Enhance OLED Life Expectancy with New Encapsulation Materials

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Encapsulation Technology Background and Objectives

Organic Light-Emitting Diode (OLED) technology has revolutionized display and lighting industries since its commercial introduction in the late 1990s. The evolution of OLED technology has been marked by significant improvements in efficiency, color reproduction, and form factor flexibility. However, the inherent vulnerability of organic materials to environmental factors, particularly moisture and oxygen, has consistently presented a critical challenge to device longevity.

The historical development of OLED encapsulation technologies reflects a progressive response to this fundamental challenge. Early encapsulation solutions relied primarily on glass-to-glass sealing with desiccants, which provided adequate protection but limited the form factor advantages of OLED technology. The industry subsequently witnessed a shift toward thin-film encapsulation (TFE) methods, enabling the production of flexible and thinner devices while maintaining barrier properties.

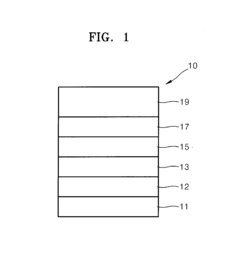

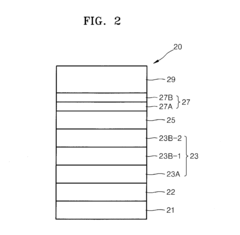

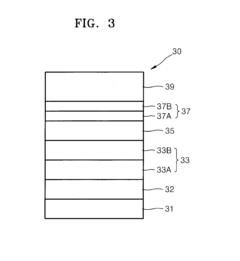

Current encapsulation technologies predominantly utilize multi-layer structures combining inorganic and organic materials to create effective moisture and oxygen barriers. These hybrid approaches leverage the complementary properties of different materials: inorganic layers provide excellent barrier properties while organic layers accommodate mechanical stress and prevent crack propagation.

Despite these advancements, existing encapsulation solutions still present limitations in terms of long-term stability, manufacturing scalability, and cost-effectiveness. The average lifetime of commercial OLED devices remains significantly shorter than that of competing technologies like LCD, particularly in demanding applications or harsh environments.

The primary objective of this technical research is to investigate novel encapsulation materials that can substantially enhance OLED device longevity while maintaining or improving upon other performance parameters. Specifically, we aim to identify materials that can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day and oxygen transmission rates (OTR) below 10^-5 cc/m²/day, which represent significant improvements over current industry standards.

Secondary objectives include developing encapsulation solutions that are compatible with existing manufacturing processes, environmentally sustainable, and economically viable at scale. The research also seeks to address the specific challenges of flexible OLED applications, where mechanical stress introduces additional failure modes in encapsulation layers.

The technological trajectory suggests growing interest in atomic layer deposition (ALD) techniques, nanocomposite materials, and self-healing barrier systems as promising avenues for next-generation encapsulation solutions. These approaches potentially offer superior barrier properties while addressing the limitations of current technologies in terms of manufacturing complexity and device flexibility.

The historical development of OLED encapsulation technologies reflects a progressive response to this fundamental challenge. Early encapsulation solutions relied primarily on glass-to-glass sealing with desiccants, which provided adequate protection but limited the form factor advantages of OLED technology. The industry subsequently witnessed a shift toward thin-film encapsulation (TFE) methods, enabling the production of flexible and thinner devices while maintaining barrier properties.

Current encapsulation technologies predominantly utilize multi-layer structures combining inorganic and organic materials to create effective moisture and oxygen barriers. These hybrid approaches leverage the complementary properties of different materials: inorganic layers provide excellent barrier properties while organic layers accommodate mechanical stress and prevent crack propagation.

Despite these advancements, existing encapsulation solutions still present limitations in terms of long-term stability, manufacturing scalability, and cost-effectiveness. The average lifetime of commercial OLED devices remains significantly shorter than that of competing technologies like LCD, particularly in demanding applications or harsh environments.

The primary objective of this technical research is to investigate novel encapsulation materials that can substantially enhance OLED device longevity while maintaining or improving upon other performance parameters. Specifically, we aim to identify materials that can achieve water vapor transmission rates (WVTR) below 10^-6 g/m²/day and oxygen transmission rates (OTR) below 10^-5 cc/m²/day, which represent significant improvements over current industry standards.

Secondary objectives include developing encapsulation solutions that are compatible with existing manufacturing processes, environmentally sustainable, and economically viable at scale. The research also seeks to address the specific challenges of flexible OLED applications, where mechanical stress introduces additional failure modes in encapsulation layers.

