How Ethylene Vinyl Acetate Facilitates Technological Growth?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution

Ethylene Vinyl Acetate (EVA) has undergone significant technological evolution since its inception, playing a crucial role in various industries and facilitating technological growth. The journey of EVA technology can be traced back to the 1950s when it was first developed as a copolymer of ethylene and vinyl acetate.

In its early stages, EVA was primarily used in the packaging industry due to its flexibility and low-temperature toughness. The 1960s and 1970s saw a rapid expansion of EVA applications, particularly in the footwear industry, where it revolutionized the production of shoe soles. This period marked the beginning of EVA's versatility in technological applications.

The 1980s brought about a significant breakthrough in EVA technology with the development of cross-linked EVA foam. This innovation opened up new possibilities in the sports and leisure industries, leading to the creation of lightweight and shock-absorbing materials for athletic equipment and protective gear.

The 1990s witnessed the integration of EVA into the solar energy sector, a pivotal moment in its technological evolution. EVA's excellent transparency, adhesion properties, and weather resistance made it an ideal encapsulant material for photovoltaic modules. This application has been instrumental in advancing solar technology and promoting sustainable energy solutions.

In the early 2000s, EVA technology saw further advancements in its formulation and processing techniques. The development of high-performance EVA grades with enhanced thermal stability and UV resistance expanded its use in demanding applications such as aerospace and automotive industries.

The past decade has seen a focus on improving the sustainability of EVA production and applications. Researchers have been exploring bio-based alternatives and recycling methods to address environmental concerns. This shift towards eco-friendly EVA solutions is driving innovation in various sectors, including packaging, construction, and consumer electronics.

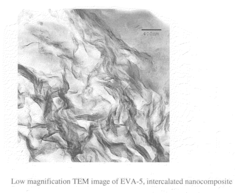

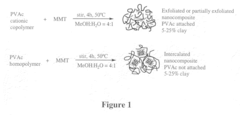

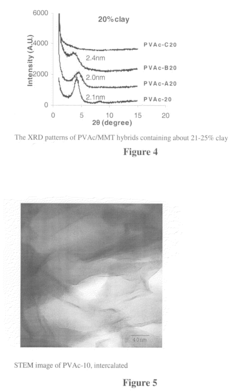

Recent technological breakthroughs in EVA include the development of nanocomposite EVA materials, which offer superior mechanical and barrier properties. These advancements are opening up new possibilities in fields such as medical devices, 3D printing, and smart packaging.

Looking ahead, the evolution of EVA technology is expected to continue, with a focus on enhancing its performance characteristics, expanding its application range, and improving its environmental profile. Emerging trends include the development of self-healing EVA materials, integration with smart technologies, and exploration of EVA's potential in advanced energy storage systems.

In its early stages, EVA was primarily used in the packaging industry due to its flexibility and low-temperature toughness. The 1960s and 1970s saw a rapid expansion of EVA applications, particularly in the footwear industry, where it revolutionized the production of shoe soles. This period marked the beginning of EVA's versatility in technological applications.

The 1980s brought about a significant breakthrough in EVA technology with the development of cross-linked EVA foam. This innovation opened up new possibilities in the sports and leisure industries, leading to the creation of lightweight and shock-absorbing materials for athletic equipment and protective gear.

The 1990s witnessed the integration of EVA into the solar energy sector, a pivotal moment in its technological evolution. EVA's excellent transparency, adhesion properties, and weather resistance made it an ideal encapsulant material for photovoltaic modules. This application has been instrumental in advancing solar technology and promoting sustainable energy solutions.

In the early 2000s, EVA technology saw further advancements in its formulation and processing techniques. The development of high-performance EVA grades with enhanced thermal stability and UV resistance expanded its use in demanding applications such as aerospace and automotive industries.

The past decade has seen a focus on improving the sustainability of EVA production and applications. Researchers have been exploring bio-based alternatives and recycling methods to address environmental concerns. This shift towards eco-friendly EVA solutions is driving innovation in various sectors, including packaging, construction, and consumer electronics.

