Ethylene Vinyl Acetate: Exploring Industrial Synergies

JUL 9, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile polymer with a rich history of technological evolution. Initially developed in the 1950s, EVA has undergone significant advancements in its production processes and applications over the past seven decades. The technology behind EVA has continuously evolved to meet the changing demands of various industries, from packaging to renewable energy.

The early stages of EVA development focused primarily on improving its basic properties, such as flexibility and impact resistance. As research progressed, scientists and engineers discovered ways to enhance EVA's thermal properties, adhesion characteristics, and chemical resistance. This led to a broadening of its application spectrum, particularly in the fields of footwear, automotive components, and wire insulation.

A significant milestone in EVA technology came with the advent of crosslinking techniques in the 1970s and 1980s. This innovation allowed for the production of EVA with improved heat resistance and mechanical properties, opening up new possibilities in industries such as solar panel encapsulation and high-performance packaging.

The 1990s and early 2000s saw a shift towards more environmentally friendly EVA production methods. Researchers began exploring ways to reduce the use of harmful chemicals and improve energy efficiency in the manufacturing process. This trend has continued into the present day, with a growing emphasis on sustainable production and recyclability.

Recent technological objectives in EVA development have centered around enhancing its performance in specific applications. For instance, in the solar industry, there is a push to develop EVA formulations that offer better UV resistance and longer service life for photovoltaic modules. In the footwear sector, efforts are being made to create EVA compounds with improved cushioning and durability.

Another key objective in EVA technology is the development of bio-based alternatives. Researchers are exploring ways to incorporate renewable resources into EVA production, aiming to reduce reliance on petroleum-based feedstocks. This aligns with the broader industry trend towards sustainability and circular economy principles.

Looking ahead, the technological evolution of EVA is expected to focus on several key areas. These include the development of EVA grades with enhanced barrier properties for packaging applications, the creation of EVA-based materials with self-healing capabilities, and the integration of EVA into advanced composite materials for aerospace and automotive industries.

The early stages of EVA development focused primarily on improving its basic properties, such as flexibility and impact resistance. As research progressed, scientists and engineers discovered ways to enhance EVA's thermal properties, adhesion characteristics, and chemical resistance. This led to a broadening of its application spectrum, particularly in the fields of footwear, automotive components, and wire insulation.

A significant milestone in EVA technology came with the advent of crosslinking techniques in the 1970s and 1980s. This innovation allowed for the production of EVA with improved heat resistance and mechanical properties, opening up new possibilities in industries such as solar panel encapsulation and high-performance packaging.

The 1990s and early 2000s saw a shift towards more environmentally friendly EVA production methods. Researchers began exploring ways to reduce the use of harmful chemicals and improve energy efficiency in the manufacturing process. This trend has continued into the present day, with a growing emphasis on sustainable production and recyclability.

Recent technological objectives in EVA development have centered around enhancing its performance in specific applications. For instance, in the solar industry, there is a push to develop EVA formulations that offer better UV resistance and longer service life for photovoltaic modules. In the footwear sector, efforts are being made to create EVA compounds with improved cushioning and durability.

Another key objective in EVA technology is the development of bio-based alternatives. Researchers are exploring ways to incorporate renewable resources into EVA production, aiming to reduce reliance on petroleum-based feedstocks. This aligns with the broader industry trend towards sustainability and circular economy principles.

Looking ahead, the technological evolution of EVA is expected to focus on several key areas. These include the development of EVA grades with enhanced barrier properties for packaging applications, the creation of EVA-based materials with self-healing capabilities, and the integration of EVA into advanced composite materials for aerospace and automotive industries.

Market Demand Analysis for EVA Applications

The market demand for Ethylene Vinyl Acetate (EVA) applications has been steadily growing across various industries due to its versatile properties and cost-effectiveness. The global EVA market size was valued at USD 7.9 billion in 2020 and is projected to reach USD 11.2 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 6.1% during the forecast period.

The automotive sector represents a significant driver for EVA demand, particularly in the production of automotive parts, interior components, and wire and cable insulation. The increasing focus on lightweight materials and fuel efficiency in vehicles has led to a surge in EVA usage. Additionally, the growing electric vehicle market has further boosted the demand for EVA in battery components and thermal management systems.

In the footwear industry, EVA has gained substantial traction due to its excellent cushioning properties and durability. The material is widely used in the production of midsoles, outsoles, and insoles for athletic and casual footwear. The rising health consciousness and increasing participation in sports activities have contributed to the growth of the athletic footwear market, consequently driving the demand for EVA.

