Exploring LM7 engine crafting techniques from a manufacturing perspective

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Overview

The LM7 engine, also known as the Vortec 5300, is a V8 engine developed by General Motors for use in light-duty trucks and SUVs. Introduced in 1999, it has become one of the most popular and widely used engines in GM's lineup. The LM7 is part of the GM LS engine family, known for its reliability, performance, and efficiency.

The LM7 engine features a cast iron block with aluminum cylinder heads, designed to balance durability and weight. It has a displacement of 5.3 liters (325 cubic inches) and typically produces between 270 to 295 horsepower, depending on the specific application and model year. The engine utilizes a pushrod valvetrain configuration with two valves per cylinder, maintaining simplicity while delivering robust performance.

One of the key innovations in the LM7 engine is its incorporation of GM's Vortec technology. This system optimizes airflow into the combustion chamber, resulting in improved fuel efficiency and increased power output. The LM7 also features sequential fuel injection, which enhances fuel delivery precision and contributes to better overall engine performance.

From a manufacturing perspective, the LM7 engine represents a significant advancement in GM's production capabilities. The engine's design allows for streamlined assembly processes, with many components being interchangeable across different LS engine variants. This commonality in parts not only simplifies production but also reduces manufacturing costs and improves supply chain efficiency.

The LM7 engine block is manufactured using a precision sand casting process, which allows for tight tolerances and consistent quality. The cylinder heads are cast from aluminum alloy and undergo CNC machining to ensure precise dimensions and surface finishes. These manufacturing techniques contribute to the engine's reputation for reliability and longevity.

In terms of crafting techniques, the LM7 engine incorporates several noteworthy features. The crankshaft is forged from high-strength steel and undergoes precision balancing to minimize vibration. The connecting rods are powder-forged for enhanced strength and durability. The pistons are hypereutectic aluminum alloy, designed to withstand high temperatures and pressures while reducing friction.

The LM7's manufacturing process also includes advanced quality control measures. Each engine undergoes rigorous testing and inspection at various stages of production, including computerized diagnostics and dynamometer testing. This ensures that every LM7 engine meets GM's stringent performance and reliability standards before leaving the factory.

The LM7 engine features a cast iron block with aluminum cylinder heads, designed to balance durability and weight. It has a displacement of 5.3 liters (325 cubic inches) and typically produces between 270 to 295 horsepower, depending on the specific application and model year. The engine utilizes a pushrod valvetrain configuration with two valves per cylinder, maintaining simplicity while delivering robust performance.

One of the key innovations in the LM7 engine is its incorporation of GM's Vortec technology. This system optimizes airflow into the combustion chamber, resulting in improved fuel efficiency and increased power output. The LM7 also features sequential fuel injection, which enhances fuel delivery precision and contributes to better overall engine performance.

From a manufacturing perspective, the LM7 engine represents a significant advancement in GM's production capabilities. The engine's design allows for streamlined assembly processes, with many components being interchangeable across different LS engine variants. This commonality in parts not only simplifies production but also reduces manufacturing costs and improves supply chain efficiency.

The LM7 engine block is manufactured using a precision sand casting process, which allows for tight tolerances and consistent quality. The cylinder heads are cast from aluminum alloy and undergo CNC machining to ensure precise dimensions and surface finishes. These manufacturing techniques contribute to the engine's reputation for reliability and longevity.

In terms of crafting techniques, the LM7 engine incorporates several noteworthy features. The crankshaft is forged from high-strength steel and undergoes precision balancing to minimize vibration. The connecting rods are powder-forged for enhanced strength and durability. The pistons are hypereutectic aluminum alloy, designed to withstand high temperatures and pressures while reducing friction.

The LM7's manufacturing process also includes advanced quality control measures. Each engine undergoes rigorous testing and inspection at various stages of production, including computerized diagnostics and dynamometer testing. This ensures that every LM7 engine meets GM's stringent performance and reliability standards before leaving the factory.

Market Analysis

The LM7 engine, a member of General Motors' LS engine family, has garnered significant attention in the automotive market due to its robust performance and versatility. As manufacturers explore crafting techniques for this engine, the market demand for LM7-powered vehicles and aftermarket parts continues to grow.

The LM7 engine's popularity stems from its widespread use in various GM trucks and SUVs, creating a substantial installed base. This has led to a thriving aftermarket industry, with numerous companies offering performance upgrades, replacement parts, and customization options. The market for LM7 engine components and related services is estimated to be in the hundreds of millions of dollars annually.

