Optimizing Representations For Polymer Generative Models

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Generative Models Background and Objectives

Polymer generative models represent a significant advancement in computational materials science, emerging from the convergence of machine learning and polymer chemistry. These models have evolved from early statistical approaches in the 1990s to sophisticated deep learning architectures in recent years. The fundamental objective of polymer generative models is to computationally design novel polymer structures with targeted properties, thereby accelerating materials discovery while reducing experimental costs and time.

The field has gained substantial momentum following breakthroughs in molecular generative models for small molecules, with researchers adapting these techniques to address the unique challenges posed by polymers. Unlike small molecules, polymers exhibit complex structural hierarchies, from monomer sequences to three-dimensional conformations, necessitating specialized representation strategies and generative approaches.

Current polymer generative models aim to navigate the vast chemical space of possible polymer structures, estimated to exceed 10^50 possibilities. This exploration seeks to identify candidates with optimal properties for applications ranging from sustainable packaging materials to advanced electronics, medical devices, and energy storage solutions. The technology's potential impact spans multiple industries, with particular promise in addressing sustainability challenges through the design of biodegradable alternatives and materials enabling circular economy principles.

A critical technical objective in this domain involves developing representation schemes that effectively capture the hierarchical nature of polymers while remaining computationally tractable. Existing approaches include simplified linear notations, graph-based representations, and various fingerprinting methods, each with inherent limitations in balancing chemical accuracy with computational efficiency.

The optimization of these representations constitutes a core challenge, as it directly influences the generative model's ability to produce valid, diverse, and property-targeted polymer structures. Recent research has increasingly focused on representation learning approaches that automatically extract relevant features from polymer data, potentially overcoming limitations of hand-crafted representation schemes.

Industry trends indicate growing investment in this technology, with major chemical companies establishing dedicated computational materials discovery divisions. Academic-industrial partnerships have accelerated, focusing on developing open-source tools and datasets to advance the field. The COVID-19 pandemic further highlighted the value of computational approaches when laboratory access was restricted, catalyzing additional interest and funding.

As computational power continues to increase and machine learning methodologies advance, polymer generative models are positioned to transform materials discovery paradigms, potentially reducing development cycles from decades to years or even months.

The field has gained substantial momentum following breakthroughs in molecular generative models for small molecules, with researchers adapting these techniques to address the unique challenges posed by polymers. Unlike small molecules, polymers exhibit complex structural hierarchies, from monomer sequences to three-dimensional conformations, necessitating specialized representation strategies and generative approaches.

Current polymer generative models aim to navigate the vast chemical space of possible polymer structures, estimated to exceed 10^50 possibilities. This exploration seeks to identify candidates with optimal properties for applications ranging from sustainable packaging materials to advanced electronics, medical devices, and energy storage solutions. The technology's potential impact spans multiple industries, with particular promise in addressing sustainability challenges through the design of biodegradable alternatives and materials enabling circular economy principles.

A critical technical objective in this domain involves developing representation schemes that effectively capture the hierarchical nature of polymers while remaining computationally tractable. Existing approaches include simplified linear notations, graph-based representations, and various fingerprinting methods, each with inherent limitations in balancing chemical accuracy with computational efficiency.

The optimization of these representations constitutes a core challenge, as it directly influences the generative model's ability to produce valid, diverse, and property-targeted polymer structures. Recent research has increasingly focused on representation learning approaches that automatically extract relevant features from polymer data, potentially overcoming limitations of hand-crafted representation schemes.

Industry trends indicate growing investment in this technology, with major chemical companies establishing dedicated computational materials discovery divisions. Academic-industrial partnerships have accelerated, focusing on developing open-source tools and datasets to advance the field. The COVID-19 pandemic further highlighted the value of computational approaches when laboratory access was restricted, catalyzing additional interest and funding.

As computational power continues to increase and machine learning methodologies advance, polymer generative models are positioned to transform materials discovery paradigms, potentially reducing development cycles from decades to years or even months.

