Dimethyl Ether's Impact on Waste Reduction Technologies

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, gaining significant attention in the field of waste reduction technologies. The evolution of DME technology can be traced back to the early 20th century when it was first synthesized. However, its potential as a clean-burning fuel and versatile chemical compound has only been fully recognized in recent decades.

The development of DME technology has been driven by the growing need for sustainable energy sources and efficient waste management solutions. As global concerns about environmental pollution and resource depletion have intensified, researchers and industry professionals have turned to DME as a potential answer to these challenges. The technology has progressed from laboratory-scale experiments to pilot plants and commercial-scale production facilities.

One of the key drivers behind DME's technological advancement has been its ability to be produced from a wide range of feedstocks, including natural gas, coal, and biomass. This versatility has made DME an attractive option for countries seeking to reduce their dependence on traditional fossil fuels and utilize local resources more effectively. The waste-to-DME conversion process has gained particular attention as a means of addressing both waste management and energy production challenges simultaneously.

The evolution of DME technology has been marked by several significant milestones. These include the development of more efficient catalysts for DME synthesis, improvements in production processes to increase yield and reduce energy consumption, and advancements in DME utilization technologies for various applications. The integration of DME production with existing industrial processes, such as methanol synthesis and biogas upgrading, has also contributed to its growing importance in the field of waste reduction.

Looking ahead, the primary objectives of DME technology in the context of waste reduction are multifaceted. First and foremost, there is a strong focus on optimizing the waste-to-DME conversion process to maximize efficiency and minimize environmental impact. This includes developing more robust and cost-effective methods for handling diverse waste streams and improving the overall energy balance of the production process.

Another key objective is to expand the range of waste materials that can be effectively converted into DME. This involves research into new pretreatment techniques, catalyst formulations, and reactor designs that can handle a broader spectrum of feedstocks, including municipal solid waste, agricultural residues, and industrial by-products. By doing so, DME technology aims to provide a more comprehensive solution to waste management challenges across various sectors.

Furthermore, there is a growing emphasis on integrating DME production with other waste reduction and renewable energy technologies. This includes exploring synergies with anaerobic digestion, gasification, and other thermochemical conversion processes to create more efficient and flexible waste-to-energy systems. The ultimate goal is to develop integrated solutions that can address multiple environmental challenges simultaneously, contributing to a more circular and sustainable economy.

The development of DME technology has been driven by the growing need for sustainable energy sources and efficient waste management solutions. As global concerns about environmental pollution and resource depletion have intensified, researchers and industry professionals have turned to DME as a potential answer to these challenges. The technology has progressed from laboratory-scale experiments to pilot plants and commercial-scale production facilities.

One of the key drivers behind DME's technological advancement has been its ability to be produced from a wide range of feedstocks, including natural gas, coal, and biomass. This versatility has made DME an attractive option for countries seeking to reduce their dependence on traditional fossil fuels and utilize local resources more effectively. The waste-to-DME conversion process has gained particular attention as a means of addressing both waste management and energy production challenges simultaneously.

The evolution of DME technology has been marked by several significant milestones. These include the development of more efficient catalysts for DME synthesis, improvements in production processes to increase yield and reduce energy consumption, and advancements in DME utilization technologies for various applications. The integration of DME production with existing industrial processes, such as methanol synthesis and biogas upgrading, has also contributed to its growing importance in the field of waste reduction.

Looking ahead, the primary objectives of DME technology in the context of waste reduction are multifaceted. First and foremost, there is a strong focus on optimizing the waste-to-DME conversion process to maximize efficiency and minimize environmental impact. This includes developing more robust and cost-effective methods for handling diverse waste streams and improving the overall energy balance of the production process.

Another key objective is to expand the range of waste materials that can be effectively converted into DME. This involves research into new pretreatment techniques, catalyst formulations, and reactor designs that can handle a broader spectrum of feedstocks, including municipal solid waste, agricultural residues, and industrial by-products. By doing so, DME technology aims to provide a more comprehensive solution to waste management challenges across various sectors.

Furthermore, there is a growing emphasis on integrating DME production with other waste reduction and renewable energy technologies. This includes exploring synergies with anaerobic digestion, gasification, and other thermochemical conversion processes to create more efficient and flexible waste-to-energy systems. The ultimate goal is to develop integrated solutions that can address multiple environmental challenges simultaneously, contributing to a more circular and sustainable economy.

