How to Drive Sustainable Practices in Industry with Ethylene Vinyl Acetate?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Sustainability Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material with significant potential for driving sustainable practices in various industries. The evolution of EVA technology has been marked by continuous improvements in its properties and applications, leading to its widespread adoption in sectors such as packaging, agriculture, and renewable energy. As global concerns about environmental sustainability grow, the focus on EVA's role in promoting eco-friendly solutions has intensified.

The primary objective of this technical research is to explore and evaluate the ways in which EVA can contribute to sustainable industrial practices. This involves examining its current applications, identifying areas for improvement, and projecting future developments that could enhance its environmental performance. The goal is to provide a comprehensive understanding of EVA's sustainability profile and its potential to address pressing environmental challenges.

One of the key trends in EVA technology is the development of bio-based and biodegradable variants. These innovations aim to reduce the material's carbon footprint and address end-of-life concerns. Additionally, there is a growing emphasis on improving EVA's recyclability and incorporating recycled content into new products, aligning with circular economy principles.

The application of EVA in solar panel encapsulation represents a significant milestone in its contribution to sustainable energy production. As the solar industry continues to expand, the demand for high-performance, durable EVA films is expected to grow, driving further innovations in this area. Research is ongoing to enhance EVA's UV resistance and thermal stability, which could lead to more efficient and longer-lasting solar panels.

In the packaging industry, EVA is being explored as a potential alternative to less sustainable materials. Its barrier properties, flexibility, and potential for bio-based formulations make it an attractive option for developing eco-friendly packaging solutions. The challenge lies in balancing performance requirements with environmental considerations, a focus area for current and future research efforts.

The agricultural sector is another domain where EVA's sustainable potential is being realized. From greenhouse films to mulch films, EVA-based products are helping to optimize crop yields while minimizing environmental impact. Ongoing research aims to develop EVA formulations that biodegrade more readily in soil, addressing concerns about plastic accumulation in agricultural environments.

As we look to the future, the technical objectives for EVA in sustainability include developing fully recyclable or biodegradable formulations, increasing the use of renewable feedstocks in its production, and improving its overall life cycle assessment. Achieving these goals will require collaborative efforts across the value chain, from raw material suppliers to end-users, as well as continued investment in research and development.

The primary objective of this technical research is to explore and evaluate the ways in which EVA can contribute to sustainable industrial practices. This involves examining its current applications, identifying areas for improvement, and projecting future developments that could enhance its environmental performance. The goal is to provide a comprehensive understanding of EVA's sustainability profile and its potential to address pressing environmental challenges.

One of the key trends in EVA technology is the development of bio-based and biodegradable variants. These innovations aim to reduce the material's carbon footprint and address end-of-life concerns. Additionally, there is a growing emphasis on improving EVA's recyclability and incorporating recycled content into new products, aligning with circular economy principles.

The application of EVA in solar panel encapsulation represents a significant milestone in its contribution to sustainable energy production. As the solar industry continues to expand, the demand for high-performance, durable EVA films is expected to grow, driving further innovations in this area. Research is ongoing to enhance EVA's UV resistance and thermal stability, which could lead to more efficient and longer-lasting solar panels.

In the packaging industry, EVA is being explored as a potential alternative to less sustainable materials. Its barrier properties, flexibility, and potential for bio-based formulations make it an attractive option for developing eco-friendly packaging solutions. The challenge lies in balancing performance requirements with environmental considerations, a focus area for current and future research efforts.

The agricultural sector is another domain where EVA's sustainable potential is being realized. From greenhouse films to mulch films, EVA-based products are helping to optimize crop yields while minimizing environmental impact. Ongoing research aims to develop EVA formulations that biodegrade more readily in soil, addressing concerns about plastic accumulation in agricultural environments.

