How to Gain Competitive Edges with Ethylene Vinyl Acetate?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Technology Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile and essential material in various industries over the past few decades. The technology behind EVA production and application has evolved significantly, driven by the growing demand for high-performance, cost-effective materials in sectors such as packaging, footwear, solar panels, and automotive components.

The development of EVA technology can be traced back to the 1950s when researchers at DuPont first synthesized this copolymer. Since then, continuous improvements in polymerization techniques, additives, and processing methods have led to a wide range of EVA grades with tailored properties. The primary objective of EVA technology has been to create a material that combines the flexibility and elasticity of rubber with the processability and cost-effectiveness of thermoplastics.

In recent years, the focus of EVA technology has shifted towards enhancing specific properties to meet the demands of emerging applications. For instance, in the solar industry, EVA encapsulants with improved UV resistance and moisture barrier properties have been developed to extend the lifespan of photovoltaic modules. Similarly, in the footwear sector, EVA foams with enhanced cushioning and durability have been engineered to meet the requirements of high-performance athletic shoes.

The current technological landscape of EVA is characterized by a push towards sustainability and circular economy principles. Researchers and manufacturers are exploring bio-based feedstocks for EVA production, as well as developing more efficient recycling processes for EVA-containing products. This aligns with the global trend towards reducing carbon footprint and minimizing environmental impact across industries.

Another significant trend in EVA technology is the integration of nanotechnology and advanced composite materials. By incorporating nanofillers or blending EVA with other polymers, researchers aim to create hybrid materials with superior mechanical, thermal, and barrier properties. This approach opens up new possibilities for EVA in high-value applications such as aerospace components and advanced medical devices.

The overarching goal of current EVA technology development is to gain competitive edges in various markets by offering tailored solutions that address specific industry challenges. This involves not only improving the material properties but also optimizing production processes to enhance cost-effectiveness and scalability. As such, research efforts are focused on developing novel catalysts for more efficient polymerization, exploring new additives for property enhancement, and refining processing techniques for better control over the final product characteristics.

In conclusion, the evolution of EVA technology reflects a continuous pursuit of innovation to meet changing market demands and address emerging challenges. By understanding this technological trajectory and aligning research and development efforts with future trends, companies can position themselves to gain significant competitive advantages in the dynamic landscape of EVA applications.

The development of EVA technology can be traced back to the 1950s when researchers at DuPont first synthesized this copolymer. Since then, continuous improvements in polymerization techniques, additives, and processing methods have led to a wide range of EVA grades with tailored properties. The primary objective of EVA technology has been to create a material that combines the flexibility and elasticity of rubber with the processability and cost-effectiveness of thermoplastics.

In recent years, the focus of EVA technology has shifted towards enhancing specific properties to meet the demands of emerging applications. For instance, in the solar industry, EVA encapsulants with improved UV resistance and moisture barrier properties have been developed to extend the lifespan of photovoltaic modules. Similarly, in the footwear sector, EVA foams with enhanced cushioning and durability have been engineered to meet the requirements of high-performance athletic shoes.

The current technological landscape of EVA is characterized by a push towards sustainability and circular economy principles. Researchers and manufacturers are exploring bio-based feedstocks for EVA production, as well as developing more efficient recycling processes for EVA-containing products. This aligns with the global trend towards reducing carbon footprint and minimizing environmental impact across industries.

Another significant trend in EVA technology is the integration of nanotechnology and advanced composite materials. By incorporating nanofillers or blending EVA with other polymers, researchers aim to create hybrid materials with superior mechanical, thermal, and barrier properties. This approach opens up new possibilities for EVA in high-value applications such as aerospace components and advanced medical devices.

The overarching goal of current EVA technology development is to gain competitive edges in various markets by offering tailored solutions that address specific industry challenges. This involves not only improving the material properties but also optimizing production processes to enhance cost-effectiveness and scalability. As such, research efforts are focused on developing novel catalysts for more efficient polymerization, exploring new additives for property enhancement, and refining processing techniques for better control over the final product characteristics.

In conclusion, the evolution of EVA technology reflects a continuous pursuit of innovation to meet changing market demands and address emerging challenges. By understanding this technological trajectory and aligning research and development efforts with future trends, companies can position themselves to gain significant competitive advantages in the dynamic landscape of EVA applications.

