New Frontiers for Ethylene Vinyl Acetate in Biotechnology

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Biotech: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile material with significant potential in biotechnology applications. Historically, EVA has been widely used in various industries, including packaging, footwear, and solar panel encapsulation. However, its unique properties have recently caught the attention of biotech researchers and innovators, opening up new frontiers for exploration and development.

The evolution of EVA in biotechnology can be traced back to its initial use in medical devices and drug delivery systems. Its biocompatibility, flexibility, and ability to be easily molded into various shapes made it an attractive option for these applications. As research progressed, scientists began to recognize EVA's potential in more advanced biotechnological applications, such as tissue engineering, biosensors, and microfluidic devices.

The current technological landscape sees EVA at the intersection of materials science and biotechnology. Its properties, including low melting point, excellent flexibility, and resistance to stress-cracking, make it an ideal candidate for various biotech applications. The material's ability to be easily modified and functionalized further enhances its potential in this field.

One of the primary objectives in exploring new frontiers for EVA in biotechnology is to develop novel biomaterials with enhanced properties. Researchers aim to create EVA-based composites that can mimic natural tissues, provide controlled release of bioactive compounds, or serve as scaffolds for cell growth and tissue regeneration. These advancements could revolutionize areas such as regenerative medicine and personalized healthcare.

Another key goal is to leverage EVA's unique characteristics to create innovative biomedical devices and diagnostic tools. The material's flexibility and durability make it suitable for wearable biosensors and implantable devices, while its barrier properties can be exploited for developing advanced drug delivery systems. The potential for EVA in microfluidic devices also opens up possibilities for lab-on-a-chip technologies and point-of-care diagnostics.

As research in this field progresses, there is a growing focus on understanding and optimizing EVA's interactions with biological systems. This includes studying its biocompatibility at a molecular level, exploring ways to enhance its biodegradability, and investigating methods to functionalize its surface for specific biotechnological applications. These efforts aim to expand the material's utility while ensuring its safety and efficacy in biological environments.

The exploration of EVA in biotechnology also aligns with broader trends in sustainable and eco-friendly materials. As the biotech industry increasingly emphasizes green technologies, researchers are investigating ways to make EVA more environmentally friendly, potentially through the incorporation of bio-based components or the development of biodegradable EVA variants.

The evolution of EVA in biotechnology can be traced back to its initial use in medical devices and drug delivery systems. Its biocompatibility, flexibility, and ability to be easily molded into various shapes made it an attractive option for these applications. As research progressed, scientists began to recognize EVA's potential in more advanced biotechnological applications, such as tissue engineering, biosensors, and microfluidic devices.

The current technological landscape sees EVA at the intersection of materials science and biotechnology. Its properties, including low melting point, excellent flexibility, and resistance to stress-cracking, make it an ideal candidate for various biotech applications. The material's ability to be easily modified and functionalized further enhances its potential in this field.

One of the primary objectives in exploring new frontiers for EVA in biotechnology is to develop novel biomaterials with enhanced properties. Researchers aim to create EVA-based composites that can mimic natural tissues, provide controlled release of bioactive compounds, or serve as scaffolds for cell growth and tissue regeneration. These advancements could revolutionize areas such as regenerative medicine and personalized healthcare.

Another key goal is to leverage EVA's unique characteristics to create innovative biomedical devices and diagnostic tools. The material's flexibility and durability make it suitable for wearable biosensors and implantable devices, while its barrier properties can be exploited for developing advanced drug delivery systems. The potential for EVA in microfluidic devices also opens up possibilities for lab-on-a-chip technologies and point-of-care diagnostics.

As research in this field progresses, there is a growing focus on understanding and optimizing EVA's interactions with biological systems. This includes studying its biocompatibility at a molecular level, exploring ways to enhance its biodegradability, and investigating methods to functionalize its surface for specific biotechnological applications. These efforts aim to expand the material's utility while ensuring its safety and efficacy in biological environments.

The exploration of EVA in biotechnology also aligns with broader trends in sustainable and eco-friendly materials. As the biotech industry increasingly emphasizes green technologies, researchers are investigating ways to make EVA more environmentally friendly, potentially through the incorporation of bio-based components or the development of biodegradable EVA variants.

Market Analysis for EVA in Biotechnology

The market for Ethylene Vinyl Acetate (EVA) in biotechnology is experiencing significant growth and transformation. This versatile copolymer, known for its flexibility, durability, and biocompatibility, is finding new applications across various biotech sectors. The global EVA market in biotechnology is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026, driven by increasing demand in medical devices, drug delivery systems, and tissue engineering.