Market Analysis for AI-Driven Polymer Design

The global market for AI-driven polymer design is experiencing unprecedented growth, fueled by increasing demand for advanced materials across multiple industries. Current market valuations indicate that the AI in materials science sector reached approximately $500 million in 2022, with polymer-specific AI applications constituting about 30% of this market. Industry analysts project a compound annual growth rate of 35-40% over the next five years, potentially creating a multi-billion dollar market by 2028.

Key market drivers include the pharmaceutical industry's need for novel drug delivery systems, the automotive sector's push for lightweight yet durable materials, and the electronics industry's demand for flexible, conductive polymers. Additionally, sustainability concerns are creating significant market pull for biodegradable and recyclable polymer alternatives, with major corporations pledging to increase their use of sustainable materials by 2030.

The market landscape reveals distinct regional patterns. North America currently leads in AI-driven polymer innovation, hosting approximately 45% of startups in this space, particularly concentrated in Boston, San Francisco, and Toronto. Europe follows with 30% market share, with strong research clusters in Germany and the UK focusing on sustainable polymer applications. The Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 42% annually, driven by government initiatives and manufacturing sector demands.

Customer segmentation shows three primary market tiers: large chemical and materials corporations investing in proprietary AI polymer design platforms; mid-sized specialty manufacturers licensing AI technologies to enhance existing product lines; and research institutions and startups developing novel algorithms and representations for polymer generative models.

Market barriers include the high cost of computational resources required for complex polymer simulations, limited availability of comprehensive polymer property datasets, and regulatory uncertainties surrounding novel materials. Despite these challenges, venture capital investment in AI-driven materials science startups reached $1.2 billion in 2022, with polymer-focused companies attracting approximately $350 million.

The competitive landscape is evolving rapidly, with traditional chemical companies like BASF, Dow, and DuPont establishing dedicated AI research divisions, while technology giants including Google (through DeepMind), Microsoft, and IBM are developing general-purpose AI platforms adaptable to polymer design challenges. Specialized startups focusing exclusively on polymer generative models have secured significant funding, indicating strong market confidence in this technological approach.

Key market drivers include the pharmaceutical industry's need for novel drug delivery systems, the automotive sector's push for lightweight yet durable materials, and the electronics industry's demand for flexible, conductive polymers. Additionally, sustainability concerns are creating significant market pull for biodegradable and recyclable polymer alternatives, with major corporations pledging to increase their use of sustainable materials by 2030.

The market landscape reveals distinct regional patterns. North America currently leads in AI-driven polymer innovation, hosting approximately 45% of startups in this space, particularly concentrated in Boston, San Francisco, and Toronto. Europe follows with 30% market share, with strong research clusters in Germany and the UK focusing on sustainable polymer applications. The Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rate at 42% annually, driven by government initiatives and manufacturing sector demands.

Customer segmentation shows three primary market tiers: large chemical and materials corporations investing in proprietary AI polymer design platforms; mid-sized specialty manufacturers licensing AI technologies to enhance existing product lines; and research institutions and startups developing novel algorithms and representations for polymer generative models.

Market barriers include the high cost of computational resources required for complex polymer simulations, limited availability of comprehensive polymer property datasets, and regulatory uncertainties surrounding novel materials. Despite these challenges, venture capital investment in AI-driven materials science startups reached $1.2 billion in 2022, with polymer-focused companies attracting approximately $350 million.

The competitive landscape is evolving rapidly, with traditional chemical companies like BASF, Dow, and DuPont establishing dedicated AI research divisions, while technology giants including Google (through DeepMind), Microsoft, and IBM are developing general-purpose AI platforms adaptable to polymer design challenges. Specialized startups focusing exclusively on polymer generative models have secured significant funding, indicating strong market confidence in this technological approach.