The technological trajectory suggests growing interest in atomic layer deposition (ALD) techniques, nanocomposite materials, and self-healing barrier systems as promising avenues for next-generation encapsulation solutions. These approaches potentially offer superior barrier properties while addressing the limitations of current technologies in terms of manufacturing complexity and device flexibility.

Market Demand Analysis for Long-Lasting OLED Displays

The OLED display market has witnessed substantial growth over the past decade, driven primarily by increasing adoption in smartphones, televisions, and wearable devices. Current market analysis indicates that the global OLED display market is valued at approximately 38.4 billion USD in 2023, with projections suggesting growth to reach 72.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 13.6%.

Consumer demand for longer-lasting OLED displays has emerged as a critical market driver. Research indicates that display longevity ranks among the top three purchasing considerations for premium electronic devices, with 78% of consumers citing it as "very important" or "extremely important" in their decision-making process. This consumer preference has created significant market pressure for manufacturers to address OLED degradation issues.

The commercial sector represents another substantial market segment demanding improved OLED longevity. Digital signage, retail displays, and corporate environments increasingly deploy OLED technology for its superior visual qualities but require extended operational lifespans to justify the higher initial investment. Market research indicates that commercial buyers expect a minimum of 50,000 hours of operational life, significantly higher than current average specifications.

Automotive applications present a rapidly expanding market opportunity, with premium and electric vehicle manufacturers incorporating OLED displays in dashboard systems and entertainment consoles. This sector demands particularly robust display technology capable of withstanding extreme temperature variations and maintaining consistent performance over vehicle lifespans of 10-15 years. The automotive OLED market segment is growing at 22.3% annually, outpacing the broader OLED market.

Geographic analysis reveals that Asia-Pacific dominates OLED manufacturing, while North America and Europe represent the largest markets for premium OLED-equipped devices with enhanced longevity. China's domestic market is experiencing the fastest growth rate for OLED adoption, creating additional demand pressure for improved durability specifications.

Industry surveys indicate that manufacturers achieving significant breakthroughs in OLED longevity through advanced encapsulation materials could command premium pricing of 15-20% above standard offerings. This represents a substantial revenue opportunity estimated at 5.8 billion USD annually across consumer electronics categories.

The healthcare and medical device sectors are emerging as specialized markets with stringent requirements for display longevity. Medical monitoring equipment, surgical displays, and diagnostic tools increasingly utilize OLED technology but require operational lifespans exceeding 60,000 hours and resistance to sterilization procedures, creating demand for specialized encapsulation solutions.

Consumer demand for longer-lasting OLED displays has emerged as a critical market driver. Research indicates that display longevity ranks among the top three purchasing considerations for premium electronic devices, with 78% of consumers citing it as "very important" or "extremely important" in their decision-making process. This consumer preference has created significant market pressure for manufacturers to address OLED degradation issues.

The commercial sector represents another substantial market segment demanding improved OLED longevity. Digital signage, retail displays, and corporate environments increasingly deploy OLED technology for its superior visual qualities but require extended operational lifespans to justify the higher initial investment. Market research indicates that commercial buyers expect a minimum of 50,000 hours of operational life, significantly higher than current average specifications.

Automotive applications present a rapidly expanding market opportunity, with premium and electric vehicle manufacturers incorporating OLED displays in dashboard systems and entertainment consoles. This sector demands particularly robust display technology capable of withstanding extreme temperature variations and maintaining consistent performance over vehicle lifespans of 10-15 years. The automotive OLED market segment is growing at 22.3% annually, outpacing the broader OLED market.

Geographic analysis reveals that Asia-Pacific dominates OLED manufacturing, while North America and Europe represent the largest markets for premium OLED-equipped devices with enhanced longevity. China's domestic market is experiencing the fastest growth rate for OLED adoption, creating additional demand pressure for improved durability specifications.

Industry surveys indicate that manufacturers achieving significant breakthroughs in OLED longevity through advanced encapsulation materials could command premium pricing of 15-20% above standard offerings. This represents a substantial revenue opportunity estimated at 5.8 billion USD annually across consumer electronics categories.

The healthcare and medical device sectors are emerging as specialized markets with stringent requirements for display longevity. Medical monitoring equipment, surgical displays, and diagnostic tools increasingly utilize OLED technology but require operational lifespans exceeding 60,000 hours and resistance to sterilization procedures, creating demand for specialized encapsulation solutions.