In the medical device sector, EVA is gaining traction due to its excellent properties for manufacturing catheters, tubing, and disposable medical equipment. The material's resistance to chemical degradation and its ability to be sterilized without losing its physical properties make it an ideal choice for these applications. The growing prevalence of chronic diseases and the aging population are fueling the demand for such medical devices, consequently boosting the EVA market.

Drug delivery systems represent another significant growth area for EVA in biotechnology. The polymer's controlled release properties make it suitable for transdermal patches, implants, and other drug delivery mechanisms. As the pharmaceutical industry continues to focus on developing targeted and sustained-release therapies, the demand for EVA in this segment is expected to rise substantially.

Tissue engineering is an emerging field where EVA is showing promise. Its biocompatibility and ability to be molded into various shapes make it an attractive material for scaffolds in tissue regeneration applications. Research in this area is still in its early stages, but the potential market for EVA in tissue engineering is substantial, with experts predicting rapid growth in the coming years.

The Asia-Pacific region is anticipated to be the fastest-growing market for EVA in biotechnology, driven by increasing healthcare expenditure, growing medical tourism, and the expansion of the biotechnology sector in countries like China and India. North America and Europe continue to be significant markets, with a focus on advanced medical technologies and a strong presence of biotechnology companies.

However, the market faces challenges such as stringent regulatory requirements for medical-grade materials and competition from alternative polymers. Manufacturers are investing in research and development to enhance the properties of EVA and expand its applications in biotechnology, which is expected to create new market opportunities.

In conclusion, the market for EVA in biotechnology is poised for substantial growth, driven by its versatility and the expanding applications in medical devices, drug delivery, and tissue engineering. As research continues and new applications emerge, EVA is likely to play an increasingly important role in the biotechnology sector, offering innovative solutions to complex biomedical challenges.

In the medical device sector, EVA is gaining traction due to its excellent properties for manufacturing catheters, tubing, and disposable medical equipment. The material's resistance to chemical degradation and its ability to be sterilized without losing its physical properties make it an ideal choice for these applications. The growing prevalence of chronic diseases and the aging population are fueling the demand for such medical devices, consequently boosting the EVA market.

Drug delivery systems represent another significant growth area for EVA in biotechnology. The polymer's controlled release properties make it suitable for transdermal patches, implants, and other drug delivery mechanisms. As the pharmaceutical industry continues to focus on developing targeted and sustained-release therapies, the demand for EVA in this segment is expected to rise substantially.

Tissue engineering is an emerging field where EVA is showing promise. Its biocompatibility and ability to be molded into various shapes make it an attractive material for scaffolds in tissue regeneration applications. Research in this area is still in its early stages, but the potential market for EVA in tissue engineering is substantial, with experts predicting rapid growth in the coming years.

The Asia-Pacific region is anticipated to be the fastest-growing market for EVA in biotechnology, driven by increasing healthcare expenditure, growing medical tourism, and the expansion of the biotechnology sector in countries like China and India. North America and Europe continue to be significant markets, with a focus on advanced medical technologies and a strong presence of biotechnology companies.

However, the market faces challenges such as stringent regulatory requirements for medical-grade materials and competition from alternative polymers. Manufacturers are investing in research and development to enhance the properties of EVA and expand its applications in biotechnology, which is expected to create new market opportunities.

In conclusion, the market for EVA in biotechnology is poised for substantial growth, driven by its versatility and the expanding applications in medical devices, drug delivery, and tissue engineering. As research continues and new applications emerge, EVA is likely to play an increasingly important role in the biotechnology sector, offering innovative solutions to complex biomedical challenges.

Current Challenges in EVA Biotech Applications

Despite the promising potential of Ethylene Vinyl Acetate (EVA) in biotechnology applications, several significant challenges currently hinder its widespread adoption and optimal utilization in this field. One of the primary obstacles is the limited biocompatibility of standard EVA formulations. While EVA is generally considered non-toxic, its interaction with biological systems can sometimes lead to undesired immune responses or inflammation, particularly in long-term implantable devices or tissue engineering scaffolds.

Another critical challenge lies in the controlled release of bioactive compounds from EVA matrices. Although EVA's semi-crystalline structure allows for drug encapsulation, achieving precise and sustained release profiles remains difficult. This is particularly problematic for applications requiring long-term, steady-state drug delivery, such as in chronic disease management or regenerative medicine.

