How to Enhance Adaptability with Ethylene Vinyl Acetate Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Solutions Background and Objectives

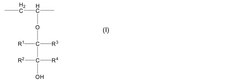

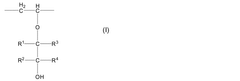

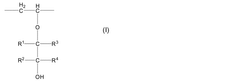

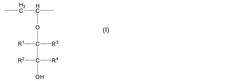

Ethylene Vinyl Acetate (EVA) solutions have emerged as a versatile and adaptable material in various industries over the past few decades. The evolution of EVA technology can be traced back to the 1950s when it was first developed as a copolymer of ethylene and vinyl acetate. Since then, its unique properties have led to widespread adoption in applications ranging from packaging and adhesives to footwear and solar panel encapsulation.

The primary objective of enhancing adaptability with EVA solutions is to expand its utility across diverse sectors while improving its performance characteristics. This goal is driven by the increasing demand for materials that can withstand varying environmental conditions, offer superior flexibility, and maintain structural integrity under different stress scenarios. As industries continue to evolve, the need for adaptable materials that can meet complex requirements has become paramount.

The technical evolution of EVA solutions has been marked by continuous improvements in polymer chemistry and processing techniques. Early developments focused on optimizing the ratio of ethylene to vinyl acetate to achieve desired properties. Subsequent advancements have included the incorporation of additives, cross-linking agents, and the development of specialized blending techniques to enhance specific characteristics such as weather resistance, thermal stability, and impact strength.

In recent years, the focus has shifted towards developing EVA solutions that can adapt to changing environmental conditions and application requirements. This includes the creation of smart EVA materials that can respond to external stimuli such as temperature, pressure, or electrical fields. The integration of nanotechnology has also opened new avenues for enhancing the adaptability of EVA solutions, allowing for the fine-tuning of material properties at the molecular level.

The current technological landscape presents both opportunities and challenges in the quest to enhance the adaptability of EVA solutions. Key areas of focus include improving the material's resistance to degradation under extreme conditions, enhancing its compatibility with other materials for composite applications, and developing EVA formulations that can self-heal or reconfigure in response to damage or stress.

As we look towards the future, the trajectory of EVA solutions is aimed at creating increasingly sophisticated materials that can seamlessly adapt to diverse and dynamic environments. This involves not only improving the intrinsic properties of EVA but also exploring novel applications that leverage its unique characteristics. The ultimate goal is to position EVA solutions as a go-to material for industries seeking adaptable, high-performance solutions to complex engineering challenges.

The primary objective of enhancing adaptability with EVA solutions is to expand its utility across diverse sectors while improving its performance characteristics. This goal is driven by the increasing demand for materials that can withstand varying environmental conditions, offer superior flexibility, and maintain structural integrity under different stress scenarios. As industries continue to evolve, the need for adaptable materials that can meet complex requirements has become paramount.

The technical evolution of EVA solutions has been marked by continuous improvements in polymer chemistry and processing techniques. Early developments focused on optimizing the ratio of ethylene to vinyl acetate to achieve desired properties. Subsequent advancements have included the incorporation of additives, cross-linking agents, and the development of specialized blending techniques to enhance specific characteristics such as weather resistance, thermal stability, and impact strength.

In recent years, the focus has shifted towards developing EVA solutions that can adapt to changing environmental conditions and application requirements. This includes the creation of smart EVA materials that can respond to external stimuli such as temperature, pressure, or electrical fields. The integration of nanotechnology has also opened new avenues for enhancing the adaptability of EVA solutions, allowing for the fine-tuning of material properties at the molecular level.

The current technological landscape presents both opportunities and challenges in the quest to enhance the adaptability of EVA solutions. Key areas of focus include improving the material's resistance to degradation under extreme conditions, enhancing its compatibility with other materials for composite applications, and developing EVA formulations that can self-heal or reconfigure in response to damage or stress.

As we look towards the future, the trajectory of EVA solutions is aimed at creating increasingly sophisticated materials that can seamlessly adapt to diverse and dynamic environments. This involves not only improving the intrinsic properties of EVA but also exploring novel applications that leverage its unique characteristics. The ultimate goal is to position EVA solutions as a go-to material for industries seeking adaptable, high-performance solutions to complex engineering challenges.

