Case Study: Fast Screening Of Photocatalysts Using Synthetic Augmentation

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalyst Screening Evolution and Objectives

Photocatalyst discovery has evolved significantly over the past several decades, transitioning from serendipitous findings to more systematic approaches. The field began in the 1970s with Fujishima and Honda's groundbreaking discovery of water splitting using TiO2 electrodes under ultraviolet light. This pivotal moment sparked worldwide interest in photocatalytic materials for environmental remediation and energy applications.

Traditional screening methods have historically relied on time-consuming synthesis and characterization processes, with researchers typically evaluating only a limited number of candidates manually. This approach, while foundational, has proven inefficient for exploring the vast chemical space of potential photocatalysts, which encompasses millions of possible compositions and structures.

The emergence of high-throughput experimental techniques in the early 2000s represented a significant advancement, enabling parallel synthesis and testing of multiple catalyst candidates. However, even these improved methods face practical limitations in terms of material consumption, equipment costs, and experimental time frames, typically allowing for the evaluation of hundreds to thousands of candidates at most.

Recent years have witnessed a paradigm shift toward computational screening approaches, leveraging density functional theory (DFT) calculations to predict electronic structures and photocatalytic properties. While these methods have expanded our capability to evaluate candidates, they remain computationally intensive for complex systems and often require experimental validation.

The integration of artificial intelligence and machine learning techniques represents the latest frontier in photocatalyst screening. These approaches can rapidly identify patterns in existing data, predict properties of novel materials, and guide experimental design. Synthetic augmentation, in particular, addresses the critical challenge of limited training data by generating synthetic examples that expand the available dataset for model training.

The primary objectives of fast screening using synthetic augmentation are multifaceted. First, to dramatically accelerate the discovery timeline for novel photocatalysts from years to months or even weeks. Second, to enable exploration of previously inaccessible regions of chemical space by overcoming data limitations. Third, to reduce research costs by minimizing unnecessary experimental iterations. Fourth, to identify materials with optimized properties for specific applications, such as water splitting, CO2 reduction, or organic pollutant degradation.

The ultimate goal is to develop a robust, generalizable framework that combines synthetic data generation, machine learning prediction, and targeted experimental validation to revolutionize how we discover and optimize photocatalytic materials. This approach promises to overcome the traditional trade-off between screening breadth and depth, potentially unlocking unprecedented advances in renewable energy technologies and environmental remediation solutions.

Traditional screening methods have historically relied on time-consuming synthesis and characterization processes, with researchers typically evaluating only a limited number of candidates manually. This approach, while foundational, has proven inefficient for exploring the vast chemical space of potential photocatalysts, which encompasses millions of possible compositions and structures.

The emergence of high-throughput experimental techniques in the early 2000s represented a significant advancement, enabling parallel synthesis and testing of multiple catalyst candidates. However, even these improved methods face practical limitations in terms of material consumption, equipment costs, and experimental time frames, typically allowing for the evaluation of hundreds to thousands of candidates at most.

Recent years have witnessed a paradigm shift toward computational screening approaches, leveraging density functional theory (DFT) calculations to predict electronic structures and photocatalytic properties. While these methods have expanded our capability to evaluate candidates, they remain computationally intensive for complex systems and often require experimental validation.

The integration of artificial intelligence and machine learning techniques represents the latest frontier in photocatalyst screening. These approaches can rapidly identify patterns in existing data, predict properties of novel materials, and guide experimental design. Synthetic augmentation, in particular, addresses the critical challenge of limited training data by generating synthetic examples that expand the available dataset for model training.

The primary objectives of fast screening using synthetic augmentation are multifaceted. First, to dramatically accelerate the discovery timeline for novel photocatalysts from years to months or even weeks. Second, to enable exploration of previously inaccessible regions of chemical space by overcoming data limitations. Third, to reduce research costs by minimizing unnecessary experimental iterations. Fourth, to identify materials with optimized properties for specific applications, such as water splitting, CO2 reduction, or organic pollutant degradation.

The ultimate goal is to develop a robust, generalizable framework that combines synthetic data generation, machine learning prediction, and targeted experimental validation to revolutionize how we discover and optimize photocatalytic materials. This approach promises to overcome the traditional trade-off between screening breadth and depth, potentially unlocking unprecedented advances in renewable energy technologies and environmental remediation solutions.