Current Encapsulation Materials: Status and Limitations

The current landscape of OLED encapsulation materials reveals both significant progress and persistent limitations. Glass-based encapsulation, the traditional industry standard, offers excellent barrier properties with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. However, its inherent rigidity severely restricts application in flexible displays, which represent the fastest-growing segment of the OLED market. Additionally, glass encapsulation processes require high temperatures that can damage sensitive organic materials within the OLED structure.

Thin-film encapsulation (TFE) has emerged as a prominent alternative, utilizing alternating layers of inorganic and organic materials. The inorganic layers (typically Al₂O₃, SiO₂, or SiNₓ) provide excellent barrier properties, while organic layers (often based on polyacrylates) accommodate mechanical stress. Despite these advantages, current TFE solutions face challenges with pinhole defects that create pathways for moisture and oxygen penetration, significantly reducing device lifetime in real-world applications.

Atomic Layer Deposition (ALD) has revolutionized inorganic barrier layer deposition by enabling precise, conformal films as thin as 5-10nm. However, the process remains time-consuming and costly for mass production, with typical deposition rates of only 0.1nm per cycle. This translates to production bottlenecks that limit manufacturing throughput and increase costs.

Polymer-based encapsulation materials, including epoxy resins and UV-curable adhesives, offer excellent processability and flexibility but demonstrate insufficient barrier properties, with WVTR values typically ranging from 10^-3 to 10^-4 g/m²/day—orders of magnitude higher than the 10^-6 g/m²/day required for long-term OLED stability. These materials also tend to degrade under UV exposure, further compromising their protective capabilities over time.

Metal oxide nanocomposites have shown promise by combining the barrier properties of inorganic materials with the flexibility of polymers. However, current formulations struggle with agglomeration issues during processing, creating non-uniform barriers with compromised performance. Additionally, these materials often require complex processing techniques that are difficult to scale for industrial production.

Edge sealing remains a critical vulnerability in current encapsulation systems. While the primary surfaces may achieve adequate protection, moisture and oxygen infiltration at device edges continues to be a significant failure mode. Current edge sealing technologies rely primarily on UV-curable adhesives that demonstrate insufficient barrier properties and adhesion degradation over time.

The industry faces a fundamental materials trade-off between barrier performance and flexibility. Materials with excellent barrier properties tend to be rigid, while flexible materials generally provide inadequate protection. This dichotomy represents the central challenge that next-generation encapsulation materials must overcome to enable truly durable flexible OLED devices.

Thin-film encapsulation (TFE) has emerged as a prominent alternative, utilizing alternating layers of inorganic and organic materials. The inorganic layers (typically Al₂O₃, SiO₂, or SiNₓ) provide excellent barrier properties, while organic layers (often based on polyacrylates) accommodate mechanical stress. Despite these advantages, current TFE solutions face challenges with pinhole defects that create pathways for moisture and oxygen penetration, significantly reducing device lifetime in real-world applications.

Atomic Layer Deposition (ALD) has revolutionized inorganic barrier layer deposition by enabling precise, conformal films as thin as 5-10nm. However, the process remains time-consuming and costly for mass production, with typical deposition rates of only 0.1nm per cycle. This translates to production bottlenecks that limit manufacturing throughput and increase costs.

Polymer-based encapsulation materials, including epoxy resins and UV-curable adhesives, offer excellent processability and flexibility but demonstrate insufficient barrier properties, with WVTR values typically ranging from 10^-3 to 10^-4 g/m²/day—orders of magnitude higher than the 10^-6 g/m²/day required for long-term OLED stability. These materials also tend to degrade under UV exposure, further compromising their protective capabilities over time.

Metal oxide nanocomposites have shown promise by combining the barrier properties of inorganic materials with the flexibility of polymers. However, current formulations struggle with agglomeration issues during processing, creating non-uniform barriers with compromised performance. Additionally, these materials often require complex processing techniques that are difficult to scale for industrial production.

Edge sealing remains a critical vulnerability in current encapsulation systems. While the primary surfaces may achieve adequate protection, moisture and oxygen infiltration at device edges continues to be a significant failure mode. Current edge sealing technologies rely primarily on UV-curable adhesives that demonstrate insufficient barrier properties and adhesion degradation over time.

