Exploring Biodegradability of PLA in Industrial Composting

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biodegradability Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer, gaining significant attention in recent years due to its potential to address environmental concerns associated with conventional plastics. The development of PLA can be traced back to the 1930s, but it wasn't until the late 20th century that its commercial production and applications began to expand rapidly.

PLA is derived from renewable resources such as corn starch, cassava roots, or sugarcane, making it an attractive alternative to petroleum-based plastics. Its biodegradability in industrial composting conditions has been a key factor driving its adoption across various industries, including packaging, textiles, and medical applications.

The evolution of PLA technology has been marked by continuous improvements in production processes, material properties, and biodegradation rates. Early challenges included high production costs and limited mechanical properties, which restricted its widespread use. However, advancements in fermentation techniques and polymer science have led to more cost-effective production methods and enhanced material characteristics.

In recent years, the focus has shifted towards optimizing PLA's biodegradability in industrial composting environments. This has become crucial as the material's increasing prevalence in consumer products necessitates efficient end-of-life management. The biodegradation process of PLA involves the breakdown of polymer chains into smaller molecules, ultimately resulting in carbon dioxide, water, and biomass.

The primary objective of exploring PLA biodegradability in industrial composting is to ensure that the material can be effectively processed in existing waste management systems. This involves understanding the factors that influence biodegradation rates, such as temperature, humidity, microbial activity, and the presence of other organic materials.

Additionally, researchers aim to develop PLA formulations that maintain their functional properties during use but degrade rapidly under specific composting conditions. This balance between durability and biodegradability is critical for the material's success in various applications.

Another important goal is to establish standardized testing methods and certification processes for PLA biodegradability. This will provide consumers and waste management facilities with clear guidelines on how to handle PLA products at the end of their lifecycle.

As environmental regulations become more stringent and consumer awareness of plastic pollution grows, the development of biodegradable materials like PLA has become increasingly important. The ongoing research into PLA biodegradability in industrial composting conditions is expected to play a crucial role in addressing global plastic waste challenges and promoting a more sustainable circular economy.

PLA is derived from renewable resources such as corn starch, cassava roots, or sugarcane, making it an attractive alternative to petroleum-based plastics. Its biodegradability in industrial composting conditions has been a key factor driving its adoption across various industries, including packaging, textiles, and medical applications.

The evolution of PLA technology has been marked by continuous improvements in production processes, material properties, and biodegradation rates. Early challenges included high production costs and limited mechanical properties, which restricted its widespread use. However, advancements in fermentation techniques and polymer science have led to more cost-effective production methods and enhanced material characteristics.

In recent years, the focus has shifted towards optimizing PLA's biodegradability in industrial composting environments. This has become crucial as the material's increasing prevalence in consumer products necessitates efficient end-of-life management. The biodegradation process of PLA involves the breakdown of polymer chains into smaller molecules, ultimately resulting in carbon dioxide, water, and biomass.

The primary objective of exploring PLA biodegradability in industrial composting is to ensure that the material can be effectively processed in existing waste management systems. This involves understanding the factors that influence biodegradation rates, such as temperature, humidity, microbial activity, and the presence of other organic materials.

Additionally, researchers aim to develop PLA formulations that maintain their functional properties during use but degrade rapidly under specific composting conditions. This balance between durability and biodegradability is critical for the material's success in various applications.

Another important goal is to establish standardized testing methods and certification processes for PLA biodegradability. This will provide consumers and waste management facilities with clear guidelines on how to handle PLA products at the end of their lifecycle.

As environmental regulations become more stringent and consumer awareness of plastic pollution grows, the development of biodegradable materials like PLA has become increasingly important. The ongoing research into PLA biodegradability in industrial composting conditions is expected to play a crucial role in addressing global plastic waste challenges and promoting a more sustainable circular economy.

Market Demand for Biodegradable Plastics

The market demand for biodegradable plastics has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. Polylactic acid (PLA), a biodegradable polymer derived from renewable resources, has emerged as a promising alternative to conventional plastics in various applications.

The global biodegradable plastics market, including PLA, is projected to expand at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is primarily fueled by the rising awareness of plastic pollution and its detrimental effects on ecosystems. Governments worldwide are implementing stricter regulations on single-use plastics, further boosting the demand for biodegradable alternatives.

PLA, in particular, has gained traction in the packaging industry, which accounts for the largest share of biodegradable plastics consumption. The food and beverage sector has shown a strong interest in PLA-based packaging solutions due to their compostability and potential to reduce carbon footprint. Additionally, the agriculture and horticulture industries are increasingly adopting PLA-based products for mulch films and plant pots.

