How to Secure Market Advantages with Ethylene Vinyl Acetate Solutions?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Evolution and Objectives

Ethylene Vinyl Acetate (EVA) technology has undergone significant evolution since its inception in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA has transformed from a niche material to a versatile solution with applications across multiple industries. The technology's progression has been driven by the continuous pursuit of enhanced performance characteristics, cost-effectiveness, and sustainability.

In the early stages, EVA was primarily used in packaging and adhesives due to its flexibility and low-temperature toughness. As manufacturing processes improved, the ability to control the vinyl acetate content more precisely led to a wider range of properties, expanding EVA's potential applications. This technological advancement allowed for the development of EVA foams, which found use in footwear, sports equipment, and automotive components.

The objectives of EVA technology have evolved in tandem with market demands and environmental concerns. Current goals focus on improving EVA's thermal stability, weatherability, and flame retardancy without compromising its core benefits. Researchers are also exploring ways to enhance EVA's barrier properties, particularly for packaging applications, to extend product shelf life and reduce food waste.

Another key objective is the development of bio-based EVA alternatives to address sustainability concerns. This involves incorporating renewable resources into the production process and improving the material's recyclability. The push towards circular economy principles has led to increased efforts in creating EVA formulations that can be more easily reprocessed or biodegraded at the end of their lifecycle.

In the realm of photovoltaic technology, EVA has become crucial as an encapsulant for solar panels. The objective here is to enhance UV resistance and prevent yellowing, thereby extending the lifespan and efficiency of solar modules. This aligns with the global shift towards renewable energy sources and the need for more durable, high-performance materials in the solar industry.

The future trajectory of EVA technology is likely to focus on smart and responsive materials. Objectives include developing EVA composites with self-healing properties, temperature-responsive characteristics, and even electrically conductive variants. These advancements aim to create EVA solutions that can adapt to changing environmental conditions or user needs, opening up new market opportunities in sectors such as wearable technology and smart packaging.

To secure market advantages with EVA solutions, companies must align their research and development efforts with these evolving objectives. This involves not only improving the material properties but also innovating in terms of processing techniques, application methods, and end-of-life solutions. By addressing the full lifecycle of EVA products, businesses can differentiate themselves in an increasingly competitive and environmentally conscious market landscape.

In the early stages, EVA was primarily used in packaging and adhesives due to its flexibility and low-temperature toughness. As manufacturing processes improved, the ability to control the vinyl acetate content more precisely led to a wider range of properties, expanding EVA's potential applications. This technological advancement allowed for the development of EVA foams, which found use in footwear, sports equipment, and automotive components.

The objectives of EVA technology have evolved in tandem with market demands and environmental concerns. Current goals focus on improving EVA's thermal stability, weatherability, and flame retardancy without compromising its core benefits. Researchers are also exploring ways to enhance EVA's barrier properties, particularly for packaging applications, to extend product shelf life and reduce food waste.

Another key objective is the development of bio-based EVA alternatives to address sustainability concerns. This involves incorporating renewable resources into the production process and improving the material's recyclability. The push towards circular economy principles has led to increased efforts in creating EVA formulations that can be more easily reprocessed or biodegraded at the end of their lifecycle.

In the realm of photovoltaic technology, EVA has become crucial as an encapsulant for solar panels. The objective here is to enhance UV resistance and prevent yellowing, thereby extending the lifespan and efficiency of solar modules. This aligns with the global shift towards renewable energy sources and the need for more durable, high-performance materials in the solar industry.

The future trajectory of EVA technology is likely to focus on smart and responsive materials. Objectives include developing EVA composites with self-healing properties, temperature-responsive characteristics, and even electrically conductive variants. These advancements aim to create EVA solutions that can adapt to changing environmental conditions or user needs, opening up new market opportunities in sectors such as wearable technology and smart packaging.

To secure market advantages with EVA solutions, companies must align their research and development efforts with these evolving objectives. This involves not only improving the material properties but also innovating in terms of processing techniques, application methods, and end-of-life solutions. By addressing the full lifecycle of EVA products, businesses can differentiate themselves in an increasingly competitive and environmentally conscious market landscape.

EVA Market Demand Analysis

The global Ethylene Vinyl Acetate (EVA) market has been experiencing significant growth, driven by increasing demand across various industries. The versatility of EVA as a copolymer has led to its widespread adoption in sectors such as packaging, footwear, solar panels, and automotive applications. This diverse range of end-use industries contributes to a robust and expanding market demand for EVA solutions.