The packaging industry has also witnessed a significant uptake of EVA, especially in flexible packaging applications. EVA's superior sealing properties, transparency, and resistance to puncture and tear make it an ideal choice for food packaging, pharmaceutical packaging, and industrial packaging solutions. The e-commerce boom and changing consumer preferences towards convenient packaging have further accelerated the demand for EVA in this sector.

In the renewable energy sector, EVA has found extensive applications in the production of solar panels. The material is used as an encapsulant in photovoltaic modules, providing excellent adhesion, weatherability, and UV resistance. With the global push towards clean energy and the increasing adoption of solar power, the demand for EVA in this sector is expected to witness substantial growth in the coming years.

The construction industry has emerged as another key market for EVA applications. The material is widely used in the production of adhesives, sealants, and waterproofing membranes. The growing construction activities in emerging economies, coupled with the increasing focus on energy-efficient buildings, have contributed to the rising demand for EVA-based products in this sector.

The automotive sector represents a significant driver for EVA demand, particularly in the production of automotive parts, interior components, and wire and cable insulation. The increasing focus on lightweight materials and fuel efficiency in vehicles has led to a surge in EVA usage. Additionally, the growing electric vehicle market has further boosted the demand for EVA in battery components and thermal management systems.

In the footwear industry, EVA has gained substantial traction due to its excellent cushioning properties and durability. The material is widely used in the production of midsoles, outsoles, and insoles for athletic and casual footwear. The rising health consciousness and increasing participation in sports activities have contributed to the growth of the athletic footwear market, consequently driving the demand for EVA.

The packaging industry has also witnessed a significant uptake of EVA, especially in flexible packaging applications. EVA's superior sealing properties, transparency, and resistance to puncture and tear make it an ideal choice for food packaging, pharmaceutical packaging, and industrial packaging solutions. The e-commerce boom and changing consumer preferences towards convenient packaging have further accelerated the demand for EVA in this sector.

In the renewable energy sector, EVA has found extensive applications in the production of solar panels. The material is used as an encapsulant in photovoltaic modules, providing excellent adhesion, weatherability, and UV resistance. With the global push towards clean energy and the increasing adoption of solar power, the demand for EVA in this sector is expected to witness substantial growth in the coming years.

The construction industry has emerged as another key market for EVA applications. The material is widely used in the production of adhesives, sealants, and waterproofing membranes. The growing construction activities in emerging economies, coupled with the increasing focus on energy-efficient buildings, have contributed to the rising demand for EVA-based products in this sector.

EVA Production Challenges and Limitations

The production of Ethylene Vinyl Acetate (EVA) faces several significant challenges and limitations that impact its industrial synergies. One of the primary issues is the high energy consumption required for the polymerization process. The reaction between ethylene and vinyl acetate monomers demands substantial heat and pressure, leading to increased production costs and environmental concerns.

Raw material availability and price volatility pose another major challenge. Ethylene, a key component in EVA production, is derived from petroleum or natural gas. Fluctuations in oil and gas prices directly affect the cost of EVA production, making it difficult for manufacturers to maintain consistent pricing and profit margins. Additionally, the supply chain for vinyl acetate monomer can be subject to disruptions, further complicating production planning.

Quality control presents a significant hurdle in EVA production. Achieving consistent product properties, such as melt flow index and vinyl acetate content, requires precise control over reaction conditions. Variations in these properties can lead to product inconsistencies, affecting downstream applications and potentially resulting in customer dissatisfaction or product recalls.

The production process also faces limitations in terms of scalability. While large-scale production is possible, increasing capacity often requires substantial capital investment in new equipment and facilities. This can be a barrier for smaller manufacturers looking to expand their production capabilities or enter the market.

Environmental and safety concerns add another layer of complexity to EVA production. The use of volatile organic compounds (VOCs) and potential emissions during the manufacturing process necessitate stringent control measures and compliance with increasingly strict environmental regulations. This often requires additional investment in pollution control technologies and safety systems.

Recycling and end-of-life management of EVA products present ongoing challenges. The cross-linked structure of many EVA applications makes recycling difficult, contributing to environmental waste. Developing effective recycling methods or biodegradable alternatives remains an area of active research and development in the industry.

Lastly, the production of specialized EVA grades for high-performance applications faces limitations in terms of process flexibility. Adapting production lines to manufacture different EVA grades with varying vinyl acetate content and other properties can be time-consuming and costly, potentially limiting a manufacturer's ability to respond quickly to changing market demands.