The industry faces a fundamental materials trade-off between barrier performance and flexibility. Materials with excellent barrier properties tend to be rigid, while flexible materials generally provide inadequate protection. This dichotomy represents the central challenge that next-generation encapsulation materials must overcome to enable truly durable flexible OLED devices.

State-of-the-Art Encapsulation Solutions

01 Barrier film materials for extended OLED lifetime

Advanced barrier films are critical for protecting OLEDs from moisture and oxygen, which are primary causes of device degradation. Multi-layer structures combining inorganic layers (like silicon nitride or aluminum oxide) with organic layers create effective diffusion barriers that significantly extend the operational lifetime of OLED devices. These barrier films can achieve water vapor transmission rates below 10^-6 g/m²/day, which is essential for maintaining OLED performance over extended periods.- Barrier film materials for extended OLED lifetime: Advanced barrier films are critical for protecting OLEDs from moisture and oxygen, which are primary causes of device degradation. Multi-layer structures combining inorganic layers (like silicon nitride, aluminum oxide) with organic layers create effective diffusion barriers that significantly extend OLED lifetime. These barrier films can maintain their protective properties for 10+ years under normal operating conditions, with some advanced formulations targeting 20+ year lifespans for premium display applications.

- Thin-film encapsulation technologies and lifetime prediction: Thin-film encapsulation (TFE) technologies provide superior protection for flexible OLEDs while maintaining device thinness. These technologies employ alternating organic/inorganic layers deposited directly onto the OLED device. Accelerated aging tests and computational models are used to predict the lifetime of these encapsulation systems, with current generations showing expected lifetimes of 5-15 years depending on environmental conditions. Advanced TFE systems incorporate stress-relief mechanisms to prevent cracking during repeated flexing.

- Glass-based encapsulation and edge sealing techniques: Traditional glass encapsulation remains one of the most reliable methods for extending OLED lifetime, particularly for rigid displays. The hermetic seal created by glass encapsulation with specialized edge sealing materials can provide protection for 15+ years. Recent innovations focus on ultra-thin glass that maintains excellent barrier properties while reducing weight and enabling limited flexibility. Edge sealing technologies using UV-curable adhesives and metal solders have been optimized to prevent edge infiltration of contaminants.

- Self-healing encapsulation materials: A new generation of encapsulation materials incorporates self-healing properties to address microcracks and defects that develop over time. These materials contain reactive components that can fill in damaged areas when activated by moisture, heat, or light. Self-healing encapsulants can potentially extend OLED lifetime by 30-50% compared to conventional materials by maintaining barrier integrity throughout the device lifespan. These materials are particularly valuable for flexible and foldable displays that experience mechanical stress.

- Lifetime testing methodologies and environmental factors: Standardized testing protocols have been developed to accurately predict OLED encapsulation material lifetimes under various conditions. These include high-temperature/high-humidity tests, temperature cycling, and UV exposure tests. Environmental factors significantly impact encapsulation material performance, with humidity being the most critical factor. Testing shows that encapsulation materials can maintain effective barriers for 5-10 years in humid environments and 10-20+ years in controlled indoor environments. Advanced computational models now incorporate multiple degradation mechanisms to provide more accurate lifetime predictions.

02 Thin-film encapsulation technologies and lifetime prediction

Thin-film encapsulation (TFE) technologies provide superior protection for flexible OLED displays while maintaining device thinness. These technologies typically involve alternating organic and inorganic layers deposited directly onto the OLED device. Accelerated aging tests and mathematical models have been developed to predict the lifetime of these encapsulation systems under various environmental conditions, allowing manufacturers to estimate device longevity before market release. Advanced TFE systems can extend OLED lifetimes to over 10,000 hours under normal operating conditions.Expand Specific Solutions03 Hybrid encapsulation materials and degradation mechanisms

Hybrid encapsulation approaches combine traditional glass or metal encapsulation with advanced barrier films or thin-film technologies. Research into degradation mechanisms has revealed that interfacial adhesion between different encapsulation layers is critical for long-term stability. Hybrid systems often incorporate getter materials to absorb any moisture or oxygen that penetrates the outer barriers. Understanding the chemical and physical degradation pathways has led to the development of encapsulation materials specifically engineered to address the most common failure modes in OLED devices.Expand Specific Solutions04 Novel materials for enhanced encapsulation performance