In the packaging industry, EVA is highly sought after for its excellent flexibility, toughness, and barrier properties. The growing e-commerce sector and the need for sustainable packaging solutions have further boosted the demand for EVA-based materials. Additionally, the footwear industry has been a major consumer of EVA, particularly in the production of midsoles for athletic shoes, due to its lightweight and shock-absorbing characteristics.

The renewable energy sector, specifically the solar panel industry, has emerged as a significant driver of EVA demand. EVA is extensively used as an encapsulant material in photovoltaic modules, providing essential protection and enhancing the longevity of solar cells. As global efforts to transition towards clean energy sources intensify, the demand for EVA in solar applications is expected to surge.

In the automotive sector, EVA finds applications in various components, including gaskets, seals, and interior parts. The trend towards lightweight vehicles and improved fuel efficiency has led to increased adoption of EVA-based materials in automotive manufacturing. This trend is likely to continue as the automotive industry evolves towards electric and hybrid vehicles.

Market analysis indicates that the Asia-Pacific region dominates the global EVA market, with China and India being key growth drivers. The rapid industrialization, expanding manufacturing sectors, and increasing consumer goods production in these countries contribute significantly to the regional demand for EVA. North America and Europe also maintain substantial market shares, primarily driven by technological advancements and the presence of major end-use industries.

The construction industry presents another promising avenue for EVA market growth. EVA-based adhesives and sealants are gaining popularity due to their excellent bonding properties and resistance to weathering. As urbanization continues and infrastructure development projects increase globally, the demand for EVA in construction applications is expected to rise.

To secure market advantages with EVA solutions, companies must focus on product innovation, sustainability, and tailored solutions for specific industry needs. Developing bio-based EVA alternatives, improving recycling technologies, and enhancing product performance characteristics will be crucial in meeting evolving market demands and regulatory requirements. Additionally, strategic partnerships with end-use industries and investments in research and development will be key to maintaining a competitive edge in the rapidly evolving EVA market landscape.

In the packaging industry, EVA is highly sought after for its excellent flexibility, toughness, and barrier properties. The growing e-commerce sector and the need for sustainable packaging solutions have further boosted the demand for EVA-based materials. Additionally, the footwear industry has been a major consumer of EVA, particularly in the production of midsoles for athletic shoes, due to its lightweight and shock-absorbing characteristics.

The renewable energy sector, specifically the solar panel industry, has emerged as a significant driver of EVA demand. EVA is extensively used as an encapsulant material in photovoltaic modules, providing essential protection and enhancing the longevity of solar cells. As global efforts to transition towards clean energy sources intensify, the demand for EVA in solar applications is expected to surge.

In the automotive sector, EVA finds applications in various components, including gaskets, seals, and interior parts. The trend towards lightweight vehicles and improved fuel efficiency has led to increased adoption of EVA-based materials in automotive manufacturing. This trend is likely to continue as the automotive industry evolves towards electric and hybrid vehicles.

Market analysis indicates that the Asia-Pacific region dominates the global EVA market, with China and India being key growth drivers. The rapid industrialization, expanding manufacturing sectors, and increasing consumer goods production in these countries contribute significantly to the regional demand for EVA. North America and Europe also maintain substantial market shares, primarily driven by technological advancements and the presence of major end-use industries.

The construction industry presents another promising avenue for EVA market growth. EVA-based adhesives and sealants are gaining popularity due to their excellent bonding properties and resistance to weathering. As urbanization continues and infrastructure development projects increase globally, the demand for EVA in construction applications is expected to rise.

To secure market advantages with EVA solutions, companies must focus on product innovation, sustainability, and tailored solutions for specific industry needs. Developing bio-based EVA alternatives, improving recycling technologies, and enhancing product performance characteristics will be crucial in meeting evolving market demands and regulatory requirements. Additionally, strategic partnerships with end-use industries and investments in research and development will be key to maintaining a competitive edge in the rapidly evolving EVA market landscape.

EVA Technical Challenges

Ethylene Vinyl Acetate (EVA) solutions face several technical challenges that impact their market adoption and performance. One of the primary issues is achieving consistent quality across different production batches. The copolymerization process of ethylene and vinyl acetate can be sensitive to variations in temperature, pressure, and catalyst activity, leading to inconsistencies in the final product's properties.