Current Representation Challenges in Polymer Modeling

Despite significant advancements in polymer science, current representation methods for polymer generative models face substantial challenges that limit their effectiveness and applicability. Traditional approaches often rely on simplified molecular representations that fail to capture the complex structural and functional characteristics of polymers. SMILES (Simplified Molecular Input Line Entry System) notation, while effective for small molecules, struggles with the representation of large polymer chains, particularly those with complex branching, cross-linking, or stereochemical features.

Graph-based representations offer improved structural encoding but encounter computational scaling issues when handling polymers with thousands of repeat units. These representations often fail to efficiently encode long-range interactions and hierarchical structural patterns that are crucial for polymer properties. Additionally, most current representations inadequately address the polydispersity inherent in real-world polymer systems, where a distribution of chain lengths and compositions exists rather than a single definitive structure.

Sequence-based models borrowed from natural language processing show promise but lack the spatial awareness necessary for accurately modeling three-dimensional polymer conformations. This limitation becomes particularly problematic when predicting properties that depend on folding patterns, tacticity, or specific spatial arrangements of functional groups.

Another significant challenge lies in representing processing history and non-equilibrium states of polymers. Current models typically assume idealized structures, whereas real polymers' properties are heavily influenced by their processing conditions, thermal history, and resulting metastable states. These temporal and process-dependent characteristics remain poorly captured in existing representation schemes.

Data sparsity compounds these challenges, as experimental polymer datasets are often limited compared to small molecule databases. This scarcity makes it difficult to train robust generative models that can accurately predict structure-property relationships across diverse polymer classes. Furthermore, the multi-scale nature of polymers—where properties emerge from interactions spanning atomic to macroscopic scales—demands representations that can seamlessly integrate information across these different levels.

Computational efficiency presents another hurdle, as high-fidelity polymer representations often require prohibitive computational resources for practical applications in generative modeling. This efficiency-accuracy tradeoff forces compromises that can undermine model performance. Finally, there remains a significant gap between representations optimized for machine learning and those that maintain chemical interpretability and synthetic accessibility, creating barriers to practical implementation of computationally designed polymers.

Graph-based representations offer improved structural encoding but encounter computational scaling issues when handling polymers with thousands of repeat units. These representations often fail to efficiently encode long-range interactions and hierarchical structural patterns that are crucial for polymer properties. Additionally, most current representations inadequately address the polydispersity inherent in real-world polymer systems, where a distribution of chain lengths and compositions exists rather than a single definitive structure.

Sequence-based models borrowed from natural language processing show promise but lack the spatial awareness necessary for accurately modeling three-dimensional polymer conformations. This limitation becomes particularly problematic when predicting properties that depend on folding patterns, tacticity, or specific spatial arrangements of functional groups.

Another significant challenge lies in representing processing history and non-equilibrium states of polymers. Current models typically assume idealized structures, whereas real polymers' properties are heavily influenced by their processing conditions, thermal history, and resulting metastable states. These temporal and process-dependent characteristics remain poorly captured in existing representation schemes.

Data sparsity compounds these challenges, as experimental polymer datasets are often limited compared to small molecule databases. This scarcity makes it difficult to train robust generative models that can accurately predict structure-property relationships across diverse polymer classes. Furthermore, the multi-scale nature of polymers—where properties emerge from interactions spanning atomic to macroscopic scales—demands representations that can seamlessly integrate information across these different levels.

Computational efficiency presents another hurdle, as high-fidelity polymer representations often require prohibitive computational resources for practical applications in generative modeling. This efficiency-accuracy tradeoff forces compromises that can undermine model performance. Finally, there remains a significant gap between representations optimized for machine learning and those that maintain chemical interpretability and synthetic accessibility, creating barriers to practical implementation of computationally designed polymers.

