Structural Applications of Ethylene Vinyl Acetate in Engineering

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Engineering: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material in engineering applications, particularly in structural contexts. The evolution of EVA's use in engineering spans several decades, with its development rooted in the polymer industry's quest for materials combining flexibility, durability, and cost-effectiveness. Initially developed in the 1950s, EVA's unique properties have led to its increasing adoption in various structural applications.

The technological trajectory of EVA in engineering has been marked by continuous improvements in material composition and processing techniques. Early applications were limited due to challenges in achieving optimal mechanical properties and long-term stability. However, advancements in polymer science and manufacturing processes have significantly enhanced EVA's performance characteristics, expanding its potential in structural engineering.

Current trends in EVA technology focus on enhancing its structural integrity, thermal resistance, and environmental durability. Researchers and engineers are exploring novel copolymer formulations and cross-linking methods to improve EVA's strength-to-weight ratio and resistance to environmental degradation. These developments aim to broaden EVA's applicability in demanding structural applications, particularly in sectors such as construction, automotive, and aerospace.

The primary objectives of EVA research and development in structural engineering applications are multifaceted. One key goal is to optimize EVA's mechanical properties, including tensile strength, impact resistance, and fatigue performance, to meet the rigorous demands of structural components. Another objective is to enhance EVA's thermal stability and fire resistance, critical factors in many engineering applications.

Furthermore, there is a growing emphasis on developing EVA composites and hybrid materials that combine the advantages of EVA with other high-performance materials. This approach aims to create synergistic effects, resulting in materials with superior mechanical, thermal, and chemical properties suitable for advanced structural applications.

Environmental considerations also play a significant role in shaping the objectives of EVA research. With increasing focus on sustainability, efforts are being made to improve the recyclability and biodegradability of EVA-based materials, aligning with global trends towards eco-friendly engineering solutions.

As the field progresses, the integration of nanotechnology in EVA formulations represents a promising frontier. Researchers are exploring the incorporation of nanoparticles and nanofibers to enhance EVA's structural properties at the molecular level, potentially leading to breakthrough applications in high-performance engineering structures.

The technological trajectory of EVA in engineering has been marked by continuous improvements in material composition and processing techniques. Early applications were limited due to challenges in achieving optimal mechanical properties and long-term stability. However, advancements in polymer science and manufacturing processes have significantly enhanced EVA's performance characteristics, expanding its potential in structural engineering.

Current trends in EVA technology focus on enhancing its structural integrity, thermal resistance, and environmental durability. Researchers and engineers are exploring novel copolymer formulations and cross-linking methods to improve EVA's strength-to-weight ratio and resistance to environmental degradation. These developments aim to broaden EVA's applicability in demanding structural applications, particularly in sectors such as construction, automotive, and aerospace.

The primary objectives of EVA research and development in structural engineering applications are multifaceted. One key goal is to optimize EVA's mechanical properties, including tensile strength, impact resistance, and fatigue performance, to meet the rigorous demands of structural components. Another objective is to enhance EVA's thermal stability and fire resistance, critical factors in many engineering applications.

Furthermore, there is a growing emphasis on developing EVA composites and hybrid materials that combine the advantages of EVA with other high-performance materials. This approach aims to create synergistic effects, resulting in materials with superior mechanical, thermal, and chemical properties suitable for advanced structural applications.

Environmental considerations also play a significant role in shaping the objectives of EVA research. With increasing focus on sustainability, efforts are being made to improve the recyclability and biodegradability of EVA-based materials, aligning with global trends towards eco-friendly engineering solutions.

As the field progresses, the integration of nanotechnology in EVA formulations represents a promising frontier. Researchers are exploring the incorporation of nanoparticles and nanofibers to enhance EVA's structural properties at the molecular level, potentially leading to breakthrough applications in high-performance engineering structures.

Market Demand Analysis for EVA Structural Applications

The market demand for Ethylene Vinyl Acetate (EVA) in structural applications within the engineering sector has shown significant growth in recent years. This trend is driven by the unique properties of EVA, including its flexibility, durability, and resistance to environmental factors. The construction industry, in particular, has emerged as a key market for EVA structural applications, with increasing adoption in areas such as roofing membranes, flooring systems, and insulation materials.