Market Analysis for Accelerated Photocatalyst Discovery

The global market for photocatalyst discovery and development is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable energy solutions. The market size for photocatalysts was valued at approximately $2.5 billion in 2022 and is projected to reach $5.3 billion by 2028, representing a compound annual growth rate of 11.4%. This growth trajectory underscores the substantial commercial interest in accelerated photocatalyst discovery technologies.

Key market segments benefiting from advanced photocatalyst screening include environmental remediation, renewable energy production, and chemical manufacturing. The water treatment sector alone accounts for 35% of the current photocatalyst market, with applications in pollutant degradation and disinfection processes. Meanwhile, the renewable energy sector, particularly hydrogen production through water splitting, represents the fastest-growing segment with a 15.7% annual growth rate.

Synthetic augmentation technologies for photocatalyst screening are positioned at the intersection of materials science, artificial intelligence, and high-throughput experimentation. This convergence creates a specialized market niche estimated at $320 million currently, with projections suggesting expansion to $780 million by 2027. Companies investing in these accelerated discovery platforms can potentially reduce research and development timelines by 40-60%, translating to significant cost savings and competitive advantages.

Regional analysis reveals Asia-Pacific as the dominant market for photocatalyst research and applications, accounting for 45% of global demand, followed by North America (28%) and Europe (20%). China and Japan lead in research output and patent filings related to photocatalyst technologies, while the United States demonstrates strength in computational screening approaches and machine learning integration.

Industry stakeholders express growing demand for screening technologies that can reduce the discovery-to-commercialization timeline from the current average of 7-10 years to 3-5 years. This market pull is evidenced by increasing corporate R&D investments, with major chemical and materials companies allocating 15-20% of their research budgets to high-throughput and AI-augmented discovery platforms.

The economic value proposition of synthetic augmentation for photocatalyst screening is compelling, with early adopters reporting ROI metrics of 300-400% over five-year implementation periods. This favorable economic outlook is attracting venture capital investment, with funding for startups in this space reaching $450 million in 2022, a 35% increase from the previous year.

Key market segments benefiting from advanced photocatalyst screening include environmental remediation, renewable energy production, and chemical manufacturing. The water treatment sector alone accounts for 35% of the current photocatalyst market, with applications in pollutant degradation and disinfection processes. Meanwhile, the renewable energy sector, particularly hydrogen production through water splitting, represents the fastest-growing segment with a 15.7% annual growth rate.

Synthetic augmentation technologies for photocatalyst screening are positioned at the intersection of materials science, artificial intelligence, and high-throughput experimentation. This convergence creates a specialized market niche estimated at $320 million currently, with projections suggesting expansion to $780 million by 2027. Companies investing in these accelerated discovery platforms can potentially reduce research and development timelines by 40-60%, translating to significant cost savings and competitive advantages.

Regional analysis reveals Asia-Pacific as the dominant market for photocatalyst research and applications, accounting for 45% of global demand, followed by North America (28%) and Europe (20%). China and Japan lead in research output and patent filings related to photocatalyst technologies, while the United States demonstrates strength in computational screening approaches and machine learning integration.

Industry stakeholders express growing demand for screening technologies that can reduce the discovery-to-commercialization timeline from the current average of 7-10 years to 3-5 years. This market pull is evidenced by increasing corporate R&D investments, with major chemical and materials companies allocating 15-20% of their research budgets to high-throughput and AI-augmented discovery platforms.

The economic value proposition of synthetic augmentation for photocatalyst screening is compelling, with early adopters reporting ROI metrics of 300-400% over five-year implementation periods. This favorable economic outlook is attracting venture capital investment, with funding for startups in this space reaching $450 million in 2022, a 35% increase from the previous year.

Current Challenges in High-Throughput Photocatalyst Screening

Despite significant advancements in photocatalyst development, high-throughput screening remains a formidable challenge in the field. Traditional experimental methods for evaluating photocatalytic performance are inherently time-consuming and resource-intensive, often requiring days or weeks to synthesize and test a single material candidate. This bottleneck severely limits the pace of discovery and optimization in photocatalysis research.

