Exploring Industrial PLA Biopolymer Developments

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biopolymer Evolution and Objectives

Polylactic acid (PLA) biopolymers have emerged as a promising sustainable alternative to traditional petroleum-based plastics. The evolution of PLA technology can be traced back to the 1930s when it was first synthesized, but its industrial applications only gained significant traction in the late 20th century. The primary objective of PLA biopolymer development is to create a biodegradable, renewable material that can effectively replace conventional plastics in various applications while minimizing environmental impact.

Over the past few decades, PLA has undergone substantial improvements in terms of production efficiency, material properties, and cost-effectiveness. Initially, PLA was limited by high production costs and inferior mechanical properties compared to traditional plastics. However, advancements in fermentation processes and polymer science have led to more economically viable production methods and enhanced material characteristics.

The current technological landscape of PLA biopolymers is characterized by a focus on optimizing production processes, expanding application areas, and improving material performance. Key objectives include increasing the heat resistance of PLA, enhancing its barrier properties, and developing more efficient biodegradation mechanisms. These goals are driven by the growing demand for sustainable packaging solutions, biomedical applications, and eco-friendly consumer products.

Recent developments in PLA technology have centered on creating blends and composites to overcome some of the material's inherent limitations. For instance, researchers are exploring the incorporation of nanoparticles and natural fibers to enhance the mechanical and thermal properties of PLA. Additionally, efforts are being made to improve the material's processability to make it more compatible with existing plastic manufacturing equipment.

The future trajectory of PLA biopolymer evolution is likely to involve further refinements in production techniques, such as the development of more efficient catalysts and the utilization of alternative feedstocks. There is also a growing interest in creating PLA-based materials with advanced functionalities, such as self-healing properties or controlled degradation rates. These innovations aim to expand the potential applications of PLA in sectors like electronics, automotive, and construction.

As environmental concerns continue to drive the demand for sustainable materials, the objectives for PLA biopolymer development are expected to align closely with circular economy principles. This includes improving the recyclability of PLA products, developing closed-loop production systems, and ensuring that end-of-life PLA materials can be effectively composted or biodegraded without leaving harmful residues.

Over the past few decades, PLA has undergone substantial improvements in terms of production efficiency, material properties, and cost-effectiveness. Initially, PLA was limited by high production costs and inferior mechanical properties compared to traditional plastics. However, advancements in fermentation processes and polymer science have led to more economically viable production methods and enhanced material characteristics.

The current technological landscape of PLA biopolymers is characterized by a focus on optimizing production processes, expanding application areas, and improving material performance. Key objectives include increasing the heat resistance of PLA, enhancing its barrier properties, and developing more efficient biodegradation mechanisms. These goals are driven by the growing demand for sustainable packaging solutions, biomedical applications, and eco-friendly consumer products.

Recent developments in PLA technology have centered on creating blends and composites to overcome some of the material's inherent limitations. For instance, researchers are exploring the incorporation of nanoparticles and natural fibers to enhance the mechanical and thermal properties of PLA. Additionally, efforts are being made to improve the material's processability to make it more compatible with existing plastic manufacturing equipment.

The future trajectory of PLA biopolymer evolution is likely to involve further refinements in production techniques, such as the development of more efficient catalysts and the utilization of alternative feedstocks. There is also a growing interest in creating PLA-based materials with advanced functionalities, such as self-healing properties or controlled degradation rates. These innovations aim to expand the potential applications of PLA in sectors like electronics, automotive, and construction.

As environmental concerns continue to drive the demand for sustainable materials, the objectives for PLA biopolymer development are expected to align closely with circular economy principles. This includes improving the recyclability of PLA products, developing closed-loop production systems, and ensuring that end-of-life PLA materials can be effectively composted or biodegraded without leaving harmful residues.

Industrial PLA Market Analysis

The industrial PLA (Polylactic Acid) market has experienced significant growth in recent years, driven by increasing environmental concerns and the shift towards sustainable materials. PLA, a biodegradable and renewable biopolymer derived from plant-based sources such as corn starch or sugarcane, has gained traction across various industries as an eco-friendly alternative to traditional petroleum-based plastics.

The global industrial PLA market is characterized by robust demand from key end-use sectors, including packaging, textiles, automotive, and consumer goods. The packaging industry, in particular, has emerged as a major consumer of PLA, with applications ranging from food packaging to disposable cutlery and containers. This surge in demand is primarily attributed to stringent regulations on single-use plastics and growing consumer awareness of environmental issues.

Market analysis indicates that the Asia-Pacific region leads in PLA production and consumption, with China and Japan at the forefront. North America and Europe follow closely, driven by supportive government policies and increasing adoption of sustainable materials in manufacturing processes. The market landscape is competitive, with several key players vying for market share through product innovations and strategic partnerships.

