Exploring Tautomerization in Chemical Vapor Deposition Processes

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CVD Tautomerization Background and Objectives

Chemical vapor deposition (CVD) has been a cornerstone in materials science and semiconductor manufacturing for decades. The process involves the deposition of thin films on substrates through chemical reactions of vapor-phase precursors. Within this context, tautomerization, a phenomenon where certain molecules can exist in two or more structural isomers that readily interconvert, has emerged as a critical factor influencing CVD processes.

The exploration of tautomerization in CVD processes aims to unravel the complex interplay between molecular structures and deposition outcomes. This investigation is driven by the need to enhance control over film properties, improve process efficiency, and enable the synthesis of novel materials. As the demand for advanced materials with precise characteristics continues to grow across industries, understanding and harnessing tautomerization becomes increasingly vital.

Historically, tautomerization has been studied extensively in solution chemistry and biochemistry. However, its role in gas-phase reactions, particularly in CVD environments, has received less attention. The unique conditions present in CVD reactors, including high temperatures, low pressures, and the presence of reactive species, create a distinct landscape for tautomeric transformations that may differ significantly from solution-based systems.

The primary objective of this research is to elucidate the mechanisms and impacts of tautomerization on CVD processes. This includes identifying key tautomeric species involved in precursor decomposition and film formation, understanding how tautomerization affects reaction pathways and kinetics, and determining the influence of tautomeric equilibria on film composition and morphology.

Furthermore, this investigation aims to develop predictive models that can anticipate tautomeric behavior under various CVD conditions. Such models would be invaluable for optimizing precursor design, refining process parameters, and ultimately achieving greater control over the properties of deposited films. The potential applications span a wide range of fields, from microelectronics and optoelectronics to energy storage and conversion technologies.

As we delve into this research, we anticipate uncovering new strategies for manipulating tautomerization to our advantage in CVD processes. This could lead to the development of novel precursors specifically designed to leverage tautomeric transitions, as well as innovative CVD techniques that exploit tautomerization for enhanced film quality and process efficiency.

By bridging the gap between fundamental chemical principles and practical CVD applications, this exploration of tautomerization promises to push the boundaries of materials engineering and open new avenues for technological advancement. The insights gained from this research are expected to contribute significantly to the evolution of CVD technology and its applications across various industrial sectors.

The exploration of tautomerization in CVD processes aims to unravel the complex interplay between molecular structures and deposition outcomes. This investigation is driven by the need to enhance control over film properties, improve process efficiency, and enable the synthesis of novel materials. As the demand for advanced materials with precise characteristics continues to grow across industries, understanding and harnessing tautomerization becomes increasingly vital.

Historically, tautomerization has been studied extensively in solution chemistry and biochemistry. However, its role in gas-phase reactions, particularly in CVD environments, has received less attention. The unique conditions present in CVD reactors, including high temperatures, low pressures, and the presence of reactive species, create a distinct landscape for tautomeric transformations that may differ significantly from solution-based systems.

The primary objective of this research is to elucidate the mechanisms and impacts of tautomerization on CVD processes. This includes identifying key tautomeric species involved in precursor decomposition and film formation, understanding how tautomerization affects reaction pathways and kinetics, and determining the influence of tautomeric equilibria on film composition and morphology.

Furthermore, this investigation aims to develop predictive models that can anticipate tautomeric behavior under various CVD conditions. Such models would be invaluable for optimizing precursor design, refining process parameters, and ultimately achieving greater control over the properties of deposited films. The potential applications span a wide range of fields, from microelectronics and optoelectronics to energy storage and conversion technologies.

As we delve into this research, we anticipate uncovering new strategies for manipulating tautomerization to our advantage in CVD processes. This could lead to the development of novel precursors specifically designed to leverage tautomeric transitions, as well as innovative CVD techniques that exploit tautomerization for enhanced film quality and process efficiency.

