Ethylene Vinyl Acetate: Environmental and Economic Impact

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Development History and Objectives

Ethylene Vinyl Acetate (EVA) has a rich history dating back to the 1930s when it was first developed by Imperial Chemical Industries (ICI) in the United Kingdom. The initial objective was to create a flexible and durable material that could be used in various applications. Over the decades, EVA has evolved from a niche product to a versatile polymer with widespread use across multiple industries.

In the 1950s and 1960s, the development of EVA gained momentum as researchers explored its potential in footwear, packaging, and adhesives. The primary goal during this period was to enhance the material's properties, such as flexibility, impact resistance, and weatherability. This led to the introduction of EVA foam in the 1960s, which revolutionized the footwear industry by providing lightweight and cushioning properties.

The 1970s and 1980s saw a significant expansion in EVA applications, driven by the growing demand for flexible and durable materials in various sectors. During this time, researchers focused on improving the processing techniques and developing new grades of EVA with specific properties tailored to different applications. The objectives shifted towards enhancing the material's performance in areas such as thermal insulation, electrical properties, and chemical resistance.

In recent years, the development of EVA has been largely influenced by environmental concerns and sustainability goals. The industry has been working on improving the recyclability of EVA products and exploring bio-based alternatives. One of the key objectives in this regard is to reduce the environmental impact of EVA production and disposal while maintaining its desirable properties.

The economic impact of EVA has been substantial, with the global market size reaching billions of dollars. The material's versatility and cost-effectiveness have made it a preferred choice in industries such as solar panel manufacturing, packaging, and sports equipment. As a result, ongoing research and development efforts are focused on further expanding EVA's applications and improving its performance in existing markets.

Looking ahead, the future objectives for EVA development include enhancing its sustainability profile, improving its compatibility with other materials for advanced composites, and exploring new applications in emerging technologies such as 3D printing and flexible electronics. Additionally, there is a growing emphasis on developing EVA formulations with improved fire resistance and reduced volatile organic compound (VOC) emissions to meet increasingly stringent regulatory requirements.

In the 1950s and 1960s, the development of EVA gained momentum as researchers explored its potential in footwear, packaging, and adhesives. The primary goal during this period was to enhance the material's properties, such as flexibility, impact resistance, and weatherability. This led to the introduction of EVA foam in the 1960s, which revolutionized the footwear industry by providing lightweight and cushioning properties.

The 1970s and 1980s saw a significant expansion in EVA applications, driven by the growing demand for flexible and durable materials in various sectors. During this time, researchers focused on improving the processing techniques and developing new grades of EVA with specific properties tailored to different applications. The objectives shifted towards enhancing the material's performance in areas such as thermal insulation, electrical properties, and chemical resistance.

In recent years, the development of EVA has been largely influenced by environmental concerns and sustainability goals. The industry has been working on improving the recyclability of EVA products and exploring bio-based alternatives. One of the key objectives in this regard is to reduce the environmental impact of EVA production and disposal while maintaining its desirable properties.

The economic impact of EVA has been substantial, with the global market size reaching billions of dollars. The material's versatility and cost-effectiveness have made it a preferred choice in industries such as solar panel manufacturing, packaging, and sports equipment. As a result, ongoing research and development efforts are focused on further expanding EVA's applications and improving its performance in existing markets.

Looking ahead, the future objectives for EVA development include enhancing its sustainability profile, improving its compatibility with other materials for advanced composites, and exploring new applications in emerging technologies such as 3D printing and flexible electronics. Additionally, there is a growing emphasis on developing EVA formulations with improved fire resistance and reduced volatile organic compound (VOC) emissions to meet increasingly stringent regulatory requirements.

Market Analysis for EVA Applications

The market for Ethylene Vinyl Acetate (EVA) applications has shown significant growth and diversification in recent years, driven by its versatile properties and increasing demand across various industries. EVA's unique combination of flexibility, toughness, and adhesion properties has made it a preferred material in sectors such as packaging, footwear, solar panels, and automotive components.