The mechanical properties of EVA also present challenges in certain biotech applications. While its flexibility is advantageous in many scenarios, it may lack the necessary strength or durability for load-bearing implants or high-stress environments within the body. Balancing the trade-off between flexibility and mechanical strength without compromising biocompatibility is an ongoing challenge for researchers and engineers.

Surface modification of EVA for enhanced cell adhesion and tissue integration is another area of difficulty. The relatively inert nature of EVA's surface can impede cell attachment and proliferation, which is crucial for tissue engineering and regenerative medicine applications. Developing effective and stable surface modification techniques that do not compromise the bulk properties of EVA remains a significant challenge.

Furthermore, the sterilization of EVA-based biomedical devices poses unique challenges. Common sterilization methods such as ethylene oxide treatment or gamma irradiation can potentially alter the material properties of EVA, affecting its performance and longevity in biological environments. Finding sterilization techniques that are both effective and minimally disruptive to EVA's structure is an ongoing area of research.

Lastly, the regulatory landscape for EVA in biotechnology applications presents hurdles for researchers and companies. As a relatively new material in this field, EVA-based products often face stringent regulatory scrutiny, requiring extensive testing and validation to ensure safety and efficacy. This can significantly extend development timelines and increase costs, potentially slowing innovation and market entry for novel EVA-based biotech solutions.

Another critical challenge lies in the controlled release of bioactive compounds from EVA matrices. Although EVA's semi-crystalline structure allows for drug encapsulation, achieving precise and sustained release profiles remains difficult. This is particularly problematic for applications requiring long-term, steady-state drug delivery, such as in chronic disease management or regenerative medicine.

The mechanical properties of EVA also present challenges in certain biotech applications. While its flexibility is advantageous in many scenarios, it may lack the necessary strength or durability for load-bearing implants or high-stress environments within the body. Balancing the trade-off between flexibility and mechanical strength without compromising biocompatibility is an ongoing challenge for researchers and engineers.

Surface modification of EVA for enhanced cell adhesion and tissue integration is another area of difficulty. The relatively inert nature of EVA's surface can impede cell attachment and proliferation, which is crucial for tissue engineering and regenerative medicine applications. Developing effective and stable surface modification techniques that do not compromise the bulk properties of EVA remains a significant challenge.

Furthermore, the sterilization of EVA-based biomedical devices poses unique challenges. Common sterilization methods such as ethylene oxide treatment or gamma irradiation can potentially alter the material properties of EVA, affecting its performance and longevity in biological environments. Finding sterilization techniques that are both effective and minimally disruptive to EVA's structure is an ongoing area of research.

Lastly, the regulatory landscape for EVA in biotechnology applications presents hurdles for researchers and companies. As a relatively new material in this field, EVA-based products often face stringent regulatory scrutiny, requiring extensive testing and validation to ensure safety and efficacy. This can significantly extend development timelines and increase costs, potentially slowing innovation and market entry for novel EVA-based biotech solutions.

Current EVA Solutions in Biotechnology

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for a wide range of applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The material's low melting point and good flow characteristics make it ideal for these applications.

- EVA in foam and insulation products: EVA is utilized in the production of foam and insulation materials due to its closed-cell structure and low thermal conductivity. It is commonly used in footwear, sports equipment, and building insulation. The material's lightweight nature and shock-absorbing properties make it particularly suitable for these applications.

- EVA in solar panel encapsulation: EVA is a preferred material for solar panel encapsulation due to its transparency, weather resistance, and electrical insulation properties. It helps protect solar cells from environmental factors and ensures long-term performance of photovoltaic modules. The material's ability to withstand UV radiation makes it particularly suitable for this application.