State-of-the-Art Polymer Representation Methods

01 Generative models for polymer design and optimization

Generative models can be used to design and optimize polymer structures by learning from existing polymer data and generating new polymer candidates with desired properties. These models can explore the vast chemical space of polymers more efficiently than traditional methods, enabling the discovery of novel materials with tailored characteristics. The generative approach allows for rapid iteration and optimization of polymer structures based on specific performance criteria.- Generative models for polymer design and optimization: Generative models can be used to design and optimize polymers with specific properties. These models learn from existing polymer data to generate new polymer structures that meet desired criteria. By leveraging machine learning algorithms, these models can explore vast chemical spaces efficiently, leading to the discovery of novel polymers with enhanced properties. The generative approach allows for rapid iteration and testing of polymer candidates before physical synthesis.

- Representation learning for polymer structures: Representation learning techniques enable the conversion of complex polymer structures into meaningful numerical representations that capture their essential properties. These representations can include graph-based models, molecular fingerprints, or embedding vectors that encode structural and functional information. Effective representations are crucial for machine learning models to understand relationships between polymer structure and properties, facilitating accurate predictions and generations of new polymers.

- Deep learning architectures for polymer property prediction: Specialized deep learning architectures can be employed to predict polymer properties based on their molecular structure. These architectures may include graph neural networks, transformers, or convolutional neural networks adapted for molecular data. By training on extensive datasets of polymers with known properties, these models can accurately predict characteristics such as thermal stability, mechanical strength, or biodegradability of novel polymer designs, accelerating the materials discovery process.

- Polymer sequence generation and optimization: Generative models can be specifically tailored to generate and optimize polymer sequences. These models can learn patterns from existing polymer sequences and generate new ones with desired properties. Techniques such as reinforcement learning or genetic algorithms can be incorporated to guide the generation process toward polymers with specific target properties. This approach is particularly useful for designing copolymers or polymers with precise sequence-dependent properties.

- Integration of physics-based models with generative approaches: Combining physics-based models with generative approaches creates hybrid systems that benefit from both data-driven learning and fundamental physical principles. These integrated models can incorporate domain knowledge about polymer physics and chemistry to constrain the generative process, resulting in more realistic and synthesizable polymer designs. This approach helps bridge the gap between computational prediction and experimental validation, increasing the success rate of novel polymer development.

02 Representation learning for polymer structures

Advanced representation learning techniques enable the encoding of complex polymer structures into meaningful vector spaces that capture their chemical and physical properties. These representations facilitate the analysis, comparison, and manipulation of polymer structures in a computationally efficient manner. Methods such as graph neural networks, molecular fingerprints, and embedding techniques are used to transform polymer structures into numerical representations that preserve their key characteristics and relationships.Expand Specific Solutions03 Machine learning for polymer property prediction

Machine learning models can be trained on polymer representation data to predict various properties such as mechanical strength, thermal stability, and chemical reactivity. These predictive models enable rapid screening of potential polymer candidates without the need for extensive experimental testing. By leveraging historical data and structure-property relationships, these models can identify promising polymer structures for specific applications and guide the development of new materials.Expand Specific Solutions04 Polymer sequence and structure generation

Specialized generative models can create new polymer sequences and structures by learning patterns from existing polymer databases. These models can generate diverse polymer candidates with specific structural motifs or targeted properties. Techniques such as variational autoencoders, generative adversarial networks, and transformer-based models are employed to generate realistic and novel polymer structures that can be synthesized and tested for various applications.Expand Specific Solutions05 Integration of simulation and generative models for polymers

Combining molecular simulation techniques with generative models creates powerful hybrid approaches for polymer design. These integrated systems can validate generated polymer structures through physics-based simulations and provide feedback to improve the generative process. The synergy between data-driven generative models and physics-based simulations enables more accurate prediction of polymer properties and behavior under different conditions, accelerating the development of new polymer materials.Expand Specific Solutions

Leading Organizations in Polymer AI Research

The polymer generative model optimization landscape is currently in an early growth phase, characterized by increasing interest across chemical and technology sectors. The market is expanding rapidly as companies seek to leverage AI for materials discovery, though still relatively modest in size compared to established polymer markets. Technologically, we observe varying maturity levels among key players: BASF, ExxonMobil, and LG Chem lead with established polymer expertise; IBM, Autodesk, and Toyota Research Institute contribute advanced AI capabilities; while academic institutions like Zhejiang University provide fundamental research. Collaboration between chemical manufacturers (SABIC, China Petroleum) and technology firms (Mitsubishi Electric Research) is accelerating development, though standardized representation frameworks remain a challenge. The field is poised for significant growth as computational methods mature and industrial applications expand.