In the packaging industry, EVA has gained traction due to its excellent sealing properties and resistance to puncture and flex-crack. The food packaging segment, in particular, has seen a surge in EVA usage, especially in flexible packaging applications. This growth is attributed to the increasing demand for convenient, lightweight, and durable packaging solutions in the food and beverage sector.

The footwear industry represents another major market for EVA applications. The material's lightweight nature, cushioning properties, and ease of molding have made it a popular choice for shoe soles and midsoles. Sports and casual footwear manufacturers have been increasingly incorporating EVA into their designs, driving market growth in this sector.

The solar energy industry has emerged as a significant driver for EVA demand. EVA is widely used as an encapsulant material in photovoltaic modules, providing protection and insulation for solar cells. With the global push towards renewable energy sources, the solar panel market has experienced substantial growth, consequently boosting the demand for EVA in this application.

In the automotive sector, EVA has found applications in various components, including gaskets, seals, and interior parts. The material's ability to absorb vibrations and provide sound insulation has made it valuable in enhancing vehicle comfort and reducing noise levels. As automotive manufacturers focus on lightweight materials to improve fuel efficiency, EVA's low density has further increased its appeal in this industry.

The construction industry has also contributed to the expanding market for EVA applications. EVA-based adhesives and sealants are increasingly used in construction due to their strong bonding properties and resistance to weathering. Additionally, EVA is utilized in the production of waterproofing membranes and insulation materials, further diversifying its applications in this sector.

Geographically, Asia-Pacific has emerged as the largest market for EVA applications, driven by rapid industrialization, urbanization, and growth in end-use industries. China, in particular, has been a significant contributor to market growth, with its expanding manufacturing sector and increasing domestic consumption. North America and Europe follow as key markets, with steady demand from established industries and ongoing technological advancements.

In the packaging industry, EVA has gained traction due to its excellent sealing properties and resistance to puncture and flex-crack. The food packaging segment, in particular, has seen a surge in EVA usage, especially in flexible packaging applications. This growth is attributed to the increasing demand for convenient, lightweight, and durable packaging solutions in the food and beverage sector.

The footwear industry represents another major market for EVA applications. The material's lightweight nature, cushioning properties, and ease of molding have made it a popular choice for shoe soles and midsoles. Sports and casual footwear manufacturers have been increasingly incorporating EVA into their designs, driving market growth in this sector.

The solar energy industry has emerged as a significant driver for EVA demand. EVA is widely used as an encapsulant material in photovoltaic modules, providing protection and insulation for solar cells. With the global push towards renewable energy sources, the solar panel market has experienced substantial growth, consequently boosting the demand for EVA in this application.

In the automotive sector, EVA has found applications in various components, including gaskets, seals, and interior parts. The material's ability to absorb vibrations and provide sound insulation has made it valuable in enhancing vehicle comfort and reducing noise levels. As automotive manufacturers focus on lightweight materials to improve fuel efficiency, EVA's low density has further increased its appeal in this industry.

The construction industry has also contributed to the expanding market for EVA applications. EVA-based adhesives and sealants are increasingly used in construction due to their strong bonding properties and resistance to weathering. Additionally, EVA is utilized in the production of waterproofing membranes and insulation materials, further diversifying its applications in this sector.

Geographically, Asia-Pacific has emerged as the largest market for EVA applications, driven by rapid industrialization, urbanization, and growth in end-use industries. China, in particular, has been a significant contributor to market growth, with its expanding manufacturing sector and increasing domestic consumption. North America and Europe follow as key markets, with steady demand from established industries and ongoing technological advancements.