By bridging the gap between fundamental chemical principles and practical CVD applications, this exploration of tautomerization promises to push the boundaries of materials engineering and open new avenues for technological advancement. The insights gained from this research are expected to contribute significantly to the evolution of CVD technology and its applications across various industrial sectors.

Market Demand for CVD Processes

Chemical Vapor Deposition (CVD) processes have become increasingly important in various industries, driving a significant market demand. The global CVD market has been experiencing steady growth, primarily fueled by the expanding semiconductor and electronics industries. As these sectors continue to advance, the need for high-quality thin film deposition techniques has surged, positioning CVD as a critical technology.

The semiconductor industry, in particular, has been a major driver of CVD market demand. With the continuous miniaturization of electronic devices and the push for more powerful and efficient chips, CVD processes play a crucial role in creating precise and uniform layers of materials on substrates. This demand extends beyond traditional silicon-based semiconductors to emerging technologies such as compound semiconductors and advanced packaging solutions.

In the solar energy sector, CVD processes are essential for the production of photovoltaic cells. As the world shifts towards renewable energy sources, the demand for more efficient and cost-effective solar panels has led to increased adoption of CVD techniques in manufacturing. This trend is expected to continue as governments and industries worldwide invest in clean energy solutions.

The aerospace and automotive industries also contribute significantly to the CVD market demand. CVD processes are used to create protective coatings and enhance the performance of various components, improving durability and efficiency. As these industries strive for lighter, stronger, and more heat-resistant materials, the demand for advanced CVD solutions continues to grow.

In the medical field, CVD processes are gaining traction for the production of biocompatible coatings and materials used in implants and medical devices. The increasing focus on personalized medicine and advanced medical technologies is expected to further drive the demand for CVD processes in this sector.

The exploration of tautomerization in CVD processes represents a potential breakthrough in enhancing the efficiency and versatility of these techniques. As industries seek more precise control over material properties and deposition processes, understanding and manipulating tautomerization could lead to new applications and improved performance across various sectors. This research direction aligns with the market's demand for innovative CVD solutions that can address complex manufacturing challenges and enable the development of next-generation products.

The semiconductor industry, in particular, has been a major driver of CVD market demand. With the continuous miniaturization of electronic devices and the push for more powerful and efficient chips, CVD processes play a crucial role in creating precise and uniform layers of materials on substrates. This demand extends beyond traditional silicon-based semiconductors to emerging technologies such as compound semiconductors and advanced packaging solutions.

In the solar energy sector, CVD processes are essential for the production of photovoltaic cells. As the world shifts towards renewable energy sources, the demand for more efficient and cost-effective solar panels has led to increased adoption of CVD techniques in manufacturing. This trend is expected to continue as governments and industries worldwide invest in clean energy solutions.

The aerospace and automotive industries also contribute significantly to the CVD market demand. CVD processes are used to create protective coatings and enhance the performance of various components, improving durability and efficiency. As these industries strive for lighter, stronger, and more heat-resistant materials, the demand for advanced CVD solutions continues to grow.

In the medical field, CVD processes are gaining traction for the production of biocompatible coatings and materials used in implants and medical devices. The increasing focus on personalized medicine and advanced medical technologies is expected to further drive the demand for CVD processes in this sector.

The exploration of tautomerization in CVD processes represents a potential breakthrough in enhancing the efficiency and versatility of these techniques. As industries seek more precise control over material properties and deposition processes, understanding and manipulating tautomerization could lead to new applications and improved performance across various sectors. This research direction aligns with the market's demand for innovative CVD solutions that can address complex manufacturing challenges and enable the development of next-generation products.

Tautomerization Challenges in CVD

Chemical vapor deposition (CVD) processes are widely used in the semiconductor industry for thin film deposition. However, tautomerization presents significant challenges in these processes, affecting the quality and properties of the deposited films. Tautomerization refers to the rapid interconversion between structural isomers, which can occur in many organic compounds used as precursors in CVD.

