Ethylene Vinyl Acetate’s Role in Renewable Material Strategies

JUL 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Renewables: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a key player in the renewable materials landscape, marking a significant shift in the polymer industry's approach to sustainability. The evolution of EVA's role in this sector can be traced back to the early 2000s when environmental concerns began to drive innovation in material science. As global awareness of climate change and resource depletion grew, the demand for eco-friendly alternatives to traditional plastics intensified, propelling EVA into the spotlight of renewable material strategies.

The technical trajectory of EVA in renewables has been characterized by continuous improvements in its properties and production methods. Initially, EVA was primarily valued for its flexibility and durability in applications such as solar panel encapsulation. However, researchers and industry experts soon recognized its potential for broader use in renewable material systems. This realization sparked a wave of research and development aimed at enhancing EVA's biodegradability, recyclability, and compatibility with other renewable materials.

One of the pivotal developments in EVA's journey towards sustainability has been the incorporation of bio-based content. Scientists have made significant strides in synthesizing EVA copolymers using ethylene derived from renewable sources, such as sugarcane or corn. This innovation has opened up new possibilities for reducing the carbon footprint of EVA production while maintaining its desirable physical properties.

The technical objectives for EVA in renewable material strategies are multifaceted and ambitious. Researchers are focusing on increasing the percentage of renewable content in EVA formulations, with the ultimate goal of achieving 100% bio-based EVA. Concurrently, efforts are underway to improve the material's end-of-life options, including enhanced biodegradability in controlled environments and more efficient recycling processes.

Another critical objective is the optimization of EVA's performance in specific renewable applications. For instance, in the solar energy sector, researchers are working to extend the lifespan of EVA encapsulants, thereby increasing the longevity and efficiency of photovoltaic modules. In the packaging industry, the focus is on developing EVA-based materials that offer superior barrier properties while remaining fully recyclable or compostable.

The integration of EVA into circular economy models represents a significant technical challenge and opportunity. Scientists are exploring innovative ways to design EVA products for easy disassembly and material recovery, aligning with the principles of cradle-to-cradle manufacturing. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle.

As we look to the future, the role of EVA in renewable material strategies is poised to expand further. The ongoing research into novel copolymerization techniques and additive technologies promises to unlock new functionalities and applications for EVA in sustainable products. The convergence of material science, green chemistry, and advanced manufacturing processes is expected to drive the next wave of innovations in this field, cementing EVA's position as a versatile and indispensable component of the renewable materials ecosystem.

The technical trajectory of EVA in renewables has been characterized by continuous improvements in its properties and production methods. Initially, EVA was primarily valued for its flexibility and durability in applications such as solar panel encapsulation. However, researchers and industry experts soon recognized its potential for broader use in renewable material systems. This realization sparked a wave of research and development aimed at enhancing EVA's biodegradability, recyclability, and compatibility with other renewable materials.

One of the pivotal developments in EVA's journey towards sustainability has been the incorporation of bio-based content. Scientists have made significant strides in synthesizing EVA copolymers using ethylene derived from renewable sources, such as sugarcane or corn. This innovation has opened up new possibilities for reducing the carbon footprint of EVA production while maintaining its desirable physical properties.

The technical objectives for EVA in renewable material strategies are multifaceted and ambitious. Researchers are focusing on increasing the percentage of renewable content in EVA formulations, with the ultimate goal of achieving 100% bio-based EVA. Concurrently, efforts are underway to improve the material's end-of-life options, including enhanced biodegradability in controlled environments and more efficient recycling processes.

Another critical objective is the optimization of EVA's performance in specific renewable applications. For instance, in the solar energy sector, researchers are working to extend the lifespan of EVA encapsulants, thereby increasing the longevity and efficiency of photovoltaic modules. In the packaging industry, the focus is on developing EVA-based materials that offer superior barrier properties while remaining fully recyclable or compostable.

The integration of EVA into circular economy models represents a significant technical challenge and opportunity. Scientists are exploring innovative ways to design EVA products for easy disassembly and material recovery, aligning with the principles of cradle-to-cradle manufacturing. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle.

