Exploring Sustainable Polyurethane Composites

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sustainable PU Evolution

The evolution of sustainable polyurethane (PU) composites represents a significant shift in materials science and engineering, driven by increasing environmental concerns and regulatory pressures. This trajectory began in the late 20th century when awareness of the environmental impact of traditional PU production and disposal methods grew. Initially, efforts focused on reducing the use of toxic isocyanates and developing bio-based polyols from renewable resources such as vegetable oils.

The early 2000s saw a surge in research towards more sustainable PU formulations. Scientists explored the use of natural fibers as reinforcements, including cellulose, hemp, and jute, to create bio-composites with enhanced mechanical properties and reduced environmental footprint. Concurrently, the development of recyclable and biodegradable PU systems gained momentum, with researchers investigating novel chemical structures that could break down under specific conditions without compromising performance during use.

A pivotal moment in sustainable PU evolution came with the introduction of CO2-based polyols around 2010. This innovation not only reduced reliance on petroleum-based raw materials but also provided a pathway for carbon capture and utilization. The technology has since been refined, leading to commercial-scale production of PU foams and elastomers with significantly lower carbon footprints.

Recent years have witnessed an acceleration in sustainable PU research, focusing on circular economy principles. This includes the development of chemically recyclable PU systems that can be depolymerized and repolymerized without loss of properties, as well as advanced sorting and recycling technologies for end-of-life PU products. Bionic design principles have also been applied to create PU composites with enhanced functionality and sustainability profiles.

Looking forward, the sustainable PU evolution is expected to continue along several key pathways. These include further integration of renewable and recycled content, development of fully bio-based PU systems, and exploration of novel curing mechanisms that eliminate the need for isocyanates altogether. Additionally, the incorporation of smart materials and nanotechnology is anticipated to yield PU composites with self-healing and adaptive properties, further extending product lifespans and reducing waste.

The trajectory of sustainable PU composites aligns closely with global sustainability goals and circular economy initiatives. As research progresses, we can expect to see a convergence of material science, green chemistry, and advanced manufacturing techniques, leading to a new generation of PU composites that balance high performance with minimal environmental impact.

The early 2000s saw a surge in research towards more sustainable PU formulations. Scientists explored the use of natural fibers as reinforcements, including cellulose, hemp, and jute, to create bio-composites with enhanced mechanical properties and reduced environmental footprint. Concurrently, the development of recyclable and biodegradable PU systems gained momentum, with researchers investigating novel chemical structures that could break down under specific conditions without compromising performance during use.

A pivotal moment in sustainable PU evolution came with the introduction of CO2-based polyols around 2010. This innovation not only reduced reliance on petroleum-based raw materials but also provided a pathway for carbon capture and utilization. The technology has since been refined, leading to commercial-scale production of PU foams and elastomers with significantly lower carbon footprints.

Recent years have witnessed an acceleration in sustainable PU research, focusing on circular economy principles. This includes the development of chemically recyclable PU systems that can be depolymerized and repolymerized without loss of properties, as well as advanced sorting and recycling technologies for end-of-life PU products. Bionic design principles have also been applied to create PU composites with enhanced functionality and sustainability profiles.

Looking forward, the sustainable PU evolution is expected to continue along several key pathways. These include further integration of renewable and recycled content, development of fully bio-based PU systems, and exploration of novel curing mechanisms that eliminate the need for isocyanates altogether. Additionally, the incorporation of smart materials and nanotechnology is anticipated to yield PU composites with self-healing and adaptive properties, further extending product lifespans and reducing waste.

The trajectory of sustainable PU composites aligns closely with global sustainability goals and circular economy initiatives. As research progresses, we can expect to see a convergence of material science, green chemistry, and advanced manufacturing techniques, leading to a new generation of PU composites that balance high performance with minimal environmental impact.

Market Demand Analysis

The market demand for sustainable polyurethane composites has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations across various industries. This surge in demand is particularly evident in sectors such as automotive, construction, and packaging, where there is a pressing need for eco-friendly materials that can reduce carbon footprints without compromising performance.

In the automotive industry, manufacturers are actively seeking lightweight, durable, and recyclable materials to improve fuel efficiency and meet emission standards. Sustainable polyurethane composites offer a promising solution, as they can replace traditional petroleum-based materials in interior components, insulation, and structural parts. The market for these materials in the automotive sector is expected to grow significantly over the next decade.