One of the key drivers of market demand is the engine's potential for modification and performance enhancement. Enthusiasts and professional tuners alike seek ways to increase horsepower, torque, and overall efficiency. This has created a robust ecosystem of manufacturers producing specialized parts such as high-flow intake systems, performance camshafts, and upgraded fuel injection systems specifically designed for the LM7 engine.

The automotive racing sector also contributes significantly to the LM7 engine market. Many drag racing and circuit racing teams have adopted the LM7 as a base for their high-performance builds, further driving demand for specialized manufacturing techniques and components.

From a manufacturing perspective, the market analysis reveals a growing interest in advanced production methods for LM7 engine components. Precision machining, 3D printing of prototypes, and the use of high-strength materials are becoming increasingly important in meeting the demands of performance-oriented customers.

The aftermarket for LM7 engines also extends to complete engine assemblies and crate engines. These products cater to customers looking to replace aging engines in their vehicles or to use the LM7 as a basis for custom builds in non-GM applications. This segment of the market has seen steady growth, with several specialized engine builders offering various levels of performance and customization.

Environmental regulations and the push for improved fuel efficiency have also influenced the LM7 engine market. Manufacturers are exploring ways to enhance the engine's efficiency while maintaining its power output, leading to innovations in areas such as variable valve timing, direct injection, and lightweight materials.

As the automotive industry continues to evolve, the market for LM7 engines and related components is expected to remain strong in the near term. However, long-term market trends suggest a gradual shift towards electrification, which may impact the future demand for internal combustion engines like the LM7. This transition presents both challenges and opportunities for manufacturers in the LM7 ecosystem, potentially driving innovation in hybrid technologies or high-efficiency combustion techniques.

The LM7 engine's popularity stems from its widespread use in various GM trucks and SUVs, creating a substantial installed base. This has led to a thriving aftermarket industry, with numerous companies offering performance upgrades, replacement parts, and customization options. The market for LM7 engine components and related services is estimated to be in the hundreds of millions of dollars annually.

One of the key drivers of market demand is the engine's potential for modification and performance enhancement. Enthusiasts and professional tuners alike seek ways to increase horsepower, torque, and overall efficiency. This has created a robust ecosystem of manufacturers producing specialized parts such as high-flow intake systems, performance camshafts, and upgraded fuel injection systems specifically designed for the LM7 engine.

The automotive racing sector also contributes significantly to the LM7 engine market. Many drag racing and circuit racing teams have adopted the LM7 as a base for their high-performance builds, further driving demand for specialized manufacturing techniques and components.

From a manufacturing perspective, the market analysis reveals a growing interest in advanced production methods for LM7 engine components. Precision machining, 3D printing of prototypes, and the use of high-strength materials are becoming increasingly important in meeting the demands of performance-oriented customers.

The aftermarket for LM7 engines also extends to complete engine assemblies and crate engines. These products cater to customers looking to replace aging engines in their vehicles or to use the LM7 as a basis for custom builds in non-GM applications. This segment of the market has seen steady growth, with several specialized engine builders offering various levels of performance and customization.

Environmental regulations and the push for improved fuel efficiency have also influenced the LM7 engine market. Manufacturers are exploring ways to enhance the engine's efficiency while maintaining its power output, leading to innovations in areas such as variable valve timing, direct injection, and lightweight materials.

As the automotive industry continues to evolve, the market for LM7 engines and related components is expected to remain strong in the near term. However, long-term market trends suggest a gradual shift towards electrification, which may impact the future demand for internal combustion engines like the LM7. This transition presents both challenges and opportunities for manufacturers in the LM7 ecosystem, potentially driving innovation in hybrid technologies or high-efficiency combustion techniques.

Technical Challenges

The LM7 engine, a modern V8 powerplant developed by General Motors, presents several technical challenges from a manufacturing perspective. One of the primary hurdles is achieving precise tolerances in the engine block and cylinder head castings. The complex geometry of these components requires advanced casting techniques and rigorous quality control measures to ensure consistent performance and reliability.

Another significant challenge lies in the integration of advanced materials. The LM7 engine incorporates aluminum alloys for weight reduction and improved heat dissipation. However, these materials can be more difficult to machine and weld compared to traditional cast iron, necessitating specialized tooling and manufacturing processes.