Market Demand Analysis for EVA Products

The global market for Ethylene Vinyl Acetate (EVA) products has been experiencing significant growth, driven by increasing demand across various industries. The versatility of EVA, with its unique combination of flexibility, toughness, and adhesion properties, has led to its widespread adoption in sectors such as packaging, footwear, solar panels, and automotive.

In the packaging industry, EVA is increasingly used for flexible packaging solutions, particularly in food and beverage applications. The material's excellent barrier properties against moisture and gases, coupled with its heat-sealing capabilities, make it an ideal choice for manufacturers looking to extend product shelf life and improve packaging performance.

The footwear industry represents another major market for EVA products. The material's lightweight nature, shock-absorbing properties, and ease of molding have made it a preferred choice for shoe soles, especially in sports and casual footwear. As consumer demand for comfortable and durable footwear continues to rise, the market for EVA in this sector is expected to expand further.

The solar energy sector has emerged as a significant driver of EVA demand. EVA encapsulants are crucial components in photovoltaic modules, providing protection and insulation for solar cells. With the global push towards renewable energy sources, the demand for solar panels is projected to grow substantially, directly impacting the EVA market.

In the automotive industry, EVA is gaining traction in various applications, including wire and cable insulation, gaskets, and interior components. The material's resistance to stress cracking and its ability to withstand extreme temperatures make it suitable for the demanding conditions in automotive applications.

The construction sector also presents opportunities for EVA products, particularly in areas such as waterproofing membranes, adhesives, and sealants. The material's durability and weather resistance properties contribute to its increasing use in building and infrastructure projects.

Geographically, Asia-Pacific remains the largest market for EVA products, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow, with growing demand in sectors such as renewable energy and sustainable packaging.

As environmental concerns gain prominence, there is an increasing focus on developing bio-based and recyclable EVA alternatives. This trend is likely to shape the future market dynamics, with manufacturers investing in research and development to meet evolving consumer preferences and regulatory requirements.

In the packaging industry, EVA is increasingly used for flexible packaging solutions, particularly in food and beverage applications. The material's excellent barrier properties against moisture and gases, coupled with its heat-sealing capabilities, make it an ideal choice for manufacturers looking to extend product shelf life and improve packaging performance.

The footwear industry represents another major market for EVA products. The material's lightweight nature, shock-absorbing properties, and ease of molding have made it a preferred choice for shoe soles, especially in sports and casual footwear. As consumer demand for comfortable and durable footwear continues to rise, the market for EVA in this sector is expected to expand further.

The solar energy sector has emerged as a significant driver of EVA demand. EVA encapsulants are crucial components in photovoltaic modules, providing protection and insulation for solar cells. With the global push towards renewable energy sources, the demand for solar panels is projected to grow substantially, directly impacting the EVA market.

In the automotive industry, EVA is gaining traction in various applications, including wire and cable insulation, gaskets, and interior components. The material's resistance to stress cracking and its ability to withstand extreme temperatures make it suitable for the demanding conditions in automotive applications.

The construction sector also presents opportunities for EVA products, particularly in areas such as waterproofing membranes, adhesives, and sealants. The material's durability and weather resistance properties contribute to its increasing use in building and infrastructure projects.

Geographically, Asia-Pacific remains the largest market for EVA products, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow, with growing demand in sectors such as renewable energy and sustainable packaging.

As environmental concerns gain prominence, there is an increasing focus on developing bio-based and recyclable EVA alternatives. This trend is likely to shape the future market dynamics, with manufacturers investing in research and development to meet evolving consumer preferences and regulatory requirements.

Current EVA Technology Status and Challenges

Ethylene Vinyl Acetate (EVA) technology has made significant strides in recent years, but it still faces several challenges in its current state. The global EVA market is experiencing steady growth, driven by increasing demand in various industries such as solar panels, packaging, and footwear. However, the technology's advancement is constrained by several factors that need to be addressed to gain a competitive edge.

One of the primary challenges in EVA technology is the optimization of its properties for specific applications. While EVA offers excellent flexibility, toughness, and adhesion, fine-tuning these characteristics for diverse end-uses remains a complex task. Manufacturers struggle to achieve the perfect balance between flexibility and strength, especially in high-performance applications like solar panel encapsulation.

The production process of EVA also presents significant challenges. Current manufacturing methods often result in inconsistent product quality, leading to variations in performance across batches. This inconsistency can be particularly problematic in industries that require high precision and reliability, such as the automotive and electronics sectors.