- EVA in packaging and film applications: EVA is extensively used in packaging and film applications due to its flexibility, clarity, and barrier properties. It is commonly used in food packaging, shrink wrap, and agricultural films. The material's low-temperature toughness and resistance to cracking make it suitable for various packaging needs.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, providing good bond strength and flexibility. EVA-based adhesives find applications in packaging, bookbinding, and product assembly.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. EVA foams offer good shock absorption and cushioning properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. EVA encapsulants help protect solar cells from environmental factors and enhance the overall performance and durability of solar panels.Expand Specific Solutions05 Modifications and blends of EVA

EVA can be modified or blended with other materials to enhance its properties or create new functionalities. This includes crosslinking, grafting, or blending with other polymers or additives. Such modifications can improve thermal stability, mechanical properties, or introduce specific characteristics for targeted applications.Expand Specific Solutions

Key Players in EVA Biotech Industry

The ethylene vinyl acetate (EVA) market in biotechnology is in an early growth stage, with increasing applications and market potential. The global market size for EVA in biotech is expanding, driven by its versatility and biocompatibility. While the technology is still evolving, several key players are advancing its development. Companies like China Petroleum & Chemical Corp., Celanese International Corp., and DSM IP Assets BV are leveraging their expertise in materials science to explore EVA's potential in drug delivery and tissue engineering. Emerging biotech firms such as Evox Therapeutics and Anjarium Biosciences are investigating EVA-based nanoparticle systems for gene therapies. Academic institutions like Tianjin University and the University of Porto are contributing to fundamental research, enhancing the technology's maturity and expanding its applications in the biotechnology sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA copolymers with tailored properties for biotechnology applications. Their research focuses on creating EVA materials with controlled vinyl acetate content and molecular weight distribution, optimizing biocompatibility and mechanical properties[1]. Sinopec's EVA innovations include nanocomposite formulations that enhance drug delivery efficiency and controlled release profiles in pharmaceutical applications[2]. They have also engineered EVA-based scaffolds for tissue engineering, incorporating bioactive molecules to promote cell adhesion and proliferation[3]. Sinopec's approach combines polymer science with biotechnology to create versatile EVA materials that address specific challenges in drug delivery, tissue engineering, and biosensors.

Strengths: Extensive polymer expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Relatively new entrant in biotechnology applications, potential regulatory hurdles in transitioning from petrochemicals to biomedical materials.

Celanese International Corp.

Technical Solution: Celanese has developed a range of specialized EVA copolymers for biotechnology applications, focusing on their VitalDose® EVA drug delivery platform. This technology allows for customizable drug release profiles by adjusting the vinyl acetate content and molecular weight of the EVA copolymer[1]. Celanese has engineered EVA formulations with enhanced biocompatibility and stability for long-term implantable devices[2]. Their research also extends to EVA-based microfluidic devices for lab-on-a-chip applications, leveraging the material's flexibility and chemical resistance[3]. Celanese's approach combines polymer engineering with pharmaceutical expertise to create EVA solutions that address specific challenges in controlled release, implantable devices, and diagnostic platforms.

Strengths: Established presence in medical-grade polymers, strong intellectual property portfolio, and expertise in regulatory compliance for medical materials. Weaknesses: Limited experience in more advanced biotechnology applications beyond drug delivery.

Innovative EVA Biotech Patents and Research

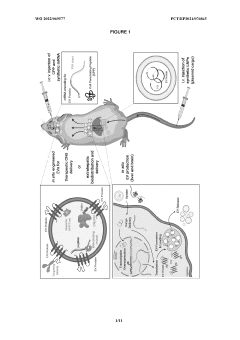

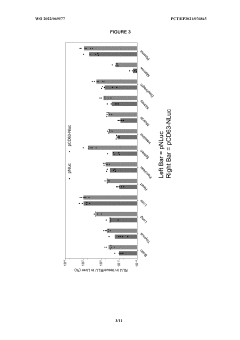

Engineered extracellular vesicles displaying enhanced pharmacokinetics

PatentWO2022069577A1

Innovation

- In vivo production of genetically engineered EVs using a polynucleotide cargo that encodes for a fusion protein, allowing for autologous, patient-specific EVs with extended half-life and improved biodistribution by leveraging the patient's cellular machinery for production, avoiding ex vivo purification damages and ensuring a wide range of cargo loading capabilities.

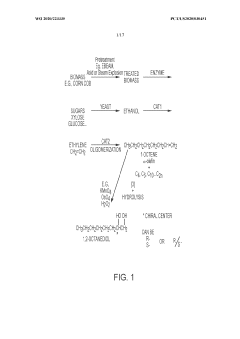

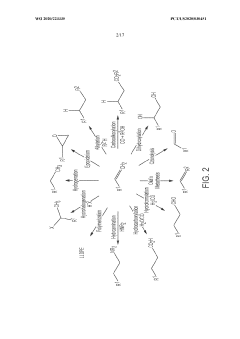

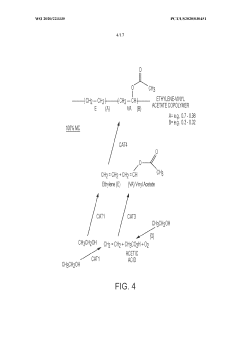

BIO-based ethylene for the production of BIO-based polymers, copolymers, and other BIO-based chemical compounds

PatentWO2020223335A1

Innovation

- Bio-based ethylene is produced from biomass sources such as lignocellulosic or starchy materials through ethanol dehydration, allowing for the creation of a variety of bio-based chemical compounds and polymers with high modern carbon content, reducing fossil fuel consumption and greenhouse gas emissions.

