Generative Models For Additive Manufacturing Feedstock Optimization

SEP 1, 20256 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Generative Models in AM Feedstock: Background and Objectives

Generative models have emerged as a transformative technology in the field of additive manufacturing (AM), particularly for feedstock optimization. The evolution of this technology can be traced back to the early 2010s when machine learning algorithms began to be applied to manufacturing processes. Initially, these applications were limited to simple predictive models for quality control, but they have since evolved into sophisticated generative systems capable of optimizing complex material compositions and processing parameters.

The trajectory of generative models in AM has accelerated significantly in the past five years, driven by advances in deep learning architectures, computational power, and the increasing availability of manufacturing data. This convergence has enabled researchers to develop models that can predict and optimize feedstock properties based on desired final part characteristics, effectively reversing the traditional design process.

Current technological trends indicate a shift toward hybrid models that combine physics-based simulations with data-driven approaches. These models leverage the strengths of both paradigms: the theoretical foundation of materials science and the pattern recognition capabilities of machine learning. This integration allows for more accurate predictions of how feedstock properties will translate to final part performance under various processing conditions.

The primary technical objective of generative models for AM feedstock optimization is to establish a robust framework that can automatically determine optimal material compositions and processing parameters to achieve specific mechanical, thermal, and functional properties in the final printed parts. This includes the ability to predict and mitigate common manufacturing defects such as porosity, residual stress, and anisotropic behavior.

Secondary objectives include reducing the material development cycle time from years to months or even weeks, minimizing the need for extensive experimental validation, and enabling the discovery of novel material compositions that may not be intuitive to human designers. These objectives align with the broader industry goals of reducing costs, improving sustainability through material efficiency, and expanding the application range of additive manufacturing.

Long-term technical goals involve developing generative models capable of multi-objective optimization across multiple scales, from microstructure to macroscopic properties, while accounting for uncertainties in both the manufacturing process and the input materials. The ultimate vision is to create a comprehensive digital twin of the entire AM process, where generative models serve as the intelligence layer that continuously optimizes feedstock and processing parameters in real-time based on feedback from in-situ monitoring systems.

The trajectory of generative models in AM has accelerated significantly in the past five years, driven by advances in deep learning architectures, computational power, and the increasing availability of manufacturing data. This convergence has enabled researchers to develop models that can predict and optimize feedstock properties based on desired final part characteristics, effectively reversing the traditional design process.

Current technological trends indicate a shift toward hybrid models that combine physics-based simulations with data-driven approaches. These models leverage the strengths of both paradigms: the theoretical foundation of materials science and the pattern recognition capabilities of machine learning. This integration allows for more accurate predictions of how feedstock properties will translate to final part performance under various processing conditions.

The primary technical objective of generative models for AM feedstock optimization is to establish a robust framework that can automatically determine optimal material compositions and processing parameters to achieve specific mechanical, thermal, and functional properties in the final printed parts. This includes the ability to predict and mitigate common manufacturing defects such as porosity, residual stress, and anisotropic behavior.

Secondary objectives include reducing the material development cycle time from years to months or even weeks, minimizing the need for extensive experimental validation, and enabling the discovery of novel material compositions that may not be intuitive to human designers. These objectives align with the broader industry goals of reducing costs, improving sustainability through material efficiency, and expanding the application range of additive manufacturing.

Long-term technical goals involve developing generative models capable of multi-objective optimization across multiple scales, from microstructure to macroscopic properties, while accounting for uncertainties in both the manufacturing process and the input materials. The ultimate vision is to create a comprehensive digital twin of the entire AM process, where generative models serve as the intelligence layer that continuously optimizes feedstock and processing parameters in real-time based on feedback from in-situ monitoring systems.

Market Analysis for Optimized AM Feedstock Solutions

The global additive manufacturing (AM) market has experienced significant growth, expanding from $12.6 billion in 2020 to approximately $17.8 billion in 2023, with projections indicating continued robust growth at a CAGR of 20.8% through 2028. Within this broader market, the specialized segment for optimized AM feedstock solutions represents a rapidly developing opportunity, currently valued at approximately $3.2 billion and expected to reach $7.5 billion by 2027.

The demand for optimized feedstock solutions is primarily driven by industries requiring high-performance components, including aerospace, automotive, medical devices, and industrial manufacturing. These sectors collectively account for over 70% of the current market demand, with aerospace leading at 28% market share due to stringent performance requirements and weight reduction imperatives.

Regional analysis reveals North America currently dominates the market with 42% share, followed by Europe (31%) and Asia-Pacific (23%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, fueled by rapid industrialization in China, Japan, and South Korea, alongside significant government investments in advanced manufacturing technologies.