Market Analysis for DME in Waste Reduction

The market for Dimethyl Ether (DME) in waste reduction technologies is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on waste management. DME, a clean-burning, non-toxic fuel, has emerged as a promising alternative in various waste reduction applications, particularly in the treatment of organic waste and the conversion of waste-to-energy processes.

In the organic waste treatment sector, DME has shown potential in enhancing the efficiency of anaerobic digestion processes. By introducing DME into the digestion system, the methane yield can be increased, leading to higher energy recovery from organic waste. This application has garnered interest from municipal waste management facilities and agricultural operations dealing with large volumes of organic waste.

The waste-to-energy market segment has also recognized the benefits of DME. As a versatile fuel, DME can be produced from various waste streams, including municipal solid waste, agricultural residues, and industrial by-products. This capability aligns well with the circular economy concept, where waste is viewed as a resource rather than a burden. The market for DME-based waste-to-energy solutions is particularly strong in regions with limited landfill capacity and high energy costs.

In the industrial sector, DME is being explored as a potential replacement for traditional solvents in waste treatment processes. Its low toxicity and high solvency make it an attractive option for industries seeking to reduce their environmental footprint while maintaining operational efficiency. This application is gaining traction in the chemical, pharmaceutical, and manufacturing industries.

The market demand for DME in waste reduction technologies is also being fueled by government initiatives and policies promoting sustainable waste management practices. Many countries have implemented regulations that incentivize the adoption of cleaner technologies, creating a favorable environment for DME-based solutions. This regulatory landscape is expected to continue driving market growth in the coming years.

Geographically, the Asia-Pacific region, particularly China and India, is expected to be a major market for DME in waste reduction technologies. These countries face significant waste management challenges due to rapid urbanization and industrial growth, making them prime candidates for innovative waste reduction solutions. Europe and North America are also showing strong interest in DME applications, driven by their advanced waste management infrastructure and commitment to reducing carbon emissions.

Despite the promising outlook, the market for DME in waste reduction technologies faces some challenges. The relatively high production costs of DME compared to conventional fuels and the need for specialized infrastructure are potential barriers to widespread adoption. However, ongoing research and development efforts are focused on improving production efficiency and reducing costs, which is expected to address these challenges in the medium to long term.

In the organic waste treatment sector, DME has shown potential in enhancing the efficiency of anaerobic digestion processes. By introducing DME into the digestion system, the methane yield can be increased, leading to higher energy recovery from organic waste. This application has garnered interest from municipal waste management facilities and agricultural operations dealing with large volumes of organic waste.

The waste-to-energy market segment has also recognized the benefits of DME. As a versatile fuel, DME can be produced from various waste streams, including municipal solid waste, agricultural residues, and industrial by-products. This capability aligns well with the circular economy concept, where waste is viewed as a resource rather than a burden. The market for DME-based waste-to-energy solutions is particularly strong in regions with limited landfill capacity and high energy costs.

In the industrial sector, DME is being explored as a potential replacement for traditional solvents in waste treatment processes. Its low toxicity and high solvency make it an attractive option for industries seeking to reduce their environmental footprint while maintaining operational efficiency. This application is gaining traction in the chemical, pharmaceutical, and manufacturing industries.

The market demand for DME in waste reduction technologies is also being fueled by government initiatives and policies promoting sustainable waste management practices. Many countries have implemented regulations that incentivize the adoption of cleaner technologies, creating a favorable environment for DME-based solutions. This regulatory landscape is expected to continue driving market growth in the coming years.

Geographically, the Asia-Pacific region, particularly China and India, is expected to be a major market for DME in waste reduction technologies. These countries face significant waste management challenges due to rapid urbanization and industrial growth, making them prime candidates for innovative waste reduction solutions. Europe and North America are also showing strong interest in DME applications, driven by their advanced waste management infrastructure and commitment to reducing carbon emissions.

Despite the promising outlook, the market for DME in waste reduction technologies faces some challenges. The relatively high production costs of DME compared to conventional fuels and the need for specialized infrastructure are potential barriers to widespread adoption. However, ongoing research and development efforts are focused on improving production efficiency and reducing costs, which is expected to address these challenges in the medium to long term.

Current DME Challenges in Waste Management

Despite the potential of Dimethyl Ether (DME) in waste reduction technologies, several challenges hinder its widespread adoption in waste management. One of the primary obstacles is the limited infrastructure for DME production and distribution. The current waste management systems are not equipped to handle DME effectively, requiring significant investments in new facilities and equipment.