Consumer preferences are shifting towards eco-friendly products, with a growing willingness to pay premium prices for sustainable alternatives. This trend is particularly evident in developed markets such as Europe and North America, where environmental consciousness is relatively high. However, emerging economies in Asia-Pacific and Latin America are also witnessing a surge in demand for biodegradable plastics, driven by urbanization and changing consumer behaviors.

The industrial composting sector plays a crucial role in realizing the full potential of PLA's biodegradability. As more municipalities and waste management facilities invest in industrial composting infrastructure, the market for compostable PLA products is expected to expand. This symbiotic relationship between PLA producers and composting facilities is likely to drive innovation in both sectors.

Despite the positive market outlook, challenges remain in the widespread adoption of PLA and other biodegradable plastics. These include higher production costs compared to conventional plastics, limited availability of industrial composting facilities, and the need for consumer education on proper disposal methods. Addressing these challenges will be crucial for sustaining the growth momentum of the biodegradable plastics market.

In conclusion, the market demand for biodegradable plastics, particularly PLA, shows strong growth potential. The convergence of environmental concerns, regulatory support, and changing consumer preferences is creating a favorable landscape for PLA adoption across various industries. As research and development efforts continue to improve PLA's properties and composting technologies advance, the market is poised for further expansion in the coming years.

The global biodegradable plastics market, including PLA, is projected to expand at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is primarily fueled by the rising awareness of plastic pollution and its detrimental effects on ecosystems. Governments worldwide are implementing stricter regulations on single-use plastics, further boosting the demand for biodegradable alternatives.

PLA, in particular, has gained traction in the packaging industry, which accounts for the largest share of biodegradable plastics consumption. The food and beverage sector has shown a strong interest in PLA-based packaging solutions due to their compostability and potential to reduce carbon footprint. Additionally, the agriculture and horticulture industries are increasingly adopting PLA-based products for mulch films and plant pots.

Consumer preferences are shifting towards eco-friendly products, with a growing willingness to pay premium prices for sustainable alternatives. This trend is particularly evident in developed markets such as Europe and North America, where environmental consciousness is relatively high. However, emerging economies in Asia-Pacific and Latin America are also witnessing a surge in demand for biodegradable plastics, driven by urbanization and changing consumer behaviors.

The industrial composting sector plays a crucial role in realizing the full potential of PLA's biodegradability. As more municipalities and waste management facilities invest in industrial composting infrastructure, the market for compostable PLA products is expected to expand. This symbiotic relationship between PLA producers and composting facilities is likely to drive innovation in both sectors.

Despite the positive market outlook, challenges remain in the widespread adoption of PLA and other biodegradable plastics. These include higher production costs compared to conventional plastics, limited availability of industrial composting facilities, and the need for consumer education on proper disposal methods. Addressing these challenges will be crucial for sustaining the growth momentum of the biodegradable plastics market.

In conclusion, the market demand for biodegradable plastics, particularly PLA, shows strong growth potential. The convergence of environmental concerns, regulatory support, and changing consumer preferences is creating a favorable landscape for PLA adoption across various industries. As research and development efforts continue to improve PLA's properties and composting technologies advance, the market is poised for further expansion in the coming years.

Current State and Challenges in PLA Composting

The current state of PLA composting in industrial settings reveals both promising advancements and significant challenges. Polylactic acid (PLA), a biodegradable polymer derived from renewable resources, has gained considerable attention as an eco-friendly alternative to traditional plastics. However, its biodegradability in industrial composting facilities has been a subject of ongoing research and debate.

Industrial composting of PLA has shown varying degrees of success, with some facilities reporting complete degradation within 3-6 months under optimal conditions. These conditions typically include temperatures between 55-70°C, high humidity levels, and the presence of specific microorganisms. However, achieving and maintaining these ideal conditions consistently across different industrial composting facilities has proven to be a significant challenge.

One of the primary obstacles in PLA composting is the variability in degradation rates. Factors such as the molecular weight of the PLA, its crystallinity, and the presence of additives can significantly impact the biodegradation process. This variability makes it difficult for composting facilities to predict and manage the decomposition timeline effectively, potentially leading to incomplete degradation or contamination of compost batches.

Another challenge is the need for specialized equipment and processes to handle PLA effectively. Many existing industrial composting facilities are not optimized for PLA degradation, lacking the necessary temperature control systems or microbial populations to break down the polymer efficiently. This gap in infrastructure has led to instances where PLA products are screened out as contaminants or only partially decompose, undermining the material's environmental benefits.

