How Ethylene Vinyl Acetate is Transforming Consumer Products?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Evolution and Goals

Ethylene Vinyl Acetate (EVA) has undergone a remarkable evolution since its inception in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA has transformed from a niche material to a versatile polymer with widespread applications across various industries. The journey of EVA began with its use in packaging and adhesives, but its unique properties quickly led to its adoption in more diverse fields.

In the 1960s and 1970s, researchers discovered EVA's potential in footwear, particularly in the production of midsoles for athletic shoes. This breakthrough marked a significant milestone in EVA's evolution, as it demonstrated the material's ability to provide cushioning, flexibility, and durability in high-performance applications. The success in footwear paved the way for EVA's expansion into other consumer products.

The 1980s and 1990s saw EVA's integration into the sports and leisure industry, with applications ranging from protective gear to water sports equipment. Its lightweight nature, coupled with excellent shock absorption properties, made it an ideal material for enhancing user comfort and safety. During this period, EVA also gained traction in the construction and automotive sectors, where its insulation and sealing properties were highly valued.

As we entered the 21st century, the focus on sustainability and eco-friendly materials propelled EVA into new territories. Researchers began exploring ways to improve EVA's biodegradability and recyclability, aligning with global efforts to reduce environmental impact. This shift in focus has led to the development of bio-based EVA formulations and more efficient recycling processes.

The current goals for EVA technology are multifaceted and ambitious. One primary objective is to further enhance EVA's performance characteristics, such as improved heat resistance, increased durability, and enhanced chemical resistance. These advancements aim to expand EVA's applicability in more demanding environments and industries.

Another crucial goal is the development of "smart" EVA materials that can respond to external stimuli, such as temperature or pressure changes. This innovation could revolutionize products like adaptive footwear or self-adjusting packaging materials. Additionally, there is a strong push towards creating fully biodegradable EVA variants without compromising on performance, addressing the growing demand for sustainable consumer products.

The integration of EVA with other advanced materials, such as nanocomposites or conductive polymers, represents another frontier in its evolution. These hybrid materials could open up new possibilities in electronics, healthcare, and advanced manufacturing. As EVA continues to transform consumer products, the overarching goal remains to balance performance, sustainability, and cost-effectiveness, ensuring its relevance in an ever-changing market landscape.

In the 1960s and 1970s, researchers discovered EVA's potential in footwear, particularly in the production of midsoles for athletic shoes. This breakthrough marked a significant milestone in EVA's evolution, as it demonstrated the material's ability to provide cushioning, flexibility, and durability in high-performance applications. The success in footwear paved the way for EVA's expansion into other consumer products.

The 1980s and 1990s saw EVA's integration into the sports and leisure industry, with applications ranging from protective gear to water sports equipment. Its lightweight nature, coupled with excellent shock absorption properties, made it an ideal material for enhancing user comfort and safety. During this period, EVA also gained traction in the construction and automotive sectors, where its insulation and sealing properties were highly valued.

As we entered the 21st century, the focus on sustainability and eco-friendly materials propelled EVA into new territories. Researchers began exploring ways to improve EVA's biodegradability and recyclability, aligning with global efforts to reduce environmental impact. This shift in focus has led to the development of bio-based EVA formulations and more efficient recycling processes.

The current goals for EVA technology are multifaceted and ambitious. One primary objective is to further enhance EVA's performance characteristics, such as improved heat resistance, increased durability, and enhanced chemical resistance. These advancements aim to expand EVA's applicability in more demanding environments and industries.

Another crucial goal is the development of "smart" EVA materials that can respond to external stimuli, such as temperature or pressure changes. This innovation could revolutionize products like adaptive footwear or self-adjusting packaging materials. Additionally, there is a strong push towards creating fully biodegradable EVA variants without compromising on performance, addressing the growing demand for sustainable consumer products.

