Evaluate Lithium Mine Water Recycling Efficiency Under Variable Feed Quality

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mine Water Recycling Background and Objectives

Water management in lithium mining operations has evolved significantly over the past decades, transitioning from traditional high-consumption practices to more sustainable approaches. The lithium extraction industry, particularly in salt flat (salar) operations in South America and hard rock mining globally, faces increasing scrutiny regarding water usage in water-stressed regions. Historical data indicates that conventional lithium extraction methods consume between 500,000 to 2 million gallons of water per ton of lithium produced, creating substantial environmental pressure on local ecosystems and communities.

The technological evolution in this field has been driven by both regulatory requirements and economic considerations. Early lithium extraction methods prioritized yield over water efficiency, but recent advancements have shifted focus toward closed-loop systems and advanced water recycling technologies. This transition represents a critical inflection point in the industry's development trajectory, as water scarcity becomes a limiting factor for production expansion in key lithium-producing regions.

Current industry objectives center on developing water recycling systems capable of maintaining high operational efficiency despite variable feed quality. This variability stems from fluctuating concentrations of contaminants including suspended solids, dissolved salts, heavy metals, and process chemicals that change based on seasonal factors, operational conditions, and geological variations. The technical goal is to achieve recycling rates exceeding 80% while maintaining water quality parameters suitable for reintroduction into extraction processes.

The global lithium demand projection, estimated to increase by 400-500% by 2030 due to electric vehicle battery production, intensifies the urgency for water-efficient extraction methods. This growth trajectory cannot be sustained under current water consumption models, particularly in arid regions like Chile's Atacama Desert, Argentina's Salar de Olaroz, or Australia's hard rock mining operations.

Recent technological innovations have demonstrated potential pathways toward this objective, including membrane filtration systems, advanced evaporation techniques, and chemical precipitation methods. However, these solutions typically perform optimally under stable feed conditions, with efficiency declining significantly when input water quality fluctuates beyond design parameters.

The primary technical challenge addressed in this research involves developing adaptive water treatment systems capable of maintaining consistent recycling efficiency despite variable input conditions. This requires integration of real-time monitoring systems, predictive analytics for feed quality variations, and modular treatment processes that can be dynamically adjusted to accommodate changing water characteristics while maintaining energy efficiency and operational continuity.

The technological evolution in this field has been driven by both regulatory requirements and economic considerations. Early lithium extraction methods prioritized yield over water efficiency, but recent advancements have shifted focus toward closed-loop systems and advanced water recycling technologies. This transition represents a critical inflection point in the industry's development trajectory, as water scarcity becomes a limiting factor for production expansion in key lithium-producing regions.

Current industry objectives center on developing water recycling systems capable of maintaining high operational efficiency despite variable feed quality. This variability stems from fluctuating concentrations of contaminants including suspended solids, dissolved salts, heavy metals, and process chemicals that change based on seasonal factors, operational conditions, and geological variations. The technical goal is to achieve recycling rates exceeding 80% while maintaining water quality parameters suitable for reintroduction into extraction processes.

The global lithium demand projection, estimated to increase by 400-500% by 2030 due to electric vehicle battery production, intensifies the urgency for water-efficient extraction methods. This growth trajectory cannot be sustained under current water consumption models, particularly in arid regions like Chile's Atacama Desert, Argentina's Salar de Olaroz, or Australia's hard rock mining operations.

Recent technological innovations have demonstrated potential pathways toward this objective, including membrane filtration systems, advanced evaporation techniques, and chemical precipitation methods. However, these solutions typically perform optimally under stable feed conditions, with efficiency declining significantly when input water quality fluctuates beyond design parameters.

The primary technical challenge addressed in this research involves developing adaptive water treatment systems capable of maintaining consistent recycling efficiency despite variable input conditions. This requires integration of real-time monitoring systems, predictive analytics for feed quality variations, and modular treatment processes that can be dynamically adjusted to accommodate changing water characteristics while maintaining energy efficiency and operational continuity.