The complexity of photocatalytic systems presents a multidimensional challenge. Researchers must simultaneously consider numerous parameters including band gap, charge carrier mobility, surface area, crystallinity, and stability under reaction conditions. Each parameter can significantly influence overall performance, creating an expansive design space that is impractical to explore comprehensively through conventional experimental approaches.

Reproducibility issues further complicate screening efforts. Minor variations in synthesis conditions can lead to substantial differences in photocatalytic activity, making it difficult to establish reliable structure-property relationships. This variability necessitates multiple experimental iterations, further slowing the discovery process.

Current high-throughput experimental platforms often suffer from scalability limitations. While parallel synthesis techniques have improved, the analytical methods required to evaluate photocatalytic performance typically remain sequential and time-intensive. This creates an imbalance where materials can be produced faster than they can be meaningfully characterized.

Data standardization represents another significant hurdle. The lack of universally accepted protocols for measuring and reporting photocatalytic activity makes it challenging to compare results across different research groups or to build comprehensive databases necessary for machine learning applications. This fragmentation of data impedes collaborative progress in the field.

Computational screening approaches, while promising, face their own set of challenges. Accurate prediction of photocatalytic performance requires sophisticated quantum mechanical calculations that are computationally expensive. Additionally, the gap between theoretical predictions and experimental reality remains substantial, particularly for complex reaction mechanisms and real-world operating conditions.

The integration of experimental and computational workflows presents technical and methodological barriers. Seamless data flow between experimental platforms, analytical instruments, and computational models requires sophisticated laboratory automation and standardized data formats that are not yet widely implemented in academic or industrial settings.

These challenges collectively highlight the need for innovative approaches that can accelerate the screening process while maintaining or improving the quality of insights gained about potential photocatalyst candidates. Synthetic augmentation techniques represent a promising direction to address these limitations by expanding the effective search space without proportionally increasing experimental burden.

The complexity of photocatalytic systems presents a multidimensional challenge. Researchers must simultaneously consider numerous parameters including band gap, charge carrier mobility, surface area, crystallinity, and stability under reaction conditions. Each parameter can significantly influence overall performance, creating an expansive design space that is impractical to explore comprehensively through conventional experimental approaches.

Reproducibility issues further complicate screening efforts. Minor variations in synthesis conditions can lead to substantial differences in photocatalytic activity, making it difficult to establish reliable structure-property relationships. This variability necessitates multiple experimental iterations, further slowing the discovery process.

Current high-throughput experimental platforms often suffer from scalability limitations. While parallel synthesis techniques have improved, the analytical methods required to evaluate photocatalytic performance typically remain sequential and time-intensive. This creates an imbalance where materials can be produced faster than they can be meaningfully characterized.

Data standardization represents another significant hurdle. The lack of universally accepted protocols for measuring and reporting photocatalytic activity makes it challenging to compare results across different research groups or to build comprehensive databases necessary for machine learning applications. This fragmentation of data impedes collaborative progress in the field.

Computational screening approaches, while promising, face their own set of challenges. Accurate prediction of photocatalytic performance requires sophisticated quantum mechanical calculations that are computationally expensive. Additionally, the gap between theoretical predictions and experimental reality remains substantial, particularly for complex reaction mechanisms and real-world operating conditions.

The integration of experimental and computational workflows presents technical and methodological barriers. Seamless data flow between experimental platforms, analytical instruments, and computational models requires sophisticated laboratory automation and standardized data formats that are not yet widely implemented in academic or industrial settings.

These challenges collectively highlight the need for innovative approaches that can accelerate the screening process while maintaining or improving the quality of insights gained about potential photocatalyst candidates. Synthetic augmentation techniques represent a promising direction to address these limitations by expanding the effective search space without proportionally increasing experimental burden.

State-of-the-Art Synthetic Augmentation Techniques

01 High-throughput screening methods for photocatalysts

Advanced high-throughput screening methodologies enable rapid evaluation of multiple photocatalyst candidates simultaneously. These approaches utilize automated systems for sample preparation, reaction monitoring, and data analysis to efficiently identify promising photocatalysts. The methods often incorporate parallel reactors, robotic handling systems, and real-time analysis techniques to accelerate the discovery process and optimize screening efficiency.- High-throughput screening methods for photocatalysts: Advanced high-throughput screening techniques enable rapid evaluation of multiple photocatalyst candidates simultaneously. These methods typically involve automated systems that can prepare, test, and analyze large arrays of photocatalyst materials under controlled conditions. By parallelizing the screening process, researchers can significantly reduce the time required to identify promising photocatalysts with desired properties such as enhanced activity, selectivity, and stability.