The production cost of DME remains relatively high compared to conventional fuels, making it less economically viable for large-scale waste management applications. This cost factor is particularly significant in developing countries where waste management budgets are often constrained. Additionally, the energy density of DME is lower than that of traditional fossil fuels, necessitating larger storage and transportation capacities, which further increases operational costs.

Technical challenges also persist in the efficient conversion of waste to DME. While the process has been demonstrated on a small scale, scaling up to industrial levels presents difficulties in maintaining consistent quality and yield. The heterogeneous nature of waste streams complicates the conversion process, requiring advanced sorting and pretreatment technologies to ensure optimal DME production.

Environmental concerns pose another challenge. Although DME is considered a cleaner alternative to conventional fuels, its production still generates some emissions. Ensuring that the overall lifecycle emissions of DME-based waste management systems are significantly lower than traditional methods is crucial for widespread acceptance and regulatory approval.

Regulatory hurdles and policy gaps further impede DME adoption in waste management. Many countries lack clear guidelines and standards for DME use in waste reduction technologies, creating uncertainty for potential investors and operators. The absence of supportive policies and incentives for DME-based waste management solutions slows down research, development, and implementation efforts.

Public awareness and acceptance of DME technology in waste management remain low. The unfamiliarity with DME and its benefits among policymakers, industry stakeholders, and the general public creates resistance to change and slows the transition from conventional waste management methods.

Lastly, the integration of DME-based technologies into existing waste management systems presents logistical and operational challenges. Retrofitting current facilities or building new ones to accommodate DME production and utilization requires careful planning, substantial investment, and potential disruptions to ongoing waste management operations.

The production cost of DME remains relatively high compared to conventional fuels, making it less economically viable for large-scale waste management applications. This cost factor is particularly significant in developing countries where waste management budgets are often constrained. Additionally, the energy density of DME is lower than that of traditional fossil fuels, necessitating larger storage and transportation capacities, which further increases operational costs.

Technical challenges also persist in the efficient conversion of waste to DME. While the process has been demonstrated on a small scale, scaling up to industrial levels presents difficulties in maintaining consistent quality and yield. The heterogeneous nature of waste streams complicates the conversion process, requiring advanced sorting and pretreatment technologies to ensure optimal DME production.

Environmental concerns pose another challenge. Although DME is considered a cleaner alternative to conventional fuels, its production still generates some emissions. Ensuring that the overall lifecycle emissions of DME-based waste management systems are significantly lower than traditional methods is crucial for widespread acceptance and regulatory approval.

Regulatory hurdles and policy gaps further impede DME adoption in waste management. Many countries lack clear guidelines and standards for DME use in waste reduction technologies, creating uncertainty for potential investors and operators. The absence of supportive policies and incentives for DME-based waste management solutions slows down research, development, and implementation efforts.

Public awareness and acceptance of DME technology in waste management remain low. The unfamiliarity with DME and its benefits among policymakers, industry stakeholders, and the general public creates resistance to change and slows the transition from conventional waste management methods.

Lastly, the integration of DME-based technologies into existing waste management systems presents logistical and operational challenges. Retrofitting current facilities or building new ones to accommodate DME production and utilization requires careful planning, substantial investment, and potential disruptions to ongoing waste management operations.

Current DME Waste Reduction Solutions

01 Improved catalytic processes for dimethyl ether production

Advanced catalytic processes can be employed to enhance the efficiency of dimethyl ether production, reducing waste generation. These processes often involve optimized reaction conditions, novel catalyst formulations, or improved reactor designs that increase yield and selectivity, thereby minimizing unwanted by-products and waste streams.- Improved catalytic processes for dimethyl ether production: Enhancing catalytic processes in dimethyl ether production can significantly reduce waste. This involves developing more efficient catalysts, optimizing reaction conditions, and improving reactor designs. These advancements lead to higher conversion rates, reduced byproduct formation, and overall process efficiency, thereby minimizing waste generation.

- Recycling and recovery systems for dimethyl ether production: Implementing recycling and recovery systems in dimethyl ether production facilities can greatly reduce waste. This includes techniques for capturing and reusing unreacted feedstock, separating and purifying byproducts, and recirculating process streams. Such systems help to maximize resource utilization and minimize the discharge of waste materials.

- Process integration and heat recovery in dimethyl ether plants: Integrating various processes within dimethyl ether production plants and implementing effective heat recovery systems can lead to significant waste reduction. This approach involves optimizing energy use, reducing cooling water consumption, and minimizing flaring. By improving overall plant efficiency, waste generation is reduced across multiple stages of production.