Environmental concerns pose another substantial challenge to EVA technology. As global sustainability initiatives gain momentum, there is increasing pressure to develop more eco-friendly EVA formulations and production processes. The current reliance on petroleum-based raw materials and energy-intensive manufacturing methods is becoming a liability in an increasingly environmentally conscious market.

Recycling and end-of-life management of EVA products remain significant hurdles. The cross-linked structure of EVA in many applications makes it difficult to recycle effectively, contributing to waste management issues. This challenge is particularly acute in industries like solar energy, where large volumes of EVA-containing panels will reach end-of-life in the coming decades.

From a geographical perspective, EVA technology development is concentrated in a few key regions, primarily Asia-Pacific, North America, and Europe. This concentration creates challenges in terms of supply chain resilience and regional market adaptations. Companies seeking to gain a competitive edge must navigate these geographical disparities in technology access and development.

The competitive landscape in EVA technology is intensifying, with major players investing heavily in research and development. However, the pace of innovation is often hindered by patent restrictions and proprietary technologies. This situation creates barriers for new entrants and limits the overall advancement of the field.

In conclusion, while EVA technology has made significant progress, it faces multifaceted challenges in its current state. Addressing these challenges – from property optimization and production consistency to environmental sustainability and recycling – will be crucial for companies aiming to gain a competitive edge in the EVA market. The ability to innovate in these areas while navigating the complex global landscape of EVA technology will likely determine the leaders in this evolving field.

One of the primary challenges in EVA technology is the optimization of its properties for specific applications. While EVA offers excellent flexibility, toughness, and adhesion, fine-tuning these characteristics for diverse end-uses remains a complex task. Manufacturers struggle to achieve the perfect balance between flexibility and strength, especially in high-performance applications like solar panel encapsulation.

The production process of EVA also presents significant challenges. Current manufacturing methods often result in inconsistent product quality, leading to variations in performance across batches. This inconsistency can be particularly problematic in industries that require high precision and reliability, such as the automotive and electronics sectors.

Environmental concerns pose another substantial challenge to EVA technology. As global sustainability initiatives gain momentum, there is increasing pressure to develop more eco-friendly EVA formulations and production processes. The current reliance on petroleum-based raw materials and energy-intensive manufacturing methods is becoming a liability in an increasingly environmentally conscious market.

Recycling and end-of-life management of EVA products remain significant hurdles. The cross-linked structure of EVA in many applications makes it difficult to recycle effectively, contributing to waste management issues. This challenge is particularly acute in industries like solar energy, where large volumes of EVA-containing panels will reach end-of-life in the coming decades.

From a geographical perspective, EVA technology development is concentrated in a few key regions, primarily Asia-Pacific, North America, and Europe. This concentration creates challenges in terms of supply chain resilience and regional market adaptations. Companies seeking to gain a competitive edge must navigate these geographical disparities in technology access and development.

The competitive landscape in EVA technology is intensifying, with major players investing heavily in research and development. However, the pace of innovation is often hindered by patent restrictions and proprietary technologies. This situation creates barriers for new entrants and limits the overall advancement of the field.

In conclusion, while EVA technology has made significant progress, it faces multifaceted challenges in its current state. Addressing these challenges – from property optimization and production consistency to environmental sustainability and recycling – will be crucial for companies aiming to gain a competitive edge in the EVA market. The ability to innovate in these areas while navigating the complex global landscape of EVA technology will likely determine the leaders in this evolving field.

Current EVA Production Methods

01 Enhanced thermal properties

EVA copolymers offer improved thermal properties, including better heat resistance and thermal stability. This makes them suitable for applications requiring high-temperature performance, such as in solar panel encapsulation or hot melt adhesives.- Enhanced thermal properties: EVA copolymers offer improved thermal properties, including better heat resistance and thermal stability. This makes them suitable for applications requiring high-temperature performance, such as in solar panel encapsulation or automotive components.

- Flexibility and impact resistance: EVA materials exhibit excellent flexibility and impact resistance, making them ideal for use in footwear, packaging, and sports equipment. These properties contribute to the durability and comfort of products incorporating EVA.

- Adhesive properties: EVA copolymers possess strong adhesive properties, making them suitable for use in hot melt adhesives, sealants, and coatings. This characteristic allows for improved bonding in various applications, including packaging and construction materials.

- Weatherability and UV resistance: EVA materials demonstrate good weatherability and UV resistance, making them suitable for outdoor applications such as greenhouse films, solar panel encapsulants, and marine products. This property ensures longevity and performance in harsh environmental conditions.