Market Demand Analysis for Sustainable Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that lithium demand is projected to triple by 2025 and increase nearly tenfold by 2030, creating significant pressure on extraction operations worldwide. This surge in demand has elevated the importance of sustainable extraction methods, particularly water-efficient processes, as traditional lithium mining is notoriously water-intensive.

Water recycling in lithium extraction has emerged as a critical market need, with mining companies facing increasing regulatory scrutiny and community opposition regarding water usage. In major lithium-producing regions such as the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), operations consume between 500,000 to 2 million liters of water per ton of lithium produced. This consumption occurs in predominantly arid regions where water scarcity already affects local communities and ecosystems.

Market research reveals that investors are increasingly prioritizing lithium producers with demonstrated water stewardship capabilities. Companies implementing advanced water recycling technologies have seen up to 30% premium valuations compared to competitors using traditional extraction methods. This market signal indicates strong financial incentives for technological innovation in water recycling efficiency.

End-users, particularly major automotive manufacturers and battery producers, are establishing sustainability requirements within their supply chains. Several leading EV manufacturers have announced targets to source lithium exclusively from operations achieving at least 70% water recycling rates by 2030, creating direct market pressure for technological advancement in this area.

The variable feed quality challenge represents a significant market opportunity, as lithium brine compositions vary substantially across different deposits. Technologies capable of maintaining high recycling efficiency despite fluctuations in feed quality command premium pricing, with current solutions achieving only 50-65% efficiency under variable conditions. Industry surveys indicate mining operators are willing to invest substantially in solutions that can maintain 80%+ recycling efficiency regardless of feed quality variations.

Geographically, the market demand for advanced water recycling technologies is strongest in Chile and Argentina, where regulatory pressures are intensifying, followed by Australia and China, where production scale drives efficiency requirements. North American lithium projects, though smaller in current production volume, show the highest growth rate in demand for water-efficient technologies as new projects seek permitting in environmentally sensitive regions.

Water recycling in lithium extraction has emerged as a critical market need, with mining companies facing increasing regulatory scrutiny and community opposition regarding water usage. In major lithium-producing regions such as the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), operations consume between 500,000 to 2 million liters of water per ton of lithium produced. This consumption occurs in predominantly arid regions where water scarcity already affects local communities and ecosystems.

Market research reveals that investors are increasingly prioritizing lithium producers with demonstrated water stewardship capabilities. Companies implementing advanced water recycling technologies have seen up to 30% premium valuations compared to competitors using traditional extraction methods. This market signal indicates strong financial incentives for technological innovation in water recycling efficiency.

End-users, particularly major automotive manufacturers and battery producers, are establishing sustainability requirements within their supply chains. Several leading EV manufacturers have announced targets to source lithium exclusively from operations achieving at least 70% water recycling rates by 2030, creating direct market pressure for technological advancement in this area.

The variable feed quality challenge represents a significant market opportunity, as lithium brine compositions vary substantially across different deposits. Technologies capable of maintaining high recycling efficiency despite fluctuations in feed quality command premium pricing, with current solutions achieving only 50-65% efficiency under variable conditions. Industry surveys indicate mining operators are willing to invest substantially in solutions that can maintain 80%+ recycling efficiency regardless of feed quality variations.

Geographically, the market demand for advanced water recycling technologies is strongest in Chile and Argentina, where regulatory pressures are intensifying, followed by Australia and China, where production scale drives efficiency requirements. North American lithium projects, though smaller in current production volume, show the highest growth rate in demand for water-efficient technologies as new projects seek permitting in environmentally sensitive regions.

Current Water Recycling Technologies and Challenges

Water recycling in lithium mining operations currently employs several key technologies, each with varying degrees of efficiency when dealing with fluctuating feed quality. Reverse osmosis (RO) systems represent one of the most widely implemented solutions, capable of removing up to 99% of dissolved solids. However, these systems face significant challenges when processing high-TDS (Total Dissolved Solids) water typical in lithium operations, often requiring extensive pre-treatment to prevent membrane fouling and scaling.