As we look to the future, the role of EVA in renewable material strategies is poised to expand further. The ongoing research into novel copolymerization techniques and additive technologies promises to unlock new functionalities and applications for EVA in sustainable products. The convergence of material science, green chemistry, and advanced manufacturing processes is expected to drive the next wave of innovations in this field, cementing EVA's position as a versatile and indispensable component of the renewable materials ecosystem.

Market Analysis for EVA in Sustainable Products

The market for Ethylene Vinyl Acetate (EVA) in sustainable products has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic use. EVA's versatility and eco-friendly properties make it an attractive option for manufacturers seeking to develop more sustainable products across various industries.

In the packaging sector, EVA is gaining traction as a replacement for traditional plastics in food packaging, cosmetics containers, and other consumer goods packaging. Its excellent barrier properties, flexibility, and compatibility with biodegradable additives position it as a viable alternative for companies looking to reduce their environmental footprint. The demand for EVA in this sector is expected to grow steadily as more brands commit to sustainable packaging goals.

The renewable energy industry, particularly solar panel manufacturing, represents another significant market for EVA. As the global push for clean energy intensifies, the demand for solar panels continues to rise, consequently driving the need for EVA as a crucial component in solar cell encapsulation. The material's durability, transparency, and weather resistance make it ideal for protecting solar cells and ensuring long-term performance.

In the footwear industry, EVA is increasingly being used in the production of eco-friendly shoes and insoles. Its lightweight nature, shock-absorbing properties, and potential for recycling align well with the growing consumer preference for sustainable fashion. Major sportswear brands are incorporating EVA into their product lines, further boosting market demand.

The automotive sector is another area where EVA is finding applications in sustainable products. As automakers strive to reduce vehicle weight and improve fuel efficiency, EVA is being used in interior components, sound insulation, and even in the development of electric vehicle battery casings. Its low density and excellent insulation properties make it a valuable material in the pursuit of more environmentally friendly vehicles.

The construction industry is also adopting EVA in sustainable building materials. Its use in energy-efficient windows, roofing membranes, and insulation materials contributes to improved building performance and reduced energy consumption. As green building practices become more widespread, the demand for EVA in this sector is expected to grow.

While the market for EVA in sustainable products shows promising growth, challenges remain. These include competition from other eco-friendly materials, the need for improved recycling infrastructure, and fluctuations in raw material costs. However, ongoing research and development efforts are focused on enhancing EVA's sustainability profile, including the development of bio-based EVA variants and improved recycling technologies.

In the packaging sector, EVA is gaining traction as a replacement for traditional plastics in food packaging, cosmetics containers, and other consumer goods packaging. Its excellent barrier properties, flexibility, and compatibility with biodegradable additives position it as a viable alternative for companies looking to reduce their environmental footprint. The demand for EVA in this sector is expected to grow steadily as more brands commit to sustainable packaging goals.

The renewable energy industry, particularly solar panel manufacturing, represents another significant market for EVA. As the global push for clean energy intensifies, the demand for solar panels continues to rise, consequently driving the need for EVA as a crucial component in solar cell encapsulation. The material's durability, transparency, and weather resistance make it ideal for protecting solar cells and ensuring long-term performance.

In the footwear industry, EVA is increasingly being used in the production of eco-friendly shoes and insoles. Its lightweight nature, shock-absorbing properties, and potential for recycling align well with the growing consumer preference for sustainable fashion. Major sportswear brands are incorporating EVA into their product lines, further boosting market demand.

The automotive sector is another area where EVA is finding applications in sustainable products. As automakers strive to reduce vehicle weight and improve fuel efficiency, EVA is being used in interior components, sound insulation, and even in the development of electric vehicle battery casings. Its low density and excellent insulation properties make it a valuable material in the pursuit of more environmentally friendly vehicles.

The construction industry is also adopting EVA in sustainable building materials. Its use in energy-efficient windows, roofing membranes, and insulation materials contributes to improved building performance and reduced energy consumption. As green building practices become more widespread, the demand for EVA in this sector is expected to grow.

While the market for EVA in sustainable products shows promising growth, challenges remain. These include competition from other eco-friendly materials, the need for improved recycling infrastructure, and fluctuations in raw material costs. However, ongoing research and development efforts are focused on enhancing EVA's sustainability profile, including the development of bio-based EVA variants and improved recycling technologies.