- Customizable properties through copolymerization: The ability to adjust the vinyl acetate content in EVA copolymers allows for customization of properties such as flexibility, clarity, and melt flow index. This versatility enables manufacturers to tailor EVA materials for specific applications across various industries.

02 Flexibility and impact resistance

EVA materials exhibit excellent flexibility and impact resistance, making them ideal for use in footwear, packaging, and automotive components. These properties contribute to improved durability and performance in various applications.Expand Specific Solutions03 Adhesive properties

EVA copolymers possess strong adhesive properties, making them suitable for use in adhesives, sealants, and coatings. This characteristic allows for improved bonding in various industries, including construction and packaging.Expand Specific Solutions04 Weatherability and UV resistance

EVA materials demonstrate good weatherability and UV resistance, making them suitable for outdoor applications such as solar panel encapsulation and greenhouse films. This property ensures longevity and performance in harsh environmental conditions.Expand Specific Solutions05 Customizable properties through copolymerization

The ability to adjust the vinyl acetate content in EVA copolymers allows for customization of properties such as flexibility, clarity, and melt flow index. This versatility enables manufacturers to tailor EVA materials for specific applications across various industries.Expand Specific Solutions

Major Players in EVA Industry

The competitive landscape for ethylene vinyl acetate (EVA) technology is characterized by a mature market with established players and ongoing innovation. The global EVA market is substantial, driven by diverse applications in industries such as packaging, footwear, and solar panels. Key players like China Petroleum & Chemical Corp., Celanese International Corp., and Wacker Chemie AG dominate the market, leveraging their extensive R&D capabilities and production capacities. The technology's maturity is evident in the involvement of major petrochemical companies and specialized chemical manufacturers. However, ongoing research at institutions like Tianjin University and Indian Institute of Technology Madras indicates potential for further advancements in EVA technology, particularly in areas of sustainability and performance enhancement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced ethylene vinyl acetate (EVA) production technologies, focusing on high-performance EVA copolymers for various applications. Their approach involves optimizing the polymerization process to achieve precise control over the vinyl acetate content, ranging from 10% to 40%, which allows for tailored properties[1]. Sinopec has also implemented a proprietary catalyst system that enhances the efficiency of the copolymerization reaction, resulting in improved product quality and reduced production costs[2]. Additionally, they have invested in developing specialty EVA grades with enhanced thermal stability and weatherability for solar panel encapsulation, which has seen growing demand in the renewable energy sector[3].

Strengths: Vertically integrated production chain, access to raw materials, and strong R&D capabilities. Weaknesses: Potential overcapacity in the domestic market and environmental regulations impacting production.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary technology platform for EVA production called VitalDose®, which focuses on creating high-quality, customizable EVA formulations for pharmaceutical and medical device applications[1]. Their process allows for precise control of vinyl acetate content, molecular weight distribution, and melt index, enabling the production of EVA with specific release profiles for drug delivery systems[2]. Celanese has also implemented advanced extrusion and molding techniques to manufacture EVA-based products with complex geometries and controlled porosity, which is particularly valuable for implantable medical devices[3]. Furthermore, they have developed EVA grades with enhanced biocompatibility and stability for long-term implantation, addressing the growing demand for advanced biomaterials in the healthcare industry[4].

Strengths: Strong expertise in specialty polymers and medical-grade materials. Extensive patent portfolio in EVA technologies. Weaknesses: Higher production costs compared to commodity EVA producers. Limited market share in non-medical EVA applications.

Key EVA Patents and Technical Literature

Ultra high solids vinyl acetate-ethylene and vinyl acetate homopolymer emulsions

PatentInactiveEP0924229B1

Innovation

- Incorporating a polymer seed, such as vinyl acetate, ethylene vinyl acetate, acrylic, or styrene acrylic polymers, into the ethylene/vinyl acetate emulsion process with a specific polyvinyl alcohol and nonionic emulsifier system to achieve broader particle size distribution and higher solids levels while maintaining low viscosity.