Evaporation ponds, while traditional and relatively simple to operate, demonstrate inconsistent performance under variable feed conditions. Their efficiency is heavily dependent on climatic factors, with recovery rates dropping significantly during periods of high humidity or precipitation. Additionally, these systems require substantial land area and face increasing environmental scrutiny due to potential groundwater contamination risks.

Ion exchange technologies have shown promising results for selective lithium recovery while simultaneously treating process water. These systems can handle moderate variations in feed quality but struggle with extremely high concentrations of competing ions, particularly magnesium and calcium, which can rapidly exhaust resin capacity and necessitate frequent regeneration cycles.

Emerging electrochemical treatment methods, including capacitive deionization and electrodialysis, offer potential advantages for variable feed quality scenarios. These technologies can be more selectively tuned to specific ion concentrations but currently face scalability challenges and higher energy consumption compared to conventional methods when implemented at commercial scale.

A significant technical challenge across all current recycling technologies is the management of silica, which tends to form difficult-to-remove precipitates at various stages of the treatment process. Silica removal efficiency decreases markedly when feed quality fluctuates, creating unpredictable maintenance requirements and system downtime.

Brine concentration technologies, such as mechanical vapor recompression and multi-effect distillation, provide high water recovery rates but exhibit substantial energy consumption profiles. Their operational efficiency decreases significantly when processing variable feed streams, as frequent adjustments to operating parameters become necessary to maintain product quality.

The integration of real-time monitoring systems with automated control mechanisms represents a critical development area. Current sensor technologies often lack the precision required for rapid detection of quality variations, resulting in delayed system responses and suboptimal treatment efficiency. Advanced predictive analytics and machine learning approaches are being explored to anticipate feed quality fluctuations and proactively adjust treatment parameters.

Evaporation ponds, while traditional and relatively simple to operate, demonstrate inconsistent performance under variable feed conditions. Their efficiency is heavily dependent on climatic factors, with recovery rates dropping significantly during periods of high humidity or precipitation. Additionally, these systems require substantial land area and face increasing environmental scrutiny due to potential groundwater contamination risks.

Ion exchange technologies have shown promising results for selective lithium recovery while simultaneously treating process water. These systems can handle moderate variations in feed quality but struggle with extremely high concentrations of competing ions, particularly magnesium and calcium, which can rapidly exhaust resin capacity and necessitate frequent regeneration cycles.

Emerging electrochemical treatment methods, including capacitive deionization and electrodialysis, offer potential advantages for variable feed quality scenarios. These technologies can be more selectively tuned to specific ion concentrations but currently face scalability challenges and higher energy consumption compared to conventional methods when implemented at commercial scale.

A significant technical challenge across all current recycling technologies is the management of silica, which tends to form difficult-to-remove precipitates at various stages of the treatment process. Silica removal efficiency decreases markedly when feed quality fluctuates, creating unpredictable maintenance requirements and system downtime.

Brine concentration technologies, such as mechanical vapor recompression and multi-effect distillation, provide high water recovery rates but exhibit substantial energy consumption profiles. Their operational efficiency decreases significantly when processing variable feed streams, as frequent adjustments to operating parameters become necessary to maintain product quality.

The integration of real-time monitoring systems with automated control mechanisms represents a critical development area. Current sensor technologies often lack the precision required for rapid detection of quality variations, resulting in delayed system responses and suboptimal treatment efficiency. Advanced predictive analytics and machine learning approaches are being explored to anticipate feed quality fluctuations and proactively adjust treatment parameters.

Existing Water Recycling Solutions for Variable Feed Quality

01 Membrane filtration technologies for lithium mine water recycling

Advanced membrane filtration systems are employed in lithium mining operations to efficiently separate lithium compounds from wastewater. These technologies include reverse osmosis, nanofiltration, and ultrafiltration processes that can selectively remove impurities while concentrating lithium ions. The membrane-based systems significantly reduce water consumption by enabling the reuse of process water, thereby improving the overall efficiency of lithium extraction operations while minimizing environmental impact.- Membrane filtration technologies for lithium mine water recycling: Advanced membrane filtration systems are employed in lithium mining operations to efficiently separate lithium compounds from wastewater. These technologies include reverse osmosis, nanofiltration, and ultrafiltration processes that can selectively remove impurities while concentrating lithium ions. The implementation of these membrane systems significantly improves water recovery rates and reduces freshwater consumption in lithium extraction processes.