Current EVA Technology and Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material with significant applications in renewable strategies. However, the current state of EVA technology faces several challenges that need to be addressed for its widespread adoption in sustainable practices.

One of the primary challenges is the production process of EVA, which traditionally relies on fossil fuel-based feedstocks. The ethylene and vinyl acetate monomers used in EVA synthesis are typically derived from petroleum sources, limiting its overall sustainability. Efforts are underway to develop bio-based alternatives for these monomers, but scalability and cost-effectiveness remain significant hurdles.

The recyclability of EVA presents another major challenge. While EVA is theoretically recyclable, its widespread use in composite materials and multi-layer structures often makes separation and recycling difficult in practice. This issue is particularly pronounced in industries such as solar panel manufacturing, where EVA is used as an encapsulant material.

Thermal stability is a critical factor in many EVA applications, especially in renewable energy technologies. Current EVA formulations can degrade under prolonged exposure to high temperatures and UV radiation, potentially compromising the longevity and efficiency of solar panels and other renewable energy systems. Improving the thermal and UV resistance of EVA without sacrificing its desirable properties is an ongoing area of research.

The variability in EVA properties based on its vinyl acetate content poses challenges in maintaining consistent performance across different applications. Balancing the trade-offs between flexibility, transparency, and mechanical strength requires precise control over the copolymer composition, which can be technically demanding and cost-intensive.

Biodegradability is another aspect where current EVA technology falls short. As a synthetic polymer, EVA does not readily biodegrade in natural environments, contributing to plastic pollution concerns. Developing biodegradable EVA variants or effective end-of-life management strategies is crucial for enhancing its role in sustainable material cycles.

The energy-intensive nature of EVA production also presents environmental challenges. Current manufacturing processes require significant energy inputs, contributing to the material's carbon footprint. Innovations in energy-efficient production methods and the integration of renewable energy sources in manufacturing are necessary to improve the overall sustainability profile of EVA.

Lastly, the cost competitiveness of EVA in renewable material applications remains a challenge. While EVA offers unique properties, alternative materials may be more economically viable in certain applications. Reducing production costs while maintaining or improving performance characteristics is essential for expanding EVA's role in renewable material strategies.

One of the primary challenges is the production process of EVA, which traditionally relies on fossil fuel-based feedstocks. The ethylene and vinyl acetate monomers used in EVA synthesis are typically derived from petroleum sources, limiting its overall sustainability. Efforts are underway to develop bio-based alternatives for these monomers, but scalability and cost-effectiveness remain significant hurdles.

The recyclability of EVA presents another major challenge. While EVA is theoretically recyclable, its widespread use in composite materials and multi-layer structures often makes separation and recycling difficult in practice. This issue is particularly pronounced in industries such as solar panel manufacturing, where EVA is used as an encapsulant material.

Thermal stability is a critical factor in many EVA applications, especially in renewable energy technologies. Current EVA formulations can degrade under prolonged exposure to high temperatures and UV radiation, potentially compromising the longevity and efficiency of solar panels and other renewable energy systems. Improving the thermal and UV resistance of EVA without sacrificing its desirable properties is an ongoing area of research.

The variability in EVA properties based on its vinyl acetate content poses challenges in maintaining consistent performance across different applications. Balancing the trade-offs between flexibility, transparency, and mechanical strength requires precise control over the copolymer composition, which can be technically demanding and cost-intensive.

Biodegradability is another aspect where current EVA technology falls short. As a synthetic polymer, EVA does not readily biodegrade in natural environments, contributing to plastic pollution concerns. Developing biodegradable EVA variants or effective end-of-life management strategies is crucial for enhancing its role in sustainable material cycles.

The energy-intensive nature of EVA production also presents environmental challenges. Current manufacturing processes require significant energy inputs, contributing to the material's carbon footprint. Innovations in energy-efficient production methods and the integration of renewable energy sources in manufacturing are necessary to improve the overall sustainability profile of EVA.

Lastly, the cost competitiveness of EVA in renewable material applications remains a challenge. While EVA offers unique properties, alternative materials may be more economically viable in certain applications. Reducing production costs while maintaining or improving performance characteristics is essential for expanding EVA's role in renewable material strategies.