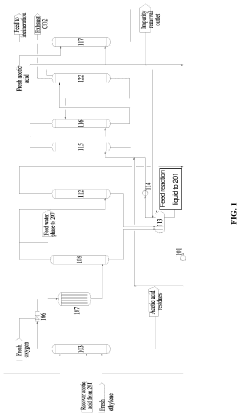

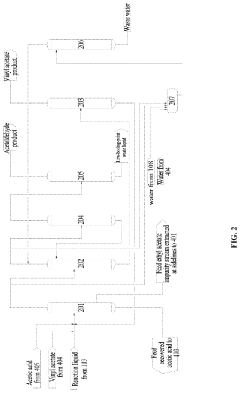

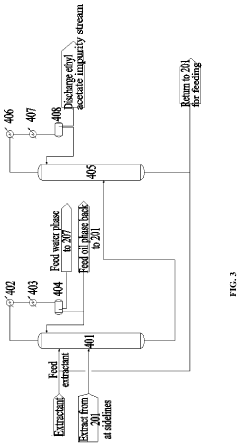

Method for producing vinyl acetate

PatentActiveUS20230312452A1

Innovation

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

EVA Sustainability and Recycling

Sustainability and recycling have become critical considerations in the EVA industry, driven by increasing environmental concerns and regulatory pressures. EVA, despite its versatility and widespread use, poses significant challenges in terms of recyclability due to its cross-linked structure and the presence of various additives.

To address these challenges, several innovative approaches are being developed. One promising method is chemical recycling, which involves breaking down EVA into its constituent monomers or other valuable chemicals. This process allows for the recovery of raw materials that can be used to produce new EVA or other products, effectively closing the loop in the material's lifecycle.

Mechanical recycling is another avenue being explored, particularly for EVA foam products. This process involves grinding used EVA materials into small particles, which can then be reprocessed into new products. While this method is less energy-intensive than chemical recycling, it often results in lower-quality recycled materials due to the degradation of polymer properties during the recycling process.

Bio-based EVA alternatives are also gaining traction as a sustainable solution. These materials are derived from renewable resources such as sugarcane or corn, reducing reliance on fossil fuels and potentially offering improved end-of-life options. However, challenges remain in scaling up production and ensuring consistent performance compared to traditional EVA.

Companies investing in EVA sustainability are exploring design for recyclability principles. This involves developing products that are easier to disassemble and recycle at the end of their life cycle. For instance, some manufacturers are working on EVA formulations that maintain performance while reducing the use of additives that complicate recycling processes.

The development of efficient collection and sorting systems is crucial for improving EVA recycling rates. Advanced technologies such as near-infrared spectroscopy and artificial intelligence are being employed to enhance the accuracy and speed of sorting EVA waste from other materials, facilitating more effective recycling processes.

Collaboration across the value chain is essential for advancing EVA sustainability. Partnerships between raw material suppliers, manufacturers, recyclers, and end-users are fostering innovation in recycling technologies and circular economy models. These collaborations are also driving the development of industry standards for EVA recycling, which will be crucial for scaling up sustainable practices.

In conclusion, while challenges persist, the EVA industry is making significant strides towards improved sustainability and recyclability. Companies that invest in these areas are likely to gain competitive advantages through enhanced brand reputation, access to environmentally conscious markets, and potential cost savings from recycled materials. As regulations tighten and consumer demand for sustainable products grows, leadership in EVA sustainability will become increasingly important for maintaining a competitive edge in the market.

To address these challenges, several innovative approaches are being developed. One promising method is chemical recycling, which involves breaking down EVA into its constituent monomers or other valuable chemicals. This process allows for the recovery of raw materials that can be used to produce new EVA or other products, effectively closing the loop in the material's lifecycle.

Mechanical recycling is another avenue being explored, particularly for EVA foam products. This process involves grinding used EVA materials into small particles, which can then be reprocessed into new products. While this method is less energy-intensive than chemical recycling, it often results in lower-quality recycled materials due to the degradation of polymer properties during the recycling process.

Bio-based EVA alternatives are also gaining traction as a sustainable solution. These materials are derived from renewable resources such as sugarcane or corn, reducing reliance on fossil fuels and potentially offering improved end-of-life options. However, challenges remain in scaling up production and ensuring consistent performance compared to traditional EVA.

Companies investing in EVA sustainability are exploring design for recyclability principles. This involves developing products that are easier to disassemble and recycle at the end of their life cycle. For instance, some manufacturers are working on EVA formulations that maintain performance while reducing the use of additives that complicate recycling processes.

The development of efficient collection and sorting systems is crucial for improving EVA recycling rates. Advanced technologies such as near-infrared spectroscopy and artificial intelligence are being employed to enhance the accuracy and speed of sorting EVA waste from other materials, facilitating more effective recycling processes.