Recent technological breakthroughs in EVA include the development of nanocomposite EVA materials, which offer superior mechanical and barrier properties. These advancements are opening up new possibilities in fields such as medical devices, 3D printing, and smart packaging.

Looking ahead, the evolution of EVA technology is expected to continue, with a focus on enhancing its performance characteristics, expanding its application range, and improving its environmental profile. Emerging trends include the development of self-healing EVA materials, integration with smart technologies, and exploration of EVA's potential in advanced energy storage systems.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been experiencing significant growth across various industries, driven by its versatile properties and technological advancements. The global EVA market has shown a steady increase in recent years, with projections indicating continued expansion in the coming decade.

In the renewable energy sector, particularly in solar panel manufacturing, EVA has become an indispensable material. Its use as an encapsulant in photovoltaic modules has led to improved efficiency and durability of solar panels. This application has seen a surge in demand, correlating with the global push towards sustainable energy solutions and the rapid growth of the solar industry.

The footwear industry represents another major market for EVA, where it is used in the production of midsoles and outsoles. The material's lightweight nature, excellent shock absorption, and durability have made it a preferred choice for athletic and casual footwear. As consumer preferences shift towards more comfortable and performance-oriented footwear, the demand for EVA in this sector continues to rise.

In the packaging industry, EVA copolymers are increasingly utilized for flexible packaging solutions. The material's clarity, toughness, and low-temperature sealing properties make it ideal for food packaging, medical packaging, and other applications requiring high-performance films. The growing e-commerce sector and changing consumer lifestyles have further boosted the demand for EVA in packaging.

The automotive sector has also contributed to the increasing market demand for EVA. Its application in automotive interiors, wire and cable insulation, and as a component in fuel tanks has grown due to its excellent electrical properties, chemical resistance, and impact strength. The trend towards electric vehicles and the need for lightweight materials in automotive design have further amplified this demand.

In the medical field, EVA has found applications in drug delivery systems, medical tubing, and prosthetics. Its biocompatibility and flexibility make it suitable for various medical devices and pharmaceutical packaging. The ongoing advancements in healthcare technology and the increasing focus on personalized medicine are expected to drive further growth in this sector.

The construction industry has also shown an increasing appetite for EVA-based products. Its use in adhesives, sealants, and as a modifier in cement and concrete has grown due to its water resistance and durability-enhancing properties. The global construction boom, particularly in developing economies, is likely to sustain this demand.

Overall, the market demand analysis for EVA reveals a positive growth trajectory across multiple industries. The material's ability to facilitate technological advancements in various sectors, coupled with its eco-friendly characteristics and cost-effectiveness, positions it as a key component in future technological developments. As industries continue to innovate and seek sustainable solutions, the demand for EVA is expected to expand further, driving research into new applications and improved formulations.

In the renewable energy sector, particularly in solar panel manufacturing, EVA has become an indispensable material. Its use as an encapsulant in photovoltaic modules has led to improved efficiency and durability of solar panels. This application has seen a surge in demand, correlating with the global push towards sustainable energy solutions and the rapid growth of the solar industry.

The footwear industry represents another major market for EVA, where it is used in the production of midsoles and outsoles. The material's lightweight nature, excellent shock absorption, and durability have made it a preferred choice for athletic and casual footwear. As consumer preferences shift towards more comfortable and performance-oriented footwear, the demand for EVA in this sector continues to rise.

In the packaging industry, EVA copolymers are increasingly utilized for flexible packaging solutions. The material's clarity, toughness, and low-temperature sealing properties make it ideal for food packaging, medical packaging, and other applications requiring high-performance films. The growing e-commerce sector and changing consumer lifestyles have further boosted the demand for EVA in packaging.

The automotive sector has also contributed to the increasing market demand for EVA. Its application in automotive interiors, wire and cable insulation, and as a component in fuel tanks has grown due to its excellent electrical properties, chemical resistance, and impact strength. The trend towards electric vehicles and the need for lightweight materials in automotive design have further amplified this demand.