The implementation of variable valve timing (VVT) technology in the LM7 engine adds another layer of complexity to the manufacturing process. The precise assembly and calibration of the VVT system demand highly skilled labor and sophisticated testing equipment to ensure proper functionality across various operating conditions.

Balancing the engine components, particularly the crankshaft and connecting rods, presents a unique challenge. The high-speed operation of the LM7 engine requires extremely tight tolerances in weight distribution to minimize vibration and ensure smooth operation. This necessitates advanced balancing techniques and equipment during the manufacturing process.

The fuel injection system of the LM7 engine, featuring sequential multi-port fuel injection, demands high-precision manufacturing of injectors and fuel rails. Ensuring consistent spray patterns and flow rates across all cylinders is crucial for optimal engine performance and emissions control, requiring stringent quality control measures during production.

Heat management is another critical aspect of LM7 engine manufacturing. The design and production of efficient cooling passages within the engine block and cylinder heads, as well as the integration of oil cooling systems, require careful consideration and advanced manufacturing techniques to maintain optimal operating temperatures under various load conditions.

Lastly, the assembly process itself presents challenges due to the engine's complexity. Ensuring proper torque specifications, gasket sealing, and component alignment across the entire engine requires a combination of skilled labor and advanced assembly line technologies. The integration of various subsystems, such as the electrical and emissions control components, further complicates the manufacturing process, demanding a high level of precision and coordination throughout the assembly stages.

Another significant challenge lies in the integration of advanced materials. The LM7 engine incorporates aluminum alloys for weight reduction and improved heat dissipation. However, these materials can be more difficult to machine and weld compared to traditional cast iron, necessitating specialized tooling and manufacturing processes.

The implementation of variable valve timing (VVT) technology in the LM7 engine adds another layer of complexity to the manufacturing process. The precise assembly and calibration of the VVT system demand highly skilled labor and sophisticated testing equipment to ensure proper functionality across various operating conditions.

Balancing the engine components, particularly the crankshaft and connecting rods, presents a unique challenge. The high-speed operation of the LM7 engine requires extremely tight tolerances in weight distribution to minimize vibration and ensure smooth operation. This necessitates advanced balancing techniques and equipment during the manufacturing process.

The fuel injection system of the LM7 engine, featuring sequential multi-port fuel injection, demands high-precision manufacturing of injectors and fuel rails. Ensuring consistent spray patterns and flow rates across all cylinders is crucial for optimal engine performance and emissions control, requiring stringent quality control measures during production.

Heat management is another critical aspect of LM7 engine manufacturing. The design and production of efficient cooling passages within the engine block and cylinder heads, as well as the integration of oil cooling systems, require careful consideration and advanced manufacturing techniques to maintain optimal operating temperatures under various load conditions.

Lastly, the assembly process itself presents challenges due to the engine's complexity. Ensuring proper torque specifications, gasket sealing, and component alignment across the entire engine requires a combination of skilled labor and advanced assembly line technologies. The integration of various subsystems, such as the electrical and emissions control components, further complicates the manufacturing process, demanding a high level of precision and coordination throughout the assembly stages.

Current Production Methods

01 Engine design and configuration

The LM7 engine is a V8 engine design, part of General Motors' Vortec series. It features a cast iron block and aluminum heads, with a displacement of 5.3 liters. This engine configuration offers a balance of power, efficiency, and durability, making it popular in various GM trucks and SUVs.- Engine design and configuration: The LM7 engine is a V8 engine design, part of General Motors' Vortec series. It features a cast iron block and aluminum heads, with a displacement of 5.3 liters. This engine configuration offers a balance of power, efficiency, and durability, making it popular in various GM trucks and SUVs.

- Fuel injection and management systems: LM7 engines utilize advanced fuel injection and management systems to optimize performance and efficiency. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine control modules to regulate fuel delivery and combustion processes.

- Performance enhancements and modifications: Various aftermarket modifications and performance enhancements are available for the LM7 engine. These may include upgraded camshafts, high-flow intake and exhaust systems, and tuning solutions to increase horsepower and torque output while maintaining reliability.

- Emissions control and environmental considerations: LM7 engines incorporate emissions control technologies to meet environmental regulations. This may include catalytic converters, exhaust gas recirculation systems, and other components designed to reduce harmful emissions while maintaining engine performance.