The integration of EVA with other advanced materials, such as nanocomposites or conductive polymers, represents another frontier in its evolution. These hybrid materials could open up new possibilities in electronics, healthcare, and advanced manufacturing. As EVA continues to transform consumer products, the overarching goal remains to balance performance, sustainability, and cost-effectiveness, ensuring its relevance in an ever-changing market landscape.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been experiencing significant growth across various consumer product sectors. This versatile copolymer has found widespread applications due to its unique properties, including flexibility, durability, and resistance to UV radiation and stress-cracking. The footwear industry has been a major driver of EVA demand, particularly in the production of athletic shoes and comfortable insoles. The material's shock-absorbing qualities and lightweight nature make it ideal for sports and casual footwear, leading to increased adoption by major brands.

In the packaging industry, EVA has gained traction for its excellent sealing properties and compatibility with food contact applications. The material's use in flexible packaging, such as films and laminates, has been growing steadily, driven by the increasing demand for convenient and sustainable packaging solutions. Additionally, the construction sector has shown a rising interest in EVA-based products, particularly in the form of adhesives, sealants, and waterproofing membranes, due to their superior bonding strength and weather resistance.

The consumer electronics market has also contributed to the growing demand for EVA. The material's cushioning properties make it suitable for protective cases and covers for smartphones, tablets, and laptops. As the global consumer electronics market continues to expand, the demand for EVA in this sector is expected to rise correspondingly.

The automotive industry has been another significant consumer of EVA, utilizing the material in various components such as gaskets, hoses, and wire insulation. The increasing focus on lightweight materials to improve fuel efficiency has further boosted the adoption of EVA in automotive applications. Moreover, the renewable energy sector, particularly solar panel manufacturing, has emerged as a promising market for EVA. The material's use as an encapsulant in photovoltaic modules has grown substantially with the global push towards clean energy solutions.

Market analysts project a compound annual growth rate (CAGR) for the global EVA market in the mid-single digits over the next five years. This growth is attributed to the material's expanding applications across diverse industries and its ability to meet evolving consumer preferences for sustainable and high-performance products. The Asia-Pacific region is expected to dominate the market growth, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

In the packaging industry, EVA has gained traction for its excellent sealing properties and compatibility with food contact applications. The material's use in flexible packaging, such as films and laminates, has been growing steadily, driven by the increasing demand for convenient and sustainable packaging solutions. Additionally, the construction sector has shown a rising interest in EVA-based products, particularly in the form of adhesives, sealants, and waterproofing membranes, due to their superior bonding strength and weather resistance.

The consumer electronics market has also contributed to the growing demand for EVA. The material's cushioning properties make it suitable for protective cases and covers for smartphones, tablets, and laptops. As the global consumer electronics market continues to expand, the demand for EVA in this sector is expected to rise correspondingly.

The automotive industry has been another significant consumer of EVA, utilizing the material in various components such as gaskets, hoses, and wire insulation. The increasing focus on lightweight materials to improve fuel efficiency has further boosted the adoption of EVA in automotive applications. Moreover, the renewable energy sector, particularly solar panel manufacturing, has emerged as a promising market for EVA. The material's use as an encapsulant in photovoltaic modules has grown substantially with the global push towards clean energy solutions.

Market analysts project a compound annual growth rate (CAGR) for the global EVA market in the mid-single digits over the next five years. This growth is attributed to the material's expanding applications across diverse industries and its ability to meet evolving consumer preferences for sustainable and high-performance products. The Asia-Pacific region is expected to dominate the market growth, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

EVA Technical Challenges

Despite its widespread use in consumer products, Ethylene Vinyl Acetate (EVA) faces several technical challenges that limit its full potential. One of the primary issues is its thermal stability. EVA tends to degrade at high temperatures, which can lead to the release of acetic acid and the formation of unsaturated compounds. This thermal degradation not only affects the material's physical properties but also raises concerns about its long-term durability in applications exposed to heat.

Another significant challenge is EVA's limited resistance to certain chemicals and solvents. While it performs well in many environments, it can be susceptible to degradation when exposed to specific organic solvents, oils, and hydrocarbons. This vulnerability restricts its use in certain industrial applications and necessitates careful consideration of the operating environment for EVA-based products.

The moisture absorption properties of EVA also present technical hurdles. Although EVA has good water vapor transmission rates, which can be beneficial in some applications, it can absorb moisture over time. This absorption can lead to changes in the material's physical properties, potentially affecting its performance and longevity in certain products, particularly those exposed to humid environments or water.