- Combinatorial approaches for photocatalyst discovery: Combinatorial methods involve systematic variation of photocatalyst composition, structure, and processing parameters to create libraries of materials for screening. These approaches often utilize gradient deposition techniques, co-sputtering, or solution-based synthesis to generate diverse arrays of photocatalyst candidates. Machine learning algorithms can be integrated to guide the exploration of complex compositional spaces and accelerate the discovery of novel photocatalysts with improved performance.

- In-situ characterization techniques for photocatalyst evaluation: Real-time monitoring and characterization techniques allow for efficient assessment of photocatalytic performance under reaction conditions. These methods include spectroscopic techniques (UV-Vis, FTIR, Raman), electrochemical measurements, and product analysis systems that can be integrated into screening platforms. In-situ characterization provides valuable insights into reaction mechanisms, intermediate formation, and catalyst deactivation pathways, enabling more effective screening and optimization of photocatalysts.

- Microfluidic and miniaturized reactor systems: Microfluidic devices and miniaturized reactor systems enable efficient screening of photocatalysts with minimal material consumption. These platforms feature precise control over reaction parameters, excellent mass and heat transfer characteristics, and compatibility with various detection methods. The small scale allows for parallel testing of multiple catalysts under identical conditions, improving reproducibility and accelerating the screening process while reducing waste generation and energy consumption.

- Computational methods for photocatalyst screening: Computational approaches such as density functional theory (DFT), molecular dynamics simulations, and machine learning models enable virtual screening of photocatalyst candidates before experimental validation. These methods can predict key properties including band gap, charge carrier mobility, surface reactivity, and stability under reaction conditions. By identifying promising candidates in silico, researchers can focus experimental efforts on the most promising materials, significantly enhancing the efficiency of the photocatalyst discovery process.

02 Combinatorial approaches for photocatalyst development

Combinatorial chemistry techniques are applied to systematically create and test diverse libraries of photocatalyst materials. These approaches involve the synthesis of material arrays with varying compositions, structures, and properties, followed by parallel testing of their photocatalytic performance. By exploring wide parameter spaces efficiently, researchers can identify optimal formulations and unexpected synergistic effects that enhance photocatalytic activity.Expand Specific Solutions03 Advanced characterization techniques for photocatalyst screening

Sophisticated analytical and characterization methods improve the efficiency of photocatalyst screening by providing detailed insights into material properties and performance. These techniques include spectroscopic methods, microscopy, electrochemical analysis, and computational modeling that help understand structure-activity relationships. Real-time monitoring of photocatalytic reactions enables rapid assessment of catalyst efficiency and stability under various conditions.Expand Specific Solutions04 Microfluidic and miniaturized systems for photocatalyst evaluation

Microfluidic devices and miniaturized reactor systems enable efficient screening of photocatalysts using minimal amounts of materials. These platforms provide precise control over reaction conditions, improved mass and heat transfer, and the ability to perform multiple parallel experiments. The integration of in-line detection methods allows for real-time monitoring of photocatalytic performance, significantly increasing throughput and reducing resource requirements.Expand Specific Solutions05 Machine learning and computational approaches for photocatalyst screening

Artificial intelligence and computational methods accelerate photocatalyst discovery by predicting performance based on material properties and reaction conditions. Machine learning algorithms analyze large datasets from experimental results to identify patterns and optimize catalyst formulations. Virtual screening techniques enable researchers to evaluate thousands of potential photocatalyst candidates in silico before experimental validation, significantly improving screening efficiency and reducing development time.Expand Specific Solutions

Leading Organizations in Photocatalyst Research and Development

The photocatalyst screening market is currently in a growth phase, with increasing demand for efficient materials discovery methods. The global market for photocatalytic materials is expanding rapidly, projected to reach significant scale as environmental applications gain prominence. Technologically, synthetic augmentation represents an emerging approach to accelerate photocatalyst development. Leading academic institutions like MIT, Peking University, and The University of Tokyo are driving fundamental research, while companies including Canon, Olympus, and Panasonic are commercializing applications. Research organizations such as The Scripps Research Institute and Naval Research Laboratory are advancing computational screening methods. The integration of AI and high-throughput experimentation by players like Renew Biopharma is creating new opportunities for rapid discovery of high-performance photocatalytic materials.