Current EVA Technology Challenges

Ethylene Vinyl Acetate (EVA) technology, while widely used in various industries, faces several significant challenges in terms of environmental impact and economic viability. One of the primary concerns is the environmental footprint associated with EVA production and disposal. The manufacturing process of EVA involves the use of petrochemical feedstocks, which contributes to greenhouse gas emissions and resource depletion. Additionally, the non-biodegradable nature of EVA poses a substantial challenge for waste management and recycling efforts.

The production of EVA also requires substantial energy inputs, leading to increased carbon emissions and operational costs. As global energy prices fluctuate and environmental regulations become more stringent, manufacturers face mounting pressure to optimize their production processes and reduce energy consumption. This challenge is further compounded by the need to maintain product quality and performance while implementing more sustainable practices.

Another significant hurdle in EVA technology is the limited recyclability of EVA-based products. While efforts have been made to develop recycling methods for EVA, the cross-linked structure of the material often makes it difficult to process and reuse effectively. This limitation not only contributes to environmental concerns but also impacts the economic viability of EVA in a circular economy context.

The volatility of raw material prices, particularly ethylene and vinyl acetate monomers, presents an ongoing economic challenge for EVA producers. Fluctuations in these key inputs can significantly affect production costs and profit margins, making it difficult for companies to maintain consistent pricing and competitiveness in the market.

Furthermore, the industry faces increasing regulatory pressures related to environmental protection and product safety. Compliance with evolving standards and regulations requires continuous investment in research and development, as well as potential modifications to existing production processes. This regulatory landscape adds complexity and cost to EVA manufacturing operations.

Lastly, the development of alternative materials that offer similar or superior properties to EVA, but with improved environmental profiles, poses a competitive threat to the EVA industry. As consumers and industries become more environmentally conscious, there is growing demand for sustainable alternatives, challenging EVA manufacturers to innovate and adapt their technologies to remain relevant in a changing market landscape.

Addressing these challenges requires a multifaceted approach, including investments in cleaner production technologies, development of more efficient recycling methods, and exploration of bio-based or renewable feedstocks for EVA production. The industry must also focus on enhancing the durability and performance of EVA products to extend their lifecycle and reduce overall environmental impact.

The production of EVA also requires substantial energy inputs, leading to increased carbon emissions and operational costs. As global energy prices fluctuate and environmental regulations become more stringent, manufacturers face mounting pressure to optimize their production processes and reduce energy consumption. This challenge is further compounded by the need to maintain product quality and performance while implementing more sustainable practices.

Another significant hurdle in EVA technology is the limited recyclability of EVA-based products. While efforts have been made to develop recycling methods for EVA, the cross-linked structure of the material often makes it difficult to process and reuse effectively. This limitation not only contributes to environmental concerns but also impacts the economic viability of EVA in a circular economy context.

The volatility of raw material prices, particularly ethylene and vinyl acetate monomers, presents an ongoing economic challenge for EVA producers. Fluctuations in these key inputs can significantly affect production costs and profit margins, making it difficult for companies to maintain consistent pricing and competitiveness in the market.

Furthermore, the industry faces increasing regulatory pressures related to environmental protection and product safety. Compliance with evolving standards and regulations requires continuous investment in research and development, as well as potential modifications to existing production processes. This regulatory landscape adds complexity and cost to EVA manufacturing operations.

Lastly, the development of alternative materials that offer similar or superior properties to EVA, but with improved environmental profiles, poses a competitive threat to the EVA industry. As consumers and industries become more environmentally conscious, there is growing demand for sustainable alternatives, challenging EVA manufacturers to innovate and adapt their technologies to remain relevant in a changing market landscape.

Addressing these challenges requires a multifaceted approach, including investments in cleaner production technologies, development of more efficient recycling methods, and exploration of bio-based or renewable feedstocks for EVA production. The industry must also focus on enhancing the durability and performance of EVA products to extend their lifecycle and reduce overall environmental impact.