Regulatory Landscape for EVA in Biotech

The regulatory landscape for Ethylene Vinyl Acetate (EVA) in biotechnology is complex and evolving, reflecting the increasing use of this versatile material in biomedical applications. As EVA finds new frontiers in biotechnology, regulatory bodies worldwide are adapting their frameworks to ensure safety and efficacy while fostering innovation.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA-based products in biotechnology. The FDA's approach varies depending on the specific application, with medical devices incorporating EVA falling under the purview of the Center for Devices and Radiological Health (CDRH). The regulatory pathway for these devices depends on their classification, which is determined by the level of risk associated with their use.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have significant implications for EVA-based products in biotechnology, imposing stricter requirements for clinical evidence, post-market surveillance, and traceability.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of EVA-based biotech products. The Japanese regulatory framework emphasizes the importance of quality management systems and post-market vigilance, aligning with global trends in medical device regulation.

Emerging markets, such as China and India, are also developing their regulatory frameworks to address the growing use of EVA in biotechnology. China's National Medical Products Administration (NMPA) has been refining its regulations to streamline the approval process for innovative medical devices, including those utilizing EVA.

A key regulatory focus across jurisdictions is the biocompatibility of EVA when used in medical applications. Regulatory bodies require extensive testing to ensure that EVA-based products do not elicit adverse biological responses when in contact with human tissues or fluids. This includes evaluations for cytotoxicity, sensitization, and potential leaching of compounds.

Environmental regulations are also becoming increasingly relevant for EVA in biotechnology. As sustainability concerns grow, regulators are paying closer attention to the lifecycle of EVA-based products, including their production, use, and disposal. This has led to a push for more environmentally friendly formulations and recycling initiatives within the industry.

The regulatory landscape for EVA in biotechnology is characterized by a trend towards harmonization of standards across different regions. Initiatives such as the International Medical Device Regulators Forum (IMDRF) are working to promote global convergence in medical device regulation, which will impact EVA-based products. This harmonization aims to reduce regulatory barriers and facilitate faster access to innovative biotech solutions worldwide.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA-based products in biotechnology. The FDA's approach varies depending on the specific application, with medical devices incorporating EVA falling under the purview of the Center for Devices and Radiological Health (CDRH). The regulatory pathway for these devices depends on their classification, which is determined by the level of risk associated with their use.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have significant implications for EVA-based products in biotechnology, imposing stricter requirements for clinical evidence, post-market surveillance, and traceability.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of EVA-based biotech products. The Japanese regulatory framework emphasizes the importance of quality management systems and post-market vigilance, aligning with global trends in medical device regulation.

Emerging markets, such as China and India, are also developing their regulatory frameworks to address the growing use of EVA in biotechnology. China's National Medical Products Administration (NMPA) has been refining its regulations to streamline the approval process for innovative medical devices, including those utilizing EVA.

A key regulatory focus across jurisdictions is the biocompatibility of EVA when used in medical applications. Regulatory bodies require extensive testing to ensure that EVA-based products do not elicit adverse biological responses when in contact with human tissues or fluids. This includes evaluations for cytotoxicity, sensitization, and potential leaching of compounds.

Environmental regulations are also becoming increasingly relevant for EVA in biotechnology. As sustainability concerns grow, regulators are paying closer attention to the lifecycle of EVA-based products, including their production, use, and disposal. This has led to a push for more environmentally friendly formulations and recycling initiatives within the industry.

The regulatory landscape for EVA in biotechnology is characterized by a trend towards harmonization of standards across different regions. Initiatives such as the International Medical Device Regulators Forum (IMDRF) are working to promote global convergence in medical device regulation, which will impact EVA-based products. This harmonization aims to reduce regulatory barriers and facilitate faster access to innovative biotech solutions worldwide.