In the construction sector, EVA-based materials are gaining traction due to their excellent weatherability and UV resistance, making them ideal for outdoor applications. The roofing industry has seen a surge in demand for EVA-based membranes, which offer superior waterproofing and longevity compared to traditional materials. This shift is partly driven by the growing emphasis on sustainable and energy-efficient building practices, as EVA-based roofing systems can contribute to improved thermal insulation and reduced energy consumption.

The flooring industry represents another significant market for EVA structural applications. EVA-based flooring materials are increasingly preferred in sports facilities, playgrounds, and industrial settings due to their shock-absorbing properties, durability, and ease of maintenance. The healthcare sector has also shown growing interest in EVA flooring solutions, particularly in hospitals and rehabilitation centers, where safety and hygiene are paramount.

In the automotive industry, EVA is finding new applications in structural components, particularly in electric vehicles (EVs). The material's lightweight nature and excellent vibration damping properties make it an attractive option for EV manufacturers looking to optimize vehicle weight and improve energy efficiency. This trend is expected to accelerate as the global automotive industry continues its shift towards electrification.

The packaging industry is another key driver of market demand for EVA structural applications. EVA-based materials are increasingly used in protective packaging solutions, offering superior cushioning and impact resistance. This trend is particularly evident in the electronics and fragile goods sectors, where product protection during transportation is critical.

Market analysts project that the global demand for EVA in structural applications will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be fueled by ongoing innovations in EVA formulations, which are expanding the material's potential applications across various engineering disciplines. Additionally, the increasing focus on sustainable and recyclable materials is likely to further boost the adoption of EVA-based solutions, as manufacturers work to develop more environmentally friendly variants of the material.

In the construction sector, EVA-based materials are gaining traction due to their excellent weatherability and UV resistance, making them ideal for outdoor applications. The roofing industry has seen a surge in demand for EVA-based membranes, which offer superior waterproofing and longevity compared to traditional materials. This shift is partly driven by the growing emphasis on sustainable and energy-efficient building practices, as EVA-based roofing systems can contribute to improved thermal insulation and reduced energy consumption.

The flooring industry represents another significant market for EVA structural applications. EVA-based flooring materials are increasingly preferred in sports facilities, playgrounds, and industrial settings due to their shock-absorbing properties, durability, and ease of maintenance. The healthcare sector has also shown growing interest in EVA flooring solutions, particularly in hospitals and rehabilitation centers, where safety and hygiene are paramount.

In the automotive industry, EVA is finding new applications in structural components, particularly in electric vehicles (EVs). The material's lightweight nature and excellent vibration damping properties make it an attractive option for EV manufacturers looking to optimize vehicle weight and improve energy efficiency. This trend is expected to accelerate as the global automotive industry continues its shift towards electrification.

The packaging industry is another key driver of market demand for EVA structural applications. EVA-based materials are increasingly used in protective packaging solutions, offering superior cushioning and impact resistance. This trend is particularly evident in the electronics and fragile goods sectors, where product protection during transportation is critical.

Market analysts project that the global demand for EVA in structural applications will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be fueled by ongoing innovations in EVA formulations, which are expanding the material's potential applications across various engineering disciplines. Additionally, the increasing focus on sustainable and recyclable materials is likely to further boost the adoption of EVA-based solutions, as manufacturers work to develop more environmentally friendly variants of the material.

Current State and Challenges of EVA in Structures

Ethylene Vinyl Acetate (EVA) has gained significant traction in structural applications within the engineering field. Currently, EVA is widely used in various industries, including construction, automotive, and aerospace, due to its unique combination of properties. The material exhibits excellent flexibility, impact resistance, and weatherability, making it suitable for diverse structural applications.

In the construction sector, EVA is increasingly utilized in building materials, such as roofing membranes, flooring systems, and insulation panels. Its ability to withstand extreme weather conditions and provide effective thermal insulation has made it a preferred choice for sustainable building designs. However, challenges persist in optimizing EVA's fire resistance properties to meet stringent safety regulations in high-rise structures.