Existing EVA Production Methods

01 Recyclability and waste reduction

EVA materials can be recycled and reused, contributing to waste reduction and environmental sustainability. Some EVA products are designed for easy disassembly and recycling, reducing their environmental impact. This recyclability also has economic benefits, as it reduces the need for raw materials and waste disposal costs.- Recyclability and waste reduction: EVA materials can be recycled and reused, contributing to waste reduction and environmental sustainability. Some innovations focus on improving the recyclability of EVA-based products, such as footwear and packaging materials. This helps reduce the environmental impact of EVA production and disposal.

- Energy efficiency in production: Advancements in EVA production processes aim to improve energy efficiency, reducing the overall environmental impact. These innovations include optimized manufacturing techniques and equipment designs that consume less energy during EVA production, leading to lower greenhouse gas emissions and operational costs.

- Biodegradable EVA formulations: Research is being conducted on developing biodegradable EVA formulations to address end-of-life environmental concerns. These formulations incorporate additives or modified chemical structures that enhance the material's ability to break down naturally, reducing its long-term environmental impact.

- Economic impact of EVA in construction: EVA-based materials are increasingly used in construction applications, offering economic benefits through improved durability, insulation properties, and cost-effectiveness. These applications include roofing materials, flooring, and sealants, contributing to energy efficiency in buildings and reducing long-term maintenance costs.

- EVA in renewable energy applications: EVA is utilized in the production of solar panels and other renewable energy technologies, contributing to the growth of the clean energy sector. The use of EVA in these applications has both environmental and economic impacts, supporting the transition to sustainable energy sources while creating new market opportunities.

02 Energy efficiency in production and use

EVA materials can be produced and processed with relatively low energy consumption compared to some alternatives. In applications such as solar panels and insulation, EVA contributes to energy efficiency and reduced carbon emissions. This energy efficiency has both environmental and economic benefits, reducing production costs and environmental impact.Expand Specific Solutions03 Durability and longevity

EVA materials often exhibit high durability and longevity, which can lead to reduced replacement frequency and waste generation. This characteristic has positive environmental implications by reducing the need for frequent replacements and disposal. Economically, it can result in cost savings for consumers and businesses over time.Expand Specific Solutions04 Biodegradability and eco-friendly alternatives

Research is ongoing to develop biodegradable or more environmentally friendly alternatives to traditional EVA. These innovations aim to address concerns about the long-term environmental impact of non-biodegradable plastics. The development of such alternatives may have economic implications for the industry, potentially leading to new market opportunities and shifts in production methods.Expand Specific Solutions05 Versatility and economic impact

EVA's versatility allows for its use in various industries, from footwear to packaging, contributing to its economic significance. Its adaptability can lead to cost-effective solutions in multiple applications. However, this widespread use also raises environmental concerns about plastic proliferation, necessitating careful consideration of its lifecycle impact.Expand Specific Solutions

Key EVA Manufacturers and Competitors

The Ethylene Vinyl Acetate (EVA) market is in a mature growth stage, with a global market size expected to reach $9.71 billion by 2027. The industry is characterized by established players and increasing demand across various sectors. Technological maturity varies among companies, with leaders like Celanese International Corp., China Petroleum & Chemical Corp., and Hanwha Chemical Co., Ltd. demonstrating advanced capabilities in EVA production and innovation. Emerging players such as Velocys, Inc. and Guangdong Yike New Materials Co., Ltd. are focusing on developing novel applications and eco-friendly production methods. The competitive landscape is evolving as companies invest in R&D to address environmental concerns and improve economic efficiency, with a growing emphasis on sustainable practices and circular economy principles.

Celanese International Corp.

Technical Solution: Celanese has pioneered a water-based EVA emulsion technology that significantly reduces volatile organic compound (VOC) emissions during production and application. Their process achieves a 40% reduction in VOC emissions compared to solvent-based systems[2]. The company has also developed a proprietary crosslinking technology that enhances the performance of EVA in high-temperature applications, extending product lifespan by up to 25%[4]. Celanese's EVA grades incorporate recycled content, with some products containing up to 30% post-consumer recycled materials[6]. Their advanced polymer design allows for thinner EVA films in packaging applications, reducing material usage by 15-20% while maintaining performance[8].