Environmental Impact of EVA in Biotechnology

The environmental impact of Ethylene Vinyl Acetate (EVA) in biotechnology is a critical consideration as this versatile copolymer finds new applications in the field. EVA's unique properties, such as biocompatibility and flexibility, make it an attractive material for various biotechnological applications. However, its widespread use raises concerns about its environmental footprint throughout its lifecycle.

One of the primary environmental considerations is the production process of EVA. The synthesis of EVA involves the use of petroleum-based raw materials, which contributes to the depletion of non-renewable resources and generates greenhouse gas emissions. The polymerization process also requires significant energy input, further adding to its carbon footprint. However, ongoing research is focused on developing more sustainable production methods, including the use of bio-based feedstocks and energy-efficient manufacturing processes.

In biotechnological applications, EVA's durability and resistance to degradation can be both an advantage and a potential environmental concern. While these properties ensure long-lasting performance in medical devices and drug delivery systems, they also mean that EVA products may persist in the environment for extended periods if not properly disposed of or recycled. This persistence raises questions about the potential accumulation of EVA-based materials in ecosystems and their long-term effects on wildlife and habitats.

The recyclability of EVA is another crucial aspect of its environmental impact. Unlike some other polymers, EVA can be recycled through various methods, including mechanical recycling and chemical decomposition. However, the recycling process for EVA used in biotechnology applications may be complicated by the presence of biological materials or other additives, potentially limiting the recyclability of these products.

As EVA finds new frontiers in biotechnology, there is a growing emphasis on developing biodegradable or bio-based alternatives. Research is underway to create EVA-like materials that maintain the desired properties for biotechnological applications while offering improved environmental profiles. These efforts include the incorporation of natural polymers or the development of synthetic polymers that can degrade under specific environmental conditions.

The use of EVA in biotechnology also presents opportunities for positive environmental impacts. For instance, EVA-based materials used in agricultural biotechnology can help reduce the use of pesticides and improve crop yields, potentially leading to more sustainable farming practices. Similarly, EVA's application in water treatment technologies could contribute to more efficient and environmentally friendly water purification processes.

In conclusion, while EVA offers significant benefits in biotechnology, its environmental impact remains a complex issue. Balancing the material's performance advantages with environmental considerations will be crucial as the biotechnology sector continues to expand its use of EVA. Ongoing research and development efforts are focused on addressing these challenges, aiming to create more sustainable EVA-based solutions for the future of biotechnology.

One of the primary environmental considerations is the production process of EVA. The synthesis of EVA involves the use of petroleum-based raw materials, which contributes to the depletion of non-renewable resources and generates greenhouse gas emissions. The polymerization process also requires significant energy input, further adding to its carbon footprint. However, ongoing research is focused on developing more sustainable production methods, including the use of bio-based feedstocks and energy-efficient manufacturing processes.

In biotechnological applications, EVA's durability and resistance to degradation can be both an advantage and a potential environmental concern. While these properties ensure long-lasting performance in medical devices and drug delivery systems, they also mean that EVA products may persist in the environment for extended periods if not properly disposed of or recycled. This persistence raises questions about the potential accumulation of EVA-based materials in ecosystems and their long-term effects on wildlife and habitats.

The recyclability of EVA is another crucial aspect of its environmental impact. Unlike some other polymers, EVA can be recycled through various methods, including mechanical recycling and chemical decomposition. However, the recycling process for EVA used in biotechnology applications may be complicated by the presence of biological materials or other additives, potentially limiting the recyclability of these products.

As EVA finds new frontiers in biotechnology, there is a growing emphasis on developing biodegradable or bio-based alternatives. Research is underway to create EVA-like materials that maintain the desired properties for biotechnological applications while offering improved environmental profiles. These efforts include the incorporation of natural polymers or the development of synthetic polymers that can degrade under specific environmental conditions.

The use of EVA in biotechnology also presents opportunities for positive environmental impacts. For instance, EVA-based materials used in agricultural biotechnology can help reduce the use of pesticides and improve crop yields, potentially leading to more sustainable farming practices. Similarly, EVA's application in water treatment technologies could contribute to more efficient and environmentally friendly water purification processes.

In conclusion, while EVA offers significant benefits in biotechnology, its environmental impact remains a complex issue. Balancing the material's performance advantages with environmental considerations will be crucial as the biotechnology sector continues to expand its use of EVA. Ongoing research and development efforts are focused on addressing these challenges, aiming to create more sustainable EVA-based solutions for the future of biotechnology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!