Despite its growth, the industrial PLA market faces challenges such as higher production costs compared to conventional plastics and limitations in certain performance characteristics. However, ongoing research and development efforts are addressing these issues, focusing on improving PLA's heat resistance, durability, and processing capabilities.

The market is witnessing a trend towards the development of high-performance PLA grades tailored for specific industrial applications. This includes PLA formulations with enhanced mechanical properties for automotive parts, improved barrier properties for packaging, and flame-retardant grades for electronics and construction materials.

Technological advancements in PLA production processes are also shaping the market dynamics. Innovations in fermentation techniques and the use of alternative feedstocks are expected to reduce production costs and expand the range of PLA applications. Additionally, the integration of PLA into additive manufacturing (3D printing) is opening new avenues for customized and on-demand production of industrial components.

The industrial PLA market is projected to maintain its growth trajectory in the coming years, driven by increasing environmental regulations, consumer preferences for sustainable products, and advancements in PLA technology. As industries continue to prioritize sustainability and circular economy principles, PLA is poised to play a crucial role in the transition towards bio-based materials in industrial applications.

The global industrial PLA market is characterized by robust demand from key end-use sectors, including packaging, textiles, automotive, and consumer goods. The packaging industry, in particular, has emerged as a major consumer of PLA, with applications ranging from food packaging to disposable cutlery and containers. This surge in demand is primarily attributed to stringent regulations on single-use plastics and growing consumer awareness of environmental issues.

Market analysis indicates that the Asia-Pacific region leads in PLA production and consumption, with China and Japan at the forefront. North America and Europe follow closely, driven by supportive government policies and increasing adoption of sustainable materials in manufacturing processes. The market landscape is competitive, with several key players vying for market share through product innovations and strategic partnerships.

Despite its growth, the industrial PLA market faces challenges such as higher production costs compared to conventional plastics and limitations in certain performance characteristics. However, ongoing research and development efforts are addressing these issues, focusing on improving PLA's heat resistance, durability, and processing capabilities.

The market is witnessing a trend towards the development of high-performance PLA grades tailored for specific industrial applications. This includes PLA formulations with enhanced mechanical properties for automotive parts, improved barrier properties for packaging, and flame-retardant grades for electronics and construction materials.

Technological advancements in PLA production processes are also shaping the market dynamics. Innovations in fermentation techniques and the use of alternative feedstocks are expected to reduce production costs and expand the range of PLA applications. Additionally, the integration of PLA into additive manufacturing (3D printing) is opening new avenues for customized and on-demand production of industrial components.

The industrial PLA market is projected to maintain its growth trajectory in the coming years, driven by increasing environmental regulations, consumer preferences for sustainable products, and advancements in PLA technology. As industries continue to prioritize sustainability and circular economy principles, PLA is poised to play a crucial role in the transition towards bio-based materials in industrial applications.

PLA Technical Challenges

Polylactic acid (PLA) biopolymers have gained significant attention in industrial applications due to their biodegradability and renewable sourcing. However, the widespread adoption of PLA in various sectors faces several technical challenges that need to be addressed to enhance its performance and competitiveness.

One of the primary challenges is the inherent brittleness of PLA, which limits its use in applications requiring high impact resistance or flexibility. This mechanical limitation stems from the polymer's high glass transition temperature and low crystallization rate. Researchers are exploring various strategies to overcome this issue, including blending PLA with other polymers, incorporating plasticizers, and developing novel copolymerization techniques.