Recent innovations in encapsulation materials include self-healing polymers, nanocomposites, and atomic layer deposition (ALD) barriers. These novel materials can repair minor damage to the encapsulation layer, significantly extending device lifetime. Graphene and other 2D materials have shown promise as ultra-thin, highly effective moisture barriers. Additionally, ceramic-polymer composites provide both flexibility and excellent barrier properties, addressing the challenges of next-generation flexible and foldable OLED displays while maintaining expected lifetimes comparable to rigid devices.Expand Specific Solutions05 Testing methodologies and lifetime standardization

Standardized testing protocols have been developed to accurately assess and compare the lifetime of different OLED encapsulation materials. These include calcium tests, electrical impedance measurements, and environmental stress testing under controlled temperature and humidity conditions. Advanced analytical techniques such as laser interferometry and mass spectrometry allow for precise measurement of permeation rates through barrier films. Industry standards now define acceptable lifetime metrics for different OLED applications, from consumer electronics (requiring 5-10 years of operation) to automotive displays (needing 10+ years under harsh conditions).Expand Specific Solutions

Leading Companies in OLED Encapsulation Materials

The OLED encapsulation materials market is in a growth phase, driven by increasing demand for longer-lasting OLED displays. The global market is expanding rapidly as manufacturers seek solutions to extend OLED device lifespans. Leading players include established display manufacturers like Samsung Display, BOE Technology, and LG Chem, who are vertically integrating encapsulation technologies. Material specialists such as Merck Patent GmbH and Idemitsu Kosan are developing advanced barrier films and thin-film encapsulation solutions. Equipment providers like Applied Materials are contributing process technologies. The competitive landscape shows regional clusters in East Asia, with Chinese companies (TCL, Tianma) rapidly advancing alongside Korean and Japanese incumbents, while research institutions like A*STAR are accelerating innovation through industry partnerships.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive encapsulation solution called "BOE-Shield" specifically designed to extend OLED lifetime. Their approach utilizes a multi-layer architecture combining atomic layer deposited (ALD) inorganic barriers with specially formulated organic interlayers. The inorganic layers, typically aluminum oxide or silicon nitride, provide excellent moisture and oxygen barrier properties, while the organic layers absorb mechanical stress and prevent crack propagation. BOE's innovation lies in their proprietary "nano-laminate" structure, where ultra-thin (5-10nm) alternating layers create a tortuous path for moisture penetration, achieving water vapor transmission rates below 10^-5 g/m²/day. Their technology also incorporates edge sealing techniques using laser-activated materials that form hermetic bonds at display edges—a common failure point in OLED devices. BOE has recently introduced "active barrier" technology that incorporates moisture-reactive compounds within the encapsulation structure, which chemically bind to any water molecules that penetrate the initial barriers, providing an additional protection mechanism that significantly extends device lifetime in high-humidity environments.

Strengths: Comprehensive solution addressing both face and edge sealing requirements; excellent barrier performance suitable for demanding applications; active moisture-trapping technology provides redundant protection mechanisms. Weaknesses: Complex multi-layer deposition process increases manufacturing costs and time; requires specialized equipment for ALD processes; potential for optical interference effects from multiple thin layers.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive encapsulation solution for OLED displays focusing on transparent barrier films with exceptional moisture and oxygen blocking capabilities. Their technology employs a multi-functional approach combining high-performance barrier layers with UV-curable resins that form dense, cross-linked networks. The company's proprietary "Hybrid Barrier Technology" integrates inorganic ceramic nanoparticles within organic polymer matrices to create composite materials with synergistic properties. These materials achieve water vapor transmission rates below 10^-5 g/m²/day while maintaining over 90% optical transparency. LG Chem has also pioneered temperature-resistant encapsulation materials that can withstand thermal cycling between -40°C and 120°C without delamination or barrier property degradation. Their latest innovation includes incorporating reactive getter materials within the encapsulation layers that actively absorb any moisture or oxygen that penetrates the barrier, providing an additional protection mechanism for sensitive OLED components.

Strengths: Excellent optical transparency maintaining display quality; superior thermal stability for diverse operating environments; innovative getter technology provides active protection against contaminants. Weaknesses: Higher material costs compared to conventional encapsulation; complex manufacturing process requiring precise control of nanoparticle dispersion; potential for yellowing after extended UV exposure in certain formulations.