The construction industry is another major driver of demand for sustainable polyurethane composites. With the global push towards green building practices, there is a growing need for insulation materials and structural components that offer superior energy efficiency and reduced environmental impact. Sustainable polyurethane composites can provide excellent thermal insulation properties while being more environmentally friendly than traditional materials.

In the packaging sector, the demand for sustainable alternatives to conventional plastics is soaring. Polyurethane composites derived from renewable sources or incorporating recycled content are gaining traction as companies strive to meet consumer expectations for eco-friendly packaging solutions. This trend is particularly strong in the food and beverage industry, where biodegradable and compostable packaging materials are highly sought after.

The healthcare industry is also showing increased interest in sustainable polyurethane composites for medical devices, implants, and wound care products. The biocompatibility and customizable properties of these materials make them attractive for various medical applications, while their sustainability aligns with the growing emphasis on environmentally responsible healthcare practices.

Market analysts project that the global sustainable polyurethane composites market will experience robust growth in the coming years. This growth is fueled by increasing awareness of environmental issues, government initiatives promoting sustainable materials, and corporate sustainability goals. Additionally, ongoing research and development efforts are expected to expand the application range of these materials, further driving market demand.

However, challenges remain in terms of cost competitiveness and performance parity with traditional materials. As technology advances and production scales up, these barriers are expected to diminish, leading to wider adoption across industries. The market trajectory suggests that sustainable polyurethane composites are poised to play a crucial role in the transition towards a more circular and sustainable economy.

In the automotive industry, manufacturers are actively seeking lightweight, durable, and recyclable materials to improve fuel efficiency and meet emission standards. Sustainable polyurethane composites offer a promising solution, as they can replace traditional petroleum-based materials in interior components, insulation, and structural parts. The market for these materials in the automotive sector is expected to grow significantly over the next decade.

The construction industry is another major driver of demand for sustainable polyurethane composites. With the global push towards green building practices, there is a growing need for insulation materials and structural components that offer superior energy efficiency and reduced environmental impact. Sustainable polyurethane composites can provide excellent thermal insulation properties while being more environmentally friendly than traditional materials.

In the packaging sector, the demand for sustainable alternatives to conventional plastics is soaring. Polyurethane composites derived from renewable sources or incorporating recycled content are gaining traction as companies strive to meet consumer expectations for eco-friendly packaging solutions. This trend is particularly strong in the food and beverage industry, where biodegradable and compostable packaging materials are highly sought after.

The healthcare industry is also showing increased interest in sustainable polyurethane composites for medical devices, implants, and wound care products. The biocompatibility and customizable properties of these materials make them attractive for various medical applications, while their sustainability aligns with the growing emphasis on environmentally responsible healthcare practices.

Market analysts project that the global sustainable polyurethane composites market will experience robust growth in the coming years. This growth is fueled by increasing awareness of environmental issues, government initiatives promoting sustainable materials, and corporate sustainability goals. Additionally, ongoing research and development efforts are expected to expand the application range of these materials, further driving market demand.

However, challenges remain in terms of cost competitiveness and performance parity with traditional materials. As technology advances and production scales up, these barriers are expected to diminish, leading to wider adoption across industries. The market trajectory suggests that sustainable polyurethane composites are poised to play a crucial role in the transition towards a more circular and sustainable economy.

Technical Challenges

The development of sustainable polyurethane composites faces several significant technical challenges that researchers and industry professionals must address. One of the primary obstacles is the sourcing of bio-based or recycled raw materials that can effectively replace traditional petroleum-based polyols and isocyanates. While progress has been made in utilizing plant-based oils and recycled polyols, achieving comparable performance to conventional polyurethanes remains a hurdle.

Another critical challenge lies in optimizing the chemical reactions and processing techniques for these sustainable alternatives. The reactivity and compatibility of bio-based components often differ from their petroleum-based counterparts, necessitating adjustments in formulation and manufacturing processes. This includes fine-tuning catalyst systems, mixing ratios, and curing conditions to ensure proper polymerization and desired material properties.

The mechanical properties of sustainable polyurethane composites present another area of concern. Achieving the right balance of strength, flexibility, and durability comparable to traditional polyurethanes is crucial for widespread adoption. Researchers are exploring various reinforcement strategies, such as incorporating natural fibers or nanoparticles, to enhance the mechanical performance of these eco-friendly alternatives.