Market Demand Analysis for Enhanced EVA Adaptability

The market demand for enhanced adaptability in Ethylene Vinyl Acetate (EVA) solutions has been steadily growing across various industries. This surge is primarily driven by the increasing need for versatile materials that can withstand diverse environmental conditions and meet the evolving requirements of modern applications.

In the packaging industry, there is a rising demand for EVA solutions with improved adaptability to enhance the performance of flexible packaging materials. Manufacturers are seeking EVA formulations that offer better heat resistance, moisture barrier properties, and compatibility with a wide range of substrates. This demand is fueled by the growing emphasis on sustainable packaging solutions and the need for materials that can maintain their integrity under various storage and transportation conditions.

The automotive sector represents another significant market for enhanced EVA adaptability. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing interest in EVA-based materials that can adapt to different temperature ranges and mechanical stresses. The demand extends to applications such as gaskets, seals, and interior components, where adaptable EVA solutions can provide superior performance and longevity.

In the renewable energy sector, particularly in solar panel manufacturing, the market for adaptable EVA encapsulants is expanding rapidly. Solar module producers are seeking EVA formulations that can withstand extreme weather conditions, resist UV degradation, and maintain their optical and mechanical properties over extended periods. This demand is driven by the global push towards sustainable energy solutions and the need for more durable and efficient solar panels.

The footwear industry is another key market segment driving the demand for enhanced EVA adaptability. Manufacturers are looking for EVA compounds that can provide improved cushioning, flexibility, and durability across various shoe designs and usage scenarios. The growing trend of customized and performance-oriented footwear is further fueling this demand.

Additionally, the medical and healthcare sectors are showing increased interest in adaptable EVA solutions. There is a growing need for materials that can be easily sterilized, maintain their properties in different medical environments, and offer biocompatibility for various medical devices and packaging applications.

The construction industry is also contributing to the market demand for enhanced EVA adaptability. EVA-based materials with improved weather resistance, thermal insulation properties, and compatibility with other construction materials are sought after for applications such as roofing membranes, sealants, and adhesives.

As industries continue to push the boundaries of material performance, the market for EVA solutions with enhanced adaptability is expected to grow further. This trend is likely to drive innovation in EVA formulations, processing techniques, and application methodologies, opening up new opportunities for material suppliers and manufacturers across various sectors.

In the packaging industry, there is a rising demand for EVA solutions with improved adaptability to enhance the performance of flexible packaging materials. Manufacturers are seeking EVA formulations that offer better heat resistance, moisture barrier properties, and compatibility with a wide range of substrates. This demand is fueled by the growing emphasis on sustainable packaging solutions and the need for materials that can maintain their integrity under various storage and transportation conditions.

The automotive sector represents another significant market for enhanced EVA adaptability. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing interest in EVA-based materials that can adapt to different temperature ranges and mechanical stresses. The demand extends to applications such as gaskets, seals, and interior components, where adaptable EVA solutions can provide superior performance and longevity.

In the renewable energy sector, particularly in solar panel manufacturing, the market for adaptable EVA encapsulants is expanding rapidly. Solar module producers are seeking EVA formulations that can withstand extreme weather conditions, resist UV degradation, and maintain their optical and mechanical properties over extended periods. This demand is driven by the global push towards sustainable energy solutions and the need for more durable and efficient solar panels.

The footwear industry is another key market segment driving the demand for enhanced EVA adaptability. Manufacturers are looking for EVA compounds that can provide improved cushioning, flexibility, and durability across various shoe designs and usage scenarios. The growing trend of customized and performance-oriented footwear is further fueling this demand.

Additionally, the medical and healthcare sectors are showing increased interest in adaptable EVA solutions. There is a growing need for materials that can be easily sterilized, maintain their properties in different medical environments, and offer biocompatibility for various medical devices and packaging applications.

The construction industry is also contributing to the market demand for enhanced EVA adaptability. EVA-based materials with improved weather resistance, thermal insulation properties, and compatibility with other construction materials are sought after for applications such as roofing membranes, sealants, and adhesives.

As industries continue to push the boundaries of material performance, the market for EVA solutions with enhanced adaptability is expected to grow further. This trend is likely to drive innovation in EVA formulations, processing techniques, and application methodologies, opening up new opportunities for material suppliers and manufacturers across various sectors.