One of the primary challenges associated with tautomerization in CVD is the unpredictable behavior of precursor molecules. The constant shifting between tautomeric forms can lead to variations in reactivity, vapor pressure, and deposition rates. This instability makes it difficult to maintain consistent process conditions and achieve uniform film growth across the substrate surface.

Furthermore, tautomerization can impact the purity of the deposited films. Different tautomeric forms may have varying affinities for incorporation into the growing film, potentially leading to compositional inhomogeneities. This can result in non-uniform electrical, optical, or mechanical properties of the deposited layers, which is particularly problematic in the production of high-performance electronic devices.

The temperature-dependent nature of tautomerization poses another challenge in CVD processes. As the precursor molecules are heated and transported to the deposition chamber, the equilibrium between tautomeric forms can shift, altering the composition of the gas phase. This dynamic behavior complicates process control and makes it difficult to predict the exact species arriving at the substrate surface.

Additionally, tautomerization can affect the decomposition pathways of precursor molecules. Different tautomers may undergo distinct fragmentation patterns, leading to the formation of unexpected byproducts or contaminants in the deposited films. This can compromise the overall quality and performance of the final product.

The presence of tautomerization also complicates the design and selection of precursor molecules for specific CVD applications. Researchers must consider not only the desired properties of the target compound but also the potential for tautomerization and its effects on the deposition process. This adds an extra layer of complexity to precursor development and optimization efforts.

Addressing these challenges requires a multifaceted approach, combining experimental techniques with advanced computational modeling. Spectroscopic methods, such as in-situ FTIR or mass spectrometry, can help monitor the gas-phase composition and identify the presence of different tautomeric species during the CVD process. Quantum chemical calculations and molecular dynamics simulations can provide insights into the energetics and kinetics of tautomerization reactions, aiding in the prediction and control of precursor behavior.

One of the primary challenges associated with tautomerization in CVD is the unpredictable behavior of precursor molecules. The constant shifting between tautomeric forms can lead to variations in reactivity, vapor pressure, and deposition rates. This instability makes it difficult to maintain consistent process conditions and achieve uniform film growth across the substrate surface.

Furthermore, tautomerization can impact the purity of the deposited films. Different tautomeric forms may have varying affinities for incorporation into the growing film, potentially leading to compositional inhomogeneities. This can result in non-uniform electrical, optical, or mechanical properties of the deposited layers, which is particularly problematic in the production of high-performance electronic devices.

The temperature-dependent nature of tautomerization poses another challenge in CVD processes. As the precursor molecules are heated and transported to the deposition chamber, the equilibrium between tautomeric forms can shift, altering the composition of the gas phase. This dynamic behavior complicates process control and makes it difficult to predict the exact species arriving at the substrate surface.

Additionally, tautomerization can affect the decomposition pathways of precursor molecules. Different tautomers may undergo distinct fragmentation patterns, leading to the formation of unexpected byproducts or contaminants in the deposited films. This can compromise the overall quality and performance of the final product.

The presence of tautomerization also complicates the design and selection of precursor molecules for specific CVD applications. Researchers must consider not only the desired properties of the target compound but also the potential for tautomerization and its effects on the deposition process. This adds an extra layer of complexity to precursor development and optimization efforts.

Addressing these challenges requires a multifaceted approach, combining experimental techniques with advanced computational modeling. Spectroscopic methods, such as in-situ FTIR or mass spectrometry, can help monitor the gas-phase composition and identify the presence of different tautomeric species during the CVD process. Quantum chemical calculations and molecular dynamics simulations can provide insights into the energetics and kinetics of tautomerization reactions, aiding in the prediction and control of precursor behavior.

