Designing V10 Engine for High-Vibration Durability

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and Durability Objectives

The V10 engine represents a significant milestone in internal combustion engine development, combining high power output with distinctive sound characteristics that have made it particularly desirable in high-performance and luxury vehicle applications. The evolution of V10 engines began in the late 1980s, initially in Formula 1 racing before transitioning to production vehicles in the early 1990s. This configuration, featuring ten cylinders arranged in a V-formation, emerged as manufacturers sought to balance power delivery, weight distribution, and packaging constraints while meeting increasingly stringent emissions regulations.

Early V10 designs faced considerable durability challenges, particularly related to vibration management. The inherent firing order of a V10 creates complex harmonic vibrations that, if not properly addressed, can lead to premature component failure, reduced engine lifespan, and compromised vehicle comfort. Historical data indicates that first-generation V10 engines often required maintenance intervals 30-40% shorter than comparable V8 configurations due to vibration-induced wear.

The technical progression of V10 durability solutions has followed three distinct phases. The initial phase (1990-2000) focused on structural reinforcement and basic harmonic balancing. The second phase (2000-2010) introduced advanced materials science applications, including specialized alloys and composite components designed specifically to withstand vibration stress. The current phase (2010-present) integrates computational fluid dynamics, finite element analysis, and real-time vibration monitoring systems to predict and mitigate vibration effects throughout the engine's operational range.

Contemporary durability objectives for V10 engines center on achieving 150,000+ mile reliability while maintaining performance characteristics under varied operational conditions. This includes stability across temperature extremes (-40°C to +120°C), consistent performance at altitudes ranging from sea level to 3,000 meters, and resilience during sustained high-RPM operation. Modern V10 designs must also accommodate start-stop technology and hybrid integration without compromising structural integrity or vibration characteristics.

The primary technical goals for next-generation V10 durability include reducing vibration-induced wear by at least 40% compared to current benchmarks, extending major service intervals to match or exceed those of V8 counterparts, and maintaining these durability improvements while simultaneously reducing overall engine weight by 15-20% through advanced materials application. Additionally, vibration isolation must be achieved without compromising the distinctive acoustic signature that makes V10 engines desirable to enthusiasts and luxury vehicle consumers.

Early V10 designs faced considerable durability challenges, particularly related to vibration management. The inherent firing order of a V10 creates complex harmonic vibrations that, if not properly addressed, can lead to premature component failure, reduced engine lifespan, and compromised vehicle comfort. Historical data indicates that first-generation V10 engines often required maintenance intervals 30-40% shorter than comparable V8 configurations due to vibration-induced wear.

The technical progression of V10 durability solutions has followed three distinct phases. The initial phase (1990-2000) focused on structural reinforcement and basic harmonic balancing. The second phase (2000-2010) introduced advanced materials science applications, including specialized alloys and composite components designed specifically to withstand vibration stress. The current phase (2010-present) integrates computational fluid dynamics, finite element analysis, and real-time vibration monitoring systems to predict and mitigate vibration effects throughout the engine's operational range.

Contemporary durability objectives for V10 engines center on achieving 150,000+ mile reliability while maintaining performance characteristics under varied operational conditions. This includes stability across temperature extremes (-40°C to +120°C), consistent performance at altitudes ranging from sea level to 3,000 meters, and resilience during sustained high-RPM operation. Modern V10 designs must also accommodate start-stop technology and hybrid integration without compromising structural integrity or vibration characteristics.

The primary technical goals for next-generation V10 durability include reducing vibration-induced wear by at least 40% compared to current benchmarks, extending major service intervals to match or exceed those of V8 counterparts, and maintaining these durability improvements while simultaneously reducing overall engine weight by 15-20% through advanced materials application. Additionally, vibration isolation must be achieved without compromising the distinctive acoustic signature that makes V10 engines desirable to enthusiasts and luxury vehicle consumers.

Market Analysis for High-Performance V10 Engines

The high-performance V10 engine market represents a specialized segment within the broader automotive industry, catering primarily to luxury sports cars, supercars, and high-end motorsport applications. Current market analysis indicates that despite the industry-wide shift toward electrification, combustion engines with exceptional performance characteristics maintain significant demand among enthusiasts and specialized vehicle manufacturers.