In the medical field, EVA has found applications in drug delivery systems, medical tubing, and prosthetics. Its biocompatibility and flexibility make it suitable for various medical devices and pharmaceutical packaging. The ongoing advancements in healthcare technology and the increasing focus on personalized medicine are expected to drive further growth in this sector.

The construction industry has also shown an increasing appetite for EVA-based products. Its use in adhesives, sealants, and as a modifier in cement and concrete has grown due to its water resistance and durability-enhancing properties. The global construction boom, particularly in developing economies, is likely to sustain this demand.

Overall, the market demand analysis for EVA reveals a positive growth trajectory across multiple industries. The material's ability to facilitate technological advancements in various sectors, coupled with its eco-friendly characteristics and cost-effectiveness, positions it as a key component in future technological developments. As industries continue to innovate and seek sustainable solutions, the demand for EVA is expected to expand further, driving research into new applications and improved formulations.

Technical Challenges

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material in various technological applications, yet its widespread adoption faces several technical challenges. One of the primary obstacles is achieving consistent quality and performance across different production batches. The copolymerization process of ethylene and vinyl acetate requires precise control of reaction conditions, including temperature, pressure, and catalyst concentrations. Variations in these parameters can lead to inconsistencies in the final product's properties, affecting its performance in technological applications.

Another significant challenge lies in optimizing the balance between flexibility and strength in EVA formulations. While increased vinyl acetate content enhances flexibility and transparency, it often comes at the cost of reduced mechanical strength and thermal stability. This trade-off poses difficulties in developing EVA compositions suitable for demanding technological applications that require both flexibility and durability.

The processing of EVA for high-tech applications presents its own set of challenges. The material's low melting point and tendency to degrade at elevated temperatures limit its use in certain high-temperature environments. Additionally, achieving uniform dispersion of additives and fillers within the EVA matrix can be problematic, potentially leading to inconsistent material properties and reduced performance in final products.

Adhesion properties of EVA, crucial for many technological applications, also present technical hurdles. While EVA generally exhibits good adhesion to various substrates, maintaining this adhesion under diverse environmental conditions and over extended periods remains challenging. This is particularly critical in applications such as solar panel encapsulation, where long-term durability is essential.

The recyclability and environmental impact of EVA pose additional technical challenges. As sustainability becomes increasingly important in technological development, finding efficient methods to recycle EVA-based products and reduce their environmental footprint is crucial. The cross-linked nature of some EVA formulations makes recycling particularly difficult, necessitating the development of new recycling technologies or alternative, more easily recyclable formulations.

Lastly, the scalability of EVA production for high-tech applications presents challenges in maintaining quality and consistency at larger scales. As demand for EVA in technological applications grows, scaling up production while ensuring uniform properties and performance becomes increasingly complex. This requires advancements in process engineering and quality control methodologies to meet the stringent requirements of high-tech industries.

Another significant challenge lies in optimizing the balance between flexibility and strength in EVA formulations. While increased vinyl acetate content enhances flexibility and transparency, it often comes at the cost of reduced mechanical strength and thermal stability. This trade-off poses difficulties in developing EVA compositions suitable for demanding technological applications that require both flexibility and durability.

The processing of EVA for high-tech applications presents its own set of challenges. The material's low melting point and tendency to degrade at elevated temperatures limit its use in certain high-temperature environments. Additionally, achieving uniform dispersion of additives and fillers within the EVA matrix can be problematic, potentially leading to inconsistent material properties and reduced performance in final products.

Adhesion properties of EVA, crucial for many technological applications, also present technical hurdles. While EVA generally exhibits good adhesion to various substrates, maintaining this adhesion under diverse environmental conditions and over extended periods remains challenging. This is particularly critical in applications such as solar panel encapsulation, where long-term durability is essential.

The recyclability and environmental impact of EVA pose additional technical challenges. As sustainability becomes increasingly important in technological development, finding efficient methods to recycle EVA-based products and reduce their environmental footprint is crucial. The cross-linked nature of some EVA formulations makes recycling particularly difficult, necessitating the development of new recycling technologies or alternative, more easily recyclable formulations.