Current Tautomerization Control Methods

01 Tautomerization in organic synthesis

Tautomerization plays a crucial role in organic synthesis, particularly in the design and development of new chemical compounds. This process involves the interconversion between structural isomers, which can significantly affect the reactivity and properties of molecules. Understanding and controlling tautomerization is essential for optimizing reaction conditions and improving product yields in various chemical processes.- Tautomerization in organic synthesis: Tautomerization plays a crucial role in organic synthesis, particularly in the design and development of new chemical compounds. This process involves the interconversion between structural isomers, which can significantly affect the reactivity and properties of molecules. Understanding and controlling tautomerization is essential for optimizing reaction conditions and improving product yields in various chemical processes.

- Tautomerization in pharmaceutical compounds: Tautomerization is a critical consideration in pharmaceutical research and development. It can influence the bioavailability, efficacy, and stability of drug molecules. Researchers study tautomeric forms of potential drug candidates to optimize their pharmacological properties and enhance their therapeutic effects. Understanding tautomerization helps in predicting drug-target interactions and designing more effective medications.

- Tautomerization in material science: Tautomerization phenomena are exploited in the development of advanced materials with unique properties. This includes the design of molecular switches, sensors, and responsive materials that can change their structure or function based on external stimuli. The ability to control tautomerization in materials can lead to the creation of smart materials with applications in electronics, optics, and energy storage.

- Computational methods for studying tautomerization: Advanced computational techniques are employed to study and predict tautomerization processes. These methods include quantum mechanical calculations, molecular dynamics simulations, and machine learning approaches. Computational studies help researchers understand the energetics and kinetics of tautomerization, predict tautomeric equilibria, and design molecules with desired tautomeric properties for various applications.

- Tautomerization in biological systems: Tautomerization plays a significant role in biological processes, including enzyme catalysis, DNA base pairing, and protein-ligand interactions. Understanding tautomerization in biological molecules is crucial for elucidating mechanisms of cellular functions, designing enzyme inhibitors, and developing new therapeutic strategies. Researchers investigate how tautomerization affects the structure and function of biomolecules in various physiological contexts.

02 Tautomerization in pharmaceutical compounds

Tautomerization is a critical consideration in the development of pharmaceutical compounds. The interconversion between tautomeric forms can influence drug efficacy, bioavailability, and stability. Researchers study tautomerization to predict and control the behavior of drug molecules in biological systems, potentially leading to more effective and safer medications.Expand Specific Solutions03 Tautomerization in material science

Tautomerization phenomena are exploited in material science to develop advanced materials with unique properties. This process can be used to create materials with switchable characteristics, such as color-changing pigments or materials with tunable electronic properties. Understanding tautomerization in solid-state materials opens up possibilities for designing responsive and adaptive materials for various applications.Expand Specific Solutions04 Analytical methods for studying tautomerization

Various analytical techniques are employed to study tautomerization processes. These include spectroscopic methods such as NMR, IR, and UV-Vis spectroscopy, as well as computational modeling approaches. Advanced analytical tools help researchers understand the kinetics and thermodynamics of tautomerization, enabling better prediction and control of these processes in different chemical systems.Expand Specific Solutions05 Tautomerization in biological systems

Tautomerization plays a significant role in biological systems, particularly in the function of enzymes and the structure of nucleic acids. Understanding tautomerization in biomolecules is crucial for elucidating mechanisms of enzyme catalysis and DNA replication. This knowledge contributes to advancements in fields such as molecular biology, genetic engineering, and biotechnology.Expand Specific Solutions