As we look to the future, the technical objectives for EVA in sustainability include developing fully recyclable or biodegradable formulations, increasing the use of renewable feedstocks in its production, and improving its overall life cycle assessment. Achieving these goals will require collaborative efforts across the value chain, from raw material suppliers to end-users, as well as continued investment in research and development.

Market Demand for Sustainable EVA Products

The market demand for sustainable Ethylene Vinyl Acetate (EVA) products has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations across various industries. This trend is particularly evident in sectors such as packaging, footwear, solar panels, and automotive, where EVA is widely used.

In the packaging industry, there is a significant shift towards eco-friendly materials. Sustainable EVA products are gaining traction as alternatives to traditional plastics, offering similar performance characteristics while reducing environmental impact. Companies are actively seeking EVA-based solutions that are biodegradable or recyclable, responding to consumer demands for more sustainable packaging options.

The footwear industry has also shown a strong interest in sustainable EVA products. Major brands are incorporating recycled EVA into their shoe designs, particularly in the midsoles and outsoles. This move not only appeals to environmentally conscious consumers but also helps companies meet their sustainability targets and improve their brand image.

In the solar energy sector, the demand for sustainable EVA encapsulants is rising. As the solar industry expands, there is an increasing focus on the lifecycle impact of solar panels. Sustainable EVA products that offer improved durability, recyclability, and reduced carbon footprint are highly sought after by solar panel manufacturers looking to enhance the overall sustainability of their products.

The automotive industry is another key driver of demand for sustainable EVA products. With the push towards electric vehicles and lighter, more fuel-efficient cars, manufacturers are exploring sustainable materials for various components. EVA's versatility makes it an attractive option for applications ranging from interior parts to noise reduction and vibration dampening solutions.

Market research indicates that the global sustainable EVA market is expected to grow significantly over the next decade. This growth is fueled by increasing awareness of environmental issues, government regulations promoting sustainable practices, and corporate commitments to reduce carbon footprints. Companies across industries are setting ambitious sustainability goals, which in turn drives the demand for eco-friendly materials like sustainable EVA.

However, challenges remain in meeting this growing demand. The production of sustainable EVA often involves higher costs compared to conventional EVA, which can be a barrier for some industries. Additionally, there is a need for further research and development to improve the performance and scalability of sustainable EVA products to match or exceed the properties of traditional EVA across all applications.

Despite these challenges, the market trajectory for sustainable EVA products remains positive. Innovations in production processes, such as the development of bio-based EVA and improved recycling technologies, are expected to further boost market growth and adoption across industries.

In the packaging industry, there is a significant shift towards eco-friendly materials. Sustainable EVA products are gaining traction as alternatives to traditional plastics, offering similar performance characteristics while reducing environmental impact. Companies are actively seeking EVA-based solutions that are biodegradable or recyclable, responding to consumer demands for more sustainable packaging options.

The footwear industry has also shown a strong interest in sustainable EVA products. Major brands are incorporating recycled EVA into their shoe designs, particularly in the midsoles and outsoles. This move not only appeals to environmentally conscious consumers but also helps companies meet their sustainability targets and improve their brand image.

In the solar energy sector, the demand for sustainable EVA encapsulants is rising. As the solar industry expands, there is an increasing focus on the lifecycle impact of solar panels. Sustainable EVA products that offer improved durability, recyclability, and reduced carbon footprint are highly sought after by solar panel manufacturers looking to enhance the overall sustainability of their products.

The automotive industry is another key driver of demand for sustainable EVA products. With the push towards electric vehicles and lighter, more fuel-efficient cars, manufacturers are exploring sustainable materials for various components. EVA's versatility makes it an attractive option for applications ranging from interior parts to noise reduction and vibration dampening solutions.

Market research indicates that the global sustainable EVA market is expected to grow significantly over the next decade. This growth is fueled by increasing awareness of environmental issues, government regulations promoting sustainable practices, and corporate commitments to reduce carbon footprints. Companies across industries are setting ambitious sustainability goals, which in turn drives the demand for eco-friendly materials like sustainable EVA.