The identification and proliferation of PLA-degrading microorganisms present both an opportunity and a challenge. While certain bacterial and fungal strains have shown promising results in accelerating PLA decomposition, their large-scale implementation in industrial composting settings remains limited. Research is ongoing to isolate and cultivate these microorganisms effectively, but scaling up their use presents logistical and economic hurdles.

Furthermore, the lack of standardized testing methods and certification processes for PLA composting has created uncertainty in the industry. Different regions and facilities may have varying definitions of what constitutes "compostable" or "biodegradable," leading to confusion among manufacturers, consumers, and waste management professionals. This inconsistency hampers the widespread adoption of PLA as a truly sustainable alternative to conventional plastics.

Despite these challenges, ongoing research and technological innovations are paving the way for improved PLA composting processes. Advances in PLA formulation, such as the development of more easily degradable blends and additives, show promise in enhancing biodegradability. Additionally, efforts to optimize industrial composting conditions specifically for PLA are underway, with some facilities implementing dedicated PLA processing lines.

Industrial composting of PLA has shown varying degrees of success, with some facilities reporting complete degradation within 3-6 months under optimal conditions. These conditions typically include temperatures between 55-70°C, high humidity levels, and the presence of specific microorganisms. However, achieving and maintaining these ideal conditions consistently across different industrial composting facilities has proven to be a significant challenge.

One of the primary obstacles in PLA composting is the variability in degradation rates. Factors such as the molecular weight of the PLA, its crystallinity, and the presence of additives can significantly impact the biodegradation process. This variability makes it difficult for composting facilities to predict and manage the decomposition timeline effectively, potentially leading to incomplete degradation or contamination of compost batches.

Another challenge is the need for specialized equipment and processes to handle PLA effectively. Many existing industrial composting facilities are not optimized for PLA degradation, lacking the necessary temperature control systems or microbial populations to break down the polymer efficiently. This gap in infrastructure has led to instances where PLA products are screened out as contaminants or only partially decompose, undermining the material's environmental benefits.

The identification and proliferation of PLA-degrading microorganisms present both an opportunity and a challenge. While certain bacterial and fungal strains have shown promising results in accelerating PLA decomposition, their large-scale implementation in industrial composting settings remains limited. Research is ongoing to isolate and cultivate these microorganisms effectively, but scaling up their use presents logistical and economic hurdles.

Furthermore, the lack of standardized testing methods and certification processes for PLA composting has created uncertainty in the industry. Different regions and facilities may have varying definitions of what constitutes "compostable" or "biodegradable," leading to confusion among manufacturers, consumers, and waste management professionals. This inconsistency hampers the widespread adoption of PLA as a truly sustainable alternative to conventional plastics.

Despite these challenges, ongoing research and technological innovations are paving the way for improved PLA composting processes. Advances in PLA formulation, such as the development of more easily degradable blends and additives, show promise in enhancing biodegradability. Additionally, efforts to optimize industrial composting conditions specifically for PLA are underway, with some facilities implementing dedicated PLA processing lines.