Key Players in CVD Industry

The exploration of tautomerization in Chemical Vapor Deposition (CVD) processes represents a niche yet crucial area of research in the semiconductor and materials science industries. The market is in its early growth stage, with a relatively small but expanding size due to increasing demand for advanced electronic devices. Technological maturity varies among key players, with companies like Applied Materials, Samsung Electronics, and Micron Technology leading in CVD innovation. These firms are investing heavily in R&D to optimize tautomerization control for enhanced material properties and device performance. Academic institutions such as MIT and industrial research centers like Southwest Research Institute are also contributing significantly to advancing the fundamental understanding of tautomerization in CVD, indicating a collaborative ecosystem driving progress in this field.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Chemical Vapor Deposition (CVD) processes that consider tautomerization effects. Their approach involves precise control of precursor chemistry and deposition conditions to manage tautomeric equilibria. They utilize in-situ spectroscopic techniques to monitor tautomer distributions during deposition[1]. Their CVD systems incorporate advanced gas delivery systems capable of handling multiple precursor tautomers simultaneously, allowing for fine-tuning of film composition and properties[2]. Applied Materials has also developed computational models to predict tautomerization behavior under various process conditions, enabling optimization of deposition parameters for specific applications[3].

Strengths: Comprehensive approach combining experimental and computational methods. Advanced in-situ monitoring capabilities. Weaknesses: May require complex and expensive equipment. Process optimization can be time-consuming.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has incorporated tautomerization considerations into their CVD processes for advanced electronics manufacturing. Their approach includes the development of custom precursors with controlled tautomeric behavior for specific applications in display and semiconductor technologies[11]. Samsung has implemented advanced in-situ monitoring systems that can detect and respond to changes in tautomer distributions during deposition, ensuring precise control over film properties[12]. They have also developed multi-chamber CVD systems that allow for sequential deposition of different tautomeric forms, enabling the creation of complex multilayer structures with tailored properties[13]. Samsung's research extends to exploring tautomerization effects in plasma-enhanced CVD processes for low-temperature applications.

Strengths: Integration of tautomerization control into large-scale manufacturing processes. Diverse applications across multiple product lines. Weaknesses: Proprietary nature of some technologies may limit broader industry adoption. High investment costs for specialized equipment.

Innovative Approaches to Tautomerization

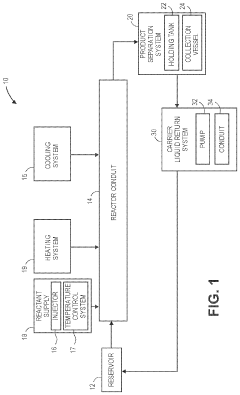

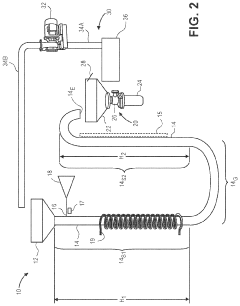

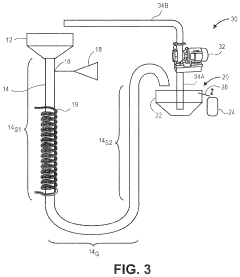

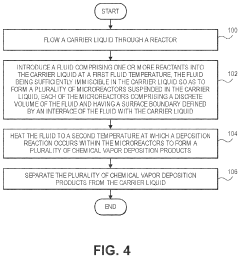

System and process for chemical vapor deposition

PatentActiveUS11371135B2

Innovation

- A microreactor system for CVD that involves flowing a carrier liquid through a reactor, where reactants are introduced to form microreactors suspended in the liquid, allowing for controlled temperature and pressure conditions to achieve uniform chemical vapor deposition products, including hollow spherical shells and carbon nanotubes.

Process for the elimination of tungsten oxidation with inert gas stabilization in chemical vapor deposition processes

PatentInactiveUS5753303A

Innovation

- Using an inert gas, such as helium, nitrogen, or argon, to pressurize and stabilize the deposition chamber, eliminating oxygen and preventing tungsten oxidation at temperatures above 400°C, thereby ensuring reliable substrate performance without reducing deposition temperatures.

Environmental Impact of CVD Processes

Chemical Vapor Deposition (CVD) processes, while essential for various industries, have significant environmental implications that warrant careful consideration. The environmental impact of CVD processes primarily stems from the use of precursor gases, energy consumption, and waste generation.