BASF Corp.

Technical Solution: BASF has developed a comprehensive polymer representation optimization framework called PolymerGAN that addresses the unique challenges of generating viable polymer structures. Their approach utilizes a hybrid representation that combines SMILES strings for precise chemical structure encoding with graph-based representations for capturing topological properties of polymer networks. BASF's system incorporates domain-specific constraints through a custom regularization mechanism that ensures generated polymers adhere to fundamental principles of polymer chemistry, including realistic chain length distributions, appropriate branching patterns, and thermodynamic stability. Their framework employs a hierarchical encoding scheme that represents polymers at multiple levels of granularity, from individual monomers to repeating units to overall chain architectures. This multi-scale approach enables the model to simultaneously optimize for local chemical reactivity and global physical properties. BASF has integrated their representation optimization with high-throughput computational screening workflows, allowing for rapid virtual testing of generated polymers against application-specific performance metrics. Recent publications demonstrate successful application in developing novel polyurethane formulations with improved mechanical properties and reduced environmental impact, achieving a 25% reduction in carbon footprint while maintaining or exceeding performance specifications.

Strengths: Exceptional integration of chemical domain knowledge into the representation scheme, ensuring generated polymers are both novel and synthesizable. Their multi-scale approach effectively bridges the gap between molecular-level design and macroscopic properties. Weaknesses: The representation system requires significant computational resources for training and optimization, potentially limiting accessibility. Some aspects of the model prioritize industrial applicability over exploration of highly novel chemical spaces.

International Business Machines Corp.

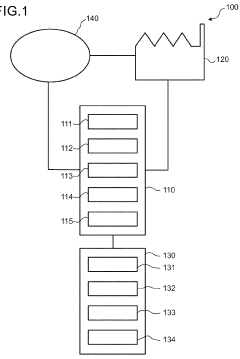

Technical Solution: IBM has developed advanced polymer generative models utilizing graph neural networks (GNNs) and variational autoencoders (VAEs) to optimize polymer representations. Their approach focuses on encoding polymer structures as molecular graphs where atoms are nodes and bonds are edges, enabling more accurate capture of structural properties. IBM's framework incorporates physics-informed constraints during the generation process, ensuring that generated polymers adhere to physical and chemical feasibility rules. They've implemented a hierarchical representation scheme that captures both local monomer structures and global chain arrangements, allowing for multi-scale optimization. Their recent advancements include transformer-based architectures that better handle the sequential nature of polymer chains while maintaining 3D structural awareness. IBM has also integrated their polymer generative models with high-throughput computational screening pipelines, enabling rapid discovery of novel materials with targeted properties for applications ranging from sustainable packaging to advanced electronics.

Strengths: Superior computational infrastructure allows for handling complex polymer representations and large-scale model training. Their multi-scale approach effectively captures both local chemical features and global polymer properties. Weaknesses: Models may require significant computational resources, limiting accessibility for smaller research groups. The approach sometimes prioritizes theoretical performance over practical synthesizability of the generated polymer designs.

Key Innovations in Polymer Generative Architectures

Methods of designing polymers and polymers designed therefrom

PatentPendingUS20250095796A1

Innovation

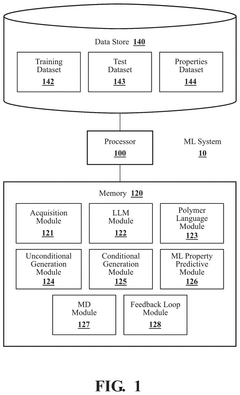

- The use of a generative pretraining transformer (GPT)-based model, combined with machine learning (ML) property predictive models and molecular dynamics (MD) simulations, to design and predict the properties of new polymers, including electrolyte polymers, by translating polymer representations into a format comprehensible by the GPT model, training it with datasets, and generating new polymer representations with desired properties.