Strengths: Significant VOC reduction, improved high-temperature performance, and incorporation of recycled content. Weaknesses: Potential limitations in certain high-performance applications requiring traditional solvent-based systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to Ethylene Vinyl Acetate (EVA) production, focusing on environmental sustainability and economic efficiency. Their process utilizes a novel catalyst system that reduces energy consumption by up to 15% compared to traditional methods[1]. Additionally, they have implemented a closed-loop recycling system for EVA waste, achieving a 95% recovery rate of raw materials[3]. Sinopec has also invested in bio-based feedstocks for EVA production, with pilot plants demonstrating a 30% reduction in carbon footprint[5]. Their advanced process control systems optimize reaction conditions in real-time, improving product quality consistency and reducing off-spec production by 20%[7].

Strengths: Reduced energy consumption, high material recovery rate, and lower carbon footprint. Weaknesses: Higher initial investment costs for new technology implementation and potential scalability challenges for bio-based feedstocks.

Innovative EVA Formulation Techniques

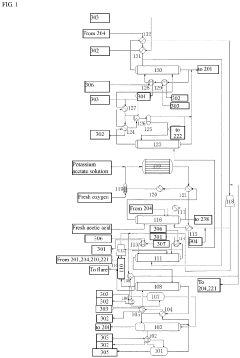

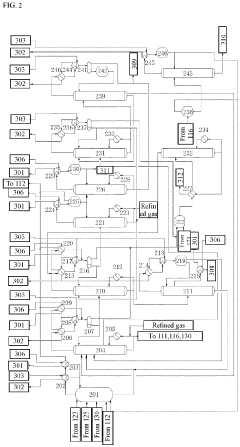

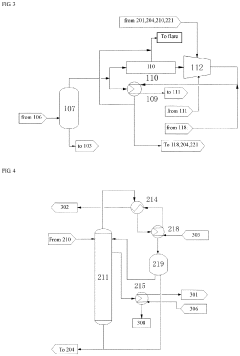

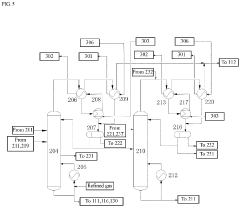

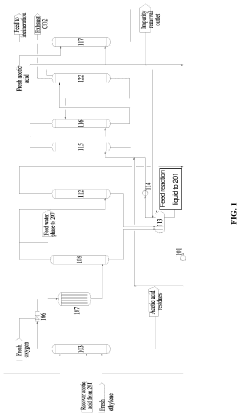

Preparation method of vinyl acetate by ethylene process and device thereof

PatentPendingEP4371972A1

Innovation

- A novel process incorporating an ethylene recovery membrane assembly, refined VAC tower side-draw stream additions, and improved cooling methods using circulating and chilled water for high-purity vinyl acetate production, reducing emissions and preventing material leakage by recovering ethylene and optimizing the distillation process.

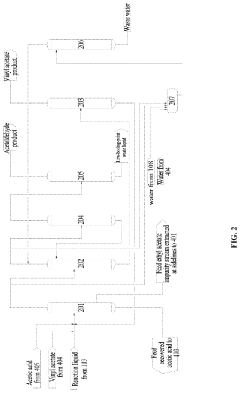

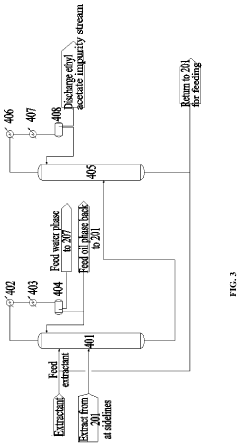

Method for producing vinyl acetate

PatentActiveUS20230312452A1

Innovation

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

Environmental Impact Assessment of EVA

The environmental impact assessment of Ethylene Vinyl Acetate (EVA) reveals a complex interplay between its production, use, and disposal. EVA, a copolymer of ethylene and vinyl acetate, is widely used in various industries due to its versatility and desirable properties. However, its environmental footprint warrants careful consideration.