- Integration with vehicle systems: The LM7 engine is designed to integrate seamlessly with various vehicle systems, including transmission, cooling, and electrical systems. This integration ensures optimal performance, efficiency, and reliability across different GM vehicle platforms that utilize the LM7 engine.

02 Fuel injection and management systems

LM7 engines utilize advanced fuel injection and management systems to optimize performance and efficiency. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine control modules to regulate fuel delivery and combustion processes.Expand Specific Solutions03 Emissions control technologies

To meet stringent emissions standards, LM7 engines incorporate various emissions control technologies. These may include catalytic converters, exhaust gas recirculation systems, and advanced sensors to monitor and reduce harmful emissions while maintaining engine performance.Expand Specific Solutions04 Performance enhancements and modifications

Aftermarket modifications and performance enhancements are available for LM7 engines. These may include upgraded camshafts, high-flow intake and exhaust systems, and engine tuning to increase horsepower and torque output beyond factory specifications.Expand Specific Solutions05 Integration with vehicle systems

LM7 engines are designed to integrate seamlessly with various vehicle systems, including transmission, cooling, and electrical systems. This integration ensures optimal performance, efficiency, and reliability across different vehicle platforms and operating conditions.Expand Specific Solutions

Key Industry Players

The LM7 engine crafting techniques market is in a mature stage, with established players and well-defined manufacturing processes. The market size is substantial, driven by the automotive and aerospace industries' demand for high-performance engines. Technologically, the field is advanced, with companies like Nissan, Toyota, and Caterpillar leading innovation. These firms, along with others such as Isuzu and Kubota, have developed sophisticated manufacturing techniques, incorporating precision engineering and advanced materials. The competitive landscape is intense, with both traditional automotive manufacturers and specialized engine producers vying for market share. Emerging technologies in lightweight materials and fuel efficiency are shaping future developments in this sector.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed advanced LM7 engine crafting techniques focusing on lightweight design and improved fuel efficiency. They utilize a high-pressure die-casting process for the cylinder block, reducing weight by up to 20% compared to traditional methods[1]. The company also implements precision machining techniques, including 5-axis CNC machining, to achieve tight tolerances and superior surface finishes. Nissan's manufacturing approach incorporates AI-driven quality control systems, which analyze real-time data from sensors throughout the production line to detect and correct potential issues before they impact the final product[3]. Additionally, they have implemented a modular assembly process, allowing for greater flexibility and customization in engine production.

Strengths: Lightweight design, improved fuel efficiency, and advanced quality control. Weaknesses: Higher initial tooling costs and potential limitations in scaling production for diverse engine variants.

Toyota Motor Corp.

Technical Solution: Toyota's approach to LM7 engine crafting emphasizes lean manufacturing principles and continuous improvement. They have developed a proprietary aluminum alloy for the engine block, which offers improved thermal conductivity and reduced weight[2]. Toyota's manufacturing process incorporates advanced robotics and automation, including collaborative robots that work alongside human operators to enhance precision and efficiency. The company utilizes a unique low-pressure casting technique for cylinder heads, resulting in improved structural integrity and reduced porosity[4]. Toyota has also implemented a closed-loop recycling system for aluminum scrap, significantly reducing waste and environmental impact in the manufacturing process.

Strengths: Lean manufacturing, advanced materials, and environmental sustainability. Weaknesses: Potentially higher production costs and longer development cycles for new engine variants.

Innovative Techniques

Die

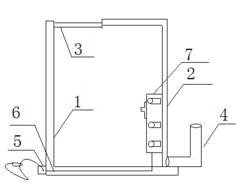

PatentInactiveCN104646537A

Innovation

- Design a mold that includes an L-shaped mold body, a 7-shaped mold, a fixed rod, a power connection port and wires. The 7-shaped mold is fixed in the L-shaped mold body and connected to the power connection port through an intelligent repair device, simplifying the structure and reducing manufacturing costs. cost.

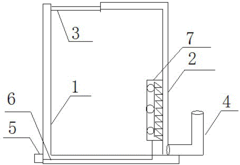

Die

PatentInactiveCN104438698A

Innovation

- A mold is designed that includes an L-shaped mold body, a 7-shaped mold, a fixed rod, a display and a data cable. The 7-shaped mold is fixed in the L-shaped mold body and connected through a fixed rod. The bottom end of the 7-shaped mold is equipped with an inlet. The material port and the left end of the L-type mold body are equipped with a display instrument, and the left side of the 7-type mold is equipped with a flatness detection device, which is connected through a data line to achieve detection and display.