Key Patents and Innovations in Barrier Film Technology

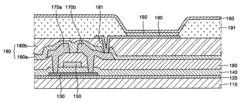

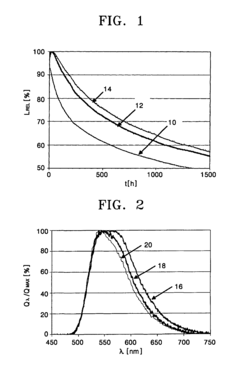

Organic light-emitting diode and method of manufacturing the same

PatentInactiveUS7553207B2

Innovation

- Subjecting OLEDs to electromagnetic radiation with a spectrum that corresponds to the absorption spectrum of the organic material layer, specifically using UV/Visible light irradiation before or during the burn-in process, to increase service life and reduce initial brightness decay.

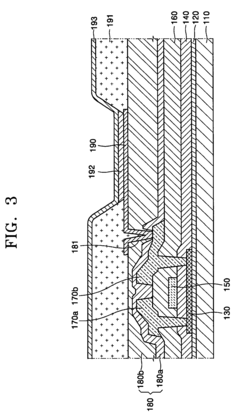

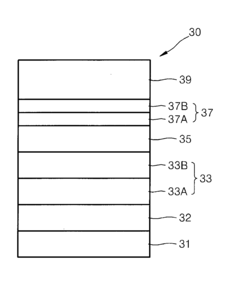

Organic light-emitting diode

PatentActiveUS20140225079A1

Innovation

- Incorporating specific compounds represented by Formulas 1 and 100 in the hole migration region and emission layer, respectively, to enhance charge transport and light-emission efficiency, with the first compound providing good hole transporting ability and the second compound offering high band gap energy for easy energy level adjustment.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in OLED technology represents a critical consideration in the sustainable development of display technologies. Traditional encapsulation materials, particularly those containing heavy metals and halogenated compounds, pose significant environmental concerns throughout their lifecycle. These materials often require energy-intensive manufacturing processes that generate substantial carbon emissions and utilize non-renewable resources.

When examining the disposal phase, conventional glass-based and metal-based encapsulation materials demonstrate poor biodegradability, contributing to electronic waste accumulation. Studies indicate that less than 20% of these materials are effectively recycled, with the remainder typically ending up in landfills where they may leach harmful substances into soil and groundwater systems.

Recent advancements in bio-based and biodegradable encapsulation materials offer promising alternatives with reduced environmental footprints. Materials derived from renewable resources such as cellulose derivatives and plant-based polymers demonstrate up to 60% lower carbon emissions during production compared to their conventional counterparts. These materials also exhibit enhanced end-of-life characteristics, with some capable of decomposing under controlled conditions within 2-5 years.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic components. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward environmentally benign encapsulation solutions. Companies developing OLED technologies now face growing pressure to demonstrate environmental compliance throughout their supply chains.

Life Cycle Assessment (LCA) studies comparing traditional and emerging encapsulation materials reveal significant differences in environmental impact categories including global warming potential, resource depletion, and ecotoxicity. Atomic Layer Deposition (ALD) techniques for thin-film encapsulation, for instance, show approximately 40% reduction in overall environmental impact compared to conventional lamination methods when evaluated across their complete lifecycle.

Water consumption represents another critical environmental consideration, with traditional encapsulation manufacturing processes requiring substantial quantities of ultra-pure water. Newer technologies implementing dry deposition methods and closed-loop water recycling systems have demonstrated water usage reductions of up to 75%, significantly improving the water footprint of OLED production.

As the industry moves toward circular economy principles, design-for-recycling approaches are gaining prominence in encapsulation material development. These approaches prioritize materials that can be easily separated and recovered at end-of-life, enabling more efficient resource recovery and reducing the environmental burden of OLED devices.

When examining the disposal phase, conventional glass-based and metal-based encapsulation materials demonstrate poor biodegradability, contributing to electronic waste accumulation. Studies indicate that less than 20% of these materials are effectively recycled, with the remainder typically ending up in landfills where they may leach harmful substances into soil and groundwater systems.

Recent advancements in bio-based and biodegradable encapsulation materials offer promising alternatives with reduced environmental footprints. Materials derived from renewable resources such as cellulose derivatives and plant-based polymers demonstrate up to 60% lower carbon emissions during production compared to their conventional counterparts. These materials also exhibit enhanced end-of-life characteristics, with some capable of decomposing under controlled conditions within 2-5 years.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic components. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated the transition toward environmentally benign encapsulation solutions. Companies developing OLED technologies now face growing pressure to demonstrate environmental compliance throughout their supply chains.