Precursor gases used in CVD processes often include toxic, corrosive, or environmentally harmful substances. These gases can contribute to air pollution if not properly managed. For instance, silane (SiH4), commonly used in silicon deposition, is highly flammable and can form explosive mixtures with air. Other precursors like metal-organic compounds may release volatile organic compounds (VOCs) during the deposition process, potentially contributing to smog formation and air quality degradation.

Energy consumption is another critical environmental concern in CVD processes. The high temperatures required for many CVD reactions, often ranging from 200°C to over 1000°C, necessitate substantial energy input. This energy demand typically relies on fossil fuel-based electricity, contributing to greenhouse gas emissions and climate change. The environmental footprint of CVD processes can be particularly significant in energy-intensive applications such as the production of solar cells or advanced semiconductor devices.

Waste generation and disposal pose additional environmental challenges. CVD processes often produce solid and liquid waste streams that may contain hazardous materials. These can include unreacted precursors, reaction by-products, and contaminated substrates. Proper handling, treatment, and disposal of these wastes are crucial to prevent soil and water pollution. In some cases, the waste streams may contain valuable materials that could be recovered and recycled, presenting opportunities for reducing environmental impact through resource conservation.

The tautomerization phenomenon in CVD processes adds another layer of complexity to environmental considerations. Tautomerization can affect the reactivity and properties of precursor molecules, potentially altering the efficiency of the deposition process and the nature of by-products formed. This can have indirect environmental implications by influencing the overall material and energy requirements of the process, as well as the composition of waste streams.

To mitigate the environmental impact of CVD processes, various strategies are being explored and implemented. These include the development of more environmentally friendly precursors, optimization of process parameters to improve efficiency and reduce waste, implementation of advanced abatement systems for exhaust gases, and exploration of low-temperature CVD techniques to reduce energy consumption. Additionally, the integration of CVD processes with renewable energy sources and the adoption of circular economy principles in waste management are emerging trends aimed at enhancing the sustainability of these critical industrial processes.

Precursor gases used in CVD processes often include toxic, corrosive, or environmentally harmful substances. These gases can contribute to air pollution if not properly managed. For instance, silane (SiH4), commonly used in silicon deposition, is highly flammable and can form explosive mixtures with air. Other precursors like metal-organic compounds may release volatile organic compounds (VOCs) during the deposition process, potentially contributing to smog formation and air quality degradation.

Energy consumption is another critical environmental concern in CVD processes. The high temperatures required for many CVD reactions, often ranging from 200°C to over 1000°C, necessitate substantial energy input. This energy demand typically relies on fossil fuel-based electricity, contributing to greenhouse gas emissions and climate change. The environmental footprint of CVD processes can be particularly significant in energy-intensive applications such as the production of solar cells or advanced semiconductor devices.

Waste generation and disposal pose additional environmental challenges. CVD processes often produce solid and liquid waste streams that may contain hazardous materials. These can include unreacted precursors, reaction by-products, and contaminated substrates. Proper handling, treatment, and disposal of these wastes are crucial to prevent soil and water pollution. In some cases, the waste streams may contain valuable materials that could be recovered and recycled, presenting opportunities for reducing environmental impact through resource conservation.

The tautomerization phenomenon in CVD processes adds another layer of complexity to environmental considerations. Tautomerization can affect the reactivity and properties of precursor molecules, potentially altering the efficiency of the deposition process and the nature of by-products formed. This can have indirect environmental implications by influencing the overall material and energy requirements of the process, as well as the composition of waste streams.

To mitigate the environmental impact of CVD processes, various strategies are being explored and implemented. These include the development of more environmentally friendly precursors, optimization of process parameters to improve efficiency and reduce waste, implementation of advanced abatement systems for exhaust gases, and exploration of low-temperature CVD techniques to reduce energy consumption. Additionally, the integration of CVD processes with renewable energy sources and the adoption of circular economy principles in waste management are emerging trends aimed at enhancing the sustainability of these critical industrial processes.