Lastly, the scalability of EVA production for high-tech applications presents challenges in maintaining quality and consistency at larger scales. As demand for EVA in technological applications grows, scaling up production while ensuring uniform properties and performance becomes increasingly complex. This requires advancements in process engineering and quality control methodologies to meet the stringent requirements of high-tech industries.

Current EVA Applications

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam density and properties can be controlled through the manufacturing process and formulation.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weather resistance, and adhesion to both glass and solar cells. The material helps protect the solar cells from environmental factors and ensures long-term performance of the solar panels. Specialized EVA formulations are developed to enhance UV stability and prevent yellowing.

- EVA in film and packaging applications: EVA is used in the production of flexible films and packaging materials. It offers good clarity, flexibility, and barrier properties, making it suitable for food packaging, agricultural films, and shrink wrap applications. The material can be blended with other polymers or modified with additives to enhance specific properties such as puncture resistance or gas permeability.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and other properties can be tailored by adjusting the EVA composition and additives.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam properties can be modified by adjusting the EVA grade and foaming process parameters.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and adhesion to both glass and solar cells. The material helps protect the solar cells from environmental factors and ensures long-term performance of the solar panels. Specialized EVA grades are developed for this application to enhance UV resistance and prevent yellowing.Expand Specific Solutions05 Modification and blending of EVA

EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with desired characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers. Such modifications can improve properties like heat resistance, mechanical strength, or compatibility with specific applications.Expand Specific Solutions

Key Industry Players

The ethylene vinyl acetate (EVA) market is in a growth phase, driven by increasing demand across various industries. The global EVA market size is projected to expand significantly, fueled by applications in solar panels, packaging, and footwear. Technologically, EVA is mature but continues to evolve, with companies like DuPont, Celanese, and Wacker Chemie leading innovation. China Petroleum & Chemical Corp. and SABIC are also key players, leveraging their petrochemical expertise. The competitive landscape is characterized by ongoing R&D efforts to enhance EVA properties and explore new applications, with a focus on sustainability and performance improvements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, including a proprietary high-pressure tubular reactor process. This technology allows for precise control of vinyl acetate content and molecular weight distribution, resulting in EVA with tailored properties for specific applications[1]. Sinopec's EVA products are used in photovoltaic encapsulants, enhancing solar panel efficiency and durability. The company has also invested in research to improve EVA's thermal stability and weathering resistance, crucial for outdoor applications[2]. Additionally, Sinopec has developed specialty EVA grades for 3D printing filaments, contributing to the growth of additive manufacturing technologies[3].

Strengths: Vertical integration from raw materials to end products, large-scale production capabilities, and strong R&D in polymer science. Weaknesses: Potential environmental concerns associated with petrochemical production and dependence on fossil fuel-based feedstocks.

Celanese International Corp.

Technical Solution: Celanese has pioneered innovative EVA technologies, focusing on high-performance grades for demanding applications. Their VitalDose® EVA drug delivery platform enables controlled release of active pharmaceutical ingredients, revolutionizing drug delivery systems[4]. Celanese has also developed EVA grades with enhanced melt strength and processability for extrusion coating and lamination processes, improving packaging materials' performance[5]. The company's EVA innovations extend to the automotive sector, where they've created grades with improved impact resistance and low-temperature flexibility for automotive interiors and safety components[6].

Strengths: Strong focus on specialty EVA grades, extensive application knowledge, and global manufacturing presence. Weaknesses: Higher production costs for specialty grades and potential vulnerability to raw material price fluctuations.

EVA Material Properties

Process for producing ethylene vinyl acetate film

PatentInactiveEP1705219A1

Innovation

- Incorporating olefinic bisoleamides, such as N,N'-ethylenebisoleamide, into ethylene copolymers with high vinyl acetate content to improve film forming properties without negatively impacting clarity, allowing for enhanced slip characteristics and easier film separation and cutting.