- Advanced separation and purification techniques: Employing advanced separation and purification techniques can help reduce waste in dimethyl ether production. This includes using innovative distillation methods, membrane technologies, and adsorption processes. These techniques allow for more efficient separation of dimethyl ether from byproducts and impurities, reducing the amount of waste generated during purification steps.

- Continuous monitoring and process control systems: Implementing continuous monitoring and advanced process control systems can contribute to waste reduction in dimethyl ether production. These systems allow for real-time adjustments to process parameters, early detection of equipment malfunctions, and optimization of reaction conditions. By maintaining optimal operating conditions, waste generation can be minimized throughout the production process.

02 Recycling and recovery of unreacted materials

Implementing recycling and recovery systems for unreacted materials in the dimethyl ether production process can significantly reduce waste. This may involve separating and reintroducing unreacted methanol or other feedstocks back into the production cycle, as well as capturing and reusing any off-gases or by-products.Expand Specific Solutions03 Process integration and heat recovery

Integrating various stages of the dimethyl ether production process and implementing effective heat recovery systems can minimize energy consumption and reduce overall waste. This may include utilizing waste heat from one process step to power another, or combining multiple reaction steps to improve efficiency and reduce intermediate waste products.Expand Specific Solutions04 Utilization of renewable feedstocks

Employing renewable feedstocks for dimethyl ether production can reduce waste associated with fossil fuel-based processes. This may involve using biomass-derived methanol or directly converting biomass to dimethyl ether, potentially reducing carbon emissions and minimizing waste streams associated with traditional fossil fuel extraction and processing.Expand Specific Solutions05 Advanced purification and separation techniques

Implementing advanced purification and separation techniques can help reduce waste in dimethyl ether production by improving product quality and minimizing the generation of off-spec material. These techniques may include novel distillation methods, membrane separation technologies, or adsorption processes that enhance the purity of the final product while reducing waste streams.Expand Specific Solutions

Key Players in DME Waste Reduction

The dimethyl ether (DME) market for waste reduction technologies is in a growth phase, driven by increasing environmental concerns and the push for cleaner fuel alternatives. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, DME production and application in waste reduction are advancing, with key players like China Petroleum & Chemical Corp., SK Energy, and BASF leading innovation efforts. These companies, along with research institutions such as Fraunhofer-Gesellschaft and the University of Southern California, are developing more efficient production methods and exploring new applications. The technology's maturity is progressing, but there's still room for improvement in terms of cost-effectiveness and large-scale implementation across various waste reduction sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced technologies for dimethyl ether (DME) production and utilization in waste reduction. Their process involves gasification of various waste materials, including municipal solid waste and biomass, to produce syngas. This syngas is then converted to DME through catalytic synthesis[1]. The company has implemented a two-step process: first, methanol synthesis from syngas, followed by methanol dehydration to DME. This approach allows for flexible feedstock utilization and efficient waste conversion[2]. Sinopec has also explored direct DME synthesis from syngas, potentially improving overall process efficiency. Their technology includes innovative catalyst designs that enhance selectivity and yield in DME production from waste-derived syngas[3].

Strengths: Extensive experience in large-scale chemical processing, established infrastructure for DME distribution. Weaknesses: Potential high capital costs for waste-to-DME facilities, dependence on consistent waste feedstock supply.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed a cutting-edge technology for DME production from waste materials, focusing on reducing environmental impact. Their process utilizes a novel dual-function catalyst system that enables direct synthesis of DME from syngas derived from waste gasification[4]. This one-step process eliminates the need for separate methanol synthesis and dehydration steps, potentially reducing capital and operating costs. The company's technology incorporates advanced heat integration and energy recovery systems, maximizing overall process efficiency. Haldor Topsøe has also developed specialized catalysts that are resistant to impurities commonly found in waste-derived syngas, ensuring long-term stability and performance[5]. Their DME production technology can be integrated with existing waste management facilities, offering a comprehensive solution for waste reduction and clean fuel production.

Strengths: Highly efficient one-step DME synthesis process, expertise in catalyst development. Weaknesses: May require significant modifications to existing waste treatment infrastructure, potential scalability challenges for smaller waste management operations.