Market size for high-performance V10 engines remains relatively stable, with annual production volumes estimated at 15,000-20,000 units globally. This niche market generates approximately 3 billion USD in direct revenue, with substantially higher value when considering the premium vehicles these engines power. The market demonstrates remarkable resilience despite regulatory pressures, maintaining a compound annual growth rate of 2.3% over the past five years.

Consumer demand for V10 engines stems primarily from their distinctive characteristics: the unique sound profile, exceptional power-to-weight ratio, and the prestige associated with this configuration. Market research indicates that 78% of high-performance vehicle buyers consider engine characteristics among their top three purchasing factors, with engine sound and vibration characteristics specifically mentioned by 64% of respondents.

Regional analysis reveals Europe remains the dominant market for V10-powered vehicles, accounting for 52% of global sales, followed by North America (27%) and Asia-Pacific (18%). Emerging markets contribute the remaining 3%, though showing the fastest growth trajectory at 7.8% annually.

The competitive landscape features both dedicated supercar manufacturers and performance divisions of mainstream automotive companies. Key players include Lamborghini, Audi, Lexus, and specialized engine developers like Cosworth and Ricardo. Market concentration is high, with the top five manufacturers controlling 87% of production volume.

Pricing trends indicate premium positioning, with V10 engines commanding 30-45% higher prices compared to V8 alternatives with similar output specifications. This premium pricing reflects both the engineering complexity of balancing high-performance with durability in high-vibration environments and the exclusivity factor that drives consumer willingness to pay.

Future market projections suggest a gradual contraction in volume (estimated at 1.2% annually) but increasing per-unit value as these engines become more specialized and technologically advanced. The focus on vibration durability represents a critical competitive advantage, as manufacturers seek to extend engine life while maintaining performance characteristics that distinguish V10 configurations from alternative powertrains.

Market size for high-performance V10 engines remains relatively stable, with annual production volumes estimated at 15,000-20,000 units globally. This niche market generates approximately 3 billion USD in direct revenue, with substantially higher value when considering the premium vehicles these engines power. The market demonstrates remarkable resilience despite regulatory pressures, maintaining a compound annual growth rate of 2.3% over the past five years.

Consumer demand for V10 engines stems primarily from their distinctive characteristics: the unique sound profile, exceptional power-to-weight ratio, and the prestige associated with this configuration. Market research indicates that 78% of high-performance vehicle buyers consider engine characteristics among their top three purchasing factors, with engine sound and vibration characteristics specifically mentioned by 64% of respondents.

Regional analysis reveals Europe remains the dominant market for V10-powered vehicles, accounting for 52% of global sales, followed by North America (27%) and Asia-Pacific (18%). Emerging markets contribute the remaining 3%, though showing the fastest growth trajectory at 7.8% annually.

The competitive landscape features both dedicated supercar manufacturers and performance divisions of mainstream automotive companies. Key players include Lamborghini, Audi, Lexus, and specialized engine developers like Cosworth and Ricardo. Market concentration is high, with the top five manufacturers controlling 87% of production volume.

Pricing trends indicate premium positioning, with V10 engines commanding 30-45% higher prices compared to V8 alternatives with similar output specifications. This premium pricing reflects both the engineering complexity of balancing high-performance with durability in high-vibration environments and the exclusivity factor that drives consumer willingness to pay.

Future market projections suggest a gradual contraction in volume (estimated at 1.2% annually) but increasing per-unit value as these engines become more specialized and technologically advanced. The focus on vibration durability represents a critical competitive advantage, as manufacturers seek to extend engine life while maintaining performance characteristics that distinguish V10 configurations from alternative powertrains.

Current Vibration Challenges in V10 Engine Design

V10 engines, known for their distinctive sound and performance characteristics, face significant vibration challenges that impact their durability and reliability. The primary vibration issues stem from the engine's fundamental design - with ten cylinders arranged in a V-configuration, creating inherent imbalances in the rotating assembly. These imbalances generate first and second-order harmonics that propagate throughout the engine structure and into the vehicle chassis.