The automotive industry has embraced EVA for its shock-absorbing capabilities and lightweight nature. It is commonly used in bumper systems, interior trim components, and sound-dampening applications. While EVA offers significant advantages in terms of energy absorption and weight reduction, engineers face challenges in enhancing its high-temperature stability for use in engine compartments and other heat-intensive areas.

In aerospace engineering, EVA has found applications in composite structures, particularly in sandwich panels and radomes. Its low dielectric constant makes it suitable for use in radar-transparent structures. However, the material's long-term durability under extreme temperature cycles and exposure to cosmic radiation remains a concern for extended space missions.

One of the primary technical challenges facing EVA in structural applications is its limited load-bearing capacity compared to traditional engineering materials like metals and high-performance plastics. Researchers are actively working on developing EVA-based composites and blends to improve its mechanical strength without compromising flexibility.

Another significant challenge is the material's susceptibility to degradation under prolonged UV exposure. While UV stabilizers have been incorporated into EVA formulations, achieving long-term stability in outdoor applications remains an ongoing research focus. Engineers are exploring novel additives and surface treatments to enhance UV resistance without affecting other desirable properties.

The processing and joining of EVA in structural applications also present technical hurdles. Traditional welding techniques are often ineffective due to the material's low melting point and thermal sensitivity. Developing efficient and reliable bonding methods for EVA-based structures is crucial for expanding its use in large-scale engineering projects.

Lastly, the recyclability and end-of-life management of EVA-based structural components pose environmental challenges. While EVA is theoretically recyclable, the presence of additives and its use in multi-material assemblies complicate the recycling process. Addressing these sustainability concerns is essential for the continued growth of EVA in structural engineering applications.

In the construction sector, EVA is increasingly utilized in building materials, such as roofing membranes, flooring systems, and insulation panels. Its ability to withstand extreme weather conditions and provide effective thermal insulation has made it a preferred choice for sustainable building designs. However, challenges persist in optimizing EVA's fire resistance properties to meet stringent safety regulations in high-rise structures.

The automotive industry has embraced EVA for its shock-absorbing capabilities and lightweight nature. It is commonly used in bumper systems, interior trim components, and sound-dampening applications. While EVA offers significant advantages in terms of energy absorption and weight reduction, engineers face challenges in enhancing its high-temperature stability for use in engine compartments and other heat-intensive areas.

In aerospace engineering, EVA has found applications in composite structures, particularly in sandwich panels and radomes. Its low dielectric constant makes it suitable for use in radar-transparent structures. However, the material's long-term durability under extreme temperature cycles and exposure to cosmic radiation remains a concern for extended space missions.

One of the primary technical challenges facing EVA in structural applications is its limited load-bearing capacity compared to traditional engineering materials like metals and high-performance plastics. Researchers are actively working on developing EVA-based composites and blends to improve its mechanical strength without compromising flexibility.

Another significant challenge is the material's susceptibility to degradation under prolonged UV exposure. While UV stabilizers have been incorporated into EVA formulations, achieving long-term stability in outdoor applications remains an ongoing research focus. Engineers are exploring novel additives and surface treatments to enhance UV resistance without affecting other desirable properties.

The processing and joining of EVA in structural applications also present technical hurdles. Traditional welding techniques are often ineffective due to the material's low melting point and thermal sensitivity. Developing efficient and reliable bonding methods for EVA-based structures is crucial for expanding its use in large-scale engineering projects.

Lastly, the recyclability and end-of-life management of EVA-based structural components pose environmental challenges. While EVA is theoretically recyclable, the presence of additives and its use in multi-material assemblies complicate the recycling process. Addressing these sustainability concerns is essential for the continued growth of EVA in structural engineering applications.

Current EVA Structural Solutions and Implementations

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to achieve different characteristics, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, where it provides good thermal stability and bonding strength. EVA-based adhesives find applications in packaging, bookbinding, and product assembly.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it an excellent choice for applications requiring thermal insulation and shock absorption. EVA foams are used in footwear, sports equipment, and building insulation.