Existing Industrial Composting Solutions for PLA

01 Biodegradation mechanisms of PLA

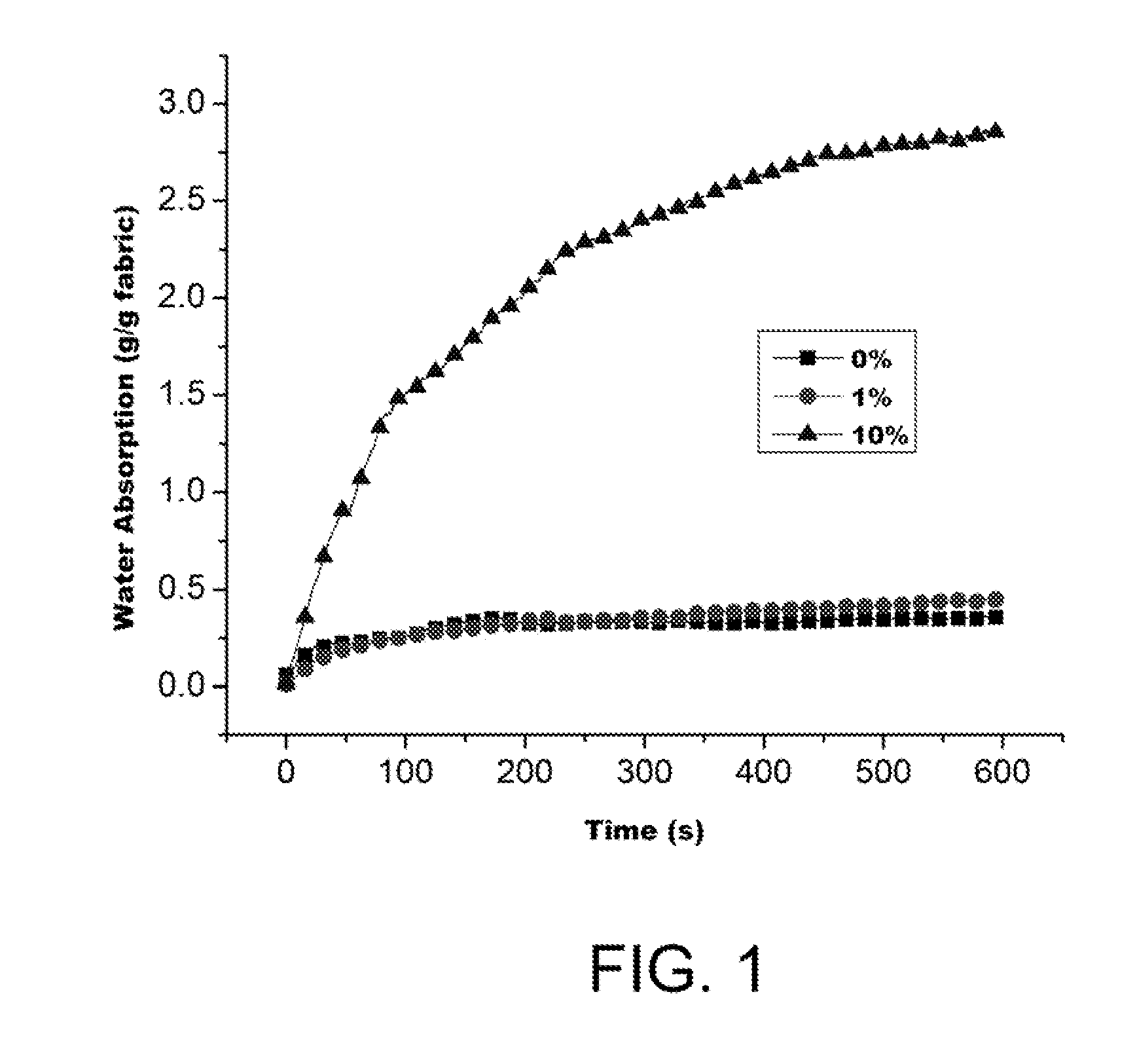

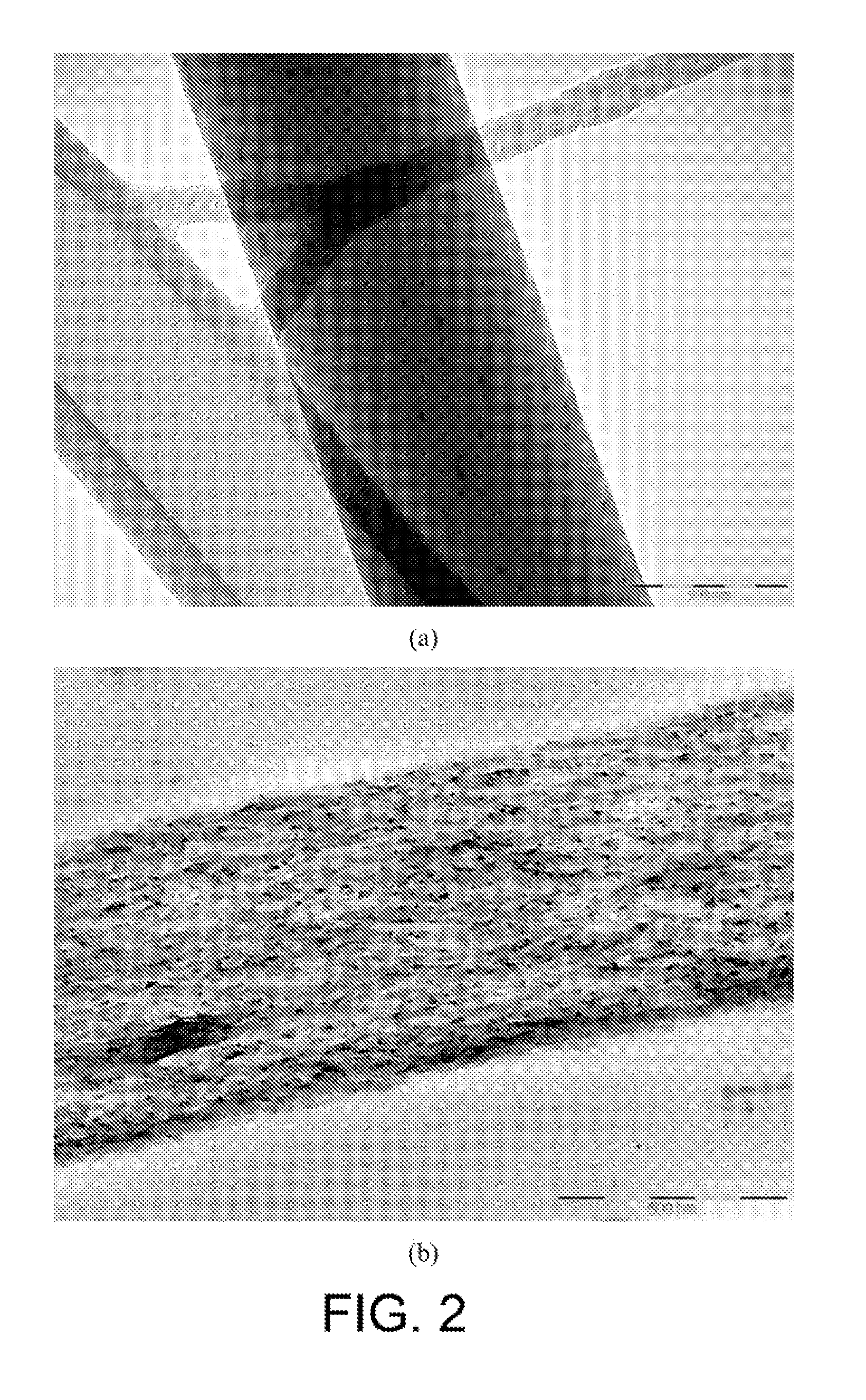

PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to chain scission of the polymer. Microorganisms then metabolize the resulting oligomers and monomers. Factors such as temperature, humidity, and microbial population influence the rate of biodegradation.- Biodegradation mechanisms of PLA: PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to chain scission of the polymer. Microorganisms then break down the resulting oligomers and monomers into carbon dioxide and water. Factors such as temperature, humidity, and microbial activity influence the rate of biodegradation.

- Enhancing PLA biodegradability: Various methods can be employed to improve PLA biodegradability. These include blending with other biodegradable polymers, incorporating additives like plasticizers or pro-oxidants, and modifying the polymer structure. Such enhancements can accelerate the degradation process and expand the range of applications for PLA-based materials.

- Environmental factors affecting PLA biodegradation: The biodegradation of PLA is significantly influenced by environmental conditions. Factors such as temperature, pH, moisture content, and the presence of specific microorganisms play crucial roles. Understanding these factors is essential for predicting and controlling the biodegradation rate of PLA in various environments, from composting facilities to marine ecosystems.

- Industrial applications of biodegradable PLA: Biodegradable PLA finds applications in various industries due to its environmental benefits. It is used in packaging, textiles, medical devices, and 3D printing. The biodegradability of PLA makes it particularly suitable for single-use items and products with short lifespans, offering a more sustainable alternative to traditional plastics.