Current EVA Technology Status and Challenges

Ethylene Vinyl Acetate (EVA) technology has made significant strides in recent years, yet it still faces several challenges in enhancing its adaptability across various applications. The current status of EVA technology is characterized by its widespread use in industries such as packaging, footwear, and solar panel encapsulation. However, the demand for more versatile and high-performance EVA solutions continues to grow, pushing the boundaries of existing technologies.

One of the primary challenges in EVA technology is achieving a balance between flexibility and strength. While EVA copolymers offer excellent flexibility, they often lack the mechanical strength required for certain applications. This limitation has led to ongoing research into optimizing the vinyl acetate content and molecular structure to enhance overall performance without compromising flexibility.

Another significant challenge lies in improving the thermal stability of EVA materials. As the applications for EVA expand into more demanding environments, such as automotive and construction industries, the need for enhanced heat resistance becomes crucial. Current EVA formulations may experience degradation or loss of properties at elevated temperatures, limiting their use in high-temperature applications.

The adaptability of EVA to various processing methods also presents a challenge. While EVA is generally easy to process, achieving consistent quality across different manufacturing techniques, such as injection molding, extrusion, and foam production, can be difficult. This variability in processing outcomes can lead to inconsistencies in product performance and properties.

Furthermore, the environmental impact of EVA production and disposal remains a concern. As sustainability becomes increasingly important, there is a growing need to develop more eco-friendly EVA formulations and improve recycling processes. The current challenge lies in maintaining the desirable properties of EVA while incorporating biodegradable or easily recyclable components.

In terms of geographical distribution, EVA technology development is primarily concentrated in regions with strong polymer and materials science industries. Countries like the United States, Japan, South Korea, and Germany are at the forefront of EVA research and innovation. However, emerging markets in Asia, particularly China and India, are rapidly expanding their EVA production capabilities, potentially shifting the global landscape of EVA technology development.

The adaptability of EVA in specialized applications, such as medical devices and advanced electronics, presents both opportunities and challenges. While EVA's biocompatibility and electrical insulation properties make it attractive for these sectors, meeting the stringent regulatory requirements and performance standards poses significant technical hurdles.

One of the primary challenges in EVA technology is achieving a balance between flexibility and strength. While EVA copolymers offer excellent flexibility, they often lack the mechanical strength required for certain applications. This limitation has led to ongoing research into optimizing the vinyl acetate content and molecular structure to enhance overall performance without compromising flexibility.

Another significant challenge lies in improving the thermal stability of EVA materials. As the applications for EVA expand into more demanding environments, such as automotive and construction industries, the need for enhanced heat resistance becomes crucial. Current EVA formulations may experience degradation or loss of properties at elevated temperatures, limiting their use in high-temperature applications.

The adaptability of EVA to various processing methods also presents a challenge. While EVA is generally easy to process, achieving consistent quality across different manufacturing techniques, such as injection molding, extrusion, and foam production, can be difficult. This variability in processing outcomes can lead to inconsistencies in product performance and properties.

Furthermore, the environmental impact of EVA production and disposal remains a concern. As sustainability becomes increasingly important, there is a growing need to develop more eco-friendly EVA formulations and improve recycling processes. The current challenge lies in maintaining the desirable properties of EVA while incorporating biodegradable or easily recyclable components.

In terms of geographical distribution, EVA technology development is primarily concentrated in regions with strong polymer and materials science industries. Countries like the United States, Japan, South Korea, and Germany are at the forefront of EVA research and innovation. However, emerging markets in Asia, particularly China and India, are rapidly expanding their EVA production capabilities, potentially shifting the global landscape of EVA technology development.

The adaptability of EVA in specialized applications, such as medical devices and advanced electronics, presents both opportunities and challenges. While EVA's biocompatibility and electrical insulation properties make it attractive for these sectors, meeting the stringent regulatory requirements and performance standards poses significant technical hurdles.

Existing EVA Adaptability Enhancement Techniques

01 Composition and blending of EVA

EVA's adaptability is enhanced through various compositions and blending techniques. This includes combining EVA with other polymers or additives to improve its properties such as flexibility, durability, and processability. The specific blend ratios and components can be tailored to meet different application requirements.- Composition and blending of EVA: EVA's adaptability is enhanced through various compositions and blending techniques. This includes combining EVA with other polymers or additives to improve its properties such as flexibility, durability, and processability. The specific composition can be tailored to meet different application requirements, demonstrating EVA's versatility in various industries.