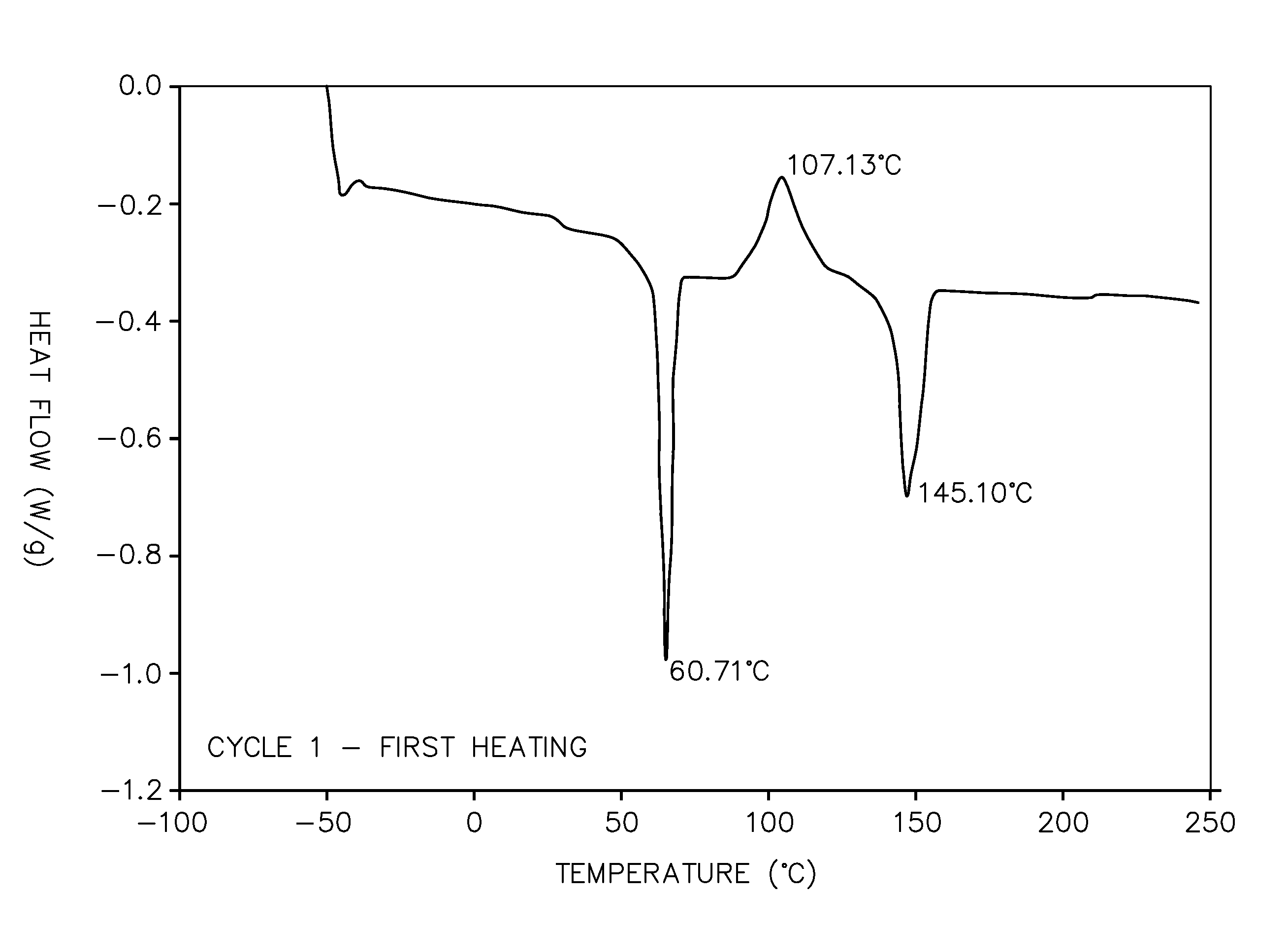

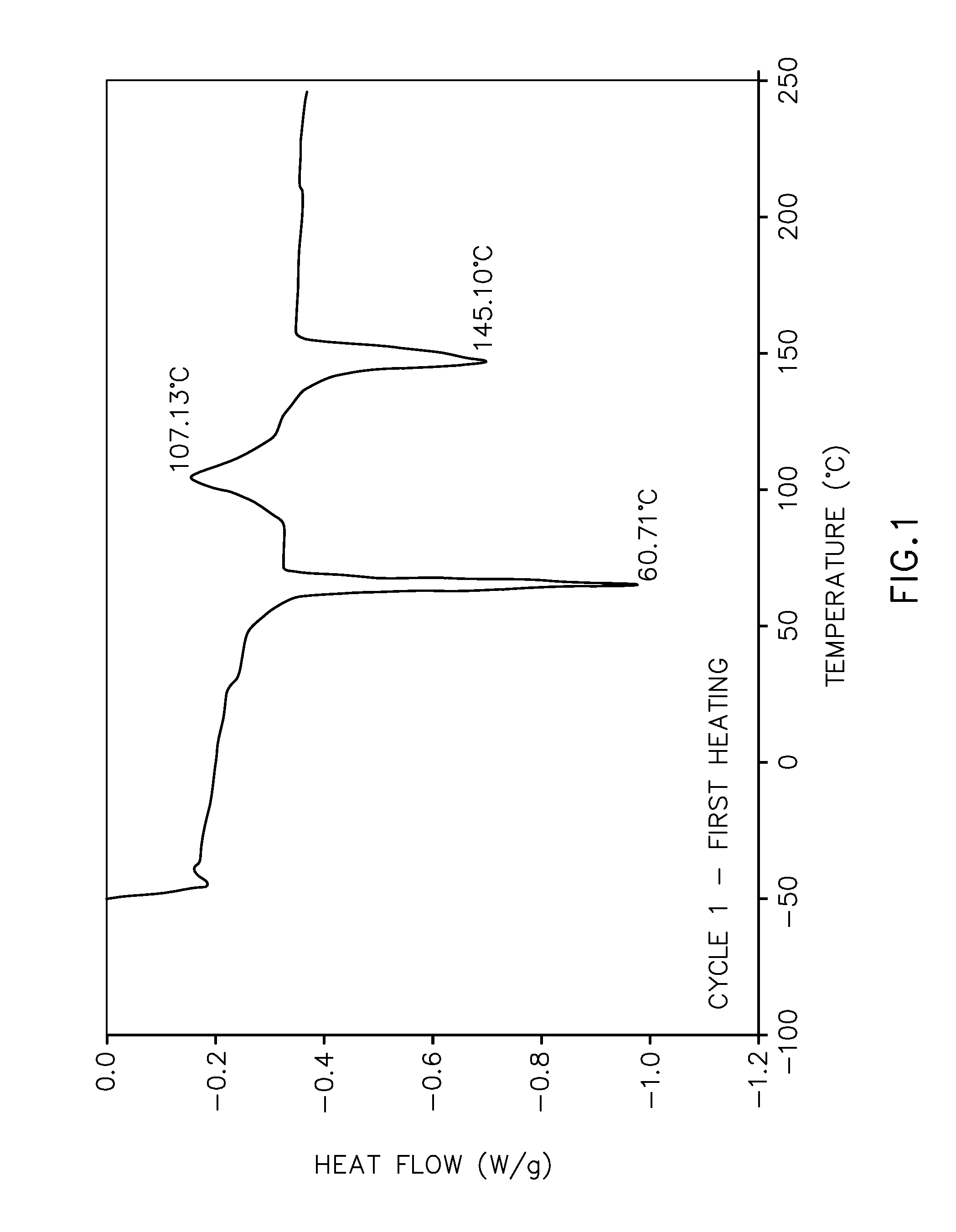

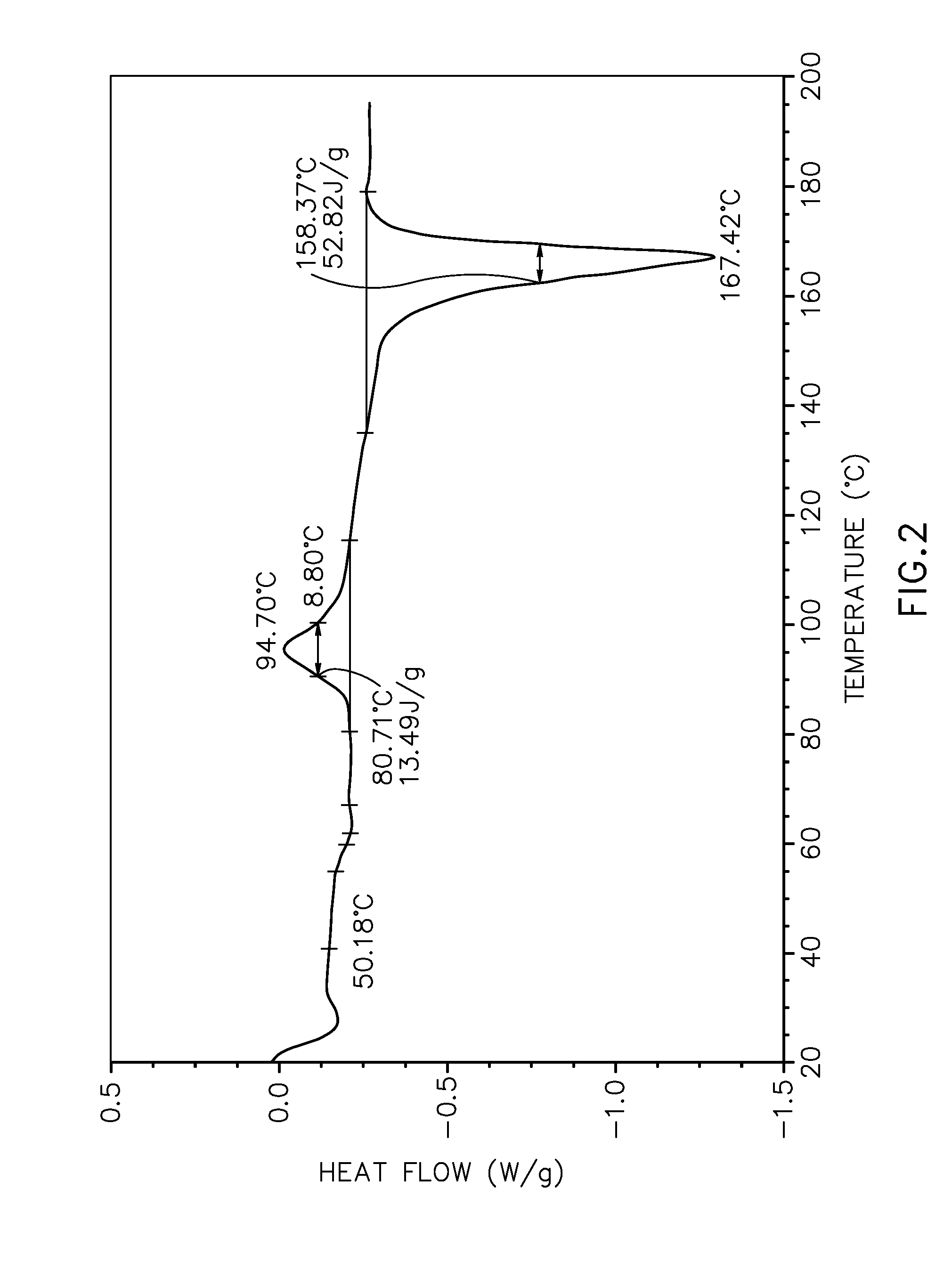

Thermal stability is another critical challenge for PLA in industrial applications. The polymer's low heat deflection temperature restricts its use in high-temperature environments or processes. This limitation is particularly problematic in automotive, electronics, and packaging industries where materials must withstand elevated temperatures during production or use. Efforts to improve PLA's thermal properties include the addition of nucleating agents, chain extenders, and the development of stereocomplex PLA structures.

The relatively slow crystallization rate of PLA compared to conventional petroleum-based polymers poses challenges in processing and manufacturing. This characteristic affects cycle times in injection molding and limits the achievable crystallinity in finished products. Consequently, it impacts the mechanical properties and heat resistance of PLA-based materials. Researchers are investigating various nucleating agents and processing techniques to enhance crystallization kinetics and control crystal morphology.

Moisture sensitivity is another significant hurdle for PLA in many industrial applications. The polymer's susceptibility to hydrolytic degradation can lead to a reduction in molecular weight and deterioration of mechanical properties during processing and use. This issue is particularly critical in high-humidity environments or applications involving contact with aqueous media. Strategies to mitigate this challenge include the development of moisture-resistant grades, surface treatments, and the use of protective coatings.