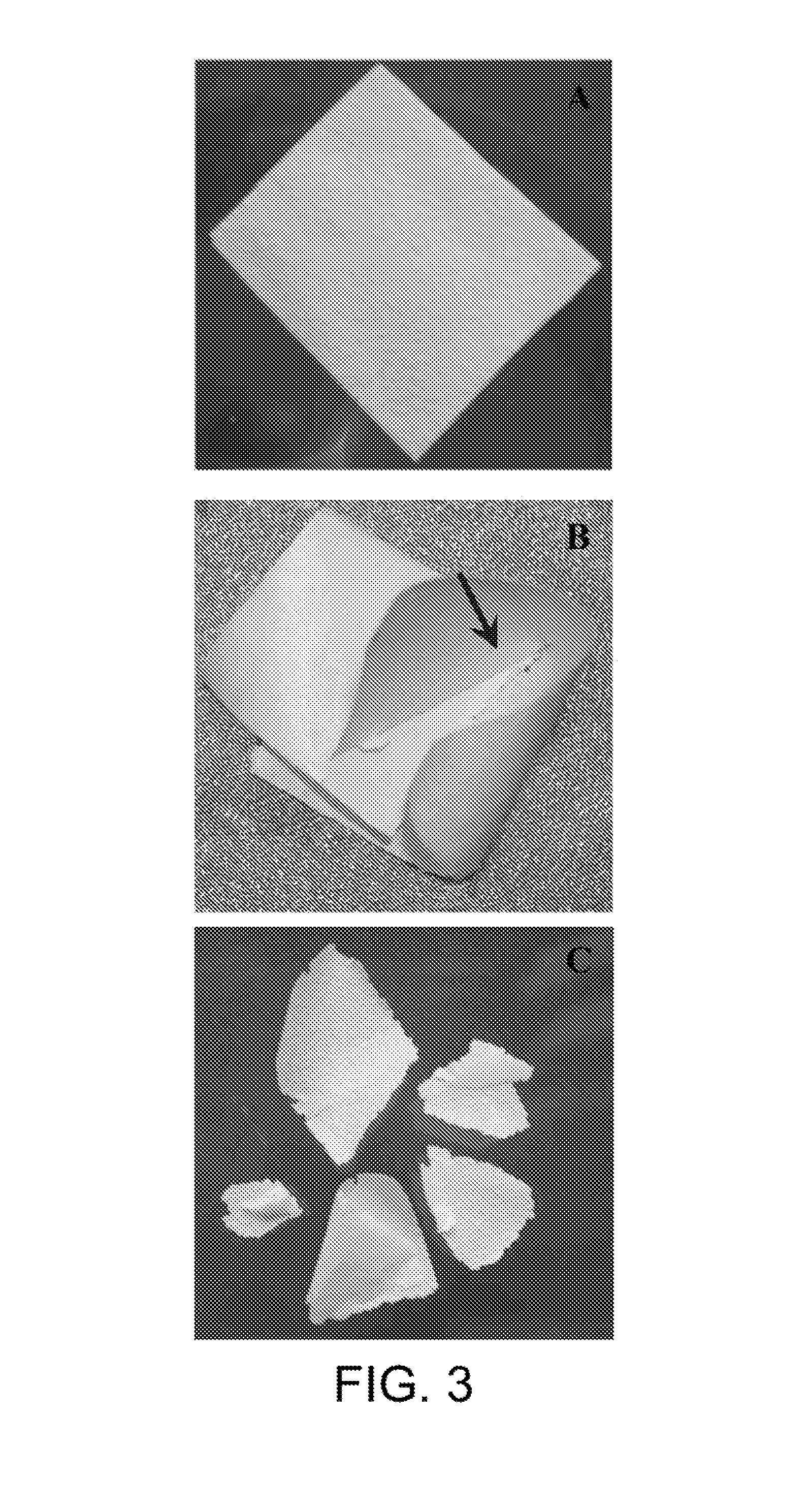

- Composting and end-of-life management of PLA products: Proper end-of-life management is crucial for realizing the full environmental benefits of PLA. Industrial composting facilities provide optimal conditions for PLA biodegradation. However, challenges remain in terms of waste sorting, collection, and processing infrastructure. Developing effective composting systems and educating consumers about proper disposal methods are key to maximizing PLA's potential as a sustainable material.

02 Enhancing PLA biodegradability

Various methods can improve PLA biodegradability, including blending with other biodegradable polymers, incorporating additives like plasticizers or pro-oxidants, and modifying the polymer structure. These approaches aim to increase the material's susceptibility to environmental degradation while maintaining its desired properties during use.Expand Specific Solutions03 Environmental conditions affecting PLA degradation

PLA biodegradation is significantly influenced by environmental factors such as temperature, humidity, pH, and the presence of specific microorganisms. Industrial composting conditions, with elevated temperatures and controlled moisture, typically accelerate the biodegradation process compared to natural environments.Expand Specific Solutions04 Applications of biodegradable PLA

Biodegradable PLA finds applications in various sectors, including packaging, agriculture, and biomedical fields. Its use in disposable items, compostable bags, and temporary medical implants leverages the material's ability to degrade under specific conditions, reducing environmental impact.Expand Specific Solutions05 Testing and standardization of PLA biodegradability

Standardized testing methods and certifications are crucial for assessing PLA biodegradability. These include composting tests, soil burial tests, and aquatic biodegradation tests. International standards provide guidelines for determining the extent and rate of biodegradation under various conditions, ensuring consistent evaluation across different PLA products.Expand Specific Solutions

Key Players in PLA and Industrial Composting

The exploration of PLA biodegradability in industrial composting is at a critical juncture, with the market for biodegradable plastics expanding rapidly. The industry is in a growth phase, driven by increasing environmental concerns and regulatory pressures. Companies like Total Research Corp, International Paper Co., and Mitsubishi Gas Chemical Co., Inc. are at the forefront of this technology, investing heavily in research and development. The technology's maturity is advancing, with academic institutions such as the University of Poitiers, Tongji University, and Cornell University contributing significant research. Collaborations between industry leaders and research institutions, like LG Chem Ltd. and the University of Houston, are accelerating progress in this field, indicating a competitive landscape that is both collaborative and innovative.