Achieving consistent and uniform foaming in EVA foam production is another technical challenge. The foaming process, crucial for applications like footwear and packaging, requires precise control of temperature, pressure, and chemical additives. Inconsistencies in this process can result in non-uniform cell structures, affecting the foam's performance characteristics such as cushioning, insulation, and overall quality.

The recyclability of EVA presents both environmental and technical challenges. While EVA is theoretically recyclable, the process is often complicated by the presence of additives and the material's cross-linked structure in many applications. Developing efficient and economically viable recycling methods for EVA-based products remains an ongoing challenge for the industry.

Lastly, the optimization of EVA's mechanical properties for specific applications continues to be a focus of research and development. Balancing properties such as flexibility, tensile strength, and impact resistance while maintaining other desirable characteristics like transparency or UV resistance often requires complex formulation and processing techniques. This challenge is particularly evident in emerging applications where EVA is being considered as a replacement for traditional materials.

Addressing these technical challenges is crucial for expanding the use of EVA in consumer products and industrial applications. Ongoing research in polymer science and materials engineering is focused on developing solutions to these issues, potentially leading to new grades of EVA with enhanced properties and broader applicability.

Another significant challenge is EVA's limited resistance to certain chemicals and solvents. While it performs well in many environments, it can be susceptible to degradation when exposed to specific organic solvents, oils, and hydrocarbons. This vulnerability restricts its use in certain industrial applications and necessitates careful consideration of the operating environment for EVA-based products.

The moisture absorption properties of EVA also present technical hurdles. Although EVA has good water vapor transmission rates, which can be beneficial in some applications, it can absorb moisture over time. This absorption can lead to changes in the material's physical properties, potentially affecting its performance and longevity in certain products, particularly those exposed to humid environments or water.

Achieving consistent and uniform foaming in EVA foam production is another technical challenge. The foaming process, crucial for applications like footwear and packaging, requires precise control of temperature, pressure, and chemical additives. Inconsistencies in this process can result in non-uniform cell structures, affecting the foam's performance characteristics such as cushioning, insulation, and overall quality.

The recyclability of EVA presents both environmental and technical challenges. While EVA is theoretically recyclable, the process is often complicated by the presence of additives and the material's cross-linked structure in many applications. Developing efficient and economically viable recycling methods for EVA-based products remains an ongoing challenge for the industry.

Lastly, the optimization of EVA's mechanical properties for specific applications continues to be a focus of research and development. Balancing properties such as flexibility, tensile strength, and impact resistance while maintaining other desirable characteristics like transparency or UV resistance often requires complex formulation and processing techniques. This challenge is particularly evident in emerging applications where EVA is being considered as a replacement for traditional materials.

Addressing these technical challenges is crucial for expanding the use of EVA in consumer products and industrial applications. Ongoing research in polymer science and materials engineering is focused on developing solutions to these issues, potentially leading to new grades of EVA with enhanced properties and broader applicability.

Current EVA Applications

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The ratio of ethylene to vinyl acetate in the copolymer can be varied to adjust its properties, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition can be adjusted to modify its characteristics, making it suitable for various applications in industries like packaging, footwear, and solar panels.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base for other adhesive systems. The vinyl acetate content can be adjusted to optimize adhesion strength and flexibility.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be crosslinked to improve its heat resistance and dimensional stability, making it suitable for applications in construction, automotive, and sports equipment industries.

- EVA in solar panel encapsulation: EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells from environmental factors. It helps improve the efficiency and longevity of photovoltaic modules by providing excellent adhesion to both glass and solar cells while maintaining flexibility to accommodate thermal expansion.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers to enhance its properties for specific applications. This includes the addition of fillers, crosslinking agents, or blending with other polymers to improve characteristics such as flame retardancy, impact resistance, or processability. These modifications expand the range of applications for EVA-based materials.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is commonly used in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and flexibility of EVA-based adhesives can be tailored by adjusting the vinyl acetate content and molecular weight.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and shock-absorbing characteristics. It is commonly used in the manufacture of shoe soles, sports equipment padding, and building insulation. The foam density and cell structure can be controlled to achieve desired properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is extensively used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. The material helps protect solar cells from environmental factors and ensures long-term performance of the modules. Additives can be incorporated to enhance UV stability and prevent yellowing.Expand Specific Solutions05 EVA in packaging and film applications