South China University of Technology

Technical Solution: South China University of Technology has developed a sophisticated photocatalyst screening system that combines computational modeling with high-throughput experimental validation. Their approach utilizes a multi-scale modeling framework that spans from quantum mechanical calculations to mesoscale simulations, enabling accurate prediction of photocatalytic performance across different length scales. The system employs synthetic data augmentation techniques based on physics-informed neural networks (PINNs) that generate realistic synthetic data while ensuring consistency with known physical laws governing photocatalysis[3]. This approach allows for the expansion of limited experimental datasets while maintaining physical realism. Their platform includes an automated microfluidic testing system that can rapidly evaluate photocatalytic activity under various reaction conditions, including different light intensities, wavelengths, and reaction media[5]. The system incorporates a comprehensive materials informatics pipeline that integrates theoretical predictions, synthetic data, and experimental results to continuously refine predictive models.

Strengths: Sophisticated multi-scale modeling approach that captures complex photocatalytic phenomena across different length scales. Physics-informed synthetic data generation ensures physically realistic predictions. Weaknesses: Complex implementation requiring interdisciplinary expertise. Computational models may still struggle with accurately predicting performance for entirely novel material classes.

Arizona Board of Regents

Technical Solution: The Arizona Board of Regents, representing Arizona's public universities, has developed a comprehensive photocatalyst screening platform that combines high-throughput computational screening with advanced experimental validation techniques. Their system employs a multi-objective optimization framework that simultaneously considers multiple performance metrics, including photocatalytic activity, stability, and cost. The platform incorporates a sophisticated synthetic data augmentation approach that uses conditional generative adversarial networks (cGANs) to create realistic synthetic data for various photocatalyst classes[5]. This synthetic data helps overcome limitations in available experimental data, particularly for novel material compositions. Their system features an automated combinatorial synthesis capability that can rapidly produce libraries of photocatalyst materials with systematically varied compositions and structures. The platform includes advanced characterization techniques, including operando spectroscopy that monitors catalyst structure and performance under actual reaction conditions[7]. Their approach also incorporates a knowledge graph framework that integrates theoretical predictions, literature data, and experimental results to guide the discovery process.

Strengths: Comprehensive multi-objective optimization framework that balances multiple performance criteria. Advanced operando characterization techniques provide insights into catalyst behavior under realistic conditions. Weaknesses: Complex infrastructure requirements spanning computational and experimental facilities. Synthetic data generation may occasionally produce physically unrealistic predictions that require experimental validation.

Key Innovations in Machine Learning for Photocatalyst Prediction

Method of fast searching and recognition of a digital image representative of at least one graphical pattern in a bank of digital images

PatentInactiveEP2082336A1

Innovation

- A method that generates compact, two-dimensional indexes for digital images using resampling and processing with mathematical operators, allowing for rapid similarity measurement and recognition, capable of processing at least 30 million images per second on a standard microcomputer with minimal computing power, and suitable for dynamic image banks and video sequences.

Image-quality improvement method for scanning charged particle microscope image, and scanning charged particle microscope device

PatentWO2015122082A1

Innovation

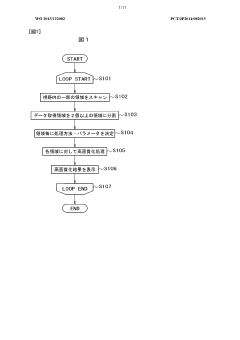

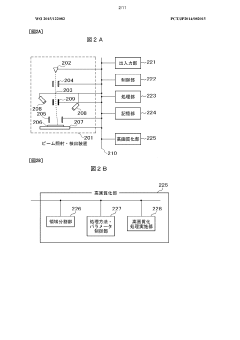

- The method involves dividing the data acquisition region into areas based on distance from unacquired regions, applying provisional processing near unacquired areas and normal processing where sufficient data is available, and using past processing results for distant regions to minimize processing time and prevent pseudo-patterns, allowing for real-time image quality enhancement and parameter adjustments during scanning.