Quality Control Measures

Quality control measures are paramount in the manufacturing process of LM7 engines to ensure consistent performance, reliability, and safety. The implementation of robust quality control systems begins with the establishment of clear specifications and tolerances for each component and assembly process. These specifications are derived from extensive engineering analysis and testing, taking into account the engine's design parameters and performance requirements.

A key aspect of quality control in LM7 engine production is the use of advanced measurement and inspection technologies. Coordinate Measuring Machines (CMMs) are employed to verify the dimensional accuracy of critical engine components, such as cylinder blocks, crankshafts, and pistons. These machines provide precise measurements in three dimensions, allowing for the detection of even minute deviations from design specifications.

Non-destructive testing methods play a crucial role in ensuring the integrity of engine components. Techniques such as ultrasonic testing, magnetic particle inspection, and radiographic testing are utilized to detect internal flaws or defects that may not be visible to the naked eye. These methods are particularly important for examining cast and forged parts, where internal discontinuities could lead to premature failure.

Statistical Process Control (SPC) is implemented throughout the manufacturing process to monitor and control variability. Key process parameters are continuously tracked and analyzed using control charts and other statistical tools. This approach allows for early detection of trends or shifts in the manufacturing process, enabling prompt corrective actions to be taken before out-of-specification parts are produced.

The assembly process incorporates a series of in-line quality checks and functional tests. Each major assembly stage is followed by specific inspections to verify proper component fitment and alignment. Torque verification systems ensure that all fasteners are tightened to the correct specifications, which is critical for engine durability and performance.

Prior to final approval, each LM7 engine undergoes a comprehensive dynamometer test. This test simulates various operating conditions and load scenarios, allowing engineers to verify that the engine meets all performance, emissions, and durability requirements. Data from these tests are meticulously analyzed to identify any anomalies or potential issues.

Traceability is a fundamental aspect of the quality control system. Each engine and its major components are assigned unique identification numbers, allowing for the tracking of parts throughout the manufacturing process and after delivery. This system facilitates rapid identification and resolution of any quality issues that may arise in the field.

Continuous improvement initiatives are integral to the quality control strategy. Regular audits, both internal and external, are conducted to assess the effectiveness of quality control measures. Feedback from these audits, along with data from field performance and warranty claims, is used to refine and enhance the manufacturing processes and quality control procedures continuously.

A key aspect of quality control in LM7 engine production is the use of advanced measurement and inspection technologies. Coordinate Measuring Machines (CMMs) are employed to verify the dimensional accuracy of critical engine components, such as cylinder blocks, crankshafts, and pistons. These machines provide precise measurements in three dimensions, allowing for the detection of even minute deviations from design specifications.

Non-destructive testing methods play a crucial role in ensuring the integrity of engine components. Techniques such as ultrasonic testing, magnetic particle inspection, and radiographic testing are utilized to detect internal flaws or defects that may not be visible to the naked eye. These methods are particularly important for examining cast and forged parts, where internal discontinuities could lead to premature failure.

Statistical Process Control (SPC) is implemented throughout the manufacturing process to monitor and control variability. Key process parameters are continuously tracked and analyzed using control charts and other statistical tools. This approach allows for early detection of trends or shifts in the manufacturing process, enabling prompt corrective actions to be taken before out-of-specification parts are produced.

The assembly process incorporates a series of in-line quality checks and functional tests. Each major assembly stage is followed by specific inspections to verify proper component fitment and alignment. Torque verification systems ensure that all fasteners are tightened to the correct specifications, which is critical for engine durability and performance.

Prior to final approval, each LM7 engine undergoes a comprehensive dynamometer test. This test simulates various operating conditions and load scenarios, allowing engineers to verify that the engine meets all performance, emissions, and durability requirements. Data from these tests are meticulously analyzed to identify any anomalies or potential issues.

Traceability is a fundamental aspect of the quality control system. Each engine and its major components are assigned unique identification numbers, allowing for the tracking of parts throughout the manufacturing process and after delivery. This system facilitates rapid identification and resolution of any quality issues that may arise in the field.