EVA is employed in the production of flexible packaging films and shrink wrap materials. Its properties such as clarity, flexibility, and heat-sealability make it suitable for food packaging, agricultural films, and stretch films. The material can be blended with other polymers or modified to enhance specific properties like barrier performance or printability.Expand Specific Solutions

Key EVA Manufacturers

The market for Ethylene Vinyl Acetate (EVA) is experiencing significant growth, driven by its versatile applications in consumer products. The industry is in a mature stage but continues to evolve with technological advancements. Major players like Celanese International Corp., China Petroleum & Chemical Corp., and Wacker Chemie AG are leading the market with their established production capabilities and research expertise. The global EVA market size is projected to expand further, fueled by increasing demand in sectors such as footwear, packaging, and solar panels. Technological innovations from companies like Velocys, Inc. and research institutions such as Tianjin University are enhancing EVA's properties and production efficiency, indicating a high level of technological maturity and ongoing development in the field.

Celanese International Corp.

Technical Solution: Celanese has developed advanced EVA copolymers with enhanced properties for various applications. Their VitalDose® EVA drug delivery technology offers controlled release of active pharmaceutical ingredients[1]. They've also introduced Ateva® EVA copolymers for flexible packaging, providing improved seal strength and hot tack performance[2]. Celanese's EVA innovations extend to solar panel encapsulants, offering increased durability and weather resistance for photovoltaic modules[3].

Strengths: Diverse product portfolio, strong R&D capabilities, global market presence. Weaknesses: Dependence on raw material prices, potential environmental concerns related to plastic production.

Wacker Chemie AG

Technical Solution: Wacker has developed VINNAPAS® EVA dispersions for adhesives and construction applications. Their technology focuses on improving adhesion, flexibility, and water resistance in various products[4]. Wacker's EVA innovations include specialty grades for 3D printing filaments, offering enhanced printability and mechanical properties[5]. They've also introduced EVA-based binders for lithium-ion battery electrodes, improving battery performance and durability[6].

Strengths: Strong focus on specialty chemicals, extensive R&D capabilities, global market presence. Weaknesses: Exposure to cyclical markets, potential regulatory challenges in chemical industry.

EVA Innovation Patents

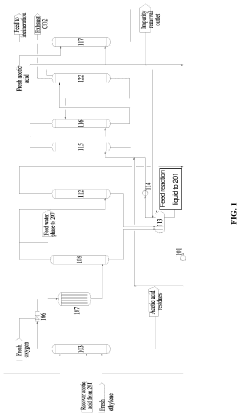

Process and apparatus for improved methods for making vinyl acetate monomer (VAM)

PatentWO2006052615A1

Innovation

- A method involving a catalyst-containing reaction channel where ethylene, acetic acid, and oxygen are passed through to form vinyl acetate monomer, with specific conditions ensuring at least 20% ethylene conversion to vinyl acetate or carbon dioxide, and at least 40% acetic acid conversion, in a single pass, using a micochannel reactor design with staged addition and efficient heat management.

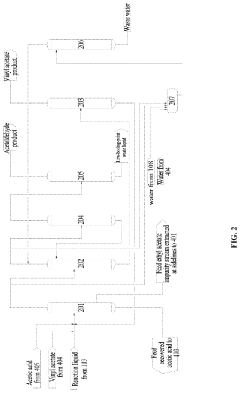

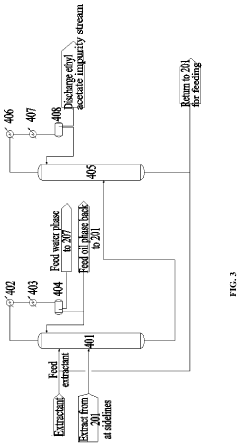

Method for producing vinyl acetate

PatentActiveUS20230312452A1

Innovation

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

EVA Environmental Impact

The environmental impact of Ethylene Vinyl Acetate (EVA) is a critical consideration as its use in consumer products continues to expand. EVA, a copolymer of ethylene and vinyl acetate, offers numerous benefits in terms of flexibility, durability, and cost-effectiveness. However, its widespread adoption also raises concerns about its ecological footprint throughout its lifecycle.