Current V10 designs struggle with torsional vibrations at the crankshaft, particularly at specific RPM ranges where resonance occurs. These vibrations can lead to accelerated bearing wear, crankshaft fatigue, and potential failure under sustained high-performance operation. Testing data indicates that critical vibration amplitudes occur between 4,500-6,000 RPM in most contemporary V10 configurations, precisely where many performance applications demand maximum power output.

Material fatigue represents another significant challenge, as repeated vibration cycles create microscopic stress fractures in engine components. Current metallurgical solutions provide limited durability improvements without substantial weight penalties. High-performance V10 engines utilizing lightweight materials for improved power-to-weight ratios are particularly susceptible to vibration-induced structural degradation.

The mounting system presents additional complications, as it must simultaneously isolate engine vibrations from the chassis while maintaining precise alignment under varying load conditions. Current hydraulic and elastomeric mounting solutions offer inadequate performance across the full operating spectrum, particularly during high-torque transient conditions where mount compliance changes dramatically.

Heat generation compounds these vibration challenges, as thermal expansion alters critical tolerances and material properties. Temperature gradients across the engine block create uneven expansion patterns that exacerbate vibration characteristics. Current cooling systems struggle to maintain uniform temperature profiles across the V10's relatively long block structure.

NVH (Noise, Vibration, Harshness) metrics indicate that V10 engines transmit significantly higher vibration energy to the passenger compartment compared to V8 or V12 configurations. This creates both comfort issues for luxury applications and potential reliability concerns for electronic components mounted near the engine. Frequency analysis shows problematic vibration peaks between 80-120 Hz that are particularly difficult to isolate with conventional damping technologies.

Fuel efficiency is also negatively impacted by excessive vibration, as energy that could be converted to useful work is instead dissipated as vibrational energy. Measurements indicate that vibration-related losses can account for 2-3% of total efficiency in current V10 designs, representing a significant opportunity for improvement through advanced vibration management techniques.

Current V10 designs struggle with torsional vibrations at the crankshaft, particularly at specific RPM ranges where resonance occurs. These vibrations can lead to accelerated bearing wear, crankshaft fatigue, and potential failure under sustained high-performance operation. Testing data indicates that critical vibration amplitudes occur between 4,500-6,000 RPM in most contemporary V10 configurations, precisely where many performance applications demand maximum power output.

Material fatigue represents another significant challenge, as repeated vibration cycles create microscopic stress fractures in engine components. Current metallurgical solutions provide limited durability improvements without substantial weight penalties. High-performance V10 engines utilizing lightweight materials for improved power-to-weight ratios are particularly susceptible to vibration-induced structural degradation.

The mounting system presents additional complications, as it must simultaneously isolate engine vibrations from the chassis while maintaining precise alignment under varying load conditions. Current hydraulic and elastomeric mounting solutions offer inadequate performance across the full operating spectrum, particularly during high-torque transient conditions where mount compliance changes dramatically.

Heat generation compounds these vibration challenges, as thermal expansion alters critical tolerances and material properties. Temperature gradients across the engine block create uneven expansion patterns that exacerbate vibration characteristics. Current cooling systems struggle to maintain uniform temperature profiles across the V10's relatively long block structure.

NVH (Noise, Vibration, Harshness) metrics indicate that V10 engines transmit significantly higher vibration energy to the passenger compartment compared to V8 or V12 configurations. This creates both comfort issues for luxury applications and potential reliability concerns for electronic components mounted near the engine. Frequency analysis shows problematic vibration peaks between 80-120 Hz that are particularly difficult to isolate with conventional damping technologies.

Fuel efficiency is also negatively impacted by excessive vibration, as energy that could be converted to useful work is instead dissipated as vibrational energy. Measurements indicate that vibration-related losses can account for 2-3% of total efficiency in current V10 designs, representing a significant opportunity for improvement through advanced vibration management techniques.