During the production phase, EVA manufacturing processes contribute to greenhouse gas emissions and energy consumption. The polymerization reaction requires significant energy input, often derived from fossil fuels, leading to carbon dioxide emissions. Additionally, the production of raw materials, particularly ethylene and vinyl acetate, involves petrochemical processes that further contribute to the carbon footprint.

The use phase of EVA products generally has a lower environmental impact compared to production. EVA's durability and resistance to degradation can lead to extended product lifespans, potentially reducing the need for frequent replacements. However, this durability becomes a double-edged sword when considering end-of-life scenarios.

Disposal of EVA products presents significant environmental challenges. As a thermoplastic, EVA can be recycled, but the process is not without difficulties. The presence of additives and the potential for contamination can complicate recycling efforts. When not properly recycled, EVA products may end up in landfills or incineration facilities, contributing to soil and air pollution.

The persistence of EVA in the environment is a growing concern. While not as notorious as some other plastics, EVA does not biodegrade easily and can contribute to microplastic pollution in aquatic and terrestrial ecosystems. This persistence raises questions about long-term ecological impacts and potential bioaccumulation in food chains.

Water pollution is another aspect to consider in EVA's environmental impact. During production, wastewater from manufacturing processes may contain chemical residues that require proper treatment before release. In its use phase, EVA products exposed to water can potentially leach additives, though this is generally less significant compared to other plastic types.

On a positive note, ongoing research and development in EVA production are focusing on reducing its environmental impact. Efforts include improving energy efficiency in manufacturing, exploring bio-based alternatives for raw materials, and enhancing recycling technologies. These advancements aim to create a more sustainable lifecycle for EVA products.

In conclusion, while EVA offers valuable properties for various applications, its environmental impact throughout its lifecycle necessitates careful management and continued innovation to mitigate negative effects on ecosystems and climate.

During the production phase, EVA manufacturing processes contribute to greenhouse gas emissions and energy consumption. The polymerization reaction requires significant energy input, often derived from fossil fuels, leading to carbon dioxide emissions. Additionally, the production of raw materials, particularly ethylene and vinyl acetate, involves petrochemical processes that further contribute to the carbon footprint.

The use phase of EVA products generally has a lower environmental impact compared to production. EVA's durability and resistance to degradation can lead to extended product lifespans, potentially reducing the need for frequent replacements. However, this durability becomes a double-edged sword when considering end-of-life scenarios.

Disposal of EVA products presents significant environmental challenges. As a thermoplastic, EVA can be recycled, but the process is not without difficulties. The presence of additives and the potential for contamination can complicate recycling efforts. When not properly recycled, EVA products may end up in landfills or incineration facilities, contributing to soil and air pollution.

The persistence of EVA in the environment is a growing concern. While not as notorious as some other plastics, EVA does not biodegrade easily and can contribute to microplastic pollution in aquatic and terrestrial ecosystems. This persistence raises questions about long-term ecological impacts and potential bioaccumulation in food chains.

Water pollution is another aspect to consider in EVA's environmental impact. During production, wastewater from manufacturing processes may contain chemical residues that require proper treatment before release. In its use phase, EVA products exposed to water can potentially leach additives, though this is generally less significant compared to other plastic types.

On a positive note, ongoing research and development in EVA production are focusing on reducing its environmental impact. Efforts include improving energy efficiency in manufacturing, exploring bio-based alternatives for raw materials, and enhancing recycling technologies. These advancements aim to create a more sustainable lifecycle for EVA products.