Ethylene-vinyl acetate copolymer of increased mechanical properties

PatentInactiveUS20080211139A1

Innovation

- Solution blending of EVA with a masterbatch of cationic poly(vinyl acetate)/silicate nanocomposite, where the silicate is substantially exfoliated, maintains mechanical properties and prevents loss of exfoliation during heat processing.

Environmental Impact

Ethylene Vinyl Acetate (EVA) has become a significant material in various technological applications, but its environmental impact warrants careful consideration. The production and use of EVA have both positive and negative effects on the environment, which must be evaluated to ensure sustainable technological growth.

On the positive side, EVA's durability and versatility contribute to the longevity of products, potentially reducing waste and the need for frequent replacements. Its use in solar panel encapsulation, for instance, enhances the efficiency and lifespan of photovoltaic systems, supporting the growth of renewable energy technologies. Additionally, EVA's application in footwear and packaging can lead to lighter products, potentially reducing transportation-related emissions.

However, the environmental concerns associated with EVA production and disposal cannot be overlooked. The manufacturing process of EVA involves the use of petrochemicals, contributing to greenhouse gas emissions and resource depletion. The energy-intensive nature of EVA production also raises questions about its carbon footprint, particularly when compared to alternative materials.

End-of-life management of EVA products presents another environmental challenge. While EVA can be recycled, the process is not widely implemented due to technical and economic barriers. Many EVA products end up in landfills or incineration facilities, contributing to waste accumulation and potential soil and air pollution.

The use of EVA in single-use plastics and disposable products exacerbates environmental concerns, as these items contribute significantly to plastic pollution in terrestrial and marine ecosystems. The slow degradation rate of EVA in natural environments further compounds this issue, potentially harming wildlife and disrupting ecosystems.

To mitigate these environmental impacts, research and development efforts are focusing on improving EVA's recyclability and exploring bio-based alternatives. Innovations in recycling technologies and the development of more environmentally friendly production processes are crucial for enhancing the sustainability of EVA use in technological applications.

As industries continue to rely on EVA for technological advancements, a balanced approach is necessary. This involves optimizing the benefits of EVA while actively addressing its environmental drawbacks through improved production methods, enhanced recycling capabilities, and the exploration of more sustainable alternatives. By doing so, the technological growth facilitated by EVA can be aligned with broader environmental sustainability goals.

On the positive side, EVA's durability and versatility contribute to the longevity of products, potentially reducing waste and the need for frequent replacements. Its use in solar panel encapsulation, for instance, enhances the efficiency and lifespan of photovoltaic systems, supporting the growth of renewable energy technologies. Additionally, EVA's application in footwear and packaging can lead to lighter products, potentially reducing transportation-related emissions.

However, the environmental concerns associated with EVA production and disposal cannot be overlooked. The manufacturing process of EVA involves the use of petrochemicals, contributing to greenhouse gas emissions and resource depletion. The energy-intensive nature of EVA production also raises questions about its carbon footprint, particularly when compared to alternative materials.

End-of-life management of EVA products presents another environmental challenge. While EVA can be recycled, the process is not widely implemented due to technical and economic barriers. Many EVA products end up in landfills or incineration facilities, contributing to waste accumulation and potential soil and air pollution.

The use of EVA in single-use plastics and disposable products exacerbates environmental concerns, as these items contribute significantly to plastic pollution in terrestrial and marine ecosystems. The slow degradation rate of EVA in natural environments further compounds this issue, potentially harming wildlife and disrupting ecosystems.

To mitigate these environmental impacts, research and development efforts are focusing on improving EVA's recyclability and exploring bio-based alternatives. Innovations in recycling technologies and the development of more environmentally friendly production processes are crucial for enhancing the sustainability of EVA use in technological applications.

As industries continue to rely on EVA for technological advancements, a balanced approach is necessary. This involves optimizing the benefits of EVA while actively addressing its environmental drawbacks through improved production methods, enhanced recycling capabilities, and the exploration of more sustainable alternatives. By doing so, the technological growth facilitated by EVA can be aligned with broader environmental sustainability goals.