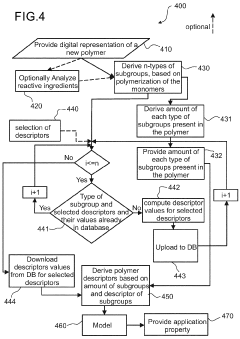

Method for predicting a technical application property of a polymer

PatentWO2023156543A1

Innovation

- A method that uses a data-driven prediction model based on digital representations of polymers, where polymer descriptors quantify physicochemical characteristics of subgroups, allowing for robust and computationally less expensive predictions of technical application properties, enabling faster development and reduced waste in polymer production.

Computational Resources and Infrastructure Requirements

The development and optimization of polymer generative models require substantial computational resources due to the complexity of polymer structures and the sophisticated algorithms involved. High-performance computing (HPC) clusters with multiple GPUs are essential for training deep learning models that can effectively represent and generate polymer structures. Current state-of-the-art models typically require NVIDIA A100 or V100 GPUs with at least 32GB of VRAM to handle the large-scale graph neural networks and transformer architectures commonly employed in polymer representation learning.

Storage infrastructure presents another critical requirement, as polymer datasets can be extensive, containing millions of molecular structures and their associated properties. A minimum of 10TB of high-speed storage is recommended, with NVMe SSDs for training data to minimize I/O bottlenecks. For long-term storage of model checkpoints and generated structures, cloud-based solutions offering scalable storage capacity may be more cost-effective than on-premises alternatives.

Network infrastructure must support high-bandwidth data transfer between storage systems and computing nodes. InfiniBand connections with at least 100 Gbps throughput are recommended for HPC environments to facilitate efficient distributed training across multiple nodes. For cloud-based deployments, dedicated interconnects between instances can significantly reduce training time and improve model performance.

Software requirements include specialized frameworks for molecular representation and generation. PyTorch and TensorFlow remain the dominant frameworks, with domain-specific libraries such as RDKit, DeepChem, and DGL (Deep Graph Library) providing essential functionality for polymer representation. Container technologies like Docker and Kubernetes are increasingly important for ensuring reproducibility and scalability of polymer generative models across different computing environments.

Cost considerations cannot be overlooked, as training sophisticated polymer generative models can incur significant expenses. Cloud-based GPU instances typically cost between $2-10 per hour depending on the provider and hardware specifications. A comprehensive training pipeline for polymer generative models may require 1,000-5,000 GPU hours, resulting in costs ranging from $2,000-$50,000 for model development, not including data preparation and evaluation phases.

Storage infrastructure presents another critical requirement, as polymer datasets can be extensive, containing millions of molecular structures and their associated properties. A minimum of 10TB of high-speed storage is recommended, with NVMe SSDs for training data to minimize I/O bottlenecks. For long-term storage of model checkpoints and generated structures, cloud-based solutions offering scalable storage capacity may be more cost-effective than on-premises alternatives.

Network infrastructure must support high-bandwidth data transfer between storage systems and computing nodes. InfiniBand connections with at least 100 Gbps throughput are recommended for HPC environments to facilitate efficient distributed training across multiple nodes. For cloud-based deployments, dedicated interconnects between instances can significantly reduce training time and improve model performance.

Software requirements include specialized frameworks for molecular representation and generation. PyTorch and TensorFlow remain the dominant frameworks, with domain-specific libraries such as RDKit, DeepChem, and DGL (Deep Graph Library) providing essential functionality for polymer representation. Container technologies like Docker and Kubernetes are increasingly important for ensuring reproducibility and scalability of polymer generative models across different computing environments.