Collaboration across the value chain is essential for advancing EVA sustainability. Partnerships between raw material suppliers, manufacturers, recyclers, and end-users are fostering innovation in recycling technologies and circular economy models. These collaborations are also driving the development of industry standards for EVA recycling, which will be crucial for scaling up sustainable practices.

In conclusion, while challenges persist, the EVA industry is making significant strides towards improved sustainability and recyclability. Companies that invest in these areas are likely to gain competitive advantages through enhanced brand reputation, access to environmentally conscious markets, and potential cost savings from recycled materials. As regulations tighten and consumer demand for sustainable products grows, leadership in EVA sustainability will become increasingly important for maintaining a competitive edge in the market.

EVA Regulatory Compliance

Regulatory compliance is a critical aspect of gaining competitive edges with Ethylene Vinyl Acetate (EVA) in the global market. As EVA finds applications across diverse industries, including packaging, solar panels, and footwear, adhering to regulatory standards becomes paramount for market access and consumer trust.

In the United States, the Food and Drug Administration (FDA) regulates EVA used in food contact materials. Manufacturers must ensure their EVA products comply with FDA regulations, particularly 21 CFR 177.1350, which outlines specific requirements for EVA copolymers in food packaging. Companies that can demonstrate consistent compliance with these standards gain a significant advantage in the food packaging sector.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts EVA manufacturers and importers. Under REACH, companies must register substances produced or imported in quantities over one tonne per year. Proactive compliance with REACH not only ensures market access but also positions companies as responsible and trustworthy suppliers in the European market.

For EVA applications in toys and childcare articles, compliance with restrictions on certain phthalates is crucial. The EU's Toy Safety Directive and similar regulations in other regions set strict limits on phthalate content. Companies that develop phthalate-free EVA formulations for these applications can differentiate themselves in the market and appeal to safety-conscious consumers.

In the rapidly growing solar panel industry, EVA encapsulants must meet specific standards for durability and performance. Compliance with IEC 61215 and IEC 61730 standards, which cover design qualification and safety requirements for photovoltaic modules, is essential. Manufacturers who can consistently meet or exceed these standards position themselves as preferred suppliers in the renewable energy sector.

Environmental regulations also play a significant role in EVA competitiveness. As sustainability becomes increasingly important, companies that can demonstrate compliance with regulations on volatile organic compound (VOC) emissions during EVA production and processing gain an edge. This is particularly relevant in regions with stringent air quality regulations, such as California in the United States.

Proactive engagement with regulatory bodies and participation in industry standards development can provide companies with a competitive advantage. By staying ahead of regulatory changes and contributing to the evolution of standards, EVA manufacturers can position themselves as industry leaders and influence the regulatory landscape in ways that align with their technological capabilities.

In the United States, the Food and Drug Administration (FDA) regulates EVA used in food contact materials. Manufacturers must ensure their EVA products comply with FDA regulations, particularly 21 CFR 177.1350, which outlines specific requirements for EVA copolymers in food packaging. Companies that can demonstrate consistent compliance with these standards gain a significant advantage in the food packaging sector.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts EVA manufacturers and importers. Under REACH, companies must register substances produced or imported in quantities over one tonne per year. Proactive compliance with REACH not only ensures market access but also positions companies as responsible and trustworthy suppliers in the European market.

For EVA applications in toys and childcare articles, compliance with restrictions on certain phthalates is crucial. The EU's Toy Safety Directive and similar regulations in other regions set strict limits on phthalate content. Companies that develop phthalate-free EVA formulations for these applications can differentiate themselves in the market and appeal to safety-conscious consumers.

In the rapidly growing solar panel industry, EVA encapsulants must meet specific standards for durability and performance. Compliance with IEC 61215 and IEC 61730 standards, which cover design qualification and safety requirements for photovoltaic modules, is essential. Manufacturers who can consistently meet or exceed these standards position themselves as preferred suppliers in the renewable energy sector.

Environmental regulations also play a significant role in EVA competitiveness. As sustainability becomes increasingly important, companies that can demonstrate compliance with regulations on volatile organic compound (VOC) emissions during EVA production and processing gain an edge. This is particularly relevant in regions with stringent air quality regulations, such as California in the United States.

Proactive engagement with regulatory bodies and participation in industry standards development can provide companies with a competitive advantage. By staying ahead of regulatory changes and contributing to the evolution of standards, EVA manufacturers can position themselves as industry leaders and influence the regulatory landscape in ways that align with their technological capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!