Sulapac Oy

Technical Solution: Sulapac has developed a unique biodegradable material made from wood and natural binders. Their technology focuses on creating fully biodegradable packaging solutions that can replace traditional plastics. The material is designed to break down in industrial composting conditions, leaving no microplastics behind. Sulapac's innovation lies in its ability to mimic the properties of plastic while being fully biodegradable, making it suitable for various packaging applications, including cosmetics and food packaging.

Strengths: Fully biodegradable, leaves no microplastics, versatile applications. Weaknesses: May require specific industrial composting conditions, potentially higher production costs compared to traditional plastics.

BioLogiQ, Inc.

Technical Solution: BioLogiQ has developed NuPlastiQ, a plant-based biopolymer that can be blended with traditional plastics to enhance biodegradability. Their technology focuses on creating hybrid materials that maintain the desired properties of plastic while significantly improving end-of-life biodegradability. The company's approach allows for the gradual integration of biodegradable elements into existing plastic production processes, potentially accelerating the adoption of more environmentally friendly packaging solutions.

Strengths: Can be integrated into existing plastic production, improves biodegradability of traditional plastics. Weaknesses: Not fully biodegradable on its own, effectiveness may vary depending on the blend ratio.

Core Innovations in PLA Biodegradation

Biodegradable chemical delivery system

PatentActiveUS20110275520A1

Innovation

- A polymeric material system comprising a hydrophobic polymeric matrix and a hydrophilic second polymeric material, where the latter forms nanocomposite fibers with PLA, enhancing degradation rates and allowing controlled release of compounds like pesticides through varying the composition and form of the polymeric material.

Establish test procedures as per international and indian standard to test the biodegradability of biodegradable plastics material, and study of effect of molecular weight of polymer on biodegradability

PatentInactiveIN202021034378A

Innovation

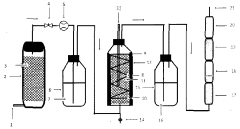

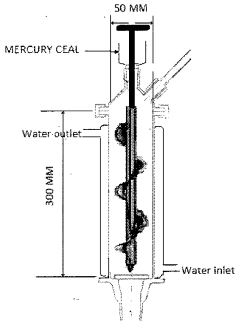

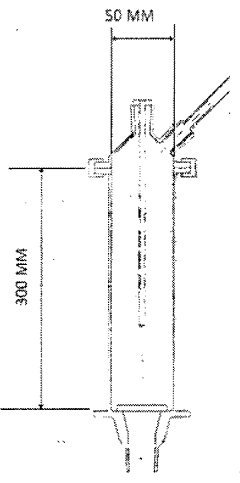

- Development of test procedures according to international and Indian standards (ISO 14855-2) for biodegradable plastics, optimizing the Microbial Oxidative Degradation Analyzer (MODA) assembly by replacing electric heaters with hot water circulation, using mass flow controllers to maintain uniform flow rates, and addressing temperature gradients to accurately study the effect of molecular weight on biodegradability.

Environmental Impact Assessment of PLA Composting

The environmental impact assessment of PLA composting is a crucial aspect of evaluating the sustainability and ecological footprint of this biodegradable polymer. PLA, or polylactic acid, has gained significant attention as an eco-friendly alternative to traditional plastics. However, its environmental benefits are largely dependent on proper end-of-life management, particularly through industrial composting processes.

Industrial composting of PLA involves controlled conditions that facilitate the material's breakdown into its constituent components. This process typically occurs in specialized facilities where temperature, humidity, and microbial activity are carefully regulated. The environmental impact of PLA composting can be assessed through several key factors.

Firstly, the energy consumption and greenhouse gas emissions associated with the composting process must be considered. Industrial composting facilities require energy for maintaining optimal conditions, which may contribute to carbon emissions. However, these emissions are generally offset by the reduction in landfill methane production that would occur if the PLA were disposed of in traditional waste streams.

Soil quality is another important consideration in the environmental impact assessment. As PLA breaks down, it releases lactic acid and other organic compounds into the soil. While these substances are generally beneficial and can enhance soil fertility, their impact on soil microbial communities and long-term soil health needs to be carefully evaluated.

Water usage and potential contamination are also significant factors. Industrial composting facilities may require substantial amounts of water to maintain proper moisture levels. Additionally, the leachate produced during the composting process must be managed to prevent potential groundwater contamination.

The end product of PLA composting, known as compost, can have both positive and negative environmental impacts. On the positive side, it can be used as a soil amendment, reducing the need for synthetic fertilizers and improving soil structure. However, the quality of the compost and the presence of any residual polymer fragments must be closely monitored to ensure its safety for agricultural use.