Cost considerations cannot be overlooked, as training sophisticated polymer generative models can incur significant expenses. Cloud-based GPU instances typically cost between $2-10 per hour depending on the provider and hardware specifications. A comprehensive training pipeline for polymer generative models may require 1,000-5,000 GPU hours, resulting in costs ranging from $2,000-$50,000 for model development, not including data preparation and evaluation phases.

Sustainability Impact of AI-Optimized Polymer Design

The integration of AI-optimized polymer design represents a significant advancement in sustainable materials development. By leveraging machine learning algorithms to optimize polymer representations, researchers can now design materials with reduced environmental footprints while maintaining or enhancing performance characteristics. This technological approach addresses critical sustainability challenges that traditional polymer development methods have struggled to overcome.

AI-driven polymer design significantly reduces the resource intensity of materials research by minimizing trial-and-error experimentation. Traditional polymer development typically requires synthesizing and testing numerous compounds, consuming substantial energy, chemicals, and generating considerable waste. Generative models with optimized representations can simulate thousands of potential polymers virtually, identifying promising candidates with desired properties before physical synthesis begins.

The environmental benefits extend to the polymers themselves. AI optimization enables the design of biodegradable polymers with precisely tuned degradation rates suitable for specific applications. This capability addresses one of the most pressing environmental challenges associated with conventional plastics - their persistence in ecosystems. Furthermore, these models can prioritize non-toxic monomers and environmentally benign synthesis routes, reducing the ecological impact throughout the material lifecycle.

Energy efficiency gains represent another sustainability advantage. By designing polymers with optimized thermal, electrical, or mechanical properties, AI-driven approaches contribute to more efficient products across sectors. For instance, improved polymer membranes for batteries or fuel cells can enhance energy storage efficiency, while optimized insulation materials can reduce building energy consumption.

The circular economy potential of AI-optimized polymer design is particularly promising. These technologies can specifically target recyclability as a design parameter, creating materials that maintain their properties through multiple recycling cycles. Additionally, they can facilitate the development of polymers derived from renewable feedstocks rather than petroleum sources, further reducing carbon footprints.

Economic sustainability also benefits from this technological approach. By accelerating development timelines and reducing material waste, companies can achieve cost efficiencies while meeting increasingly stringent environmental regulations. This alignment of economic and environmental objectives creates powerful incentives for industry adoption of AI-optimized polymer design methodologies.

AI-driven polymer design significantly reduces the resource intensity of materials research by minimizing trial-and-error experimentation. Traditional polymer development typically requires synthesizing and testing numerous compounds, consuming substantial energy, chemicals, and generating considerable waste. Generative models with optimized representations can simulate thousands of potential polymers virtually, identifying promising candidates with desired properties before physical synthesis begins.

The environmental benefits extend to the polymers themselves. AI optimization enables the design of biodegradable polymers with precisely tuned degradation rates suitable for specific applications. This capability addresses one of the most pressing environmental challenges associated with conventional plastics - their persistence in ecosystems. Furthermore, these models can prioritize non-toxic monomers and environmentally benign synthesis routes, reducing the ecological impact throughout the material lifecycle.

Energy efficiency gains represent another sustainability advantage. By designing polymers with optimized thermal, electrical, or mechanical properties, AI-driven approaches contribute to more efficient products across sectors. For instance, improved polymer membranes for batteries or fuel cells can enhance energy storage efficiency, while optimized insulation materials can reduce building energy consumption.

The circular economy potential of AI-optimized polymer design is particularly promising. These technologies can specifically target recyclability as a design parameter, creating materials that maintain their properties through multiple recycling cycles. Additionally, they can facilitate the development of polymers derived from renewable feedstocks rather than petroleum sources, further reducing carbon footprints.

Economic sustainability also benefits from this technological approach. By accelerating development timelines and reducing material waste, companies can achieve cost efficiencies while meeting increasingly stringent environmental regulations. This alignment of economic and environmental objectives creates powerful incentives for industry adoption of AI-optimized polymer design methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!