The cost-competitiveness of PLA compared to traditional petroleum-based polymers remains a challenge, particularly in bulk applications. While the price gap has narrowed in recent years, further improvements in production efficiency and economies of scale are necessary to make PLA more economically viable across a broader range of industries. This involves optimizing fermentation processes, enhancing purification techniques, and developing more efficient polymerization methods.

Addressing these technical challenges is crucial for expanding the industrial applications of PLA biopolymers. Ongoing research and development efforts focus on enhancing PLA's performance characteristics while maintaining its eco-friendly attributes, paving the way for more sustainable material solutions across various sectors.

One of the primary challenges is the inherent brittleness of PLA, which limits its use in applications requiring high impact resistance or flexibility. This mechanical limitation stems from the polymer's high glass transition temperature and low crystallization rate. Researchers are exploring various strategies to overcome this issue, including blending PLA with other polymers, incorporating plasticizers, and developing novel copolymerization techniques.

Thermal stability is another critical challenge for PLA in industrial applications. The polymer's low heat deflection temperature restricts its use in high-temperature environments or processes. This limitation is particularly problematic in automotive, electronics, and packaging industries where materials must withstand elevated temperatures during production or use. Efforts to improve PLA's thermal properties include the addition of nucleating agents, chain extenders, and the development of stereocomplex PLA structures.

The relatively slow crystallization rate of PLA compared to conventional petroleum-based polymers poses challenges in processing and manufacturing. This characteristic affects cycle times in injection molding and limits the achievable crystallinity in finished products. Consequently, it impacts the mechanical properties and heat resistance of PLA-based materials. Researchers are investigating various nucleating agents and processing techniques to enhance crystallization kinetics and control crystal morphology.

Moisture sensitivity is another significant hurdle for PLA in many industrial applications. The polymer's susceptibility to hydrolytic degradation can lead to a reduction in molecular weight and deterioration of mechanical properties during processing and use. This issue is particularly critical in high-humidity environments or applications involving contact with aqueous media. Strategies to mitigate this challenge include the development of moisture-resistant grades, surface treatments, and the use of protective coatings.