However, challenges remain in meeting this growing demand. The production of sustainable EVA often involves higher costs compared to conventional EVA, which can be a barrier for some industries. Additionally, there is a need for further research and development to improve the performance and scalability of sustainable EVA products to match or exceed the properties of traditional EVA across all applications.

Despite these challenges, the market trajectory for sustainable EVA products remains positive. Innovations in production processes, such as the development of bio-based EVA and improved recycling technologies, are expected to further boost market growth and adoption across industries.

Current State and Challenges in EVA Sustainability

The current state of Ethylene Vinyl Acetate (EVA) sustainability in industry presents both promising advancements and significant challenges. EVA, a versatile copolymer, has found widespread use in various sectors, including packaging, solar panels, and footwear. However, its petroleum-based origin and limited recyclability pose substantial environmental concerns.

In recent years, there has been a growing focus on improving the sustainability of EVA production and usage. Some manufacturers have made strides in incorporating bio-based feedstocks, reducing the reliance on fossil fuels. Additionally, efforts to enhance the recyclability of EVA-containing products have shown progress, with some companies developing innovative recycling technologies specifically for EVA materials.

Despite these advancements, several challenges persist in achieving truly sustainable practices with EVA. One major hurdle is the energy-intensive production process, which contributes significantly to the material's carbon footprint. Reducing energy consumption and transitioning to renewable energy sources in EVA manufacturing remain critical challenges for the industry.

Another pressing issue is the end-of-life management of EVA products. While some recycling methods exist, they are often not economically viable or widely available. The cross-linked structure of EVA in certain applications, such as in solar panels, makes recycling particularly challenging. This leads to a substantial amount of EVA waste ending up in landfills or incineration facilities.

The variability in EVA formulations across different applications also complicates recycling efforts. Different grades and additives used in EVA products can make it difficult to establish standardized recycling processes. This heterogeneity in composition poses a significant obstacle to large-scale, efficient recycling initiatives.

Furthermore, the lack of comprehensive life cycle assessments for EVA products in various applications hinders the development of targeted sustainability strategies. Without a clear understanding of the environmental impacts across the entire life cycle, it becomes challenging to prioritize and implement the most effective sustainability measures.

The regulatory landscape surrounding EVA sustainability is also evolving, with increasing pressure on industries to adopt more environmentally friendly practices. However, the absence of uniform global standards for sustainable EVA production and recycling creates a fragmented approach to addressing these challenges.

In conclusion, while progress has been made in enhancing the sustainability of EVA, significant obstacles remain. Overcoming these challenges will require concerted efforts from manufacturers, researchers, and policymakers to develop innovative solutions for cleaner production, improved recyclability, and more effective waste management strategies.

In recent years, there has been a growing focus on improving the sustainability of EVA production and usage. Some manufacturers have made strides in incorporating bio-based feedstocks, reducing the reliance on fossil fuels. Additionally, efforts to enhance the recyclability of EVA-containing products have shown progress, with some companies developing innovative recycling technologies specifically for EVA materials.

Despite these advancements, several challenges persist in achieving truly sustainable practices with EVA. One major hurdle is the energy-intensive production process, which contributes significantly to the material's carbon footprint. Reducing energy consumption and transitioning to renewable energy sources in EVA manufacturing remain critical challenges for the industry.

Another pressing issue is the end-of-life management of EVA products. While some recycling methods exist, they are often not economically viable or widely available. The cross-linked structure of EVA in certain applications, such as in solar panels, makes recycling particularly challenging. This leads to a substantial amount of EVA waste ending up in landfills or incineration facilities.

The variability in EVA formulations across different applications also complicates recycling efforts. Different grades and additives used in EVA products can make it difficult to establish standardized recycling processes. This heterogeneity in composition poses a significant obstacle to large-scale, efficient recycling initiatives.