In conclusion, while EVA offers valuable properties for various applications, its environmental impact throughout its lifecycle necessitates careful management and continued innovation to mitigate negative effects on ecosystems and climate.

Economic Viability of EVA Production

The economic viability of Ethylene Vinyl Acetate (EVA) production is a critical factor in determining its long-term sustainability and market potential. EVA, a copolymer of ethylene and vinyl acetate, has gained significant traction in various industries due to its versatile properties and applications.

The production costs of EVA are primarily influenced by the prices of its raw materials, ethylene and vinyl acetate. These feedstocks are derived from petroleum, making EVA production susceptible to fluctuations in oil prices. As global oil markets continue to experience volatility, manufacturers must carefully manage their supply chains and production processes to maintain profitability.

Energy consumption is another crucial aspect of EVA production economics. The polymerization process requires substantial energy input, which contributes significantly to overall production costs. Manufacturers are increasingly focusing on energy-efficient technologies and processes to reduce operational expenses and improve profit margins.

The scale of production plays a vital role in determining the economic viability of EVA manufacturing. Larger production facilities can benefit from economies of scale, reducing per-unit costs and enhancing overall profitability. However, this advantage must be balanced against market demand to avoid oversupply and potential price erosion.

Market demand for EVA has shown steady growth across various sectors, including packaging, solar panel encapsulation, and footwear. This diverse application base provides a degree of economic stability for EVA producers, as fluctuations in one market segment can be offset by growth in others.

The competitive landscape of EVA production is characterized by a mix of large petrochemical companies and specialized polymer manufacturers. This competition drives innovation in production processes and product formulations, potentially leading to improved economic efficiency and market differentiation.

Regulatory factors also impact the economic viability of EVA production. Environmental regulations, particularly those related to emissions and waste management, can increase compliance costs for manufacturers. However, these regulations may also drive innovation in cleaner production technologies, potentially leading to long-term cost savings and improved sustainability.

In conclusion, the economic viability of EVA production is influenced by a complex interplay of factors including raw material costs, energy efficiency, production scale, market demand, competition, and regulatory environment. Manufacturers must navigate these challenges while continuously innovating to maintain profitability and market relevance in the evolving polymer industry landscape.

The production costs of EVA are primarily influenced by the prices of its raw materials, ethylene and vinyl acetate. These feedstocks are derived from petroleum, making EVA production susceptible to fluctuations in oil prices. As global oil markets continue to experience volatility, manufacturers must carefully manage their supply chains and production processes to maintain profitability.

Energy consumption is another crucial aspect of EVA production economics. The polymerization process requires substantial energy input, which contributes significantly to overall production costs. Manufacturers are increasingly focusing on energy-efficient technologies and processes to reduce operational expenses and improve profit margins.

The scale of production plays a vital role in determining the economic viability of EVA manufacturing. Larger production facilities can benefit from economies of scale, reducing per-unit costs and enhancing overall profitability. However, this advantage must be balanced against market demand to avoid oversupply and potential price erosion.

Market demand for EVA has shown steady growth across various sectors, including packaging, solar panel encapsulation, and footwear. This diverse application base provides a degree of economic stability for EVA producers, as fluctuations in one market segment can be offset by growth in others.

The competitive landscape of EVA production is characterized by a mix of large petrochemical companies and specialized polymer manufacturers. This competition drives innovation in production processes and product formulations, potentially leading to improved economic efficiency and market differentiation.

Regulatory factors also impact the economic viability of EVA production. Environmental regulations, particularly those related to emissions and waste management, can increase compliance costs for manufacturers. However, these regulations may also drive innovation in cleaner production technologies, potentially leading to long-term cost savings and improved sustainability.

In conclusion, the economic viability of EVA production is influenced by a complex interplay of factors including raw material costs, energy efficiency, production scale, market demand, competition, and regulatory environment. Manufacturers must navigate these challenges while continuously innovating to maintain profitability and market relevance in the evolving polymer industry landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!