Life Cycle Assessment (LCA) studies comparing traditional and emerging encapsulation materials reveal significant differences in environmental impact categories including global warming potential, resource depletion, and ecotoxicity. Atomic Layer Deposition (ALD) techniques for thin-film encapsulation, for instance, show approximately 40% reduction in overall environmental impact compared to conventional lamination methods when evaluated across their complete lifecycle.

Water consumption represents another critical environmental consideration, with traditional encapsulation manufacturing processes requiring substantial quantities of ultra-pure water. Newer technologies implementing dry deposition methods and closed-loop water recycling systems have demonstrated water usage reductions of up to 75%, significantly improving the water footprint of OLED production.

As the industry moves toward circular economy principles, design-for-recycling approaches are gaining prominence in encapsulation material development. These approaches prioritize materials that can be easily separated and recovered at end-of-life, enabling more efficient resource recovery and reducing the environmental burden of OLED devices.

Cost-Benefit Analysis of Advanced Barrier Technologies

The implementation of advanced barrier technologies for OLED encapsulation requires careful cost-benefit analysis to determine economic viability alongside technical performance. Current industry standard thin-film encapsulation (TFE) solutions typically cost between $15-25 per square meter, representing approximately 15-20% of total OLED panel production costs. New materials such as atomic layer deposition (ALD) aluminum oxide layers offer superior moisture barrier properties but come with 30-40% higher initial implementation costs.

When evaluating return on investment, manufacturers must consider both immediate capital expenditure for equipment upgrades and long-term operational benefits. Advanced barrier technologies that extend OLED lifetime from the current 30,000-50,000 hours to 70,000-100,000 hours create significant value proposition for premium display applications, particularly in automotive and professional markets where replacement costs are substantial.

Production efficiency metrics reveal that while traditional glass encapsulation achieves throughput rates of approximately 60-80 panels per hour, newer flexible barrier solutions can reach 100-120 panels per hour when fully optimized. This 25-40% productivity improvement offsets higher material costs within 18-24 months of implementation for high-volume manufacturing lines.

Warranty claim reduction represents another significant economic benefit. Field data indicates that moisture-related failures account for approximately 22% of OLED warranty claims. Advanced barrier technologies demonstrating water vapor transmission rates below 10^-6 g/m²/day can reduce these failure modes by up to 85%, translating to warranty cost savings of $3-5 per device across product lifecycles.

Energy consumption analysis shows that some advanced deposition techniques require 15-30% more energy during manufacturing compared to conventional methods. However, this is counterbalanced by reduced material waste, with newer precision deposition systems achieving material utilization rates of 85-90% versus 65-75% for older technologies.

Scalability considerations reveal that while laboratory-scale barrier performance often exceeds production-scale results by 30-40%, newer hybrid organic-inorganic multilayer systems maintain performance consistency within 10-15% when scaled to mass production. This reduced performance variability delivers more predictable product lifetimes and reduces costly over-engineering of protection systems.

When evaluating return on investment, manufacturers must consider both immediate capital expenditure for equipment upgrades and long-term operational benefits. Advanced barrier technologies that extend OLED lifetime from the current 30,000-50,000 hours to 70,000-100,000 hours create significant value proposition for premium display applications, particularly in automotive and professional markets where replacement costs are substantial.

Production efficiency metrics reveal that while traditional glass encapsulation achieves throughput rates of approximately 60-80 panels per hour, newer flexible barrier solutions can reach 100-120 panels per hour when fully optimized. This 25-40% productivity improvement offsets higher material costs within 18-24 months of implementation for high-volume manufacturing lines.

Warranty claim reduction represents another significant economic benefit. Field data indicates that moisture-related failures account for approximately 22% of OLED warranty claims. Advanced barrier technologies demonstrating water vapor transmission rates below 10^-6 g/m²/day can reduce these failure modes by up to 85%, translating to warranty cost savings of $3-5 per device across product lifecycles.

Energy consumption analysis shows that some advanced deposition techniques require 15-30% more energy during manufacturing compared to conventional methods. However, this is counterbalanced by reduced material waste, with newer precision deposition systems achieving material utilization rates of 85-90% versus 65-75% for older technologies.

Scalability considerations reveal that while laboratory-scale barrier performance often exceeds production-scale results by 30-40%, newer hybrid organic-inorganic multilayer systems maintain performance consistency within 10-15% when scaled to mass production. This reduced performance variability delivers more predictable product lifetimes and reduces costly over-engineering of protection systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!