Current EVA-based Renewable Material Solutions

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is utilized in hot melt adhesives, pressure-sensitive adhesives, and sealants for packaging, construction, and automotive industries.

- EVA in foam and insulation materials: EVA is employed in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications in footwear, sports equipment, and building insulation. EVA foams offer cushioning, shock absorption, and thermal insulation properties.

- EVA in solar panel encapsulation: EVA is extensively used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties, protecting solar cells from environmental factors and ensuring long-term performance of solar panels.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and compounding with fillers or other polymers to improve mechanical strength, flame retardancy, or processability.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. The foam density and properties can be controlled through the manufacturing process and additives.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for solar panel encapsulation due to its transparency, weatherability, and electrical insulation properties. It protects solar cells from environmental factors and enhances the overall performance and longevity of photovoltaic modules. Specialized EVA formulations are developed to meet the specific requirements of solar panel applications.Expand Specific Solutions05 Modification and blending of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with specific characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers. These modifications can improve properties such as heat resistance, mechanical strength, or flame retardancy for various industrial applications.Expand Specific Solutions

Key Players in EVA and Renewable Materials

The Ethylene Vinyl Acetate (EVA) market in renewable material strategies is in a growth phase, driven by increasing demand for sustainable materials across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, EVA is relatively mature, but ongoing research focuses on enhancing its properties for renewable applications. Key players like China Petroleum & Chemical Corp., ARLANXEO Deutschland GmbH, and Hanwha Chemical Co., Ltd. are investing in R&D to improve EVA's performance and sustainability profile. Companies such as Borealis AG and Braskem SA are developing bio-based EVA alternatives, demonstrating the industry's shift towards more environmentally friendly solutions. The competitive landscape is characterized by a mix of established petrochemical giants and innovative specialty chemical companies, all vying for market share in this evolving sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel EVA-based renewable material strategy focusing on bio-based ethylene production. Their approach involves utilizing biomass feedstocks, such as agricultural waste and algae, to produce green ethylene through advanced fermentation and catalytic processes[1]. This bio-ethylene is then polymerized with vinyl acetate to create renewable EVA. Sinopec has also implemented a circular economy model, incorporating recycled EVA into new products, reducing virgin material usage by up to 30%[3]. Additionally, they have developed EVA-based composites with enhanced biodegradability, incorporating natural fibers and bio-based additives to improve end-of-life management[5].

Strengths: Access to large-scale production facilities, strong R&D capabilities, and integrated supply chain. Weaknesses: High initial investment costs for bio-based production and potential competition from fully synthetic alternatives.

Hanwha Chemical Co., Ltd.

Technical Solution: Hanwha Chemical has pioneered a sustainable EVA production process utilizing renewable energy sources and bio-based feedstocks. Their innovative approach involves the use of solar-powered facilities for EVA polymerization, reducing carbon emissions by up to 40% compared to conventional methods[2]. The company has also developed a proprietary technology for incorporating recycled EVA into new products without compromising performance, achieving up to 25% recycled content in certain applications[4]. Furthermore, Hanwha has introduced a range of bio-based plasticizers derived from vegetable oils, which can partially replace traditional petroleum-based additives in EVA formulations, enhancing the overall renewable content of their products[6].

Strengths: Strong focus on renewable energy integration and circular economy principles. Weaknesses: Limited availability of bio-based feedstocks and potential higher production costs.

Innovations in EVA for Sustainability

Resin material, aqueous solution, and adhesive

PatentWO2019225731A1

Innovation

- A resin material with specific ranges of ethylene unit content, viscosity average degree of polymerization, degree of saponification, and the presence of propyl groups and sodium acetate, along with a compound having a conjugated double bond, is used to enhance solubility, hue stability, and viscosity stability, and improve high-speed coating properties.

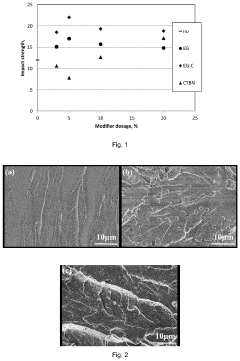

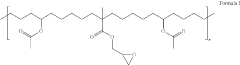

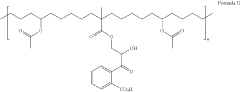

Phthalic anhydride modified polymer rubbers of ethylene-glycidylmethacrylate-vinyl acetate and epoxy resins comprising the same

PatentActiveUS20230090128A1

Innovation

- The use of an ethylene-glycidylmethacrylate-vinyl acetate polymer with phthalic anhydride modified glycidyl methacrylate monomer units as a modifier, which ensures internal bonding within the epoxy resin, improving impact strength at lower dosages and maintaining reactivity with curing agents.