The cost-competitiveness of PLA compared to traditional petroleum-based polymers remains a challenge, particularly in bulk applications. While the price gap has narrowed in recent years, further improvements in production efficiency and economies of scale are necessary to make PLA more economically viable across a broader range of industries. This involves optimizing fermentation processes, enhancing purification techniques, and developing more efficient polymerization methods.

Addressing these technical challenges is crucial for expanding the industrial applications of PLA biopolymers. Ongoing research and development efforts focus on enhancing PLA's performance characteristics while maintaining its eco-friendly attributes, paving the way for more sustainable material solutions across various sectors.

Current PLA Production Methods

01 PLA biopolymer synthesis and production methods

Various methods for synthesizing and producing PLA biopolymers, including fermentation processes, polymerization techniques, and optimization of production conditions. These methods aim to improve the efficiency and quality of PLA production for various applications.- PLA biopolymer synthesis and production methods: Various methods for synthesizing and producing PLA biopolymers, including fermentation processes, polymerization techniques, and optimization of production parameters to enhance yield and quality of the biopolymer.

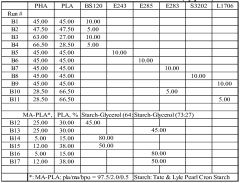

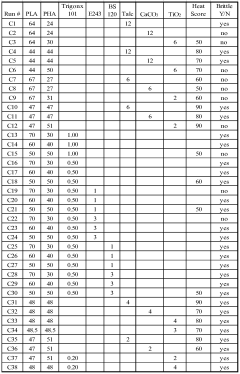

- PLA biopolymer blends and composites: Development of PLA-based blends and composites with other materials to improve mechanical properties, thermal stability, and biodegradability. This includes the incorporation of natural fibers, nanoparticles, or other polymers to create enhanced PLA-based materials.

- PLA biopolymer applications in medical and pharmaceutical fields: Utilization of PLA biopolymers in medical devices, drug delivery systems, tissue engineering scaffolds, and other biomedical applications due to their biocompatibility and biodegradability properties.

- PLA biopolymer processing and manufacturing techniques: Advanced processing and manufacturing techniques for PLA biopolymers, including extrusion, injection molding, 3D printing, and other fabrication methods to create various products and components.

- PLA biopolymer modification and functionalization: Methods for modifying and functionalizing PLA biopolymers to enhance their properties, such as improving hydrophilicity, increasing thermal stability, or adding specific functional groups for targeted applications.

02 PLA biopolymer blends and composites

Development of PLA-based blends and composites with other materials to enhance properties such as mechanical strength, thermal stability, and biodegradability. These blends and composites expand the range of applications for PLA biopolymers in various industries.Expand Specific Solutions03 PLA biopolymer modifications and functionalization

Techniques for modifying and functionalizing PLA biopolymers to improve their properties and performance. This includes chemical modifications, surface treatments, and the incorporation of additives to enhance specific characteristics of PLA materials.Expand Specific Solutions04 PLA biopolymer applications in medical and pharmaceutical fields

Utilization of PLA biopolymers in medical and pharmaceutical applications, including drug delivery systems, tissue engineering scaffolds, and biodegradable implants. The biocompatibility and controlled degradation properties of PLA make it suitable for various medical uses.Expand Specific Solutions05 PLA biopolymer processing and manufacturing techniques

Advanced processing and manufacturing techniques for PLA biopolymers, including extrusion, injection molding, and 3D printing. These methods focus on optimizing the production of PLA-based products while maintaining their desired properties and performance characteristics.Expand Specific Solutions

Key PLA Industry Players

The industrial PLA biopolymer market is in a growth phase, driven by increasing demand for sustainable materials. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, PLA biopolymers are advancing, but there's still room for improvement in performance and cost-effectiveness. Key players like International Paper Co., CJ CheilJedang Corp., and Arkema, Inc. are investing heavily in R&D to enhance PLA properties and production efficiency. Universities such as Zhejiang University and University of Florida are contributing to fundamental research, while companies like TotalEnergies OneTech SAS and LG Chem Ltd. are focusing on industrial applications and scaling up production. This collaborative ecosystem is accelerating the maturation of PLA technology, positioning it as a viable alternative to traditional plastics.

METabolic EXplorer SA

Technical Solution: METabolic EXplorer has developed a unique fermentation-based process for producing PDO (1,3-propanediol), a key building block for biobased polymers including PLA. Their technology utilizes renewable feedstocks and engineered microorganisms to efficiently convert raw materials into PDO. This PDO can then be used in the production of various biopolymers, including modified PLA with enhanced properties. The company's process is designed to be more cost-effective and environmentally friendly than traditional petrochemical routes, potentially reducing the overall cost of PLA production.