Safety Considerations in CVD

Chemical Vapor Deposition (CVD) processes, while essential in various industries, present significant safety challenges that must be carefully addressed. The use of volatile precursors, high temperatures, and potentially hazardous by-products necessitates a comprehensive approach to safety management.

One of the primary safety concerns in CVD processes is the handling and storage of precursor materials. Many of these substances are pyrophoric, meaning they can spontaneously ignite when exposed to air. Proper storage in inert atmospheres and the use of specialized handling equipment are crucial to prevent accidents. Additionally, the implementation of robust ventilation systems is essential to mitigate the risks associated with potential leaks or spills.

The high temperatures employed in CVD reactors pose another significant safety risk. Thermal management systems must be meticulously designed and maintained to prevent overheating and potential equipment failures. Regular inspections and the use of advanced temperature monitoring devices are vital to ensure safe operation.

Byproducts generated during CVD processes can be toxic, corrosive, or flammable. The installation of efficient scrubbing systems and proper waste management protocols is necessary to minimize environmental impact and protect personnel. Furthermore, the use of personal protective equipment (PPE) tailored to the specific hazards of the CVD process is mandatory for all operators and maintenance staff.

Emergency response planning is a critical aspect of CVD safety. This includes the development of clear evacuation procedures, installation of emergency shutdown systems, and regular drills to ensure all personnel are prepared to respond effectively in case of an incident. The integration of automated safety systems, such as gas detectors and fire suppression equipment, provides an additional layer of protection.

Training and education play a pivotal role in maintaining a safe CVD environment. Operators must be thoroughly versed in the specific hazards associated with the process, proper equipment operation, and emergency procedures. Regular refresher courses and safety audits help to reinforce best practices and identify potential areas for improvement.

In the context of tautomerization in CVD processes, additional safety considerations may arise. The potential for unexpected chemical reactions or the formation of unanticipated byproducts due to tautomeric shifts must be carefully evaluated. This may require enhanced monitoring systems and more frequent analysis of process outputs to ensure safety parameters remain within acceptable limits.

One of the primary safety concerns in CVD processes is the handling and storage of precursor materials. Many of these substances are pyrophoric, meaning they can spontaneously ignite when exposed to air. Proper storage in inert atmospheres and the use of specialized handling equipment are crucial to prevent accidents. Additionally, the implementation of robust ventilation systems is essential to mitigate the risks associated with potential leaks or spills.

The high temperatures employed in CVD reactors pose another significant safety risk. Thermal management systems must be meticulously designed and maintained to prevent overheating and potential equipment failures. Regular inspections and the use of advanced temperature monitoring devices are vital to ensure safe operation.

Byproducts generated during CVD processes can be toxic, corrosive, or flammable. The installation of efficient scrubbing systems and proper waste management protocols is necessary to minimize environmental impact and protect personnel. Furthermore, the use of personal protective equipment (PPE) tailored to the specific hazards of the CVD process is mandatory for all operators and maintenance staff.

Emergency response planning is a critical aspect of CVD safety. This includes the development of clear evacuation procedures, installation of emergency shutdown systems, and regular drills to ensure all personnel are prepared to respond effectively in case of an incident. The integration of automated safety systems, such as gas detectors and fire suppression equipment, provides an additional layer of protection.

Training and education play a pivotal role in maintaining a safe CVD environment. Operators must be thoroughly versed in the specific hazards associated with the process, proper equipment operation, and emergency procedures. Regular refresher courses and safety audits help to reinforce best practices and identify potential areas for improvement.

In the context of tautomerization in CVD processes, additional safety considerations may arise. The potential for unexpected chemical reactions or the formation of unanticipated byproducts due to tautomeric shifts must be carefully evaluated. This may require enhanced monitoring systems and more frequent analysis of process outputs to ensure safety parameters remain within acceptable limits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!