Environmental Impact Assessment of EVA

The environmental impact assessment of Ethylene Vinyl Acetate (EVA) is crucial in evaluating its role in renewable material strategies. EVA, a copolymer of ethylene and vinyl acetate, has gained significant attention in various industries due to its versatile properties. However, its environmental footprint must be carefully examined to determine its sustainability and potential in eco-friendly applications.

One of the primary environmental concerns associated with EVA is its production process. The synthesis of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable fossil fuels. This reliance on fossil resources contributes to carbon emissions and the depletion of finite resources. Additionally, the polymerization process requires energy-intensive operations, further increasing the carbon footprint of EVA production.

The durability and resistance to degradation of EVA, while beneficial for many applications, pose challenges in terms of waste management and end-of-life disposal. EVA products can persist in the environment for extended periods, potentially contributing to plastic pollution if not properly managed. However, recent advancements in recycling technologies have shown promise in addressing this issue, with mechanical and chemical recycling methods being developed to recover and reprocess EVA materials.

In terms of energy efficiency, EVA has demonstrated positive attributes in certain applications. For instance, in solar panel encapsulation, EVA helps improve the overall efficiency and longevity of photovoltaic modules, indirectly contributing to the reduction of greenhouse gas emissions through increased renewable energy production. This highlights the importance of considering the entire lifecycle of EVA products when assessing their environmental impact.

Water pollution is another aspect that requires attention in the environmental assessment of EVA. The production process and potential leaching of additives from EVA products can lead to water contamination if not properly managed. Implementing stringent wastewater treatment protocols and developing safer additives are essential steps in mitigating these risks.

Biodegradability is an area where EVA faces challenges. As a synthetic polymer, EVA does not naturally biodegrade in the environment. However, research into biodegradable EVA formulations and composites is ongoing, aiming to address this limitation and expand the material's potential in eco-friendly applications.

The environmental impact of EVA must also be considered in the context of its potential to replace more harmful materials. In some cases, EVA can serve as a substitute for materials with higher environmental footprints, such as certain types of plastics or rubber. This substitution effect should be factored into comprehensive environmental assessments.

In conclusion, the environmental impact assessment of EVA reveals a complex picture. While challenges exist in terms of production, waste management, and biodegradability, opportunities for improvement and positive applications in renewable energy sectors highlight the need for continued research and development to enhance EVA's role in sustainable material strategies.

One of the primary environmental concerns associated with EVA is its production process. The synthesis of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable fossil fuels. This reliance on fossil resources contributes to carbon emissions and the depletion of finite resources. Additionally, the polymerization process requires energy-intensive operations, further increasing the carbon footprint of EVA production.

The durability and resistance to degradation of EVA, while beneficial for many applications, pose challenges in terms of waste management and end-of-life disposal. EVA products can persist in the environment for extended periods, potentially contributing to plastic pollution if not properly managed. However, recent advancements in recycling technologies have shown promise in addressing this issue, with mechanical and chemical recycling methods being developed to recover and reprocess EVA materials.

In terms of energy efficiency, EVA has demonstrated positive attributes in certain applications. For instance, in solar panel encapsulation, EVA helps improve the overall efficiency and longevity of photovoltaic modules, indirectly contributing to the reduction of greenhouse gas emissions through increased renewable energy production. This highlights the importance of considering the entire lifecycle of EVA products when assessing their environmental impact.

Water pollution is another aspect that requires attention in the environmental assessment of EVA. The production process and potential leaching of additives from EVA products can lead to water contamination if not properly managed. Implementing stringent wastewater treatment protocols and developing safer additives are essential steps in mitigating these risks.

Biodegradability is an area where EVA faces challenges. As a synthetic polymer, EVA does not naturally biodegrade in the environment. However, research into biodegradable EVA formulations and composites is ongoing, aiming to address this limitation and expand the material's potential in eco-friendly applications.