Thermal stability and fire resistance pose additional challenges for sustainable polyurethane composites. Many bio-based materials exhibit lower thermal resistance compared to conventional polyurethanes, limiting their application in high-temperature environments. Developing effective flame retardant systems that are both environmentally friendly and compatible with sustainable polyurethane formulations is an ongoing area of research.

The long-term stability and degradation behavior of sustainable polyurethane composites also require careful consideration. While biodegradability is often a desired attribute for environmental reasons, it must be balanced with the need for durability in certain applications. Understanding and controlling the degradation mechanisms of these materials in various environmental conditions is essential for their successful implementation.

Cost-effectiveness remains a significant hurdle in the widespread adoption of sustainable polyurethane composites. The production of bio-based raw materials and the development of new processing techniques often come with higher costs compared to well-established petroleum-based systems. Scaling up production and improving efficiency in the supply chain are necessary steps to make these sustainable alternatives economically viable.

Lastly, ensuring consistent quality and reproducibility across different batches of sustainable polyurethane composites presents a challenge. The variability in natural raw materials and the complexity of formulations can lead to inconsistencies in the final product. Developing robust quality control measures and standardization protocols is crucial for the successful commercialization of these materials.

Another critical challenge lies in optimizing the chemical reactions and processing techniques for these sustainable alternatives. The reactivity and compatibility of bio-based components often differ from their petroleum-based counterparts, necessitating adjustments in formulation and manufacturing processes. This includes fine-tuning catalyst systems, mixing ratios, and curing conditions to ensure proper polymerization and desired material properties.

The mechanical properties of sustainable polyurethane composites present another area of concern. Achieving the right balance of strength, flexibility, and durability comparable to traditional polyurethanes is crucial for widespread adoption. Researchers are exploring various reinforcement strategies, such as incorporating natural fibers or nanoparticles, to enhance the mechanical performance of these eco-friendly alternatives.

Thermal stability and fire resistance pose additional challenges for sustainable polyurethane composites. Many bio-based materials exhibit lower thermal resistance compared to conventional polyurethanes, limiting their application in high-temperature environments. Developing effective flame retardant systems that are both environmentally friendly and compatible with sustainable polyurethane formulations is an ongoing area of research.

The long-term stability and degradation behavior of sustainable polyurethane composites also require careful consideration. While biodegradability is often a desired attribute for environmental reasons, it must be balanced with the need for durability in certain applications. Understanding and controlling the degradation mechanisms of these materials in various environmental conditions is essential for their successful implementation.

Cost-effectiveness remains a significant hurdle in the widespread adoption of sustainable polyurethane composites. The production of bio-based raw materials and the development of new processing techniques often come with higher costs compared to well-established petroleum-based systems. Scaling up production and improving efficiency in the supply chain are necessary steps to make these sustainable alternatives economically viable.

Lastly, ensuring consistent quality and reproducibility across different batches of sustainable polyurethane composites presents a challenge. The variability in natural raw materials and the complexity of formulations can lead to inconsistencies in the final product. Developing robust quality control measures and standardization protocols is crucial for the successful commercialization of these materials.

Current PU Solutions

01 Bio-based polyurethane composites

Development of sustainable polyurethane composites using bio-based materials such as plant-derived polyols or natural fibers. These composites aim to reduce the environmental impact by incorporating renewable resources and potentially improving biodegradability.- Bio-based polyurethane composites: Development of sustainable polyurethane composites using bio-based materials such as plant-derived polyols or natural fibers. These composites aim to reduce the environmental impact by incorporating renewable resources and potentially improving biodegradability.

- Recycling and upcycling of polyurethane composites: Methods for recycling and upcycling polyurethane composite materials to improve sustainability. This includes techniques for breaking down and reprocessing used polyurethane composites, as well as incorporating recycled content into new products.

- Energy-efficient production of polyurethane composites: Innovative manufacturing processes and technologies that reduce energy consumption and emissions in the production of polyurethane composites. This may include optimized curing methods, low-temperature processing, or the use of alternative energy sources.