- Evaporation and crystallization systems for lithium recovery: Evaporation and crystallization technologies are utilized to recover lithium from mine wastewater by concentrating the solution through controlled evaporation processes. These systems often incorporate solar evaporation ponds combined with mechanical evaporators to accelerate the process. The crystallized lithium compounds can be harvested while the purified water is recycled back into the mining operation, significantly improving water efficiency in arid mining regions.

- Ion exchange and adsorption methods for lithium extraction: Ion exchange and adsorption technologies enable selective extraction of lithium from mine wastewater using specialized resins or adsorbents. These materials can selectively capture lithium ions while allowing other components to pass through, facilitating efficient water recycling. The lithium can later be recovered through desorption processes, and the regenerated materials can be reused multiple times, enhancing the overall efficiency of the water recycling system.

- Integrated water treatment and recycling systems: Comprehensive water treatment systems that combine multiple technologies are implemented to maximize water recycling efficiency in lithium mining operations. These integrated systems typically include pre-treatment stages, primary treatment processes, and polishing steps to ensure water quality meets requirements for reuse. By incorporating sensors, automated controls, and energy recovery mechanisms, these systems optimize water and energy usage while minimizing waste discharge.

- Zero liquid discharge systems for lithium mining operations: Zero liquid discharge (ZLD) technologies are implemented in lithium mining to eliminate wastewater discharge by recovering all water for reuse. These systems typically combine multiple treatment stages including evaporation, crystallization, and membrane processes to concentrate contaminants into solid waste while recovering purified water. ZLD systems significantly reduce environmental impact and water consumption in lithium extraction, particularly important in water-scarce regions where lithium mining often occurs.

02 Evaporation and crystallization systems for lithium recovery

Evaporation and crystallization technologies are utilized to recover lithium from mine wastewater by concentrating the lithium-rich solution through controlled evaporation processes. These systems often incorporate solar evaporation ponds or mechanical evaporators followed by crystallization units that precipitate lithium compounds for collection. The integration of these technologies allows for efficient water recycling while simultaneously recovering valuable lithium products, thereby enhancing the economic viability of lithium mining operations.Expand Specific Solutions03 Ion exchange and adsorption methods for lithium extraction

Ion exchange and adsorption technologies utilize specialized resins or adsorbents that selectively capture lithium ions from mine wastewater. These systems can efficiently separate lithium from other elements present in the solution, allowing for the purification and concentration of lithium compounds. The treated water can then be recycled back into the mining process, significantly reducing freshwater requirements. These methods are particularly effective for processing low-concentration lithium brines and can achieve high recovery rates with minimal environmental impact.Expand Specific Solutions04 Integrated water treatment and recycling systems

Comprehensive water management systems for lithium mining operations integrate multiple treatment technologies to maximize water recycling efficiency. These systems typically include pre-treatment stages for removing suspended solids, followed by advanced purification processes and final polishing steps. By combining various treatment methods in a single integrated system, mining operations can achieve higher water recovery rates while maintaining water quality suitable for reuse in different mining processes. These integrated approaches often incorporate automation and monitoring systems to optimize performance and reduce operational costs.Expand Specific Solutions05 Energy-efficient water recovery technologies

Energy-efficient technologies for lithium mine water recycling focus on reducing the power consumption associated with water treatment processes. These innovations include low-energy membrane systems, heat recovery mechanisms, renewable energy integration, and process optimization techniques. By minimizing energy requirements, these technologies not only reduce operational costs but also decrease the carbon footprint of lithium mining operations. Advanced energy recovery systems can capture and reuse thermal energy from various mining processes, further enhancing the overall efficiency of water recycling systems.Expand Specific Solutions