Another significant challenge lies in balancing the vinyl acetate content to optimize performance characteristics. Higher vinyl acetate content generally increases flexibility and transparency but can compromise strength and heat resistance. Finding the right balance for specific applications requires extensive research and development efforts.

The processing of EVA also presents technical hurdles. The material's low melting point and tendency to degrade at high temperatures limit the processing window, making it challenging to incorporate additives or blend with other polymers without compromising the material's integrity. This narrow processing range can lead to difficulties in achieving desired product specifications consistently.

Adhesion properties of EVA, while generally good, can be problematic in certain applications. Improving adhesion to a wide range of substrates, especially in multi-layer structures, remains an ongoing challenge. This is particularly crucial in packaging and construction applications where EVA is frequently used as an adhesive layer.

Weatherability and UV resistance pose another set of challenges for EVA solutions. In outdoor applications, such as solar panel encapsulation, EVA can degrade over time, leading to yellowing, loss of transparency, and reduced performance. Developing effective UV stabilizers and antioxidants that do not compromise other properties is an area of active research.

The recyclability of EVA products is becoming increasingly important as environmental concerns grow. However, the cross-linked structure of many EVA formulations makes recycling difficult. Developing easily recyclable EVA grades without sacrificing performance is a significant technical challenge facing the industry.

Lastly, the flammability of EVA is a concern in many applications, particularly in construction and automotive industries. Improving flame retardancy without negatively impacting other properties or significantly increasing costs remains a complex technical challenge. Innovative flame retardant systems that are both effective and environmentally friendly are in high demand.

Another significant challenge lies in balancing the vinyl acetate content to optimize performance characteristics. Higher vinyl acetate content generally increases flexibility and transparency but can compromise strength and heat resistance. Finding the right balance for specific applications requires extensive research and development efforts.

The processing of EVA also presents technical hurdles. The material's low melting point and tendency to degrade at high temperatures limit the processing window, making it challenging to incorporate additives or blend with other polymers without compromising the material's integrity. This narrow processing range can lead to difficulties in achieving desired product specifications consistently.

Adhesion properties of EVA, while generally good, can be problematic in certain applications. Improving adhesion to a wide range of substrates, especially in multi-layer structures, remains an ongoing challenge. This is particularly crucial in packaging and construction applications where EVA is frequently used as an adhesive layer.

Weatherability and UV resistance pose another set of challenges for EVA solutions. In outdoor applications, such as solar panel encapsulation, EVA can degrade over time, leading to yellowing, loss of transparency, and reduced performance. Developing effective UV stabilizers and antioxidants that do not compromise other properties is an area of active research.

The recyclability of EVA products is becoming increasingly important as environmental concerns grow. However, the cross-linked structure of many EVA formulations makes recycling difficult. Developing easily recyclable EVA grades without sacrificing performance is a significant technical challenge facing the industry.

Lastly, the flammability of EVA is a concern in many applications, particularly in construction and automotive industries. Improving flame retardancy without negatively impacting other properties or significantly increasing costs remains a complex technical challenge. Innovative flame retardant systems that are both effective and environmentally friendly are in high demand.

Current EVA Solutions

01 Versatility and wide range of applications

Ethylene Vinyl Acetate (EVA) offers versatility and can be used in various industries. It is suitable for applications such as packaging, footwear, solar panels, and adhesives due to its flexibility, durability, and ease of processing.- Versatility and wide range of applications: Ethylene Vinyl Acetate (EVA) offers versatility and can be used in various applications across different industries. Its properties make it suitable for use in products such as footwear, packaging materials, solar panel encapsulation, and adhesives. This versatility contributes to its market advantages and widespread adoption.

- Improved physical and mechanical properties: EVA copolymers exhibit enhanced physical and mechanical properties compared to traditional materials. These properties include flexibility, toughness, and impact resistance. The improved characteristics make EVA an attractive option for manufacturers seeking durable and high-performance materials.

- Environmental sustainability: EVA materials can be formulated to be more environmentally friendly and sustainable. Some EVA compositions are recyclable or biodegradable, aligning with growing market demands for eco-friendly products. This sustainability aspect provides a competitive advantage in markets with increasing environmental regulations.

- Cost-effectiveness and processing ease: EVA offers cost advantages in terms of raw material pricing and processing. It can be easily processed using various methods such as injection molding, extrusion, and blow molding. The material's compatibility with different processing techniques contributes to its cost-effectiveness in manufacturing.