- Durability and longevity enhancements: Techniques to improve the durability and longevity of polyurethane composites, thereby reducing the need for frequent replacement and enhancing overall sustainability. This may include the development of self-healing properties or improved resistance to environmental factors.

- Sustainable additives and fillers: Incorporation of sustainable additives and fillers in polyurethane composites to enhance performance while maintaining or improving environmental compatibility. This may include the use of natural minerals, recycled materials, or biodegradable additives.

02 Recycling and upcycling of polyurethane composites

Methods for recycling and upcycling polyurethane composite materials to improve sustainability. This includes techniques for breaking down and reprocessing used polyurethane products, as well as incorporating recycled content into new composites.Expand Specific Solutions03 Energy-efficient production processes

Development of energy-efficient manufacturing processes for polyurethane composites. This involves optimizing reaction conditions, reducing waste, and implementing cleaner production technologies to minimize the environmental footprint of composite production.Expand Specific Solutions04 Durability and longevity improvements

Enhancing the durability and longevity of polyurethane composites to promote sustainability. This includes developing composites with improved resistance to degradation, weathering, and wear, thereby extending product lifespans and reducing the need for frequent replacements.Expand Specific Solutions05 Sustainable additives and fillers

Incorporation of sustainable additives and fillers in polyurethane composites to enhance their environmental profile. This may include the use of natural minerals, recycled materials, or biodegradable substances to improve the overall sustainability of the composite while maintaining or enhancing its performance properties.Expand Specific Solutions

Industry Leaders

The exploration of sustainable polyurethane composites is in a growth phase, with increasing market demand driven by environmental concerns and regulatory pressures. The global market for these materials is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like BASF Corp., Wanhua Chemical Group, and Covestro Deutschland AG leading innovation. These firms are developing bio-based polyols, improving recycling processes, and enhancing the overall sustainability profile of polyurethane composites. Academic institutions such as Tongji University and Sichuan University are contributing to fundamental research, while companies like Henkel AG & Co. KGaA and Dow Global Technologies LLC are focusing on application-specific developments, indicating a maturing but still evolving technological landscape.

BASF Corp.

Technical Solution: BASF has developed a range of sustainable polyurethane composites using bio-based and recycled raw materials. Their approach includes using natural oils, such as castor oil, as polyol components and incorporating recycled PET into the polyurethane matrix. They have also developed water-blown foam systems to reduce the use of harmful blowing agents. BASF's sustainable polyurethanes offer improved durability, reduced carbon footprint, and enhanced thermal insulation properties, making them suitable for various applications in construction, automotive, and furniture industries.

Strengths: Extensive R&D capabilities, wide range of sustainable solutions, global market presence. Weaknesses: Higher production costs compared to traditional polyurethanes, potential limitations in certain high-performance applications.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a series of sustainable polyurethane composites under their "WANNATE" brand. Their approach focuses on using bio-based isocyanates and polyols derived from renewable resources such as corn and soybean oil. They have also introduced recycled content into their formulations and developed novel catalysts to improve the biodegradability of polyurethane products. Wanhua's sustainable polyurethanes offer improved environmental performance while maintaining mechanical properties comparable to traditional polyurethanes, making them suitable for applications in footwear, automotive interiors, and construction materials.

Strengths: Strong expertise in isocyanate chemistry, vertically integrated production, cost-competitive solutions. Weaknesses: Relatively newer entrant in sustainable polyurethanes compared to some competitors, potential challenges in global market expansion.

Key Innovations

Filled polyurethane composites with lightweight fillers

PatentActiveUS20170114211A1

Innovation

- The use of a polyurethane composite formulation comprising highly reactive isocyanates, particulate fillers with bulk densities of 1 g/cm3 or greater, and lightweight fillers with densities between 0.01 g/cm3 and 1 g/cm3, along with optional fiber materials, to enhance mechanical properties while maintaining low density.