Key Industry Players in Lithium Water Management

The lithium mine water recycling efficiency market is in a growth phase, driven by increasing environmental regulations and water scarcity concerns in mining operations. The market is expanding rapidly as lithium demand surges for electric vehicle batteries, with projections indicating significant growth over the next decade. Technologically, solutions are advancing from basic filtration to sophisticated closed-loop systems. Leading players include established mining companies like Albemarle Corp., POSCO Holdings, and Eramet SA, who are investing heavily in water efficiency technologies. Battery manufacturers such as BYD, Samsung SDI, and LG Chem are also driving innovation to secure sustainable supply chains. Research institutions like Columbia University and the Chinese Academy of Sciences are developing breakthrough technologies, while specialized companies like Ascend Elements and Pure Battery Technologies are creating innovative recycling solutions that address variable feed quality challenges.

Albemarle Corp.

Technical Solution: Albemarle has developed an advanced closed-loop water recycling system specifically designed for lithium mining operations that can handle variable feed quality. Their proprietary Direct Lithium Extraction (DLE) technology incorporates multi-stage filtration and selective adsorption processes that can adapt to fluctuating brine compositions. The system employs ion-selective membranes and specialized resins that selectively capture lithium ions while allowing other elements to be filtered out. This approach enables water recovery rates of up to 90% even when dealing with brines containing variable concentrations of contaminants such as magnesium, calcium, and boron. Albemarle's system includes real-time monitoring capabilities that automatically adjust treatment parameters based on incoming water quality, optimizing both lithium recovery and water recycling efficiency.

Strengths: Industry-leading water recovery rates; adaptive technology for variable feed conditions; reduced freshwater consumption by up to 60% compared to traditional evaporation methods. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; energy-intensive for highly contaminated feeds.

Pure Battery Technologies Pty Ltd.

Technical Solution: Pure Battery Technologies has developed an innovative water recycling system specifically designed for lithium extraction operations called AquaLoop™. Their approach focuses on handling variable feed quality through a combination of electrocoagulation, advanced oxidation, and selective membrane filtration. The system incorporates a proprietary feed characterization module that continuously analyzes incoming water composition and automatically adjusts treatment parameters to maintain optimal performance. PBT's technology achieves water recycling rates of 80-90% while effectively removing contaminants that could interfere with lithium extraction processes. Their system is particularly effective at handling brines with variable organic content and suspended solids, which often challenge conventional treatment approaches. The modular design allows for easy scaling and integration with existing lithium extraction operations, with each module capable of processing 50-200 m³/day depending on feed quality.

Strengths: Excellent handling of organic contaminants; lower maintenance requirements than competing systems; compact footprint suitable for remote operations. Weaknesses: Higher energy consumption for highly contaminated feeds; requires specialized consumables; slightly longer startup time when feed quality changes dramatically.

Critical Technologies for Efficient Water Treatment

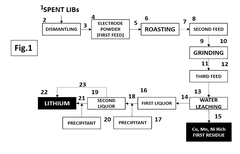

A process for selective extraction-separation-recovery of lithium from spent lithium based batteries of any/mixed chemistry

PatentPendingIN202111040165A

Innovation

- A selective process involving high-temperature roasting, followed by water leaching and precipitation steps, which allows for the separation and recovery of lithium with high purity (99%) and the generation of a residue rich in cobalt, nickel, and manganese, using a combination of pyrometallurgy and hydrometallurgy, and utilizing additives like hydroxide or carbonate salts to enhance the extraction efficiency.