- EVA in solar panel encapsulation: EVA is a preferred material for encapsulating solar cells in photovoltaic modules. It provides excellent transparency, weather resistance, and electrical insulation properties. The use of EVA in solar panel encapsulation helps to protect the cells from environmental factors and enhance the overall performance and longevity of solar panels.

- Modifications and blends of EVA: EVA can be modified or blended with other materials to enhance its properties for specific applications. This includes crosslinking, grafting, or blending with other polymers or additives. Such modifications can improve properties like heat resistance, mechanical strength, or compatibility with other materials, expanding the range of applications for EVA-based products.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly employed in hot melt adhesives, pressure-sensitive adhesives, and sealants. The addition of EVA can improve the flexibility and tack of adhesive compositions.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It is often used in the manufacture of shoe soles, sports equipment padding, and building insulation materials.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps to improve the durability and efficiency of photovoltaic modules.Expand Specific Solutions05 Modification and blending of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers to improve mechanical properties, flame retardancy, or processability.Expand Specific Solutions

Key Players in EVA Structural Engineering

The structural applications of Ethylene Vinyl Acetate (EVA) in engineering are in a mature stage of development, with a growing market size due to its versatile properties. The global EVA market is expected to expand significantly in the coming years, driven by increasing demand in various industries. Key players like Celanese International Corp., DuPont de Nemours, Inc., and Kuraray Co., Ltd. are at the forefront of technological advancements in EVA applications. These companies, along with others such as China Petroleum & Chemical Corp. and Braskem SA, are investing heavily in research and development to improve EVA's performance characteristics and expand its use in structural engineering applications. The technology's maturity is evident in its widespread adoption across industries, but ongoing innovations continue to enhance its properties and broaden its applicability.

Celanese International Corp.

Technical Solution: Celanese has developed a range of EVA copolymers for structural applications in engineering. Their VitalDose® EVA technology is used in drug delivery systems and medical devices, offering controlled release properties[1]. For engineering applications, Celanese's EVA grades provide excellent flexibility, impact resistance, and weatherability. They have implemented a crosslinking process that enhances the material's mechanical properties and thermal stability, making it suitable for demanding structural applications[2]. Celanese's EVA compounds are also used in solar panel encapsulation, where they provide long-term durability and weather resistance[3].

Strengths: Wide range of EVA grades for various applications, advanced crosslinking technology, expertise in medical and solar applications. Weaknesses: May face competition in commodity EVA markets, potential sensitivity to raw material price fluctuations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed EVA copolymers with enhanced structural properties for engineering applications. Their Elvax® resin technology offers a balance of flexibility, toughness, and adhesion strength[4]. DuPont has focused on improving the thermal stability of EVA through advanced stabilization packages, allowing for higher processing temperatures and expanded use in automotive and industrial applications[5]. They have also developed EVA-based nanocomposites, incorporating nanoclays or carbon nanotubes to enhance mechanical properties and barrier performance[6]. DuPont's EVA innovations extend to foam applications, where they have engineered EVA formulations with controlled cell structures for improved cushioning and energy absorption in sports equipment and protective gear[7].

Strengths: Strong R&D capabilities, diverse product portfolio, expertise in nanocomposite technology. Weaknesses: Higher cost compared to commodity EVA producers, potential environmental concerns with nanoparticle use.

Key Innovations in EVA Structural Engineering

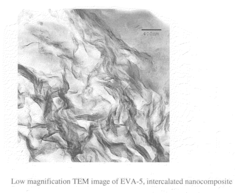

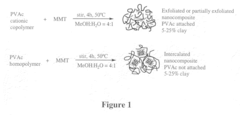

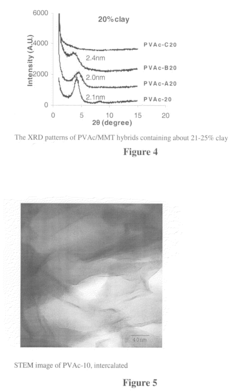

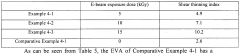

Ethylene-vinyl acetate copolymer of increased mechanical properties

PatentInactiveUS20080211139A1

Innovation

- Solution blending of EVA with a masterbatch of cationic poly(vinyl acetate)/silicate nanocomposite, where the silicate is substantially exfoliated, maintains mechanical properties and prevents loss of exfoliation during heat processing.