Furthermore, the lack of comprehensive life cycle assessments for EVA products in various applications hinders the development of targeted sustainability strategies. Without a clear understanding of the environmental impacts across the entire life cycle, it becomes challenging to prioritize and implement the most effective sustainability measures.

The regulatory landscape surrounding EVA sustainability is also evolving, with increasing pressure on industries to adopt more environmentally friendly practices. However, the absence of uniform global standards for sustainable EVA production and recycling creates a fragmented approach to addressing these challenges.

In conclusion, while progress has been made in enhancing the sustainability of EVA, significant obstacles remain. Overcoming these challenges will require concerted efforts from manufacturers, researchers, and policymakers to develop innovative solutions for cleaner production, improved recyclability, and more effective waste management strategies.

Existing Sustainable EVA Solutions

01 Composition and synthesis of EVA copolymers

Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and ratio of these monomers can be adjusted to achieve desired properties such as flexibility, toughness, and adhesion. Various polymerization methods and catalysts are employed to control the molecular weight and distribution of the copolymer.- Composition and synthesis of EVA copolymers: Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and ratio of these monomers can be adjusted to achieve desired properties. Various polymerization methods and catalysts are used to control the molecular structure and characteristics of the resulting EVA copolymer.

- Modification and blending of EVA: EVA copolymers can be modified or blended with other materials to enhance their properties. This includes crosslinking, grafting, or mixing with other polymers or additives. Such modifications can improve mechanical strength, thermal stability, or specific functional properties of the EVA-based materials.

- EVA in adhesive applications: EVA copolymers are widely used in adhesive formulations due to their excellent adhesion properties and flexibility. They can be used as base polymers in hot melt adhesives, pressure-sensitive adhesives, and other bonding applications. The adhesive properties can be tailored by adjusting the vinyl acetate content and molecular weight of the EVA copolymer.

- EVA in foam and encapsulation applications: EVA copolymers are utilized in the production of foams and encapsulation materials. They can be formulated to create closed-cell foams with excellent cushioning and insulation properties. In encapsulation applications, EVA is used to protect sensitive components from environmental factors and mechanical stress.

- EVA in film and packaging applications: EVA copolymers are extensively used in the production of flexible films and packaging materials. Their properties, such as clarity, flexibility, and heat-sealability, make them suitable for various packaging applications. EVA can be used alone or in combination with other polymers to create multi-layer films with enhanced barrier properties.

02 EVA blends and modifications

EVA copolymers can be blended with other polymers or modified with additives to enhance specific properties. These blends and modifications can improve characteristics such as impact resistance, thermal stability, and processability. Techniques like crosslinking, grafting, and the addition of fillers or compatibilizers are used to tailor the performance of EVA-based materials for various applications.Expand Specific Solutions03 EVA foam production and properties

EVA foams are produced by incorporating blowing agents into the polymer matrix and subjecting it to specific processing conditions. The resulting foam structure provides properties such as low density, excellent cushioning, and good thermal insulation. Various techniques are employed to control cell size, distribution, and overall foam morphology to suit different applications.Expand Specific Solutions04 EVA in adhesive and sealant applications

EVA copolymers are widely used in adhesive and sealant formulations due to their excellent adhesion properties, flexibility, and compatibility with various substrates. The vinyl acetate content and molecular weight of the EVA can be adjusted to optimize adhesion strength, cohesive properties, and processing characteristics for specific end-use requirements.Expand Specific Solutions05 EVA in packaging and film applications

EVA copolymers are extensively used in packaging and film applications due to their flexibility, clarity, and barrier properties. The copolymer can be processed into films with varying thicknesses and can be co-extruded with other materials to create multi-layer structures. EVA films find applications in food packaging, agricultural films, and shrink wrap, among others.Expand Specific Solutions

Key Players in Sustainable EVA Industry

The ethylene vinyl acetate (EVA) market is in a growth phase, driven by increasing demand in various industries such as solar panels, packaging, and footwear. The global market size is projected to expand significantly in the coming years, with a compound annual growth rate exceeding 5%. Technologically, EVA production is mature, but innovation continues in application development and sustainability. Key players like LyondellBasell, Celanese, and BASF are investing in research and development to improve EVA properties and production efficiency. Chinese companies, including Sinopec and Wanhua Chemical, are also making strides in EVA technology. The industry is focusing on developing bio-based and recyclable EVA to meet growing sustainability demands, with companies like Borealis and Resonac leading in this area.