- Customizable properties for specific applications: The properties of EVA can be tailored by adjusting the vinyl acetate content and molecular weight. This customization allows manufacturers to create EVA formulations with specific characteristics suited for particular applications, such as varying degrees of flexibility, clarity, or adhesion strength.

02 Enhanced thermal and electrical properties

EVA exhibits excellent thermal insulation and electrical resistance properties. This makes it ideal for use in solar panel encapsulation, wire and cable insulation, and other applications requiring thermal management or electrical insulation.Expand Specific Solutions03 Improved product performance and durability

The incorporation of EVA in various products can lead to improved performance and durability. It enhances the shock absorption properties in footwear, increases the weather resistance of outdoor products, and improves the overall lifespan of materials it is used in.Expand Specific Solutions04 Cost-effectiveness and processing advantages

EVA offers cost-effectiveness in manufacturing processes due to its ease of processing, low melting point, and ability to be blended with other materials. This results in reduced production costs and increased efficiency in various industries.Expand Specific Solutions05 Environmental sustainability

EVA can be recycled and reprocessed, contributing to environmental sustainability. It is also being developed into bio-based versions, reducing reliance on fossil fuels and decreasing the carbon footprint of products using this material.Expand Specific Solutions

Key EVA Industry Players

The ethylene vinyl acetate (EVA) market is in a mature growth stage, characterized by steady demand across various industries. The global market size is substantial, with projections indicating continued expansion due to increasing applications in sectors like packaging, solar panels, and footwear. Technologically, EVA production is well-established, with major players like China Petroleum & Chemical Corp., Celanese International Corp., and Kuraray Co., Ltd. leading the field. These companies have advanced manufacturing capabilities and extensive R&D efforts, focusing on product innovations and process improvements. The competitive landscape is intense, with established petrochemical giants and specialized chemical manufacturers vying for market share through product differentiation and cost-effective production methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA production technologies, including a proprietary high-pressure tubular reactor process. This technology allows for precise control of vinyl acetate content and molecular weight distribution, resulting in EVA products with superior properties[1]. Sinopec's EVA solutions are used in various applications, including solar panel encapsulation, where their products have shown excellent weatherability and low water absorption rates[2]. The company has also invested in research to improve EVA foam quality, developing a crosslinking technology that enhances the foam's compression set and thermal stability[3].

Strengths: Vertically integrated production, strong R&D capabilities, and a wide range of EVA grades. Weaknesses: Potential environmental concerns and dependence on fossil fuel feedstocks.

Celanese International Corp.

Technical Solution: Celanese has developed a range of EVA solutions under its VitalDose® platform, specifically designed for controlled release drug delivery systems. Their EVA technology allows for customizable drug release profiles by adjusting the vinyl acetate content and molecular weight[4]. The company has also introduced EVA grades with enhanced thermal stability and optical clarity for film applications. Celanese's EVA products feature a unique stabilization package that prevents gel formation during processing, ensuring consistent quality in end products[5]. Additionally, they have developed specialty EVA grades for 3D printing filaments, offering improved flexibility and impact resistance compared to traditional materials[6].

Strengths: Strong focus on specialty applications, extensive product portfolio, and global manufacturing presence. Weaknesses: Higher production costs for specialty grades and potential competition from bio-based alternatives.

EVA Core Patents Analysis

Ultra high solids vinyl acetate-ethylene and vinyl acetate homopolymer emulsions

PatentInactiveEP0924229B1

Innovation

- Incorporating a polymer seed, such as vinyl acetate, ethylene vinyl acetate, acrylic, or styrene acrylic polymers, into the ethylene/vinyl acetate emulsion process with a specific polyvinyl alcohol and nonionic emulsifier system to achieve broader particle size distribution and higher solids levels while maintaining low viscosity.