- EVA in construction and building materials: EVA's adaptability is evident in its use in construction and building materials. It can be incorporated into various products such as insulation materials, roofing membranes, and flooring systems. EVA's properties, including weather resistance and thermal insulation, make it suitable for enhancing the performance of these materials.

- EVA in adhesive applications: The adaptability of EVA is demonstrated in its use in adhesive formulations. EVA-based adhesives offer excellent bonding properties, flexibility, and resistance to environmental factors. These adhesives can be customized for various substrates and applications, showcasing EVA's versatility in the adhesive industry.

- EVA in packaging and film applications: EVA's adaptability is utilized in packaging and film applications. Its properties such as clarity, flexibility, and sealability make it suitable for various packaging solutions. EVA can be used in food packaging, shrink wrap, and protective films, demonstrating its versatility in meeting different packaging requirements.

- EVA in footwear and sports equipment: The adaptability of EVA is evident in its use in footwear and sports equipment. Its lightweight nature, cushioning properties, and durability make it ideal for shoe soles, insoles, and various sports accessories. EVA can be molded and shaped to meet specific design requirements, showcasing its versatility in these applications.

02 EVA in foam applications

EVA's adaptability extends to foam applications, where it can be used to create lightweight, flexible, and durable materials. The foaming process can be controlled to achieve specific densities and properties, making EVA foams suitable for various industries including footwear, packaging, and automotive.Expand Specific Solutions03 EVA in adhesive formulations

EVA's adaptability is utilized in adhesive formulations, where it can be modified to enhance bonding strength, heat resistance, and flexibility. These adaptations make EVA-based adhesives suitable for a wide range of applications, from packaging to construction materials.Expand Specific Solutions04 EVA in film and sheet applications

The adaptability of EVA in film and sheet applications is demonstrated through its ability to be processed into various thicknesses and configurations. EVA films and sheets can be tailored for specific properties such as clarity, barrier performance, and heat-sealability, making them suitable for packaging, solar panel encapsulation, and agricultural films.Expand Specific Solutions05 EVA in footwear and sports equipment

EVA's adaptability is particularly evident in footwear and sports equipment applications. Its properties can be modified to provide cushioning, shock absorption, and durability. The material can be molded into various shapes and densities to meet specific performance requirements in athletic shoes, insoles, and protective gear.Expand Specific Solutions

Key Players in EVA Solutions Industry

The market for Ethylene Vinyl Acetate (EVA) solutions is in a mature growth stage, with a global market size estimated to reach $9.7 billion by 2027. The technology's adaptability has led to its widespread use across various industries, including packaging, footwear, and solar panels. Key players like Kuraray Co., Ltd., Borealis AG, and Hanwha Chemical Co., Ltd. are driving innovation in EVA formulations, focusing on enhancing properties such as flexibility, durability, and thermal resistance. The competitive landscape is characterized by ongoing R&D efforts to develop specialized EVA grades for emerging applications, particularly in renewable energy and advanced packaging solutions.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed advanced EVA solutions with enhanced adaptability through their EVAL™ EVOH copolymer technology. This innovative approach combines ethylene vinyl alcohol (EVOH) with EVA to create a hybrid material that offers superior barrier properties and flexibility[1]. The company has also introduced a new grade of EVA, PEVA™, which demonstrates improved heat resistance and adhesion properties[2]. Kuraray's research focuses on optimizing the vinyl acetate content and molecular weight distribution to tailor the EVA properties for specific applications, such as solar panel encapsulation and flexible packaging[3].

Strengths: Superior barrier properties, improved heat resistance, and tailored solutions for specific industries. Weaknesses: Potentially higher production costs due to specialized copolymer technology.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary EVA production process that enhances adaptability through precise control of the vinyl acetate content. Their technology allows for the production of EVA with VA content ranging from 10% to 40%, enabling customization for various applications[4]. Sinopec has also implemented a continuous solution polymerization process that improves product consistency and reduces production costs[5]. Additionally, they have invested in research to develop EVA grades with improved thermal stability and weatherability for use in photovoltaic encapsulants[6].