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Environmental Impact of EVA in Structures

The environmental impact of Ethylene Vinyl Acetate (EVA) in structural applications is a complex issue that requires careful consideration. EVA, as a versatile copolymer, has found widespread use in various engineering structures due to its favorable properties. However, its environmental footprint throughout its lifecycle must be thoroughly examined.

During the production phase of EVA, the primary environmental concerns stem from the energy-intensive processes and the potential release of volatile organic compounds (VOCs). The polymerization of ethylene and vinyl acetate monomers requires significant energy inputs, contributing to greenhouse gas emissions. Additionally, the use of solvents and other chemicals in the manufacturing process may lead to air and water pollution if not properly managed.

In its application within structures, EVA generally exhibits good environmental performance. Its durability and resistance to weathering contribute to extended service life, reducing the need for frequent replacements and thereby minimizing waste generation. The material's low thermal conductivity also enhances energy efficiency in buildings, potentially lowering overall energy consumption and associated environmental impacts.

However, the end-of-life phase presents significant challenges. EVA is not biodegradable, and its disposal in landfills can lead to long-term environmental persistence. Incineration of EVA-containing materials may release harmful emissions if not conducted under controlled conditions. Recycling options for EVA are limited, particularly when it is used in composite structures or bonded with other materials, making material recovery and circular economy principles difficult to implement.

The use of EVA in structural applications also raises concerns about potential leaching of additives and degradation products into the environment. While EVA itself is generally considered inert, various additives used to enhance its properties may pose risks to ecosystems if they migrate from the material over time.

On a positive note, ongoing research is focused on developing more environmentally friendly EVA formulations and improving end-of-life management strategies. Efforts to incorporate bio-based components into EVA production and enhance its recyclability are promising avenues for reducing its environmental impact. Additionally, life cycle assessment (LCA) studies are being conducted to provide a more comprehensive understanding of EVA's environmental performance across different applications and scenarios.

In conclusion, while EVA offers valuable properties for structural applications in engineering, its environmental impact remains a concern that requires ongoing attention and improvement efforts from industry stakeholders and researchers alike.

During the production phase of EVA, the primary environmental concerns stem from the energy-intensive processes and the potential release of volatile organic compounds (VOCs). The polymerization of ethylene and vinyl acetate monomers requires significant energy inputs, contributing to greenhouse gas emissions. Additionally, the use of solvents and other chemicals in the manufacturing process may lead to air and water pollution if not properly managed.

In its application within structures, EVA generally exhibits good environmental performance. Its durability and resistance to weathering contribute to extended service life, reducing the need for frequent replacements and thereby minimizing waste generation. The material's low thermal conductivity also enhances energy efficiency in buildings, potentially lowering overall energy consumption and associated environmental impacts.

However, the end-of-life phase presents significant challenges. EVA is not biodegradable, and its disposal in landfills can lead to long-term environmental persistence. Incineration of EVA-containing materials may release harmful emissions if not conducted under controlled conditions. Recycling options for EVA are limited, particularly when it is used in composite structures or bonded with other materials, making material recovery and circular economy principles difficult to implement.

The use of EVA in structural applications also raises concerns about potential leaching of additives and degradation products into the environment. While EVA itself is generally considered inert, various additives used to enhance its properties may pose risks to ecosystems if they migrate from the material over time.

On a positive note, ongoing research is focused on developing more environmentally friendly EVA formulations and improving end-of-life management strategies. Efforts to incorporate bio-based components into EVA production and enhance its recyclability are promising avenues for reducing its environmental impact. Additionally, life cycle assessment (LCA) studies are being conducted to provide a more comprehensive understanding of EVA's environmental performance across different applications and scenarios.

In conclusion, while EVA offers valuable properties for structural applications in engineering, its environmental impact remains a concern that requires ongoing attention and improvement efforts from industry stakeholders and researchers alike.