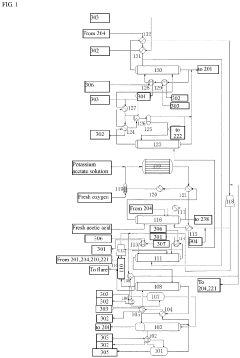

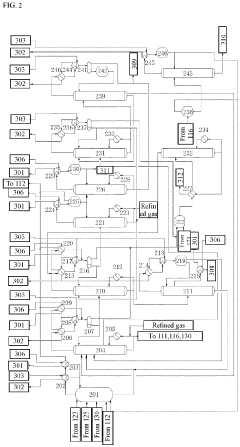

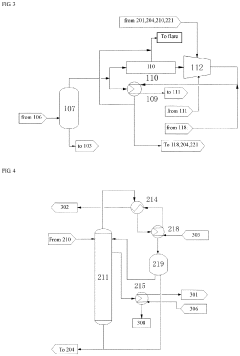

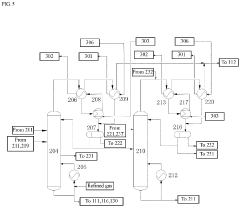

Preparation method of vinyl acetate by ethylene process and device thereof

PatentPendingEP4371972A1

Innovation

- A novel process incorporating an ethylene recovery membrane assembly, refined VAC tower side-draw stream additions, and improved cooling methods using circulating and chilled water for high-purity vinyl acetate production, reducing emissions and preventing material leakage by recovering ethylene and optimizing the distillation process.

EVA Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) solutions is complex and multifaceted, encompassing various aspects of production, distribution, and application. Understanding and navigating this landscape is crucial for companies seeking to secure market advantages in the EVA industry.

At the global level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) play a significant role in setting standards for EVA products. These standards ensure consistency in quality, performance, and safety across different manufacturers and applications.

In the United States, the Food and Drug Administration (FDA) regulates EVA materials used in food contact applications, medical devices, and pharmaceutical packaging. Compliance with FDA regulations is essential for companies targeting these sectors. The Environmental Protection Agency (EPA) also oversees aspects of EVA production and disposal, particularly concerning emissions and waste management.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects EVA manufacturers and importers. REACH requires companies to register chemicals, assess their hazards, and communicate safety information to users. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive impacts the use of certain additives in EVA formulations for electronic applications.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees environmental aspects of EVA production, while the State Administration for Market Regulation governs product quality and safety standards. Japan's regulatory landscape includes the Chemical Substances Control Law and various industry-specific regulations.

Emerging markets present both opportunities and challenges in terms of regulatory compliance. As these markets develop their regulatory frameworks, companies must stay informed and adaptable to maintain compliance and competitive advantage.

Sustainability and circular economy initiatives are increasingly influencing EVA regulations globally. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which could impact EVA manufacturers and users, particularly in packaging and consumer goods sectors.

To secure market advantages, companies must not only comply with current regulations but also anticipate future regulatory trends. This may involve investing in research and development to create more environmentally friendly EVA formulations or developing innovative recycling technologies to address end-of-life concerns.

Collaboration with regulatory bodies, participation in industry associations, and engagement in public consultations can help companies shape future regulations and position themselves advantageously in the market. By staying ahead of regulatory changes, companies can turn compliance into a competitive edge, differentiating their products and services in the global EVA market.

At the global level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) play a significant role in setting standards for EVA products. These standards ensure consistency in quality, performance, and safety across different manufacturers and applications.

In the United States, the Food and Drug Administration (FDA) regulates EVA materials used in food contact applications, medical devices, and pharmaceutical packaging. Compliance with FDA regulations is essential for companies targeting these sectors. The Environmental Protection Agency (EPA) also oversees aspects of EVA production and disposal, particularly concerning emissions and waste management.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects EVA manufacturers and importers. REACH requires companies to register chemicals, assess their hazards, and communicate safety information to users. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive impacts the use of certain additives in EVA formulations for electronic applications.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees environmental aspects of EVA production, while the State Administration for Market Regulation governs product quality and safety standards. Japan's regulatory landscape includes the Chemical Substances Control Law and various industry-specific regulations.

Emerging markets present both opportunities and challenges in terms of regulatory compliance. As these markets develop their regulatory frameworks, companies must stay informed and adaptable to maintain compliance and competitive advantage.

Sustainability and circular economy initiatives are increasingly influencing EVA regulations globally. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which could impact EVA manufacturers and users, particularly in packaging and consumer goods sectors.

To secure market advantages, companies must not only comply with current regulations but also anticipate future regulatory trends. This may involve investing in research and development to create more environmentally friendly EVA formulations or developing innovative recycling technologies to address end-of-life concerns.