One of the primary environmental challenges associated with EVA is its production process. The manufacturing of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to carbon emissions and the depletion of finite resources. Additionally, the production process may release volatile organic compounds (VOCs) and other pollutants, potentially impacting air quality in surrounding areas.

The durability of EVA, while beneficial for product longevity, presents a double-edged sword from an environmental perspective. On one hand, products made with EVA tend to last longer, reducing the need for frequent replacements and potentially decreasing overall waste. On the other hand, this durability means that EVA products can persist in the environment for extended periods when discarded improperly.

Recycling EVA presents both opportunities and challenges. While technically recyclable, the process is not as straightforward as with some other materials. EVA's cross-linked structure can make it difficult to break down and reprocess effectively. Furthermore, the presence of additives and other materials in EVA-based products can complicate recycling efforts, often leading to downcycling rather than true recycling.

The end-of-life disposal of EVA products is another area of environmental concern. When incinerated, EVA can release harmful emissions, including carbon dioxide and potentially toxic compounds. If sent to landfills, EVA products contribute to the growing problem of plastic waste accumulation, as they do not biodegrade readily.

However, it's important to note that ongoing research and development efforts are focused on mitigating these environmental impacts. Innovations in bio-based EVA formulations, using renewable resources as feedstock, show promise in reducing the carbon footprint of production. Additionally, advancements in recycling technologies are improving the ability to recover and reuse EVA materials more effectively.

The environmental impact of EVA also varies depending on its specific application. In some cases, the use of EVA can lead to positive environmental outcomes. For instance, in solar panel encapsulation, EVA plays a crucial role in extending the lifespan of photovoltaic cells, thereby supporting the growth of renewable energy technologies.

As the use of EVA in consumer products continues to grow, balancing its performance benefits with environmental considerations becomes increasingly important. This necessitates a holistic approach, considering the entire lifecycle of EVA-based products from production to disposal, and driving innovations that can minimize negative environmental impacts while maximizing the material's beneficial properties.

One of the primary environmental challenges associated with EVA is its production process. The manufacturing of EVA involves the use of petrochemical feedstocks, which are derived from non-renewable resources. This reliance on fossil fuels contributes to carbon emissions and the depletion of finite resources. Additionally, the production process may release volatile organic compounds (VOCs) and other pollutants, potentially impacting air quality in surrounding areas.

The durability of EVA, while beneficial for product longevity, presents a double-edged sword from an environmental perspective. On one hand, products made with EVA tend to last longer, reducing the need for frequent replacements and potentially decreasing overall waste. On the other hand, this durability means that EVA products can persist in the environment for extended periods when discarded improperly.

Recycling EVA presents both opportunities and challenges. While technically recyclable, the process is not as straightforward as with some other materials. EVA's cross-linked structure can make it difficult to break down and reprocess effectively. Furthermore, the presence of additives and other materials in EVA-based products can complicate recycling efforts, often leading to downcycling rather than true recycling.

The end-of-life disposal of EVA products is another area of environmental concern. When incinerated, EVA can release harmful emissions, including carbon dioxide and potentially toxic compounds. If sent to landfills, EVA products contribute to the growing problem of plastic waste accumulation, as they do not biodegrade readily.

However, it's important to note that ongoing research and development efforts are focused on mitigating these environmental impacts. Innovations in bio-based EVA formulations, using renewable resources as feedstock, show promise in reducing the carbon footprint of production. Additionally, advancements in recycling technologies are improving the ability to recover and reuse EVA materials more effectively.

The environmental impact of EVA also varies depending on its specific application. In some cases, the use of EVA can lead to positive environmental outcomes. For instance, in solar panel encapsulation, EVA plays a crucial role in extending the lifespan of photovoltaic cells, thereby supporting the growth of renewable energy technologies.

As the use of EVA in consumer products continues to grow, balancing its performance benefits with environmental considerations becomes increasingly important. This necessitates a holistic approach, considering the entire lifecycle of EVA-based products from production to disposal, and driving innovations that can minimize negative environmental impacts while maximizing the material's beneficial properties.