Cost-Benefit Analysis of EVA Structural Applications

The cost-benefit analysis of Ethylene Vinyl Acetate (EVA) structural applications reveals a complex interplay of economic factors that influence its adoption in engineering projects. Initial investment costs for EVA-based structures are generally higher compared to traditional materials like concrete or steel. This is primarily due to the specialized manufacturing processes and the relatively lower production volumes of EVA components.

However, the long-term benefits of EVA structural applications often outweigh these upfront costs. EVA's lightweight nature significantly reduces transportation and installation expenses, leading to lower overall project costs. The material's durability and resistance to environmental factors contribute to extended service life and reduced maintenance requirements, resulting in substantial savings over time.

Energy efficiency is another crucial factor in the cost-benefit equation. EVA's excellent insulation properties can lead to significant reductions in heating and cooling costs for buildings, potentially offsetting the initial investment within a few years of operation. This aspect is particularly valuable in regions with extreme climates or high energy prices.

The versatility of EVA allows for innovative design solutions that may not be possible with traditional materials. This can lead to improved space utilization and enhanced functionality, potentially increasing the value of the structure or enabling new revenue streams. Additionally, the ability to incorporate EVA into modular construction techniques can result in faster project completion times, reducing labor costs and allowing for earlier occupancy or use of the structure.

From an environmental perspective, EVA's recyclability and potential for reuse in other applications contribute to its sustainability profile. This can lead to cost savings in waste management and aligns with increasingly stringent environmental regulations, potentially avoiding future compliance-related expenses.

However, it's important to note that the cost-benefit ratio can vary significantly depending on the specific application and local conditions. Factors such as raw material prices, energy costs, labor rates, and regulatory environment all play a role in determining the economic viability of EVA structural applications. As such, a detailed analysis considering these variables is essential for each project to accurately assess the financial implications of choosing EVA over alternative materials.

In conclusion, while the initial costs of EVA structural applications may be higher, the long-term economic benefits, including reduced maintenance, improved energy efficiency, and enhanced design flexibility, often present a compelling case for its use in engineering projects. As production scales up and technology advances, it is likely that the cost-benefit ratio will continue to improve, further solidifying EVA's position as a valuable material in structural engineering.

However, the long-term benefits of EVA structural applications often outweigh these upfront costs. EVA's lightweight nature significantly reduces transportation and installation expenses, leading to lower overall project costs. The material's durability and resistance to environmental factors contribute to extended service life and reduced maintenance requirements, resulting in substantial savings over time.

Energy efficiency is another crucial factor in the cost-benefit equation. EVA's excellent insulation properties can lead to significant reductions in heating and cooling costs for buildings, potentially offsetting the initial investment within a few years of operation. This aspect is particularly valuable in regions with extreme climates or high energy prices.

The versatility of EVA allows for innovative design solutions that may not be possible with traditional materials. This can lead to improved space utilization and enhanced functionality, potentially increasing the value of the structure or enabling new revenue streams. Additionally, the ability to incorporate EVA into modular construction techniques can result in faster project completion times, reducing labor costs and allowing for earlier occupancy or use of the structure.

From an environmental perspective, EVA's recyclability and potential for reuse in other applications contribute to its sustainability profile. This can lead to cost savings in waste management and aligns with increasingly stringent environmental regulations, potentially avoiding future compliance-related expenses.

However, it's important to note that the cost-benefit ratio can vary significantly depending on the specific application and local conditions. Factors such as raw material prices, energy costs, labor rates, and regulatory environment all play a role in determining the economic viability of EVA structural applications. As such, a detailed analysis considering these variables is essential for each project to accurately assess the financial implications of choosing EVA over alternative materials.

In conclusion, while the initial costs of EVA structural applications may be higher, the long-term economic benefits, including reduced maintenance, improved energy efficiency, and enhanced design flexibility, often present a compelling case for its use in engineering projects. As production scales up and technology advances, it is likely that the cost-benefit ratio will continue to improve, further solidifying EVA's position as a valuable material in structural engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!