Improved coolant flow paths and strategic placement of cooling jackets help prevent hot spots that could lead to pre-ignition or increased NOx formation. This thermal management contributes to more consistent combustion and lower emissions across various engine load conditions.

To address the challenge of cold-start emissions, which are typically higher due to incomplete combustion, the L92 engine's cylinder heads feature rapid warm-up technologies. These include isolated coolant passages that allow for quicker heating of critical components, reducing the time required for the engine to reach its optimal operating temperature and minimizing cold-start emissions.

In conclusion, the cylinder head innovations in the L92 engine design reflect a concerted effort to meet increasingly stringent emissions regulations. Through a combination of advanced port designs, variable valve timing, direct injection, and thermal management strategies, engineers have successfully reduced emissions while maintaining performance and efficiency. As regulations continue to evolve, further innovations in cylinder head design will likely be necessary to ensure compliance and environmental sustainability.

Material Advancements

Material advancements have played a crucial role in enhancing the performance and efficiency of cylinder heads in L92 engine designs. The evolution of materials used in cylinder head construction has significantly impacted engine durability, thermal management, and overall performance.

Traditionally, cast iron was the primary material used for cylinder heads due to its strength and cost-effectiveness. However, the automotive industry has increasingly shifted towards aluminum alloys for cylinder head construction in modern engines, including the L92. This transition has been driven by the need for lighter weight components to improve fuel efficiency and reduce overall vehicle mass.

Aluminum alloys, particularly those in the 300 series, have become the material of choice for L92 cylinder heads. These alloys offer an excellent balance of strength, thermal conductivity, and weight reduction. The use of aluminum has allowed for more complex internal cooling passages, improving heat dissipation and enabling higher compression ratios without compromising engine reliability.

Recent advancements in metallurgy have led to the development of high-silicon aluminum alloys specifically tailored for cylinder head applications. These alloys exhibit improved thermal stability and wear resistance, addressing some of the historical concerns associated with aluminum cylinder heads, such as valve seat recession and thread strength.

Composite materials have also begun to make inroads in cylinder head design. Carbon fiber reinforced polymers (CFRP) are being explored for certain non-load bearing components of the cylinder head, such as valve covers, further reducing weight while maintaining structural integrity.

Coatings and surface treatments have emerged as another area of material innovation in L92 cylinder heads. Thermal barrier coatings, such as ceramic-based compounds, are being applied to combustion chamber surfaces to improve thermal efficiency and reduce heat transfer to the cooling system. These coatings can withstand extreme temperatures and help to maintain more consistent combustion chamber temperatures, potentially improving engine performance and emissions.

Nanotechnology is beginning to influence material choices for cylinder heads as well. Nano-engineered aluminum alloys with dispersed nanoparticles are showing promise in enhancing strength and wear resistance without significantly increasing weight. These materials could potentially allow for even lighter cylinder head designs without compromising durability.

The ongoing research in advanced manufacturing techniques, such as 3D printing of metal alloys, is opening new possibilities for cylinder head design. Additive manufacturing allows for the creation of complex internal structures that were previously impossible or impractical to produce using traditional casting methods. This technology could lead to optimized cooling channels and weight reduction in future L92 engine iterations.

Traditionally, cast iron was the primary material used for cylinder heads due to its strength and cost-effectiveness. However, the automotive industry has increasingly shifted towards aluminum alloys for cylinder head construction in modern engines, including the L92. This transition has been driven by the need for lighter weight components to improve fuel efficiency and reduce overall vehicle mass.

Aluminum alloys, particularly those in the 300 series, have become the material of choice for L92 cylinder heads. These alloys offer an excellent balance of strength, thermal conductivity, and weight reduction. The use of aluminum has allowed for more complex internal cooling passages, improving heat dissipation and enabling higher compression ratios without compromising engine reliability.

Recent advancements in metallurgy have led to the development of high-silicon aluminum alloys specifically tailored for cylinder head applications. These alloys exhibit improved thermal stability and wear resistance, addressing some of the historical concerns associated with aluminum cylinder heads, such as valve seat recession and thread strength.

Composite materials have also begun to make inroads in cylinder head design. Carbon fiber reinforced polymers (CFRP) are being explored for certain non-load bearing components of the cylinder head, such as valve covers, further reducing weight while maintaining structural integrity.

Coatings and surface treatments have emerged as another area of material innovation in L92 cylinder heads. Thermal barrier coatings, such as ceramic-based compounds, are being applied to combustion chamber surfaces to improve thermal efficiency and reduce heat transfer to the cooling system. These coatings can withstand extreme temperatures and help to maintain more consistent combustion chamber temperatures, potentially improving engine performance and emissions.

Nanotechnology is beginning to influence material choices for cylinder heads as well. Nano-engineered aluminum alloys with dispersed nanoparticles are showing promise in enhancing strength and wear resistance without significantly increasing weight. These materials could potentially allow for even lighter cylinder head designs without compromising durability.

The ongoing research in advanced manufacturing techniques, such as 3D printing of metal alloys, is opening new possibilities for cylinder head design. Additive manufacturing allows for the creation of complex internal structures that were previously impossible or impractical to produce using traditional casting methods. This technology could lead to optimized cooling channels and weight reduction in future L92 engine iterations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!