Environmental Impact and Sustainability Considerations

The rapid development of photocatalyst screening technologies using synthetic augmentation presents significant implications for environmental sustainability. Photocatalytic processes inherently align with green chemistry principles, offering potential for solar-powered chemical transformations that reduce dependency on fossil fuel-derived energy sources. By accelerating the discovery of more efficient photocatalysts through synthetic augmentation methods, researchers can potentially develop materials that operate under milder conditions with lower energy requirements, thereby reducing the carbon footprint associated with chemical manufacturing processes.

The environmental benefits extend to waste reduction in research and development phases. Traditional photocatalyst screening methods require extensive laboratory resources, including chemicals, solvents, and energy-intensive equipment. Synthetic augmentation approaches minimize physical experimentation by leveraging computational models and data augmentation techniques, resulting in fewer chemical waste streams and reduced laboratory resource consumption. This aligns with circular economy principles by optimizing resource utilization in the innovation pipeline.

Water purification represents a critical application area where advanced photocatalysts can deliver substantial environmental benefits. Efficient photocatalysts can degrade persistent organic pollutants, pharmaceuticals, and industrial contaminants in wastewater without requiring additional chemical treatments. The accelerated discovery of specialized photocatalysts through synthetic augmentation could address region-specific water contamination challenges, particularly in developing regions where water treatment infrastructure is limited.

Carbon dioxide reduction capabilities of next-generation photocatalysts offer promising pathways for greenhouse gas mitigation. By converting CO₂ into value-added chemicals or fuels using solar energy, these materials could contribute to carbon-neutral or negative-emission technologies. The rapid screening methodologies enabled by synthetic augmentation can specifically target this application space, potentially accelerating progress toward practical carbon capture and utilization systems.

Life cycle assessment considerations must be integrated into photocatalyst screening protocols. While computational approaches reduce immediate environmental impacts, the long-term sustainability of discovered materials depends on factors including raw material sourcing, synthesis energy requirements, operational stability, and end-of-life management. Synthetic augmentation platforms should incorporate these parameters into screening criteria to ensure that environmental benefits extend throughout the material lifecycle.

Regulatory frameworks and sustainability certifications will increasingly influence photocatalyst development trajectories. Materials discovered through accelerated screening methods must comply with evolving environmental regulations, including restrictions on hazardous substances and nanomaterial safety protocols. Integrating these considerations into early-stage screening can prevent downstream sustainability challenges and market barriers for promising photocatalytic technologies.

The environmental benefits extend to waste reduction in research and development phases. Traditional photocatalyst screening methods require extensive laboratory resources, including chemicals, solvents, and energy-intensive equipment. Synthetic augmentation approaches minimize physical experimentation by leveraging computational models and data augmentation techniques, resulting in fewer chemical waste streams and reduced laboratory resource consumption. This aligns with circular economy principles by optimizing resource utilization in the innovation pipeline.

Water purification represents a critical application area where advanced photocatalysts can deliver substantial environmental benefits. Efficient photocatalysts can degrade persistent organic pollutants, pharmaceuticals, and industrial contaminants in wastewater without requiring additional chemical treatments. The accelerated discovery of specialized photocatalysts through synthetic augmentation could address region-specific water contamination challenges, particularly in developing regions where water treatment infrastructure is limited.

Carbon dioxide reduction capabilities of next-generation photocatalysts offer promising pathways for greenhouse gas mitigation. By converting CO₂ into value-added chemicals or fuels using solar energy, these materials could contribute to carbon-neutral or negative-emission technologies. The rapid screening methodologies enabled by synthetic augmentation can specifically target this application space, potentially accelerating progress toward practical carbon capture and utilization systems.

Life cycle assessment considerations must be integrated into photocatalyst screening protocols. While computational approaches reduce immediate environmental impacts, the long-term sustainability of discovered materials depends on factors including raw material sourcing, synthesis energy requirements, operational stability, and end-of-life management. Synthetic augmentation platforms should incorporate these parameters into screening criteria to ensure that environmental benefits extend throughout the material lifecycle.

Regulatory frameworks and sustainability certifications will increasingly influence photocatalyst development trajectories. Materials discovered through accelerated screening methods must comply with evolving environmental regulations, including restrictions on hazardous substances and nanomaterial safety protocols. Integrating these considerations into early-stage screening can prevent downstream sustainability challenges and market barriers for promising photocatalytic technologies.