Strengths: Innovative fermentation technology for producing biopolymer precursors. Potential for cost reduction in PLA production. Weaknesses: Relatively small scale compared to major chemical companies. Dependence on partnerships for full PLA production and commercialization.

Floreon Technology Ltd.

Technical Solution: Floreon has developed a proprietary additive technology that significantly enhances the properties of standard PLA. Their formulation, when compounded with PLA, results in a biopolymer with improved impact resistance, heat tolerance, and processing characteristics. This allows Floreon-enhanced PLA to compete more effectively with traditional plastics in a wider range of applications, including automotive parts, consumer electronics, and industrial components. The company's technology is designed to be compatible with existing PLA production and processing equipment, facilitating easy adoption by manufacturers.

Strengths: Unique additive technology that enhances PLA properties without compromising biodegradability. Easily integrated into existing PLA production processes. Weaknesses: Reliance on PLA producers for base material. Potential challenges in scaling up production to meet large-scale industrial demand.

PLA Material Innovations

Thermoformed articles made from reactive extrusion products of biobased materials

PatentActiveUS8231954B2

Innovation

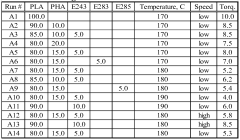

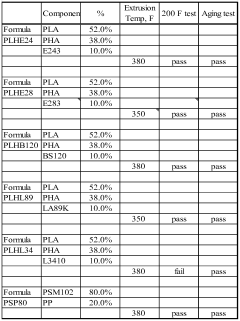

- Development of thermoformable composite materials comprising blends of PLA and polyhydroxyalkanoates (PHAs) with specific additives, processed via extrusion, to enhance thermal and mechanical performance, achieving a Vicat softening point up to 180°C and heat distortion index up to 160°C, thereby improving resistance to deformation at higher temperatures.

Thermoformed articles made from reactive extrusion products of biobased materials

PatentWO2011071666A1

Innovation

- Development of thermoformable composite materials through blending PHAs and PLA with additives, processed via extrusion, to enhance thermal and mechanical performance while maintaining sustainability, with specific formulations achieving higher heat distortion indices and Vicat softening points.

PLA Environmental Impact

Polylactic acid (PLA) biopolymers have gained significant attention in recent years due to their potential to reduce environmental impact compared to traditional petroleum-based plastics. As a biodegradable and compostable material derived from renewable resources, PLA offers several environmental benefits throughout its lifecycle.

The production of PLA requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. Studies have shown that PLA production can reduce carbon dioxide emissions by up to 80% compared to petroleum-based polymers. Additionally, the use of renewable feedstocks, such as corn or sugarcane, helps to decrease reliance on finite fossil fuel resources.

PLA's biodegradability is a key environmental advantage. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months, significantly reducing plastic waste accumulation in landfills and oceans. This characteristic aligns with circular economy principles and helps mitigate the long-term environmental impacts associated with persistent plastic pollution.

However, it is important to note that PLA's environmental benefits are contingent on proper end-of-life management. While industrially compostable, PLA does not readily biodegrade in natural environments or home composting systems. Inadequate disposal infrastructure and consumer awareness can limit the realization of PLA's full environmental potential.

The recyclability of PLA presents both challenges and opportunities. While technically recyclable, the current recycling infrastructure is not widely equipped to handle PLA separately from other plastics. Contamination of PLA in conventional plastic recycling streams can pose issues for recyclers. Efforts are underway to develop more efficient PLA recycling processes and establish dedicated collection systems.

Land use and food security concerns have been raised regarding the agricultural feedstocks used for PLA production. The expansion of crops for bioplastics could potentially compete with food production or lead to land-use changes. However, ongoing research into alternative feedstocks, such as agricultural waste or algae, aims to address these concerns and further improve PLA's environmental profile.

Water consumption in PLA production is another aspect to consider. While generally lower than that of petroleum-based plastics, the cultivation of feedstock crops can have significant water requirements. Sustainable water management practices and the development of drought-resistant crop varieties are important considerations for minimizing PLA's water footprint.

The production of PLA requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. Studies have shown that PLA production can reduce carbon dioxide emissions by up to 80% compared to petroleum-based polymers. Additionally, the use of renewable feedstocks, such as corn or sugarcane, helps to decrease reliance on finite fossil fuel resources.

PLA's biodegradability is a key environmental advantage. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months, significantly reducing plastic waste accumulation in landfills and oceans. This characteristic aligns with circular economy principles and helps mitigate the long-term environmental impacts associated with persistent plastic pollution.