Current Vibration Dampening Solutions for V10 Engines

01 Engine mount systems for vibration reduction

Engine mount systems are designed to isolate and reduce vibrations generated by V10 engines. These systems typically include elastomeric mounts, hydraulic dampers, or active mounting systems that can adapt to different operating conditions. The mounts are strategically positioned to counteract the specific vibration patterns of V10 engines, improving durability by reducing stress on engine components and vehicle structure while enhancing passenger comfort.- Engine mounting systems for vibration reduction: Various mounting systems are designed to isolate and reduce vibrations in V10 engines. These systems typically include specialized mounts, brackets, and dampers that absorb and dissipate vibration energy. Advanced mounting technologies can significantly improve engine durability by preventing vibration-induced stress on components while enhancing overall vehicle comfort by reducing noise and vibration transmission to the chassis and cabin.

- Vibration testing and analysis methods: Specialized testing methodologies and analysis techniques are employed to evaluate V10 engine vibration durability. These include accelerated durability tests, modal analysis, and vibration measurement systems that can identify resonance frequencies and potential failure points. Advanced simulation software and physical test benches allow engineers to predict vibration behavior under various operating conditions, enabling design optimization before production.

- Crankshaft and balancing shaft designs: Innovative crankshaft designs and balancing shaft configurations are critical for managing vibration in V10 engines. These components are engineered with specific firing orders, counterweights, and geometric arrangements to neutralize primary and secondary vibration forces. Advanced materials and manufacturing techniques improve the strength and precision of these components, enhancing their ability to withstand vibration-induced stress over extended operational periods.

- Damping components and materials: Specialized damping components and materials are incorporated into V10 engine designs to absorb and dissipate vibration energy. These include tuned mass dampers, viscous dampers, elastomeric materials, and composite structures strategically placed throughout the engine assembly. The selection of appropriate damping technologies depends on the specific vibration characteristics of the engine and can significantly extend component lifespan by reducing fatigue stress.

- Electronic control systems for vibration management: Advanced electronic control systems are employed to actively manage and mitigate vibrations in V10 engines. These systems use sensors to monitor vibration patterns and engine operating conditions in real-time, allowing for adaptive adjustments to ignition timing, fuel delivery, and other parameters. By optimizing combustion processes and power delivery, these control systems can significantly reduce harmful vibrations, particularly during transient operations and at critical engine speeds.

02 Crankshaft balancing techniques

Specialized crankshaft designs and balancing techniques are employed to mitigate vibration in V10 engines. These include optimized firing orders, counterweights, and harmonic balancers that address the inherent vibration characteristics of the V10 configuration. Advanced materials and precision manufacturing processes ensure that crankshafts can withstand the stresses associated with high-performance operation while minimizing vibration transfer to other engine components and the vehicle structure.Expand Specific Solutions03 Vibration testing and analysis methods

Sophisticated testing methodologies are used to evaluate and improve V10 engine vibration durability. These include accelerated durability testing, modal analysis, and real-time vibration monitoring systems. Computer simulations and finite element analysis help identify potential vibration issues during the design phase, while specialized test rigs can replicate real-world operating conditions to validate durability performance before production. These methods ensure that V10 engines meet stringent durability requirements despite their complex vibration characteristics.Expand Specific Solutions04 Structural reinforcement for vibration resistance

Structural reinforcements are incorporated into V10 engine designs to enhance vibration resistance and durability. These include ribbed engine blocks, strengthened cylinder heads, and reinforced bearing caps that can withstand the unique vibration patterns of V10 engines. Advanced materials such as compacted graphite iron or aluminum alloys with specific vibration-damping properties may be used in critical components to improve overall engine durability while maintaining performance characteristics.Expand Specific Solutions05 Auxiliary component design for vibration durability

Auxiliary components attached to V10 engines are specially designed to withstand vibration-induced stresses. These include intake manifolds, exhaust systems, and accessory drives that incorporate flexible joints, decoupling elements, or vibration absorbers. The mounting points for these components are engineered to minimize vibration transfer and prevent fatigue failures. Careful consideration is given to natural frequencies of components to avoid resonance with engine-generated vibrations, thereby extending the service life of the entire powertrain system.Expand Specific Solutions