Lastly, the overall life cycle assessment of PLA, including its production, use, and composting, should be compared to alternative materials and disposal methods. This comprehensive evaluation helps determine whether industrial composting of PLA truly offers environmental benefits over other options, such as recycling or landfilling of conventional plastics.

Industrial composting of PLA involves controlled conditions that facilitate the material's breakdown into its constituent components. This process typically occurs in specialized facilities where temperature, humidity, and microbial activity are carefully regulated. The environmental impact of PLA composting can be assessed through several key factors.

Firstly, the energy consumption and greenhouse gas emissions associated with the composting process must be considered. Industrial composting facilities require energy for maintaining optimal conditions, which may contribute to carbon emissions. However, these emissions are generally offset by the reduction in landfill methane production that would occur if the PLA were disposed of in traditional waste streams.

Soil quality is another important consideration in the environmental impact assessment. As PLA breaks down, it releases lactic acid and other organic compounds into the soil. While these substances are generally beneficial and can enhance soil fertility, their impact on soil microbial communities and long-term soil health needs to be carefully evaluated.

Water usage and potential contamination are also significant factors. Industrial composting facilities may require substantial amounts of water to maintain proper moisture levels. Additionally, the leachate produced during the composting process must be managed to prevent potential groundwater contamination.

The end product of PLA composting, known as compost, can have both positive and negative environmental impacts. On the positive side, it can be used as a soil amendment, reducing the need for synthetic fertilizers and improving soil structure. However, the quality of the compost and the presence of any residual polymer fragments must be closely monitored to ensure its safety for agricultural use.

Lastly, the overall life cycle assessment of PLA, including its production, use, and composting, should be compared to alternative materials and disposal methods. This comprehensive evaluation helps determine whether industrial composting of PLA truly offers environmental benefits over other options, such as recycling or landfilling of conventional plastics.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development, production, and disposal of materials like PLA in industrial composting settings. At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradable plastics, including ISO 17088 and ISO 16929, which define specifications and testing methods for compostable plastics.

In the European Union, the EN 13432 standard is widely recognized and serves as a benchmark for biodegradable and compostable packaging materials. This standard outlines specific criteria for biodegradability, disintegration, and ecotoxicity that materials must meet to be certified as compostable. The EU has also implemented directives such as the Packaging and Packaging Waste Directive (94/62/EC) and the Single-Use Plastics Directive (EU) 2019/904, which aim to reduce plastic waste and promote the use of biodegradable alternatives.

In the United States, the regulatory landscape is more fragmented, with different states implementing their own regulations. However, the Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability and compostability. The American Society for Testing and Materials (ASTM) has developed standards such as ASTM D6400 for compostable plastics, which are widely used in the industry.

Many countries have implemented or are in the process of implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These regulations often incentivize the use of biodegradable materials like PLA in packaging and other applications.

Certification systems have emerged to help consumers and businesses identify products that meet specific biodegradability and compostability standards. Organizations like TÜV Austria (OK Compost) and the Biodegradable Products Institute (BPI) provide certification services based on established standards.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are adapting to address new challenges and opportunities. There is a growing focus on harmonizing standards across different regions and ensuring that claims of biodegradability are substantiated by rigorous scientific evidence. Future regulations may also address the need for improved infrastructure to support the industrial composting of biodegradable plastics like PLA.

In the European Union, the EN 13432 standard is widely recognized and serves as a benchmark for biodegradable and compostable packaging materials. This standard outlines specific criteria for biodegradability, disintegration, and ecotoxicity that materials must meet to be certified as compostable. The EU has also implemented directives such as the Packaging and Packaging Waste Directive (94/62/EC) and the Single-Use Plastics Directive (EU) 2019/904, which aim to reduce plastic waste and promote the use of biodegradable alternatives.

In the United States, the regulatory landscape is more fragmented, with different states implementing their own regulations. However, the Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability and compostability. The American Society for Testing and Materials (ASTM) has developed standards such as ASTM D6400 for compostable plastics, which are widely used in the industry.

Many countries have implemented or are in the process of implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These regulations often incentivize the use of biodegradable materials like PLA in packaging and other applications.

Certification systems have emerged to help consumers and businesses identify products that meet specific biodegradability and compostability standards. Organizations like TÜV Austria (OK Compost) and the Biodegradable Products Institute (BPI) provide certification services based on established standards.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are adapting to address new challenges and opportunities. There is a growing focus on harmonizing standards across different regions and ensuring that claims of biodegradability are substantiated by rigorous scientific evidence. Future regulations may also address the need for improved infrastructure to support the industrial composting of biodegradable plastics like PLA.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!