Raw material availability and price volatility pose another major challenge. Ethylene, a key component in EVA production, is derived from petroleum or natural gas. Fluctuations in oil and gas prices directly affect the cost of EVA production, making it difficult for manufacturers to maintain consistent pricing and profit margins. Additionally, the supply chain for vinyl acetate monomer can be subject to disruptions, further complicating production planning.

Quality control presents a significant hurdle in EVA production. Achieving consistent product properties, such as melt flow index and vinyl acetate content, requires precise control over reaction conditions. Variations in these properties can lead to product inconsistencies, affecting downstream applications and potentially resulting in customer dissatisfaction or product recalls.

The production process also faces limitations in terms of scalability. While large-scale production is possible, increasing capacity often requires substantial capital investment in new equipment and facilities. This can be a barrier for smaller manufacturers looking to expand their production capabilities or enter the market.

Environmental and safety concerns add another layer of complexity to EVA production. The use of volatile organic compounds (VOCs) and potential emissions during the manufacturing process necessitate stringent control measures and compliance with increasingly strict environmental regulations. This often requires additional investment in pollution control technologies and safety systems.

Recycling and end-of-life management of EVA products present ongoing challenges. The cross-linked structure of many EVA applications makes recycling difficult, contributing to environmental waste. Developing effective recycling methods or biodegradable alternatives remains an area of active research and development in the industry.

Lastly, the production of specialized EVA grades for high-performance applications faces limitations in terms of process flexibility. Adapting production lines to manufacture different EVA grades with varying vinyl acetate content and other properties can be time-consuming and costly, potentially limiting a manufacturer's ability to respond quickly to changing market demands.

Current EVA Formulation Techniques

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for a wide range of applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It is commonly used in footwear, sports equipment, and building insulation. The foam structure and properties can be controlled through the manufacturing process and additives.

- EVA in solar panel encapsulation: EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells. It helps to enhance the durability and efficiency of photovoltaic modules by providing a protective barrier against environmental factors.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with specific characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers to improve mechanical properties, flame retardancy, or other desired attributes.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The material's low melting point and good flow characteristics make it ideal for these applications.Expand Specific Solutions03 EVA in foam and insulation products

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure provides excellent thermal insulation properties, making it suitable for applications in construction, packaging, and footwear industries. EVA foams offer good shock absorption and cushioning properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect solar cells from environmental factors and ensures long-term performance of the solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties for specific applications. This includes crosslinking, grafting, and the addition of fillers or compatibilizers. These modifications can improve the material's mechanical properties, thermal stability, and chemical resistance.Expand Specific Solutions

Key Players in EVA Industry

The industrial synergies of Ethylene Vinyl Acetate (EVA) market is in a mature growth stage, with a significant global market size. Major players like China Petroleum & Chemical Corp., DuPont, and Braskem dominate the industry, leveraging their extensive R&D capabilities and production capacities. The technology is well-established, with companies like Kuraray and LG Chem focusing on product innovations and applications in diverse sectors. Emerging players such as Wuhan Hengde Science & Technology are also contributing to market competitiveness. The industry sees ongoing research collaborations between corporations and academic institutions like Sichuan University and Beijing University of Chemical Technology, driving technological advancements and new applications for EVA.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, focusing on improving product quality and process efficiency. Their approach involves a high-pressure tubular reactor system with optimized catalyst formulations, enabling the production of EVA with varying vinyl acetate (VA) content (3-40%) [1]. Sinopec has also implemented a proprietary separation and purification process that enhances product consistency and reduces impurities. Additionally, they have explored the use of metallocene catalysts to produce EVA with improved optical and mechanical properties, suitable for high-performance applications in solar panel encapsulation and advanced packaging [2][3].

Strengths: Large-scale production capabilities, diverse product range, and strong R&D infrastructure. Weaknesses: Potential environmental concerns associated with petrochemical processes and dependence on fossil fuel feedstocks.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of EVA technologies, focusing on specialty grades for high-value applications. Their approach includes the use of advanced catalysts and controlled polymerization techniques to produce EVA with precise molecular weight distribution and VA content. DuPont's EVA innovations include the development of crosslinkable EVA grades for photovoltaic encapsulants, which offer improved durability and weather resistance [4]. They have also pioneered EVA foam technologies, utilizing chemical foaming agents and controlled expansion processes to create lightweight, cushioning materials for footwear and automotive applications [5]. Furthermore, DuPont has explored the incorporation of nanofillers into EVA matrices to enhance mechanical and barrier properties for packaging applications [6].