Scalability and Industrial Implementation Strategies

The scalability of photocatalyst screening technologies using synthetic augmentation represents a critical bridge between laboratory research and industrial application. Current implementation strategies focus on transitioning from small-scale experimental setups to large-volume production environments. The primary challenge lies in maintaining the accuracy and reliability of screening results while significantly increasing throughput capacity.

Industrial implementation requires robust infrastructure that can handle high-throughput screening operations. Companies pioneering this field have developed modular systems that can be expanded incrementally as demand increases. These systems typically incorporate automated sample handling, parallel processing capabilities, and integrated data management platforms that can process the enormous datasets generated during large-scale screening operations.

Cost considerations remain paramount in scaling synthetic augmentation techniques. The initial capital investment for establishing comprehensive screening facilities is substantial, necessitating strategic planning for return on investment. However, analysis indicates that the long-term economic benefits—particularly through accelerated discovery of high-performance photocatalysts—can justify these expenditures. Companies have reported up to 60% reduction in development timelines when implementing these advanced screening methodologies at scale.

Technical standardization presents another crucial aspect of industrial implementation. Organizations such as the International Consortium for Photocatalyst Standards (ICPS) have begun developing protocols for consistent evaluation metrics across different screening platforms. These standards facilitate technology transfer between research institutions and industrial partners, ensuring that laboratory discoveries can be effectively translated into commercial applications.

Resource optimization strategies have emerged as essential components of scalable implementation. Advanced algorithms now enable predictive maintenance of screening equipment, minimizing downtime and maximizing operational efficiency. Additionally, cloud-based computational resources allow companies to dynamically allocate processing power based on screening demands, avoiding the need for constant maximum-capacity infrastructure.

Workforce development represents an often-overlooked aspect of scaling these technologies. The complexity of synthetic augmentation techniques requires specialized training programs for technical staff. Leading companies have established partnerships with academic institutions to develop curriculum specifically addressing the interdisciplinary skills needed for operating advanced screening platforms.

Environmental considerations must also be integrated into scaling strategies. Sustainable implementation approaches include closed-loop systems for reagent recycling, energy-efficient equipment design, and waste minimization protocols. These considerations not only reduce operational costs but also align with increasingly stringent regulatory requirements in chemical manufacturing sectors.

Industrial implementation requires robust infrastructure that can handle high-throughput screening operations. Companies pioneering this field have developed modular systems that can be expanded incrementally as demand increases. These systems typically incorporate automated sample handling, parallel processing capabilities, and integrated data management platforms that can process the enormous datasets generated during large-scale screening operations.

Cost considerations remain paramount in scaling synthetic augmentation techniques. The initial capital investment for establishing comprehensive screening facilities is substantial, necessitating strategic planning for return on investment. However, analysis indicates that the long-term economic benefits—particularly through accelerated discovery of high-performance photocatalysts—can justify these expenditures. Companies have reported up to 60% reduction in development timelines when implementing these advanced screening methodologies at scale.

Technical standardization presents another crucial aspect of industrial implementation. Organizations such as the International Consortium for Photocatalyst Standards (ICPS) have begun developing protocols for consistent evaluation metrics across different screening platforms. These standards facilitate technology transfer between research institutions and industrial partners, ensuring that laboratory discoveries can be effectively translated into commercial applications.

Resource optimization strategies have emerged as essential components of scalable implementation. Advanced algorithms now enable predictive maintenance of screening equipment, minimizing downtime and maximizing operational efficiency. Additionally, cloud-based computational resources allow companies to dynamically allocate processing power based on screening demands, avoiding the need for constant maximum-capacity infrastructure.

Workforce development represents an often-overlooked aspect of scaling these technologies. The complexity of synthetic augmentation techniques requires specialized training programs for technical staff. Leading companies have established partnerships with academic institutions to develop curriculum specifically addressing the interdisciplinary skills needed for operating advanced screening platforms.

Environmental considerations must also be integrated into scaling strategies. Sustainable implementation approaches include closed-loop systems for reagent recycling, energy-efficient equipment design, and waste minimization protocols. These considerations not only reduce operational costs but also align with increasingly stringent regulatory requirements in chemical manufacturing sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!