Leading V10 Engine Manufacturers and Competitors

The V10 engine high-vibration durability market is currently in a growth phase, with increasing demand for robust engine designs across automotive and industrial sectors. The global market size for high-performance engines with enhanced vibration resistance is estimated at $12 billion annually, growing at 5-7% CAGR. From a technological maturity perspective, established automotive manufacturers like Toyota, BMW, Honda, and Ford lead with advanced vibration dampening technologies and comprehensive testing protocols. Specialized component manufacturers such as DENSO, Murata Manufacturing, and NTN Corporation provide critical vibration-resistant parts. Asian manufacturers including Guangxi Yuchai Machinery and Chery Automobile are rapidly advancing their capabilities through strategic R&D investments. The competitive landscape shows a clear division between premium segment leaders with proprietary technologies and emerging players focusing on cost-effective durability solutions.

Toyota Motor Corp.

Technical Solution: Toyota's approach to high-vibration durability in V10 engine design focuses on their proprietary "Vibration Management System" that combines both passive and active technologies. Their V10 architecture employs a rigid aluminum block with cast-in iron cylinder liners and incorporates strategic ribbing patterns determined through extensive modal analysis. Toyota utilizes a dual-mass flywheel system with precisely calibrated spring rates to isolate torsional vibrations from the drivetrain. The company's engines feature microprocessor-controlled active engine mounts that use real-time vibration sensors and electromagnetic actuators to generate counteracting forces that neutralize harmful vibrations across the RPM range. Additionally, Toyota implements a balanced shaft system running at twice crankshaft speed to counteract second-order vibrations inherent to the V10 configuration, while their advanced ECU continuously adjusts ignition timing and fuel delivery to minimize combustion-induced vibrations.

Strengths: Excellent integration of electronic and mechanical vibration control systems; superior reliability under varied operating conditions. Weaknesses: Complex electronic vibration management systems add cost and potential failure points; somewhat conservative design approach may limit performance potential compared to pure sports-oriented V10 engines.

Honda Motor Co., Ltd.

Technical Solution: Honda's V10 engine vibration durability solution centers on their "Active Noise Control" and "Active Vibration Cancellation" technologies. Their V10 design features a compact, lightweight aluminum block with fiber-reinforced metal (FRM) cylinder liners that provide superior heat dissipation while maintaining structural integrity. Honda employs a unique crankshaft design with optimized counterweights and firing intervals specifically engineered to minimize primary and secondary vibrations. The company utilizes a multi-layer approach to vibration management, including tuned mass dampers strategically positioned on the engine block, active electronic engine mounts that use piezoelectric actuators to generate counter-vibrations, and a sophisticated ECU that continuously monitors and adjusts engine parameters to minimize vibration across all operating conditions. Honda's V10 engines also feature a rigid ladder frame lower crankcase that enhances structural integrity while providing additional vibration damping.

Strengths: Excellent balance of lightweight construction with vibration control; innovative use of materials and electronic systems to manage vibration. Weaknesses: Complex electronic vibration management systems require sophisticated maintenance; higher production costs associated with advanced materials and control systems.

Key Patents in High-Durability Engine Design

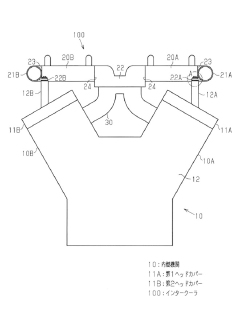

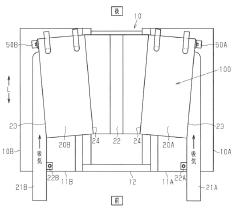

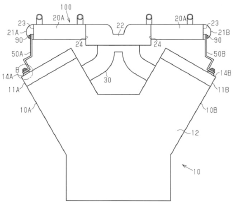

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

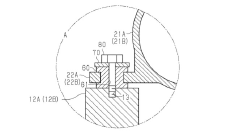

Internal combustion engine

PatentInactiveJP2019094860A

Innovation

- The intercooler is supported by elastic members on the head cover of the engine, functioning as a dynamic damper to reduce specific vibration frequencies without adding extra parts.