Strengths: Wide range of VA content capabilities, cost-effective production process, and focus on renewable energy applications. Weaknesses: Potential limitations in ultra-high VA content EVA production compared to some competitors.

Core Innovations in EVA Adaptability Research

Method for producing modified ethylene-vinyl alcohol copolymer and resin composition including same

PatentWO2023120705A1

Innovation

- A method involving the use of a catalyst solution containing zinc ions and sulfonate ions in an acetone solution to melt-knead EVOH with a monovalent epoxy compound, optimizing the reaction conditions to achieve a modified EVOH with enhanced barrier properties, stretchability, and improved melt stability.

Floor covering adhesive composition comprising a vinyl acetate-ethylene copolymer

PatentActiveUS20160289512A1

Innovation

- Aqueous emulsifier-stabilized polymer dispersion of vinyl acetate-ethylene copolymer, comprising tackifying resin, fillers, and specific monomer ratios, is developed through radically initiated emulsion polymerization, optimizing monomer composition and polymerization conditions to minimize VOC emissions and maintain high adhesive performance.

Environmental Impact of EVA Solutions

The environmental impact of Ethylene Vinyl Acetate (EVA) solutions is a critical consideration in their application and development. EVA, a copolymer of ethylene and vinyl acetate, has gained widespread use in various industries due to its versatility and adaptability. However, its environmental footprint requires careful examination.

EVA production involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. The manufacturing process also consumes significant energy, further increasing its environmental burden. Despite these concerns, EVA's durability and longevity in many applications can offset some of its initial environmental costs by reducing the need for frequent replacements.

In terms of waste management, EVA presents both challenges and opportunities. While it is not biodegradable, EVA can be recycled through mechanical and chemical processes. Advanced recycling technologies are being developed to improve the efficiency and quality of recycled EVA, potentially reducing its overall environmental impact.

The use of EVA in solar panel encapsulation demonstrates its potential positive environmental contributions. By enhancing the durability and efficiency of solar panels, EVA indirectly supports the growth of renewable energy, potentially offsetting its own environmental costs.

Water pollution is another concern associated with EVA production and disposal. Proper wastewater treatment and management practices are essential to mitigate the release of harmful chemicals and microplastics into aquatic ecosystems.

Efforts to enhance the environmental profile of EVA solutions are ongoing. Research into bio-based alternatives and the incorporation of recycled content in EVA formulations shows promise in reducing its reliance on virgin fossil resources. Additionally, the development of more energy-efficient production processes and the use of renewable energy in manufacturing can significantly reduce the carbon footprint of EVA production.

The adaptability of EVA solutions also plays a role in their environmental impact. By tailoring EVA formulations to specific applications, it is possible to optimize material usage and reduce waste. This adaptability allows for the creation of thinner, lighter, yet equally effective products, potentially reducing material consumption and associated environmental impacts.

As environmental regulations become more stringent, the EVA industry is likely to face increased pressure to improve its sustainability profile. This may drive innovation in cleaner production technologies, more efficient recycling methods, and the development of environmentally friendly additives and formulations.

EVA production involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. The manufacturing process also consumes significant energy, further increasing its environmental burden. Despite these concerns, EVA's durability and longevity in many applications can offset some of its initial environmental costs by reducing the need for frequent replacements.

In terms of waste management, EVA presents both challenges and opportunities. While it is not biodegradable, EVA can be recycled through mechanical and chemical processes. Advanced recycling technologies are being developed to improve the efficiency and quality of recycled EVA, potentially reducing its overall environmental impact.

The use of EVA in solar panel encapsulation demonstrates its potential positive environmental contributions. By enhancing the durability and efficiency of solar panels, EVA indirectly supports the growth of renewable energy, potentially offsetting its own environmental costs.

Water pollution is another concern associated with EVA production and disposal. Proper wastewater treatment and management practices are essential to mitigate the release of harmful chemicals and microplastics into aquatic ecosystems.

Efforts to enhance the environmental profile of EVA solutions are ongoing. Research into bio-based alternatives and the incorporation of recycled content in EVA formulations shows promise in reducing its reliance on virgin fossil resources. Additionally, the development of more energy-efficient production processes and the use of renewable energy in manufacturing can significantly reduce the carbon footprint of EVA production.