Strengths: Strong focus on specialty grades, extensive intellectual property portfolio, and global market presence. Weaknesses: Higher production costs for specialty grades and potential challenges in scaling up niche technologies.

Innovative EVA Copolymer Developments

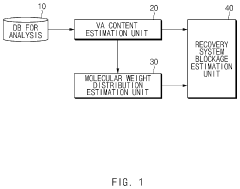

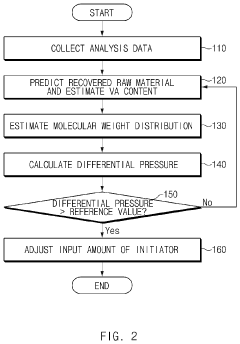

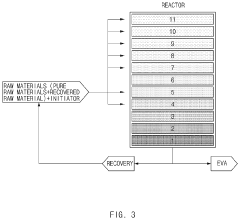

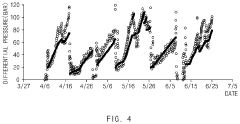

System for controlling ethylene vinyl acetate copolymerization process and method of controlling the same

PatentActiveUS20200010592A1

Innovation

- A system and method that includes a database for analysis, a VA content estimation unit, a molecular weight distribution estimation unit, and a recovery system blockage estimation unit to predict and control the blockage by estimating VA content and molecular weight distribution, adjusting processing conditions to prevent blockage in the recovery process.

Process for producing ethylene vinyl acetate film

PatentInactiveEP1705219A1

Innovation

- Incorporating olefinic bisoleamides, such as N,N'-ethylenebisoleamide, into ethylene copolymers with high vinyl acetate content to improve film forming properties without negatively impacting clarity, allowing for enhanced slip characteristics and easier film separation and cutting.

Environmental Impact of EVA Production

The production of Ethylene Vinyl Acetate (EVA) has significant environmental implications that warrant careful consideration. The manufacturing process involves the copolymerization of ethylene and vinyl acetate, which requires substantial energy inputs and generates various emissions and waste streams. One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during production, which can contribute to air pollution and smog formation if not properly controlled.

Energy consumption in EVA production is another critical environmental factor. The polymerization process typically requires high temperatures and pressures, leading to substantial energy use and associated greenhouse gas emissions. However, advancements in process efficiency and the adoption of cleaner energy sources have the potential to mitigate these impacts.

Water usage and wastewater generation are also important aspects of EVA's environmental footprint. The production process often involves water-based cooling systems and cleaning operations, which can result in the discharge of contaminated water if not properly treated. Implementing closed-loop water systems and advanced wastewater treatment technologies can help reduce water consumption and minimize the release of pollutants into aquatic ecosystems.

Solid waste management is another environmental challenge in EVA production. The process generates various by-products and off-spec materials that require proper disposal or recycling. Developing effective waste reduction strategies and exploring opportunities for material recovery can help minimize the environmental impact of solid waste generation.

The raw materials used in EVA production, particularly ethylene and vinyl acetate, are derived from fossil fuel sources, which raises concerns about resource depletion and carbon footprint. Exploring alternative feedstocks, such as bio-based materials, could potentially reduce the reliance on non-renewable resources and lower the overall environmental impact of EVA production.

End-of-life considerations for EVA products also play a role in their environmental impact. While EVA is recyclable, the mixed polymer nature of the material can present challenges in recycling processes. Developing more efficient recycling technologies and promoting circular economy principles in EVA product design and disposal can help address these issues.

As industries increasingly focus on sustainability, there is growing pressure to improve the environmental performance of EVA production. This has led to research and development efforts aimed at enhancing process efficiency, reducing emissions, and exploring more sustainable production methods. Innovations in catalysis, process intensification, and green chemistry offer promising avenues for minimizing the environmental footprint of EVA manufacturing.

Energy consumption in EVA production is another critical environmental factor. The polymerization process typically requires high temperatures and pressures, leading to substantial energy use and associated greenhouse gas emissions. However, advancements in process efficiency and the adoption of cleaner energy sources have the potential to mitigate these impacts.

Water usage and wastewater generation are also important aspects of EVA's environmental footprint. The production process often involves water-based cooling systems and cleaning operations, which can result in the discharge of contaminated water if not properly treated. Implementing closed-loop water systems and advanced wastewater treatment technologies can help reduce water consumption and minimize the release of pollutants into aquatic ecosystems.