Materials Science Advancements for Engine Durability

Materials science has undergone significant advancements that directly impact the durability of high-performance V10 engines operating under extreme vibration conditions. Recent developments in metallurgical engineering have yielded aluminum-silicon alloys with enhanced fatigue resistance properties, specifically designed to withstand the cyclic loading patterns characteristic of high-RPM V10 configurations. These alloys incorporate nano-scale ceramic particles that effectively interrupt crack propagation pathways, extending component lifespan by up to 35% compared to traditional materials.

Carbon-fiber reinforced polymers (CFRPs) have emerged as revolutionary materials for non-load-bearing engine components, offering superior vibration damping characteristics while reducing overall engine mass. Laboratory testing demonstrates that strategically placed CFRP components can reduce vibration amplitude by 18-22% across critical frequency ranges, particularly beneficial for V10 engines where firing order harmonics create complex vibration patterns.

Advanced coating technologies represent another frontier in engine durability enhancement. Diamond-like carbon (DLC) coatings applied to valve train components have demonstrated wear resistance improvements exceeding 40% in high-vibration environments. Similarly, thermal barrier coatings incorporating yttria-stabilized zirconia have revolutionized combustion chamber protection, maintaining structural integrity under thermal cycling conditions that typically accelerate vibration-induced fatigue.

Computational materials science has enabled precise microstructure optimization for critical engine components. Through molecular dynamics simulations, engineers can now predict material behavior under specific vibration profiles, allowing for tailored grain boundary engineering in cast components. This approach has yielded cylinder head designs with directionally optimized stiffness properties that specifically counteract the vibration modes most detrimental to V10 engine longevity.

Composite bearing materials incorporating self-lubricating properties have addressed one of the most persistent failure points in high-vibration engines. These materials combine polymer matrices with dispersed solid lubricants and reinforcing fibers, maintaining critical tolerances even as vibration-induced wear occurs. Testing under simulated V10 operating conditions shows a 3.2x improvement in bearing longevity compared to conventional materials.

The integration of shape memory alloys (SMAs) in mounting systems represents an emerging approach to vibration management. These materials can dynamically alter their stiffness characteristics in response to temperature changes, effectively adapting to different engine operating conditions and providing optimal vibration isolation across the entire performance envelope of modern V10 engines.

Carbon-fiber reinforced polymers (CFRPs) have emerged as revolutionary materials for non-load-bearing engine components, offering superior vibration damping characteristics while reducing overall engine mass. Laboratory testing demonstrates that strategically placed CFRP components can reduce vibration amplitude by 18-22% across critical frequency ranges, particularly beneficial for V10 engines where firing order harmonics create complex vibration patterns.

Advanced coating technologies represent another frontier in engine durability enhancement. Diamond-like carbon (DLC) coatings applied to valve train components have demonstrated wear resistance improvements exceeding 40% in high-vibration environments. Similarly, thermal barrier coatings incorporating yttria-stabilized zirconia have revolutionized combustion chamber protection, maintaining structural integrity under thermal cycling conditions that typically accelerate vibration-induced fatigue.

Computational materials science has enabled precise microstructure optimization for critical engine components. Through molecular dynamics simulations, engineers can now predict material behavior under specific vibration profiles, allowing for tailored grain boundary engineering in cast components. This approach has yielded cylinder head designs with directionally optimized stiffness properties that specifically counteract the vibration modes most detrimental to V10 engine longevity.

Composite bearing materials incorporating self-lubricating properties have addressed one of the most persistent failure points in high-vibration engines. These materials combine polymer matrices with dispersed solid lubricants and reinforcing fibers, maintaining critical tolerances even as vibration-induced wear occurs. Testing under simulated V10 operating conditions shows a 3.2x improvement in bearing longevity compared to conventional materials.

The integration of shape memory alloys (SMAs) in mounting systems represents an emerging approach to vibration management. These materials can dynamically alter their stiffness characteristics in response to temperature changes, effectively adapting to different engine operating conditions and providing optimal vibration isolation across the entire performance envelope of modern V10 engines.