Collaboration with regulatory bodies, participation in industry associations, and engagement in public consultations can help companies shape future regulations and position themselves advantageously in the market. By staying ahead of regulatory changes, companies can turn compliance into a competitive edge, differentiating their products and services in the global EVA market.

EVA Sustainability Aspects

Ethylene Vinyl Acetate (EVA) solutions are increasingly being recognized for their potential to contribute to sustainability goals across various industries. The sustainability aspects of EVA are multifaceted, encompassing environmental, economic, and social dimensions.

From an environmental perspective, EVA offers several advantages. Its production process is relatively energy-efficient compared to some alternative materials, resulting in a lower carbon footprint. Additionally, EVA is recyclable, which aligns with circular economy principles and helps reduce waste. Some EVA formulations are biodegradable, further enhancing their eco-friendly profile.

In terms of durability and longevity, EVA-based products often exhibit excellent resistance to weathering, UV radiation, and chemical degradation. This extended lifespan contributes to resource conservation by reducing the need for frequent replacements. Moreover, the lightweight nature of EVA materials can lead to reduced transportation emissions when used in packaging or automotive applications.

EVA's versatility allows for its use in sustainable product design across multiple sectors. In the renewable energy industry, EVA is a crucial component in solar panel encapsulation, contributing to the efficiency and longevity of photovoltaic systems. In construction, EVA-based materials can enhance building insulation, leading to improved energy efficiency and reduced heating and cooling costs.

The economic sustainability of EVA solutions is evident in their cost-effectiveness and performance benefits. The material's flexibility in formulation allows manufacturers to optimize properties for specific applications, potentially reducing overall production costs and improving product performance. This adaptability can lead to increased market competitiveness and long-term economic viability for businesses adopting EVA technologies.

From a social sustainability standpoint, EVA's safety profile is generally favorable. It is non-toxic and does not release harmful chemicals during normal use, making it suitable for applications in food packaging, medical devices, and children's products. This contributes to public health and safety, aligning with corporate social responsibility goals.

However, it is important to note that the sustainability of EVA is not without challenges. The base material is derived from fossil fuels, which raises concerns about long-term resource availability and environmental impact. Efforts are underway to develop bio-based alternatives, which could further enhance the sustainability profile of EVA solutions in the future.

In conclusion, the sustainability aspects of EVA solutions offer significant market advantages. By leveraging these attributes, companies can position themselves as environmentally responsible, economically sound, and socially conscious, potentially gaining a competitive edge in increasingly sustainability-focused markets.

From an environmental perspective, EVA offers several advantages. Its production process is relatively energy-efficient compared to some alternative materials, resulting in a lower carbon footprint. Additionally, EVA is recyclable, which aligns with circular economy principles and helps reduce waste. Some EVA formulations are biodegradable, further enhancing their eco-friendly profile.

In terms of durability and longevity, EVA-based products often exhibit excellent resistance to weathering, UV radiation, and chemical degradation. This extended lifespan contributes to resource conservation by reducing the need for frequent replacements. Moreover, the lightweight nature of EVA materials can lead to reduced transportation emissions when used in packaging or automotive applications.

EVA's versatility allows for its use in sustainable product design across multiple sectors. In the renewable energy industry, EVA is a crucial component in solar panel encapsulation, contributing to the efficiency and longevity of photovoltaic systems. In construction, EVA-based materials can enhance building insulation, leading to improved energy efficiency and reduced heating and cooling costs.

The economic sustainability of EVA solutions is evident in their cost-effectiveness and performance benefits. The material's flexibility in formulation allows manufacturers to optimize properties for specific applications, potentially reducing overall production costs and improving product performance. This adaptability can lead to increased market competitiveness and long-term economic viability for businesses adopting EVA technologies.

From a social sustainability standpoint, EVA's safety profile is generally favorable. It is non-toxic and does not release harmful chemicals during normal use, making it suitable for applications in food packaging, medical devices, and children's products. This contributes to public health and safety, aligning with corporate social responsibility goals.

However, it is important to note that the sustainability of EVA is not without challenges. The base material is derived from fossil fuels, which raises concerns about long-term resource availability and environmental impact. Efforts are underway to develop bio-based alternatives, which could further enhance the sustainability profile of EVA solutions in the future.

In conclusion, the sustainability aspects of EVA solutions offer significant market advantages. By leveraging these attributes, companies can position themselves as environmentally responsible, economically sound, and socially conscious, potentially gaining a competitive edge in increasingly sustainability-focused markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!