The adaptability of EVA solutions also plays a role in their environmental impact. By tailoring EVA formulations to specific applications, it is possible to optimize material usage and reduce waste. This adaptability allows for the creation of thinner, lighter, yet equally effective products, potentially reducing material consumption and associated environmental impacts.

As environmental regulations become more stringent, the EVA industry is likely to face increased pressure to improve its sustainability profile. This may drive innovation in cleaner production technologies, more efficient recycling methods, and the development of environmentally friendly additives and formulations.

Cost-Benefit Analysis of Enhanced EVA Adaptability

Enhancing the adaptability of Ethylene Vinyl Acetate (EVA) solutions presents both significant opportunities and potential challenges from a cost-benefit perspective. The primary advantage lies in the expanded application range of EVA-based products, potentially opening new markets and increasing revenue streams. Improved adaptability can lead to enhanced performance in diverse environmental conditions, thereby increasing product reliability and customer satisfaction.

From a manufacturing standpoint, the development of more adaptable EVA solutions may initially incur higher research and development costs. However, these investments can be offset by the reduced need for multiple product variants, streamlining production processes and inventory management. This consolidation can result in economies of scale, potentially lowering per-unit production costs over time.

The improved adaptability of EVA solutions can also contribute to extended product lifecycles. Products that can withstand a broader range of conditions are likely to have longer service lives, reducing replacement frequency and associated costs for end-users. This increased durability can be a strong selling point, potentially justifying premium pricing and improving profit margins.

However, the pursuit of enhanced adaptability may require more complex formulations or manufacturing processes. This complexity could lead to increased raw material costs or the need for specialized equipment, potentially raising production expenses. The challenge lies in balancing these increased costs against the added value and market potential of the improved products.

From an environmental and regulatory perspective, more adaptable EVA solutions could potentially reduce waste by decreasing the need for application-specific products. This aligns with growing sustainability demands and could provide a competitive edge in markets with stringent environmental regulations. However, it's crucial to consider potential increases in energy consumption or the use of additives that might impact the product's overall environmental footprint.

Market acceptance of enhanced EVA solutions will play a critical role in determining the cost-benefit ratio. While improved adaptability offers clear advantages, customers may be hesitant to adopt new formulations, especially if they come at a higher price point. Effective marketing strategies and clear demonstration of value will be essential to overcome potential resistance and capitalize on the benefits of enhanced adaptability.

In conclusion, while enhancing the adaptability of EVA solutions presents clear potential benefits in terms of market expansion, operational efficiency, and product performance, careful consideration must be given to the associated costs and challenges. The success of this endeavor will largely depend on striking the right balance between investment in innovation and the tangible value delivered to end-users.

From a manufacturing standpoint, the development of more adaptable EVA solutions may initially incur higher research and development costs. However, these investments can be offset by the reduced need for multiple product variants, streamlining production processes and inventory management. This consolidation can result in economies of scale, potentially lowering per-unit production costs over time.

The improved adaptability of EVA solutions can also contribute to extended product lifecycles. Products that can withstand a broader range of conditions are likely to have longer service lives, reducing replacement frequency and associated costs for end-users. This increased durability can be a strong selling point, potentially justifying premium pricing and improving profit margins.

However, the pursuit of enhanced adaptability may require more complex formulations or manufacturing processes. This complexity could lead to increased raw material costs or the need for specialized equipment, potentially raising production expenses. The challenge lies in balancing these increased costs against the added value and market potential of the improved products.

From an environmental and regulatory perspective, more adaptable EVA solutions could potentially reduce waste by decreasing the need for application-specific products. This aligns with growing sustainability demands and could provide a competitive edge in markets with stringent environmental regulations. However, it's crucial to consider potential increases in energy consumption or the use of additives that might impact the product's overall environmental footprint.

Market acceptance of enhanced EVA solutions will play a critical role in determining the cost-benefit ratio. While improved adaptability offers clear advantages, customers may be hesitant to adopt new formulations, especially if they come at a higher price point. Effective marketing strategies and clear demonstration of value will be essential to overcome potential resistance and capitalize on the benefits of enhanced adaptability.

In conclusion, while enhancing the adaptability of EVA solutions presents clear potential benefits in terms of market expansion, operational efficiency, and product performance, careful consideration must be given to the associated costs and challenges. The success of this endeavor will largely depend on striking the right balance between investment in innovation and the tangible value delivered to end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!