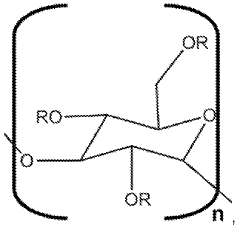

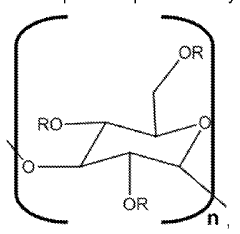

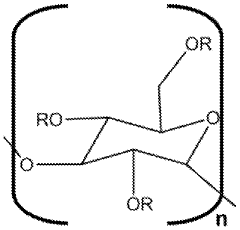

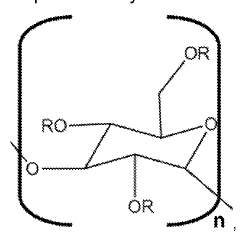

Polyurethane polymers comprising polysaccharides

PatentWO2018017789A1

Innovation

- The development of polyurethane polymers incorporating polysaccharides such as poly alpha-1,3-glucan, poly alpha-1,3-glucan ester compounds, and poly alpha-1,3-glucan ether compounds, which are derived from enzymatic syntheses or genetic engineering, to replace traditional petroleum-based materials, offering a renewable and sustainable option for polyurethane compositions.

Environmental Impact

The environmental impact of polyurethane composites has been a growing concern in recent years, prompting researchers and industry professionals to explore sustainable alternatives. Traditional polyurethane composites, while versatile and widely used, often rely on petroleum-based raw materials and energy-intensive production processes, contributing to greenhouse gas emissions and resource depletion.

One of the primary environmental challenges associated with polyurethane composites is their end-of-life disposal. These materials are typically difficult to recycle or biodegrade, leading to accumulation in landfills or incineration, both of which have negative environmental consequences. The release of toxic substances during the degradation process of conventional polyurethanes poses risks to ecosystems and human health.

To address these issues, sustainable polyurethane composites are being developed with a focus on reducing environmental impact throughout their lifecycle. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and cellulose are increasingly being used as alternatives to petroleum-based polyols. These bio-based materials not only reduce reliance on fossil fuels but also often exhibit lower toxicity and improved biodegradability.

Another approach to enhancing the sustainability of polyurethane composites involves the incorporation of recycled materials. Post-consumer plastics, industrial waste, and even carbon dioxide captured from industrial emissions are being explored as potential feedstocks for polyurethane production. This not only diverts waste from landfills but also reduces the overall carbon footprint of the manufacturing process.

The use of water-based systems and solvent-free technologies in polyurethane composite production has gained traction as a means to reduce volatile organic compound (VOC) emissions and improve air quality. These environmentally friendly production methods also contribute to safer working conditions and reduced energy consumption during manufacturing.

Efforts to improve the recyclability and biodegradability of polyurethane composites are ongoing. Researchers are developing novel chemical structures and additives that facilitate easier separation and recovery of component materials at the end of the product's life. Additionally, the integration of biodegradable segments into polyurethane chains shows promise for creating composites that can decompose naturally under specific environmental conditions.

The adoption of sustainable polyurethane composites has the potential to significantly reduce the environmental footprint of various industries, including automotive, construction, and consumer goods. As regulations tighten and consumer awareness grows, the demand for these eco-friendly alternatives is expected to increase, driving further innovation in the field.

One of the primary environmental challenges associated with polyurethane composites is their end-of-life disposal. These materials are typically difficult to recycle or biodegrade, leading to accumulation in landfills or incineration, both of which have negative environmental consequences. The release of toxic substances during the degradation process of conventional polyurethanes poses risks to ecosystems and human health.

To address these issues, sustainable polyurethane composites are being developed with a focus on reducing environmental impact throughout their lifecycle. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and cellulose are increasingly being used as alternatives to petroleum-based polyols. These bio-based materials not only reduce reliance on fossil fuels but also often exhibit lower toxicity and improved biodegradability.

Another approach to enhancing the sustainability of polyurethane composites involves the incorporation of recycled materials. Post-consumer plastics, industrial waste, and even carbon dioxide captured from industrial emissions are being explored as potential feedstocks for polyurethane production. This not only diverts waste from landfills but also reduces the overall carbon footprint of the manufacturing process.

The use of water-based systems and solvent-free technologies in polyurethane composite production has gained traction as a means to reduce volatile organic compound (VOC) emissions and improve air quality. These environmentally friendly production methods also contribute to safer working conditions and reduced energy consumption during manufacturing.

Efforts to improve the recyclability and biodegradability of polyurethane composites are ongoing. Researchers are developing novel chemical structures and additives that facilitate easier separation and recovery of component materials at the end of the product's life. Additionally, the integration of biodegradable segments into polyurethane chains shows promise for creating composites that can decompose naturally under specific environmental conditions.