The environmental impact of EVA must also be considered in the context of its potential to replace more harmful materials. In some cases, EVA can serve as a substitute for materials with higher environmental footprints, such as certain types of plastics or rubber. This substitution effect should be factored into comprehensive environmental assessments.

In conclusion, the environmental impact assessment of EVA reveals a complex picture. While challenges exist in terms of production, waste management, and biodegradability, opportunities for improvement and positive applications in renewable energy sectors highlight the need for continued research and development to enhance EVA's role in sustainable material strategies.

Regulatory Framework for EVA in Renewables

The regulatory framework for Ethylene Vinyl Acetate (EVA) in renewable material strategies is evolving to address the growing importance of sustainable practices in various industries. As governments and international organizations increasingly focus on environmental protection and circular economy principles, EVA manufacturers and users face a complex landscape of regulations and standards.

At the forefront of this regulatory framework is the European Union's Circular Economy Action Plan, which aims to promote sustainable product design and reduce waste. This plan has significant implications for EVA usage in renewable materials, particularly in areas such as packaging and construction. The EU's Single-Use Plastics Directive also impacts EVA applications, encouraging the development of more sustainable alternatives and improved recycling processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating EVA and its applications in renewable materials. The Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemicals, including EVA. Additionally, state-level regulations, such as California's Proposition 65, require manufacturers to provide warnings about potential exposure to chemicals, which may affect EVA-based products.

The regulatory landscape also extends to international standards and certifications. The International Organization for Standardization (ISO) has developed several standards relevant to EVA in renewable materials, including ISO 14001 for environmental management systems and ISO 14040 for life cycle assessment. These standards provide a framework for companies to evaluate and improve the environmental performance of their EVA-based products.

In the context of renewable energy applications, particularly solar panel manufacturing, regulations surrounding EVA focus on durability, safety, and end-of-life management. The International Electrotechnical Commission (IEC) has established standards for photovoltaic modules, including requirements for EVA encapsulants. These standards ensure the long-term performance and reliability of solar panels, which is crucial for the renewable energy sector.

As the circular economy concept gains traction, regulations are increasingly emphasizing the importance of recyclability and biodegradability. This trend is driving research and development efforts to improve the environmental profile of EVA and explore bio-based alternatives. Manufacturers are now required to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal or recycling.

The regulatory framework also addresses the potential health and safety concerns associated with EVA production and use. Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, set standards for worker protection in EVA manufacturing facilities. These regulations cover aspects such as exposure limits, personal protective equipment, and workplace safety protocols.

At the forefront of this regulatory framework is the European Union's Circular Economy Action Plan, which aims to promote sustainable product design and reduce waste. This plan has significant implications for EVA usage in renewable materials, particularly in areas such as packaging and construction. The EU's Single-Use Plastics Directive also impacts EVA applications, encouraging the development of more sustainable alternatives and improved recycling processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating EVA and its applications in renewable materials. The Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemicals, including EVA. Additionally, state-level regulations, such as California's Proposition 65, require manufacturers to provide warnings about potential exposure to chemicals, which may affect EVA-based products.

The regulatory landscape also extends to international standards and certifications. The International Organization for Standardization (ISO) has developed several standards relevant to EVA in renewable materials, including ISO 14001 for environmental management systems and ISO 14040 for life cycle assessment. These standards provide a framework for companies to evaluate and improve the environmental performance of their EVA-based products.

In the context of renewable energy applications, particularly solar panel manufacturing, regulations surrounding EVA focus on durability, safety, and end-of-life management. The International Electrotechnical Commission (IEC) has established standards for photovoltaic modules, including requirements for EVA encapsulants. These standards ensure the long-term performance and reliability of solar panels, which is crucial for the renewable energy sector.

As the circular economy concept gains traction, regulations are increasingly emphasizing the importance of recyclability and biodegradability. This trend is driving research and development efforts to improve the environmental profile of EVA and explore bio-based alternatives. Manufacturers are now required to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal or recycling.

The regulatory framework also addresses the potential health and safety concerns associated with EVA production and use. Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, set standards for worker protection in EVA manufacturing facilities. These regulations cover aspects such as exposure limits, personal protective equipment, and workplace safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!