EVA Regulatory Landscape

The regulatory landscape for Ethylene Vinyl Acetate (EVA) is complex and multifaceted, reflecting the material's widespread use in consumer products across various industries. As EVA continues to transform consumer goods, regulatory bodies worldwide have implemented stringent guidelines to ensure product safety and environmental sustainability.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA's use in food contact materials. The FDA has established specific regulations under 21 CFR 177.1350, which outline the conditions under which EVA can be safely used in food packaging and processing equipment. These regulations specify the permissible composition of EVA copolymers and set limits on extractives to prevent potential contamination of food products.

The European Union has implemented comprehensive regulations through the European Chemicals Agency (ECHA) under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) framework. This system requires manufacturers and importers of EVA to register their substances and provide detailed safety information. Additionally, the EU has specific directives for food contact materials, such as Regulation (EC) No 1935/2004, which sets general principles for all materials that come into contact with food.

In the realm of toy safety, regulatory bodies have imposed strict standards on the use of EVA. The U.S. Consumer Product Safety Commission (CPSC) enforces the Consumer Product Safety Improvement Act (CPSIA), which includes limits on phthalates and other potentially harmful substances in children's toys and childcare articles. Similarly, the EU's Toy Safety Directive 2009/48/EC sets stringent requirements for toys containing EVA, particularly concerning chemical properties and flammability.

Environmental regulations also significantly impact the EVA industry. Many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations aim to promote sustainable practices and reduce the environmental impact of EVA-based products.

As the use of EVA in renewable energy applications grows, particularly in solar panel encapsulation, new regulatory challenges emerge. Governments worldwide are developing standards for the durability, performance, and end-of-life management of solar panels, which directly affect EVA manufacturers and users in this sector.

The global nature of EVA production and trade necessitates compliance with international trade regulations. The World Trade Organization (WTO) plays a role in harmonizing standards and resolving trade disputes related to EVA and its applications. Additionally, regional trade agreements often include provisions that affect the production, import, and export of EVA-based products.

As consumer awareness of environmental and health issues increases, many countries are implementing more stringent labeling requirements for products containing EVA. These regulations aim to provide consumers with transparent information about product composition and potential risks, further shaping the regulatory landscape for EVA in consumer products.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA's use in food contact materials. The FDA has established specific regulations under 21 CFR 177.1350, which outline the conditions under which EVA can be safely used in food packaging and processing equipment. These regulations specify the permissible composition of EVA copolymers and set limits on extractives to prevent potential contamination of food products.

The European Union has implemented comprehensive regulations through the European Chemicals Agency (ECHA) under the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) framework. This system requires manufacturers and importers of EVA to register their substances and provide detailed safety information. Additionally, the EU has specific directives for food contact materials, such as Regulation (EC) No 1935/2004, which sets general principles for all materials that come into contact with food.

In the realm of toy safety, regulatory bodies have imposed strict standards on the use of EVA. The U.S. Consumer Product Safety Commission (CPSC) enforces the Consumer Product Safety Improvement Act (CPSIA), which includes limits on phthalates and other potentially harmful substances in children's toys and childcare articles. Similarly, the EU's Toy Safety Directive 2009/48/EC sets stringent requirements for toys containing EVA, particularly concerning chemical properties and flammability.

Environmental regulations also significantly impact the EVA industry. Many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations aim to promote sustainable practices and reduce the environmental impact of EVA-based products.

As the use of EVA in renewable energy applications grows, particularly in solar panel encapsulation, new regulatory challenges emerge. Governments worldwide are developing standards for the durability, performance, and end-of-life management of solar panels, which directly affect EVA manufacturers and users in this sector.

The global nature of EVA production and trade necessitates compliance with international trade regulations. The World Trade Organization (WTO) plays a role in harmonizing standards and resolving trade disputes related to EVA and its applications. Additionally, regional trade agreements often include provisions that affect the production, import, and export of EVA-based products.

As consumer awareness of environmental and health issues increases, many countries are implementing more stringent labeling requirements for products containing EVA. These regulations aim to provide consumers with transparent information about product composition and potential risks, further shaping the regulatory landscape for EVA in consumer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!