Continuous improvement initiatives are integral to the quality control strategy. Regular audits, both internal and external, are conducted to assess the effectiveness of quality control measures. Feedback from these audits, along with data from field performance and warranty claims, is used to refine and enhance the manufacturing processes and quality control procedures continuously.

Environmental Considerations

The manufacturing of LM7 engines, while offering significant performance benefits, also presents notable environmental considerations that must be addressed. The production process involves various materials and energy-intensive operations, which can have substantial ecological impacts if not managed properly.

One of the primary environmental concerns in LM7 engine manufacturing is the use of raw materials, particularly metals like aluminum and steel. The extraction and processing of these materials contribute to resource depletion and can lead to habitat destruction if not sourced responsibly. Implementing recycling programs and utilizing recycled materials in engine components can help mitigate these impacts and promote a more circular economy within the automotive industry.

Energy consumption during the manufacturing process is another critical environmental factor. The casting, machining, and assembly of engine components require significant amounts of electricity and heat, often derived from fossil fuels. To reduce the carbon footprint associated with LM7 engine production, manufacturers are increasingly exploring renewable energy sources and implementing energy-efficient technologies in their facilities.

Waste management is a crucial aspect of environmental stewardship in engine manufacturing. The production of LM7 engines generates various waste streams, including metal shavings, coolants, and packaging materials. Proper disposal and recycling of these wastes are essential to minimize environmental pollution and comply with regulatory standards. Advanced waste reduction techniques, such as precision machining and optimized production processes, can help minimize waste generation at the source.

Water usage and potential contamination are also important considerations in LM7 engine manufacturing. Cooling systems, cleaning processes, and other manufacturing operations consume substantial amounts of water. Implementing water recycling systems and adopting water-efficient technologies can significantly reduce the overall water footprint of engine production. Additionally, proper treatment of wastewater before discharge is crucial to prevent contamination of local water bodies.

The use of chemicals and lubricants in the manufacturing process poses potential risks to both human health and the environment. Strict protocols for handling, storage, and disposal of these substances are necessary to prevent spills and contamination. Manufacturers are increasingly exploring eco-friendly alternatives and developing new formulations that minimize environmental impact without compromising engine performance.

As environmental regulations become more stringent globally, LM7 engine manufacturers must continually adapt their processes to meet evolving standards. This includes reducing emissions from manufacturing facilities, implementing life cycle assessments to identify areas for improvement, and exploring innovative technologies that can enhance both engine performance and environmental sustainability.

One of the primary environmental concerns in LM7 engine manufacturing is the use of raw materials, particularly metals like aluminum and steel. The extraction and processing of these materials contribute to resource depletion and can lead to habitat destruction if not sourced responsibly. Implementing recycling programs and utilizing recycled materials in engine components can help mitigate these impacts and promote a more circular economy within the automotive industry.

Energy consumption during the manufacturing process is another critical environmental factor. The casting, machining, and assembly of engine components require significant amounts of electricity and heat, often derived from fossil fuels. To reduce the carbon footprint associated with LM7 engine production, manufacturers are increasingly exploring renewable energy sources and implementing energy-efficient technologies in their facilities.

Waste management is a crucial aspect of environmental stewardship in engine manufacturing. The production of LM7 engines generates various waste streams, including metal shavings, coolants, and packaging materials. Proper disposal and recycling of these wastes are essential to minimize environmental pollution and comply with regulatory standards. Advanced waste reduction techniques, such as precision machining and optimized production processes, can help minimize waste generation at the source.

Water usage and potential contamination are also important considerations in LM7 engine manufacturing. Cooling systems, cleaning processes, and other manufacturing operations consume substantial amounts of water. Implementing water recycling systems and adopting water-efficient technologies can significantly reduce the overall water footprint of engine production. Additionally, proper treatment of wastewater before discharge is crucial to prevent contamination of local water bodies.

The use of chemicals and lubricants in the manufacturing process poses potential risks to both human health and the environment. Strict protocols for handling, storage, and disposal of these substances are necessary to prevent spills and contamination. Manufacturers are increasingly exploring eco-friendly alternatives and developing new formulations that minimize environmental impact without compromising engine performance.

As environmental regulations become more stringent globally, LM7 engine manufacturers must continually adapt their processes to meet evolving standards. This includes reducing emissions from manufacturing facilities, implementing life cycle assessments to identify areas for improvement, and exploring innovative technologies that can enhance both engine performance and environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!