Method for lithium battery recycling

PatentWO2025198659A1

Innovation

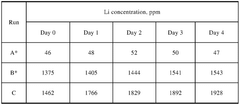

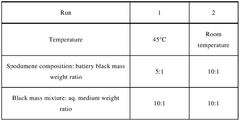

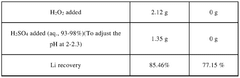

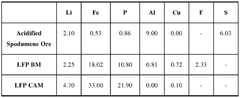

- A method involving the selective leaching of Li from spent LFP batteries using a spodumene composition, adjusting the pH to 2.5-3.0, and adding hydrogen peroxide as an oxidizer, with the LFP and spodumene mixed in a specific weight ratio, to form a black mass leaching mixture that is agitated and filtered, reducing the need for excessive chemicals and improving lithium recovery.

Environmental Impact Assessment and Compliance

Lithium mining operations face increasing scrutiny regarding their environmental footprint, particularly concerning water usage and potential contamination. The environmental impact assessment of water recycling systems in lithium extraction facilities must consider multiple regulatory frameworks at local, national, and international levels. Current environmental regulations in major lithium-producing regions such as Chile, Argentina, Australia, and China impose strict requirements on water discharge quality, groundwater protection, and overall water management practices.

Water recycling efficiency directly correlates with reduced environmental impact through minimized freshwater withdrawal from often water-stressed regions. Analysis of several operational lithium mines indicates that advanced recycling systems can reduce freshwater consumption by 40-60% compared to conventional operations. However, variable feed quality introduces significant challenges to maintaining consistent compliance with environmental standards, as fluctuations in contaminant concentrations may exceed treatment system design parameters.

Regulatory compliance frameworks typically require continuous monitoring of key parameters including total dissolved solids (TDS), specific metal concentrations, pH levels, and temperature of recycled and discharged water. The implementation of real-time monitoring systems with automated alerts has become standard practice in modern lithium operations to ensure immediate response to potential compliance issues. These systems generate substantial environmental performance data that can be leveraged for optimization and reporting purposes.

Life cycle assessment (LCA) studies of lithium mining operations demonstrate that water recycling systems, despite their energy requirements, generally result in net positive environmental outcomes when considering the full spectrum of environmental indicators. The carbon footprint associated with water treatment and recycling is typically offset by the avoided impacts of freshwater extraction and wastewater discharge.

Community engagement represents another critical dimension of environmental compliance. Local stakeholders, particularly indigenous communities in lithium-rich regions like the "Lithium Triangle" in South America, increasingly demand transparent reporting on water usage and recycling efficiency. Several leading lithium producers have established community environmental monitoring programs where local representatives participate in water sampling and analysis processes.

Future regulatory trends point toward more stringent requirements for water recycling efficiency and closed-loop systems. The European Union's proposed battery regulations, for instance, may include supply chain due diligence requirements related to water management practices. Companies investing in advanced water recycling technologies that can handle variable feed quality are better positioned to navigate this evolving regulatory landscape and secure their social license to operate in water-sensitive regions.

Water recycling efficiency directly correlates with reduced environmental impact through minimized freshwater withdrawal from often water-stressed regions. Analysis of several operational lithium mines indicates that advanced recycling systems can reduce freshwater consumption by 40-60% compared to conventional operations. However, variable feed quality introduces significant challenges to maintaining consistent compliance with environmental standards, as fluctuations in contaminant concentrations may exceed treatment system design parameters.

Regulatory compliance frameworks typically require continuous monitoring of key parameters including total dissolved solids (TDS), specific metal concentrations, pH levels, and temperature of recycled and discharged water. The implementation of real-time monitoring systems with automated alerts has become standard practice in modern lithium operations to ensure immediate response to potential compliance issues. These systems generate substantial environmental performance data that can be leveraged for optimization and reporting purposes.

Life cycle assessment (LCA) studies of lithium mining operations demonstrate that water recycling systems, despite their energy requirements, generally result in net positive environmental outcomes when considering the full spectrum of environmental indicators. The carbon footprint associated with water treatment and recycling is typically offset by the avoided impacts of freshwater extraction and wastewater discharge.

Community engagement represents another critical dimension of environmental compliance. Local stakeholders, particularly indigenous communities in lithium-rich regions like the "Lithium Triangle" in South America, increasingly demand transparent reporting on water usage and recycling efficiency. Several leading lithium producers have established community environmental monitoring programs where local representatives participate in water sampling and analysis processes.