However, it is important to note that PLA's environmental benefits are contingent on proper end-of-life management. While industrially compostable, PLA does not readily biodegrade in natural environments or home composting systems. Inadequate disposal infrastructure and consumer awareness can limit the realization of PLA's full environmental potential.

The recyclability of PLA presents both challenges and opportunities. While technically recyclable, the current recycling infrastructure is not widely equipped to handle PLA separately from other plastics. Contamination of PLA in conventional plastic recycling streams can pose issues for recyclers. Efforts are underway to develop more efficient PLA recycling processes and establish dedicated collection systems.

Land use and food security concerns have been raised regarding the agricultural feedstocks used for PLA production. The expansion of crops for bioplastics could potentially compete with food production or lead to land-use changes. However, ongoing research into alternative feedstocks, such as agricultural waste or algae, aims to address these concerns and further improve PLA's environmental profile.

Water consumption in PLA production is another aspect to consider. While generally lower than that of petroleum-based plastics, the cultivation of feedstock crops can have significant water requirements. Sustainable water management practices and the development of drought-resistant crop varieties are important considerations for minimizing PLA's water footprint.

PLA Regulatory Framework

The regulatory framework surrounding PLA (Polylactic Acid) biopolymers plays a crucial role in shaping the industry's development and adoption. As a biodegradable and renewable material, PLA is subject to various regulations and standards across different regions and sectors.

In the United States, the Food and Drug Administration (FDA) has approved PLA for food contact applications, which has significantly expanded its use in packaging and disposable food service items. The FDA's approval process involves rigorous testing to ensure the material's safety for consumers. Additionally, the Environmental Protection Agency (EPA) regulates the disposal and recycling of PLA products under the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented comprehensive regulations for bioplastics, including PLA, through the European Committee for Standardization (CEN). The EN 13432 standard sets criteria for biodegradability and compostability of packaging materials, which PLA must meet to be certified as compostable in industrial facilities. This standard has been widely adopted and influences global practices in the bioplastics industry.

In Asia, countries like Japan and China have developed their own regulatory frameworks for biopolymers. Japan's BiomassPla certification system promotes the use of plant-derived plastics, including PLA, and sets standards for biodegradability and biomass content. China has implemented the GB/T 20197 standard for biodegradable plastics, which includes specifications for PLA materials.

The regulatory landscape also extends to end-of-life management for PLA products. Many countries have implemented extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal or recycling. These regulations incentivize the development of more sustainable PLA formulations and recycling technologies.

As the PLA industry continues to grow, regulatory bodies are adapting to address emerging challenges. For instance, there is ongoing work to develop standards for differentiating between industrial and home compostable PLA products, as well as regulations to prevent the contamination of conventional plastic recycling streams with PLA materials.

The global nature of the PLA market necessitates harmonization of regulations across different regions. International organizations such as the International Organization for Standardization (ISO) are working to develop globally recognized standards for bioplastics, including PLA. These efforts aim to facilitate international trade and ensure consistent quality and safety standards worldwide.

In the United States, the Food and Drug Administration (FDA) has approved PLA for food contact applications, which has significantly expanded its use in packaging and disposable food service items. The FDA's approval process involves rigorous testing to ensure the material's safety for consumers. Additionally, the Environmental Protection Agency (EPA) regulates the disposal and recycling of PLA products under the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented comprehensive regulations for bioplastics, including PLA, through the European Committee for Standardization (CEN). The EN 13432 standard sets criteria for biodegradability and compostability of packaging materials, which PLA must meet to be certified as compostable in industrial facilities. This standard has been widely adopted and influences global practices in the bioplastics industry.

In Asia, countries like Japan and China have developed their own regulatory frameworks for biopolymers. Japan's BiomassPla certification system promotes the use of plant-derived plastics, including PLA, and sets standards for biodegradability and biomass content. China has implemented the GB/T 20197 standard for biodegradable plastics, which includes specifications for PLA materials.

The regulatory landscape also extends to end-of-life management for PLA products. Many countries have implemented extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal or recycling. These regulations incentivize the development of more sustainable PLA formulations and recycling technologies.

As the PLA industry continues to grow, regulatory bodies are adapting to address emerging challenges. For instance, there is ongoing work to develop standards for differentiating between industrial and home compostable PLA products, as well as regulations to prevent the contamination of conventional plastic recycling streams with PLA materials.

The global nature of the PLA market necessitates harmonization of regulations across different regions. International organizations such as the International Organization for Standardization (ISO) are working to develop globally recognized standards for bioplastics, including PLA. These efforts aim to facilitate international trade and ensure consistent quality and safety standards worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!