Solid waste management is another environmental challenge in EVA production. The process generates various by-products and off-spec materials that require proper disposal or recycling. Developing effective waste reduction strategies and exploring opportunities for material recovery can help minimize the environmental impact of solid waste generation.

The raw materials used in EVA production, particularly ethylene and vinyl acetate, are derived from fossil fuel sources, which raises concerns about resource depletion and carbon footprint. Exploring alternative feedstocks, such as bio-based materials, could potentially reduce the reliance on non-renewable resources and lower the overall environmental impact of EVA production.

End-of-life considerations for EVA products also play a role in their environmental impact. While EVA is recyclable, the mixed polymer nature of the material can present challenges in recycling processes. Developing more efficient recycling technologies and promoting circular economy principles in EVA product design and disposal can help address these issues.

As industries increasingly focus on sustainability, there is growing pressure to improve the environmental performance of EVA production. This has led to research and development efforts aimed at enhancing process efficiency, reducing emissions, and exploring more sustainable production methods. Innovations in catalysis, process intensification, and green chemistry offer promising avenues for minimizing the environmental footprint of EVA manufacturing.

Cross-industry EVA Application Potential

Ethylene Vinyl Acetate (EVA) exhibits remarkable versatility across various industries, showcasing its potential for cross-industry synergies. In the automotive sector, EVA's excellent shock absorption properties make it ideal for manufacturing car bumpers, dashboards, and interior components. Its ability to withstand extreme temperatures and resist UV radiation also makes it suitable for exterior automotive applications.

The construction industry benefits from EVA's waterproofing and adhesive properties. It is widely used in roofing membranes, sealants, and insulation materials, contributing to energy-efficient building solutions. EVA's flexibility and durability make it an excellent choice for flooring applications, including sports surfaces and playground safety mats.

In the renewable energy sector, EVA plays a crucial role in solar panel encapsulation. Its transparency, weather resistance, and electrical insulation properties protect photovoltaic cells, extending the lifespan of solar panels. This application demonstrates EVA's potential to bridge traditional industries with emerging green technologies.

The footwear industry extensively utilizes EVA in the production of shoe soles and midsoles. Its lightweight nature, cushioning properties, and resistance to wear and tear make it an ideal material for both athletic and casual footwear. This application showcases EVA's ability to enhance product performance across different market segments.

In the packaging industry, EVA copolymers are used to produce flexible films and heat-sealable layers. These materials find applications in food packaging, pharmaceutical blister packs, and protective packaging for electronics. EVA's barrier properties and compatibility with various additives make it adaptable to diverse packaging requirements.

The medical industry benefits from EVA's biocompatibility and flexibility. It is used in the production of medical tubing, drug delivery systems, and prosthetic components. EVA's ability to be sterilized without degradation further enhances its suitability for medical applications.

These cross-industry applications highlight EVA's potential to create synergies between seemingly unrelated sectors. By leveraging its unique properties, EVA can foster innovation and collaboration across industries, leading to the development of novel products and solutions that address multiple market needs simultaneously.

The construction industry benefits from EVA's waterproofing and adhesive properties. It is widely used in roofing membranes, sealants, and insulation materials, contributing to energy-efficient building solutions. EVA's flexibility and durability make it an excellent choice for flooring applications, including sports surfaces and playground safety mats.

In the renewable energy sector, EVA plays a crucial role in solar panel encapsulation. Its transparency, weather resistance, and electrical insulation properties protect photovoltaic cells, extending the lifespan of solar panels. This application demonstrates EVA's potential to bridge traditional industries with emerging green technologies.

The footwear industry extensively utilizes EVA in the production of shoe soles and midsoles. Its lightweight nature, cushioning properties, and resistance to wear and tear make it an ideal material for both athletic and casual footwear. This application showcases EVA's ability to enhance product performance across different market segments.

In the packaging industry, EVA copolymers are used to produce flexible films and heat-sealable layers. These materials find applications in food packaging, pharmaceutical blister packs, and protective packaging for electronics. EVA's barrier properties and compatibility with various additives make it adaptable to diverse packaging requirements.

The medical industry benefits from EVA's biocompatibility and flexibility. It is used in the production of medical tubing, drug delivery systems, and prosthetic components. EVA's ability to be sterilized without degradation further enhances its suitability for medical applications.

These cross-industry applications highlight EVA's potential to create synergies between seemingly unrelated sectors. By leveraging its unique properties, EVA can foster innovation and collaboration across industries, leading to the development of novel products and solutions that address multiple market needs simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!