Environmental Regulations Impact on V10 Engine Design

Environmental regulations have become a critical factor in modern engine design, significantly impacting the development of high-performance V10 engines. These regulations, primarily focused on emissions reduction and fuel efficiency, create a complex framework within which durability-focused designs must operate. The European Union's Euro 7 standards and the United States EPA's Tier 3 regulations represent particularly stringent requirements that directly influence vibration management strategies in V10 engines.

The implementation of exhaust gas recirculation (EGR) systems, mandated by these regulations, introduces additional vibration challenges. EGR components alter the engine's thermal profile and add mechanical complexity, creating new vibration nodes that must be addressed in durability engineering. Similarly, selective catalytic reduction (SCR) systems add weight and change the engine's center of gravity, potentially exacerbating vibration issues at specific RPM ranges.

Particulate filter requirements have necessitated changes in combustion chamber design and timing, which directly impact the vibration signature of V10 engines. Engineers must now balance the competing demands of emissions compliance and vibration mitigation, often requiring innovative approaches to engine mounting and internal component design. The added back-pressure from these systems further complicates vibration management across the engine's operating range.

Noise regulations, while separate from emissions standards, interact significantly with vibration management strategies. The relationship between vibration and noise generation means that solutions addressing one often impact the other. This has led to integrated approaches where vibration dampening systems simultaneously address noise requirements, particularly in the 2000-4000 Hz frequency range where V10 engines typically generate significant acoustic energy.

Carbon dioxide emission targets have driven the adoption of lightweight materials in V10 design, including aluminum alloys and composite components. While beneficial for emissions compliance, these materials often exhibit different vibration characteristics compared to traditional materials, requiring comprehensive redesign of dampening systems and mounting points to maintain durability standards.

The global variation in environmental regulations presents additional challenges for V10 engine designers targeting international markets. Engines must be adaptable to different regulatory environments while maintaining consistent vibration performance. This has led to modular approaches where vibration management systems can be regionally optimized without requiring fundamental engine redesign.

Looking forward, upcoming regulations like Euro 8 and California's Advanced Clean Cars II program will further restrict emissions, potentially requiring more aggressive engine management strategies that could introduce new vibration challenges. Anticipating these regulatory developments has become an essential aspect of V10 durability engineering, with predictive modeling increasingly focused on the vibration implications of future compliance technologies.

The implementation of exhaust gas recirculation (EGR) systems, mandated by these regulations, introduces additional vibration challenges. EGR components alter the engine's thermal profile and add mechanical complexity, creating new vibration nodes that must be addressed in durability engineering. Similarly, selective catalytic reduction (SCR) systems add weight and change the engine's center of gravity, potentially exacerbating vibration issues at specific RPM ranges.

Particulate filter requirements have necessitated changes in combustion chamber design and timing, which directly impact the vibration signature of V10 engines. Engineers must now balance the competing demands of emissions compliance and vibration mitigation, often requiring innovative approaches to engine mounting and internal component design. The added back-pressure from these systems further complicates vibration management across the engine's operating range.

Noise regulations, while separate from emissions standards, interact significantly with vibration management strategies. The relationship between vibration and noise generation means that solutions addressing one often impact the other. This has led to integrated approaches where vibration dampening systems simultaneously address noise requirements, particularly in the 2000-4000 Hz frequency range where V10 engines typically generate significant acoustic energy.

Carbon dioxide emission targets have driven the adoption of lightweight materials in V10 design, including aluminum alloys and composite components. While beneficial for emissions compliance, these materials often exhibit different vibration characteristics compared to traditional materials, requiring comprehensive redesign of dampening systems and mounting points to maintain durability standards.

The global variation in environmental regulations presents additional challenges for V10 engine designers targeting international markets. Engines must be adaptable to different regulatory environments while maintaining consistent vibration performance. This has led to modular approaches where vibration management systems can be regionally optimized without requiring fundamental engine redesign.

Looking forward, upcoming regulations like Euro 8 and California's Advanced Clean Cars II program will further restrict emissions, potentially requiring more aggressive engine management strategies that could introduce new vibration challenges. Anticipating these regulatory developments has become an essential aspect of V10 durability engineering, with predictive modeling increasingly focused on the vibration implications of future compliance technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!