Future regulatory trends point toward more stringent requirements for water recycling efficiency and closed-loop systems. The European Union's proposed battery regulations, for instance, may include supply chain due diligence requirements related to water management practices. Companies investing in advanced water recycling technologies that can handle variable feed quality are better positioned to navigate this evolving regulatory landscape and secure their social license to operate in water-sensitive regions.

Economic Feasibility of Advanced Water Recycling Systems

The economic feasibility of advanced water recycling systems in lithium mining operations represents a critical consideration for sustainable resource management. Initial capital investments for these systems typically range from $2-10 million depending on capacity requirements and technology sophistication, with operational costs averaging $0.5-2 per cubic meter of treated water. These figures vary significantly based on energy costs, which constitute 30-40% of operational expenses.

Return on investment calculations indicate that advanced recycling systems can achieve payback periods of 2-5 years in water-scarce regions where fresh water procurement costs exceed $5 per cubic meter. This economic equation becomes particularly favorable when considering the avoided costs of regulatory compliance, which can reach millions annually for operations failing to meet discharge standards.

Variable feed quality presents distinct economic challenges, as fluctuations in contaminant concentrations necessitate adaptive treatment capabilities. Systems equipped with real-time monitoring and automated adjustment features command premium prices but deliver superior performance under variable conditions. Cost-benefit analyses demonstrate that such adaptive systems typically reduce operational disruptions by 60-75%, translating to significant production continuity benefits.

Economies of scale play a decisive role in feasibility assessments. Large-scale operations processing over 5,000 cubic meters daily achieve unit treatment costs approximately 40% lower than small-scale implementations. This differential underscores the importance of capacity planning in investment decisions.

Energy efficiency innovations have substantially improved the economic profile of advanced recycling systems. Modern membrane technologies and energy recovery devices reduce energy consumption by 30-50% compared to conventional systems, directly impacting operational costs. Similarly, chemical consumption optimization through precision dosing systems has yielded 15-25% reductions in treatment chemical expenses.

Life-cycle cost analyses reveal that while conventional treatment systems may offer lower initial investments, advanced recycling systems deliver superior long-term value when accounting for water recovery rates, operational reliability, and regulatory compliance benefits. The economic advantage becomes particularly pronounced in operations facing water scarcity, stringent discharge regulations, or high-value lithium deposits where production continuity carries premium value.

Return on investment calculations indicate that advanced recycling systems can achieve payback periods of 2-5 years in water-scarce regions where fresh water procurement costs exceed $5 per cubic meter. This economic equation becomes particularly favorable when considering the avoided costs of regulatory compliance, which can reach millions annually for operations failing to meet discharge standards.

Variable feed quality presents distinct economic challenges, as fluctuations in contaminant concentrations necessitate adaptive treatment capabilities. Systems equipped with real-time monitoring and automated adjustment features command premium prices but deliver superior performance under variable conditions. Cost-benefit analyses demonstrate that such adaptive systems typically reduce operational disruptions by 60-75%, translating to significant production continuity benefits.

Economies of scale play a decisive role in feasibility assessments. Large-scale operations processing over 5,000 cubic meters daily achieve unit treatment costs approximately 40% lower than small-scale implementations. This differential underscores the importance of capacity planning in investment decisions.

Energy efficiency innovations have substantially improved the economic profile of advanced recycling systems. Modern membrane technologies and energy recovery devices reduce energy consumption by 30-50% compared to conventional systems, directly impacting operational costs. Similarly, chemical consumption optimization through precision dosing systems has yielded 15-25% reductions in treatment chemical expenses.

Life-cycle cost analyses reveal that while conventional treatment systems may offer lower initial investments, advanced recycling systems deliver superior long-term value when accounting for water recovery rates, operational reliability, and regulatory compliance benefits. The economic advantage becomes particularly pronounced in operations facing water scarcity, stringent discharge regulations, or high-value lithium deposits where production continuity carries premium value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!