Celanese International Corp.

Technical Solution: Celanese has developed a sustainable EVA production process that utilizes bio-based feedstocks and renewable energy sources. Their approach involves using ethanol derived from agricultural waste as a key raw material, reducing the carbon footprint of EVA production by up to 30% compared to traditional methods[1]. The company has also implemented a closed-loop recycling system for EVA waste, allowing for the recovery and reuse of up to 95% of production scrap[2]. Additionally, Celanese has invested in advanced catalysts that improve the efficiency of the polymerization process, resulting in lower energy consumption and reduced emissions[3].

Strengths: Significant reduction in carbon footprint, high recycling efficiency, and improved energy efficiency. Weaknesses: Potential higher production costs and reliance on agricultural waste availability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a green EVA production technology that incorporates CO2 utilization. Their innovative process captures CO2 emissions from other industrial processes and uses it as a feedstock for EVA production, effectively reducing greenhouse gas emissions[4]. The company has also implemented a heat integration system that recovers waste heat from the polymerization process, reducing overall energy consumption by up to 20%[5]. Sinopec's approach includes the use of bio-based acetic acid, derived from sustainable sources, as a key component in EVA production, further enhancing the sustainability of their process[6].

Strengths: CO2 utilization reduces greenhouse gas emissions, significant energy savings through heat integration, and use of bio-based raw materials. Weaknesses: Potential challenges in scaling up CO2 capture and utilization technology.

Core Innovations in EVA Sustainability

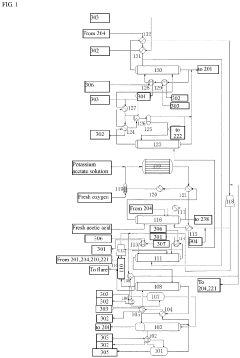

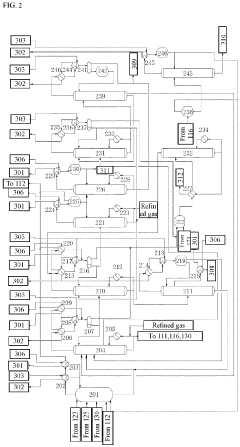

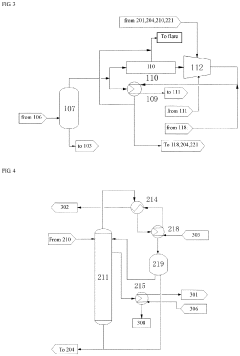

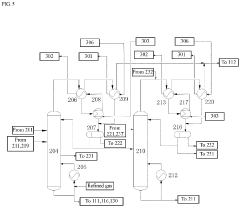

Preparation method of vinyl acetate by ethylene process and device thereof

PatentPendingEP4371972A1

Innovation

- A novel process incorporating an ethylene recovery membrane assembly, refined VAC tower side-draw stream additions, and improved cooling methods using circulating and chilled water for high-purity vinyl acetate production, reducing emissions and preventing material leakage by recovering ethylene and optimizing the distillation process.

Integrated process for the production of vinyl acetate from acetic acid via ethyl acetate

PatentInactiveEP2382179A1

Innovation

- An integrated process involving the hydrogenation of acetic acid to form ethyl acetate with high selectivity, followed by pyrolysis to produce ethylene, and subsequent reaction with molecular oxygen over a suitable catalyst to form vinyl acetate, using a bimetallic catalyst system such as platinum and copper or palladium and cobalt supported on a catalyst support.