Regulatory Compliance

Regulatory compliance plays a crucial role in the widespread adoption and technological growth facilitated by Ethylene Vinyl Acetate (EVA). As EVA finds applications across various industries, adherence to regulatory standards ensures its safe and effective use while promoting innovation and market expansion.

In the medical and pharmaceutical sectors, EVA-based products must comply with stringent regulations set by agencies such as the FDA and EMA. These regulations cover aspects like biocompatibility, sterilization processes, and material purity. Manufacturers must demonstrate that EVA-based medical devices and drug delivery systems meet safety and efficacy standards through rigorous testing and documentation.

The food packaging industry also faces strict regulatory requirements for EVA usage. Agencies like the FDA and EFSA have established guidelines for food contact materials, including EVA. Compliance with these regulations ensures that EVA-based packaging does not leach harmful substances into food products, maintaining consumer safety and product integrity.

In the renewable energy sector, particularly solar panel manufacturing, EVA encapsulants must meet specific regulatory standards. These include durability requirements, fire safety regulations, and environmental impact assessments. Compliance with these standards drives technological advancements in EVA formulations, leading to more efficient and sustainable solar panel designs.

The construction industry utilizes EVA in various applications, such as adhesives and sealants. Regulatory compliance in this sector focuses on fire safety, emissions standards, and structural integrity. Adherence to building codes and environmental regulations pushes manufacturers to develop innovative EVA-based products that meet both performance and safety requirements.

As EVA finds increasing use in electronics and electrical applications, compliance with regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) becomes essential. These directives drive the development of EVA formulations that are free from restricted substances and promote recyclability, fostering technological growth in eco-friendly electronics.

The automotive industry's use of EVA in components like gaskets, seals, and wire insulation is subject to strict safety and performance regulations. Compliance with these standards encourages the development of advanced EVA formulations that can withstand harsh operating conditions while meeting environmental and safety requirements.

Regulatory compliance also extends to the manufacturing processes of EVA itself. Environmental regulations governing emissions, waste management, and energy efficiency drive technological advancements in production methods. This leads to the development of cleaner, more efficient manufacturing processes that reduce the environmental footprint of EVA production.

In the medical and pharmaceutical sectors, EVA-based products must comply with stringent regulations set by agencies such as the FDA and EMA. These regulations cover aspects like biocompatibility, sterilization processes, and material purity. Manufacturers must demonstrate that EVA-based medical devices and drug delivery systems meet safety and efficacy standards through rigorous testing and documentation.

The food packaging industry also faces strict regulatory requirements for EVA usage. Agencies like the FDA and EFSA have established guidelines for food contact materials, including EVA. Compliance with these regulations ensures that EVA-based packaging does not leach harmful substances into food products, maintaining consumer safety and product integrity.

In the renewable energy sector, particularly solar panel manufacturing, EVA encapsulants must meet specific regulatory standards. These include durability requirements, fire safety regulations, and environmental impact assessments. Compliance with these standards drives technological advancements in EVA formulations, leading to more efficient and sustainable solar panel designs.

The construction industry utilizes EVA in various applications, such as adhesives and sealants. Regulatory compliance in this sector focuses on fire safety, emissions standards, and structural integrity. Adherence to building codes and environmental regulations pushes manufacturers to develop innovative EVA-based products that meet both performance and safety requirements.

As EVA finds increasing use in electronics and electrical applications, compliance with regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) becomes essential. These directives drive the development of EVA formulations that are free from restricted substances and promote recyclability, fostering technological growth in eco-friendly electronics.

The automotive industry's use of EVA in components like gaskets, seals, and wire insulation is subject to strict safety and performance regulations. Compliance with these standards encourages the development of advanced EVA formulations that can withstand harsh operating conditions while meeting environmental and safety requirements.

Regulatory compliance also extends to the manufacturing processes of EVA itself. Environmental regulations governing emissions, waste management, and energy efficiency drive technological advancements in production methods. This leads to the development of cleaner, more efficient manufacturing processes that reduce the environmental footprint of EVA production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!