Core DME Innovations for Waste Management

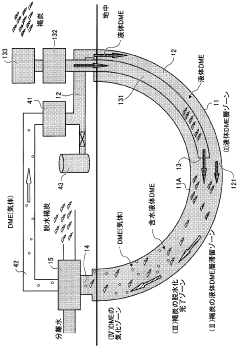

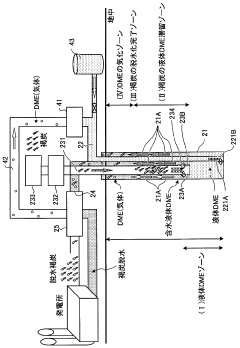

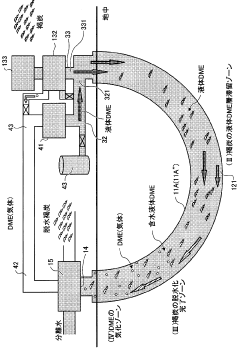

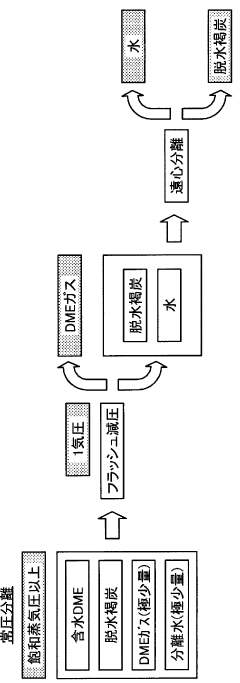

Dehydration system and dehydration process for water-containing substances

PatentWO2009022726A1

Innovation

- A dehydration system utilizing dimethyl ether (DME) that brings DME into contact with a water-containing substance through a contact portion in a well system, leveraging height differences and hydrostatic pressure to facilitate water absorption and evaporation, allowing for efficient separation with lower energy input.

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Environmental Impact Assessment of DME

The environmental impact assessment of Dimethyl Ether (DME) in waste reduction technologies reveals both positive and negative effects on ecosystems and human health. DME, as a clean-burning fuel alternative, offers significant potential for reducing harmful emissions compared to traditional fossil fuels. When used in waste-to-energy processes, DME can help mitigate greenhouse gas emissions from landfills and waste treatment facilities.

One of the primary environmental benefits of DME in waste reduction is its ability to lower carbon dioxide emissions. When produced from renewable sources or waste materials, DME can achieve near-carbon neutrality, contributing to climate change mitigation efforts. Additionally, DME combustion produces minimal particulate matter and sulfur oxides, leading to improved air quality in urban areas where waste management facilities are often located.

However, the production of DME from waste materials may have some environmental drawbacks. The process can be energy-intensive, potentially offsetting some of the emissions benefits if not powered by renewable energy sources. There are also concerns about potential leaks during storage and transportation, as DME is a volatile compound that can contribute to ground-level ozone formation if released into the atmosphere.

Water usage and potential contamination are additional environmental considerations in DME production from waste. The synthesis process requires significant water inputs, which may strain local water resources in water-scarce regions. Proper wastewater treatment is essential to prevent the release of pollutants into aquatic ecosystems.

Land use changes associated with DME production facilities and waste collection infrastructure must also be evaluated. While DME can reduce the need for landfill space, the construction of production plants may impact local habitats and biodiversity. Careful site selection and environmental impact studies are crucial to minimize these effects.

The lifecycle assessment of DME in waste reduction technologies indicates a net positive environmental impact when properly implemented. By diverting waste from landfills and incinerators, DME production can help conserve natural resources and reduce the overall environmental footprint of waste management systems. However, ongoing monitoring and adherence to strict environmental regulations are necessary to ensure that the benefits of DME utilization outweigh any potential negative impacts on ecosystems and human health.

One of the primary environmental benefits of DME in waste reduction is its ability to lower carbon dioxide emissions. When produced from renewable sources or waste materials, DME can achieve near-carbon neutrality, contributing to climate change mitigation efforts. Additionally, DME combustion produces minimal particulate matter and sulfur oxides, leading to improved air quality in urban areas where waste management facilities are often located.

However, the production of DME from waste materials may have some environmental drawbacks. The process can be energy-intensive, potentially offsetting some of the emissions benefits if not powered by renewable energy sources. There are also concerns about potential leaks during storage and transportation, as DME is a volatile compound that can contribute to ground-level ozone formation if released into the atmosphere.

Water usage and potential contamination are additional environmental considerations in DME production from waste. The synthesis process requires significant water inputs, which may strain local water resources in water-scarce regions. Proper wastewater treatment is essential to prevent the release of pollutants into aquatic ecosystems.

Land use changes associated with DME production facilities and waste collection infrastructure must also be evaluated. While DME can reduce the need for landfill space, the construction of production plants may impact local habitats and biodiversity. Careful site selection and environmental impact studies are crucial to minimize these effects.