Environmental Impact Assessment of EVA

The environmental impact assessment of Ethylene Vinyl Acetate (EVA) is crucial for driving sustainable practices in industry. EVA, a copolymer of ethylene and vinyl acetate, is widely used in various applications due to its versatility and desirable properties. However, its production and use have significant environmental implications that must be carefully evaluated.

The production of EVA involves the polymerization of ethylene and vinyl acetate monomers, which are derived from fossil fuels. This process contributes to greenhouse gas emissions and energy consumption. The extraction and processing of raw materials for EVA production also have environmental consequences, including habitat disruption and resource depletion. Additionally, the use of chemical additives and catalysts in the manufacturing process may lead to the release of potentially harmful substances into the environment.

During its lifecycle, EVA products can have both positive and negative environmental impacts. On the positive side, EVA's durability and lightweight nature can contribute to energy savings in transportation and extended product lifespans. However, the disposal of EVA products at the end of their life cycle presents challenges. EVA is not biodegradable and can persist in the environment for extended periods, contributing to plastic pollution if not properly managed.

The recycling of EVA products is another important consideration in the environmental impact assessment. While EVA can be recycled, the process is often complex and energy-intensive due to the presence of various additives and the cross-linked structure of the material. Improving recycling technologies and implementing effective collection systems are crucial for minimizing the environmental footprint of EVA.

Water and air pollution are also potential concerns associated with EVA production and use. Emissions from manufacturing facilities may include volatile organic compounds (VOCs) and particulate matter, which can affect air quality and human health. Wastewater from production processes may contain pollutants that require treatment before release into the environment.

To mitigate the environmental impact of EVA, industries are exploring various sustainable practices. These include optimizing production processes to reduce energy consumption and emissions, developing bio-based alternatives to traditional EVA, and improving end-of-life management strategies. Additionally, life cycle assessments (LCAs) are being conducted to identify hotspots in the EVA value chain and prioritize areas for environmental improvement.

In conclusion, a comprehensive environmental impact assessment of EVA is essential for driving sustainable practices in the industry. By understanding the full lifecycle impacts of EVA, from raw material extraction to end-of-life disposal, stakeholders can make informed decisions and implement strategies to minimize negative environmental consequences while maximizing the benefits of this versatile material.

The production of EVA involves the polymerization of ethylene and vinyl acetate monomers, which are derived from fossil fuels. This process contributes to greenhouse gas emissions and energy consumption. The extraction and processing of raw materials for EVA production also have environmental consequences, including habitat disruption and resource depletion. Additionally, the use of chemical additives and catalysts in the manufacturing process may lead to the release of potentially harmful substances into the environment.

During its lifecycle, EVA products can have both positive and negative environmental impacts. On the positive side, EVA's durability and lightweight nature can contribute to energy savings in transportation and extended product lifespans. However, the disposal of EVA products at the end of their life cycle presents challenges. EVA is not biodegradable and can persist in the environment for extended periods, contributing to plastic pollution if not properly managed.

The recycling of EVA products is another important consideration in the environmental impact assessment. While EVA can be recycled, the process is often complex and energy-intensive due to the presence of various additives and the cross-linked structure of the material. Improving recycling technologies and implementing effective collection systems are crucial for minimizing the environmental footprint of EVA.

Water and air pollution are also potential concerns associated with EVA production and use. Emissions from manufacturing facilities may include volatile organic compounds (VOCs) and particulate matter, which can affect air quality and human health. Wastewater from production processes may contain pollutants that require treatment before release into the environment.

To mitigate the environmental impact of EVA, industries are exploring various sustainable practices. These include optimizing production processes to reduce energy consumption and emissions, developing bio-based alternatives to traditional EVA, and improving end-of-life management strategies. Additionally, life cycle assessments (LCAs) are being conducted to identify hotspots in the EVA value chain and prioritize areas for environmental improvement.