The adoption of sustainable polyurethane composites has the potential to significantly reduce the environmental footprint of various industries, including automotive, construction, and consumer goods. As regulations tighten and consumer awareness grows, the demand for these eco-friendly alternatives is expected to increase, driving further innovation in the field.

Regulatory Framework

The regulatory framework surrounding sustainable polyurethane composites is complex and evolving, reflecting the growing emphasis on environmental protection and sustainable development. At the international level, the United Nations Sustainable Development Goals (SDGs) provide a broad framework that influences policies related to sustainable materials, including polyurethane composites. Specifically, SDG 12 (Responsible Consumption and Production) and SDG 13 (Climate Action) have direct implications for the development and use of these materials.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the production and use of chemical substances, including those used in polyurethane composites. REACH requires manufacturers to register chemicals and provide safety information, promoting the use of less harmful alternatives where possible. The EU's Circular Economy Action Plan also impacts the regulatory landscape, encouraging the development of more sustainable and recyclable materials.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). Recent amendments to TSCA have strengthened the EPA's authority to evaluate and regulate chemicals, potentially affecting the development of sustainable polyurethane composites. Additionally, state-level regulations, such as California's Proposition 65, require businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

Many countries have implemented or are developing Extended Producer Responsibility (EPR) programs, which hold manufacturers responsible for the entire lifecycle of their products, including disposal. These regulations incentivize the development of more sustainable and easily recyclable materials, including polyurethane composites.

The automotive industry, a significant user of polyurethane composites, faces stringent regulations regarding fuel efficiency and emissions. These regulations indirectly promote the use of lightweight, sustainable materials like advanced polyurethane composites. For instance, the Corporate Average Fuel Economy (CAFE) standards in the U.S. and similar regulations in other countries drive innovation in materials science to reduce vehicle weight and improve fuel efficiency.

In the construction sector, building codes and green building standards are increasingly incorporating requirements for sustainable materials. Programs like LEED (Leadership in Energy and Environmental Design) in the U.S. and BREEAM (Building Research Establishment Environmental Assessment Method) in the UK provide incentives for using environmentally friendly materials, potentially boosting the adoption of sustainable polyurethane composites.

As awareness of microplastics pollution grows, regulations addressing this issue are emerging. While primarily focused on single-use plastics, these regulations may eventually extend to other polymer-based materials, potentially affecting the development and use of polyurethane composites. This evolving regulatory landscape underscores the need for continued innovation in sustainable materials science to meet both environmental goals and regulatory requirements.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the production and use of chemical substances, including those used in polyurethane composites. REACH requires manufacturers to register chemicals and provide safety information, promoting the use of less harmful alternatives where possible. The EU's Circular Economy Action Plan also impacts the regulatory landscape, encouraging the development of more sustainable and recyclable materials.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). Recent amendments to TSCA have strengthened the EPA's authority to evaluate and regulate chemicals, potentially affecting the development of sustainable polyurethane composites. Additionally, state-level regulations, such as California's Proposition 65, require businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

Many countries have implemented or are developing Extended Producer Responsibility (EPR) programs, which hold manufacturers responsible for the entire lifecycle of their products, including disposal. These regulations incentivize the development of more sustainable and easily recyclable materials, including polyurethane composites.

The automotive industry, a significant user of polyurethane composites, faces stringent regulations regarding fuel efficiency and emissions. These regulations indirectly promote the use of lightweight, sustainable materials like advanced polyurethane composites. For instance, the Corporate Average Fuel Economy (CAFE) standards in the U.S. and similar regulations in other countries drive innovation in materials science to reduce vehicle weight and improve fuel efficiency.

In the construction sector, building codes and green building standards are increasingly incorporating requirements for sustainable materials. Programs like LEED (Leadership in Energy and Environmental Design) in the U.S. and BREEAM (Building Research Establishment Environmental Assessment Method) in the UK provide incentives for using environmentally friendly materials, potentially boosting the adoption of sustainable polyurethane composites.

As awareness of microplastics pollution grows, regulations addressing this issue are emerging. While primarily focused on single-use plastics, these regulations may eventually extend to other polymer-based materials, potentially affecting the development and use of polyurethane composites. This evolving regulatory landscape underscores the need for continued innovation in sustainable materials science to meet both environmental goals and regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!