The lifecycle assessment of DME in waste reduction technologies indicates a net positive environmental impact when properly implemented. By diverting waste from landfills and incinerators, DME production can help conserve natural resources and reduce the overall environmental footprint of waste management systems. However, ongoing monitoring and adherence to strict environmental regulations are necessary to ensure that the benefits of DME utilization outweigh any potential negative impacts on ecosystems and human health.

Regulatory Framework for DME Usage

The regulatory framework for Dimethyl Ether (DME) usage is a critical aspect of its implementation in waste reduction technologies. As DME gains traction as an alternative fuel and chemical feedstock, governments and regulatory bodies worldwide are developing and refining policies to ensure its safe and sustainable use.

At the international level, organizations such as the International Organization for Standardization (ISO) have established guidelines for DME production, storage, and handling. These standards provide a foundation for national regulatory bodies to develop their own frameworks, ensuring consistency in safety measures and quality control across borders.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating DME usage. The agency has included DME in its Renewable Fuel Standard program, recognizing its potential as a renewable fuel when produced from biomass feedstocks. This inclusion provides incentives for DME production from waste materials, aligning with waste reduction goals.

The Department of Energy (DOE) has also been actively supporting research and development of DME technologies, particularly in the context of waste-to-energy applications. Their regulatory guidance focuses on promoting energy efficiency and emissions reduction in DME production processes.

European Union regulations on DME are primarily governed by the Renewable Energy Directive (RED) and the Fuel Quality Directive (FQD). These directives set targets for renewable energy use in transportation and establish sustainability criteria for biofuels, including DME derived from waste sources.

In Asia, countries like China and Japan have implemented specific regulations to promote DME as a clean alternative fuel. China's Ministry of Environmental Protection has issued standards for DME production and use, particularly in industrial applications and as a substitute for liquefied petroleum gas (LPG).

Safety regulations are a paramount concern in DME usage. Regulatory bodies worldwide have established strict guidelines for DME storage, transportation, and handling. These regulations often mirror those for LPG due to similarities in physical properties, but with additional considerations for DME's unique characteristics.

As DME's role in waste reduction technologies expands, regulatory frameworks are evolving to address specific concerns. These include emissions standards for DME-powered vehicles, guidelines for DME production from various waste streams, and regulations governing the integration of DME into existing energy infrastructure.

The regulatory landscape for DME usage in waste reduction technologies is dynamic and continues to develop as the technology matures. Policymakers are increasingly recognizing DME's potential to contribute to circular economy goals, leading to more supportive regulatory environments in many jurisdictions.

At the international level, organizations such as the International Organization for Standardization (ISO) have established guidelines for DME production, storage, and handling. These standards provide a foundation for national regulatory bodies to develop their own frameworks, ensuring consistency in safety measures and quality control across borders.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating DME usage. The agency has included DME in its Renewable Fuel Standard program, recognizing its potential as a renewable fuel when produced from biomass feedstocks. This inclusion provides incentives for DME production from waste materials, aligning with waste reduction goals.

The Department of Energy (DOE) has also been actively supporting research and development of DME technologies, particularly in the context of waste-to-energy applications. Their regulatory guidance focuses on promoting energy efficiency and emissions reduction in DME production processes.

European Union regulations on DME are primarily governed by the Renewable Energy Directive (RED) and the Fuel Quality Directive (FQD). These directives set targets for renewable energy use in transportation and establish sustainability criteria for biofuels, including DME derived from waste sources.

In Asia, countries like China and Japan have implemented specific regulations to promote DME as a clean alternative fuel. China's Ministry of Environmental Protection has issued standards for DME production and use, particularly in industrial applications and as a substitute for liquefied petroleum gas (LPG).

Safety regulations are a paramount concern in DME usage. Regulatory bodies worldwide have established strict guidelines for DME storage, transportation, and handling. These regulations often mirror those for LPG due to similarities in physical properties, but with additional considerations for DME's unique characteristics.

As DME's role in waste reduction technologies expands, regulatory frameworks are evolving to address specific concerns. These include emissions standards for DME-powered vehicles, guidelines for DME production from various waste streams, and regulations governing the integration of DME into existing energy infrastructure.

The regulatory landscape for DME usage in waste reduction technologies is dynamic and continues to develop as the technology matures. Policymakers are increasingly recognizing DME's potential to contribute to circular economy goals, leading to more supportive regulatory environments in many jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!