In conclusion, a comprehensive environmental impact assessment of EVA is essential for driving sustainable practices in the industry. By understanding the full lifecycle impacts of EVA, from raw material extraction to end-of-life disposal, stakeholders can make informed decisions and implement strategies to minimize negative environmental consequences while maximizing the benefits of this versatile material.

Circular Economy Strategies for EVA

Circular economy strategies for Ethylene Vinyl Acetate (EVA) are crucial in driving sustainable practices within the industry. These strategies focus on minimizing waste, maximizing resource efficiency, and extending the lifecycle of EVA products. One key approach is the implementation of closed-loop recycling systems, where post-consumer EVA products are collected, processed, and reintegrated into the production cycle. This not only reduces the demand for virgin materials but also decreases the environmental impact associated with waste disposal.

Another important strategy is the development of bio-based EVA alternatives. By utilizing renewable resources such as plant-based feedstocks, manufacturers can reduce their reliance on fossil fuels and decrease carbon emissions. These bio-based EVA materials often maintain similar performance characteristics to traditional EVA while offering improved environmental credentials.

Design for recyclability is a fundamental principle in circular economy strategies for EVA. This involves creating products that are easily disassembled, sorted, and recycled at the end of their useful life. By incorporating modular designs and using compatible materials, manufacturers can facilitate the recovery and reuse of EVA components, thereby extending their lifespan and reducing waste.

The adoption of advanced recycling technologies is also crucial in promoting circular economy practices for EVA. Chemical recycling methods, such as pyrolysis and depolymerization, can break down EVA into its constituent monomers or other valuable chemical feedstocks. These processes enable the production of high-quality recycled materials that can be used in a wide range of applications, effectively closing the loop in the EVA lifecycle.

Collaboration across the value chain is essential for implementing successful circular economy strategies. This includes partnerships between raw material suppliers, manufacturers, retailers, and waste management companies to establish efficient collection and recycling systems. By working together, stakeholders can overcome logistical challenges and create economies of scale that make circular practices economically viable.

Lastly, the development of innovative business models, such as product-as-a-service or leasing arrangements, can promote the circular use of EVA products. These models incentivize manufacturers to design for durability and repairability, as they retain ownership of the products throughout their lifecycle. This shift from a linear to a circular approach not only reduces waste but also creates new revenue streams and enhances customer relationships.

Another important strategy is the development of bio-based EVA alternatives. By utilizing renewable resources such as plant-based feedstocks, manufacturers can reduce their reliance on fossil fuels and decrease carbon emissions. These bio-based EVA materials often maintain similar performance characteristics to traditional EVA while offering improved environmental credentials.

Design for recyclability is a fundamental principle in circular economy strategies for EVA. This involves creating products that are easily disassembled, sorted, and recycled at the end of their useful life. By incorporating modular designs and using compatible materials, manufacturers can facilitate the recovery and reuse of EVA components, thereby extending their lifespan and reducing waste.

The adoption of advanced recycling technologies is also crucial in promoting circular economy practices for EVA. Chemical recycling methods, such as pyrolysis and depolymerization, can break down EVA into its constituent monomers or other valuable chemical feedstocks. These processes enable the production of high-quality recycled materials that can be used in a wide range of applications, effectively closing the loop in the EVA lifecycle.

Collaboration across the value chain is essential for implementing successful circular economy strategies. This includes partnerships between raw material suppliers, manufacturers, retailers, and waste management companies to establish efficient collection and recycling systems. By working together, stakeholders can overcome logistical challenges and create economies of scale that make circular practices economically viable.

Lastly, the development of innovative business models, such as product-as-a-service or leasing arrangements, can promote the circular use of EVA products. These models incentivize manufacturers to design for durability and repairability, as they retain ownership of the products throughout their lifecycle. This shift from a linear to a circular approach not only reduces waste but also creates new revenue streams and enhances customer relationships.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!