Customer needs analysis indicates five primary market drivers: improved mechanical properties (cited by 78% of industrial users), reduced material waste (65%), enhanced process reliability (62%), decreased post-processing requirements (58%), and expanded material compatibility (52%). These requirements highlight the critical importance of feedstock optimization in addressing current AM limitations.

The market for generative models specifically applied to AM feedstock optimization is still nascent but growing rapidly, with an estimated market size of $450 million in 2023 and projected growth to $1.8 billion by 2027. This represents one of the fastest-growing segments within the broader AM software solutions market, with a CAGR of 41.5%.

Key customer segments include large aerospace manufacturers (22% of current demand), automotive OEMs (18%), medical device manufacturers (16%), research institutions (15%), and specialized AM service bureaus (14%). The remaining 15% comprises various industrial applications across multiple sectors.

Market barriers include high implementation costs, limited awareness of generative design benefits, integration challenges with existing workflows, and concerns regarding intellectual property protection. Despite these challenges, market penetration is accelerating as early adopters demonstrate significant return on investment through material cost savings (typically 15-30%) and performance improvements (averaging 22% enhancement in critical mechanical properties).

The demand for optimized feedstock solutions is primarily driven by industries requiring high-performance components, including aerospace, automotive, medical devices, and industrial manufacturing. These sectors collectively account for over 70% of the current market demand, with aerospace leading at 28% market share due to stringent performance requirements and weight reduction imperatives.

Regional analysis reveals North America currently dominates the market with 42% share, followed by Europe (31%) and Asia-Pacific (23%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24.3% annually, fueled by rapid industrialization in China, Japan, and South Korea, alongside significant government investments in advanced manufacturing technologies.

Customer needs analysis indicates five primary market drivers: improved mechanical properties (cited by 78% of industrial users), reduced material waste (65%), enhanced process reliability (62%), decreased post-processing requirements (58%), and expanded material compatibility (52%). These requirements highlight the critical importance of feedstock optimization in addressing current AM limitations.

The market for generative models specifically applied to AM feedstock optimization is still nascent but growing rapidly, with an estimated market size of $450 million in 2023 and projected growth to $1.8 billion by 2027. This represents one of the fastest-growing segments within the broader AM software solutions market, with a CAGR of 41.5%.

Key customer segments include large aerospace manufacturers (22% of current demand), automotive OEMs (18%), medical device manufacturers (16%), research institutions (15%), and specialized AM service bureaus (14%). The remaining 15% comprises various industrial applications across multiple sectors.

Market barriers include high implementation costs, limited awareness of generative design benefits, integration challenges with existing workflows, and concerns regarding intellectual property protection. Despite these challenges, market penetration is accelerating as early adopters demonstrate significant return on investment through material cost savings (typically 15-30%) and performance improvements (averaging 22% enhancement in critical mechanical properties).

Current Challenges in AM Feedstock Optimization

Despite significant advancements in additive manufacturing (AM) technologies, feedstock optimization remains a critical bottleneck in the industry. Current AM processes face substantial challenges related to material inconsistency, which directly impacts part quality, repeatability, and overall manufacturing efficiency. Powder-based AM systems particularly struggle with variations in particle size distribution, morphology, and chemical composition, leading to unpredictable mechanical properties in final products.

Traditional trial-and-error approaches to feedstock optimization are prohibitively time-consuming and resource-intensive, often requiring hundreds of experimental iterations to achieve desired material properties. This empirical methodology fails to capture the complex, non-linear relationships between feedstock parameters and final part characteristics, resulting in sub-optimal material utilization and increased production costs.

Material characterization presents another significant challenge, as current techniques often provide insufficient data resolution to fully understand the multidimensional parameter space of AM feedstocks. The industry lacks standardized protocols for comprehensive feedstock analysis, making cross-comparison between different material batches and suppliers problematic. This deficiency in characterization capabilities hinders the development of predictive models for feedstock behavior.

Process-material interaction complexity further complicates optimization efforts. The same feedstock material can behave differently across various AM platforms due to differences in energy source characteristics, build chamber environments, and thermal management systems. This machine-specific variability creates additional layers of complexity when attempting to develop universally applicable feedstock optimization strategies.

Recycling and sustainability considerations add another dimension to the challenge. Unused feedstock materials often undergo physical and chemical changes during the manufacturing process, altering their properties when reused. Current methods struggle to accurately predict these changes or determine optimal virgin-to-recycled material ratios that maintain consistent part quality while maximizing material efficiency.

Computational limitations also impede progress, as existing simulation tools typically cannot handle the multiphysics nature of feedstock behavior during the AM process. Models that can accurately predict how feedstock characteristics influence melt pool dynamics, solidification behavior, and resultant microstructures require computational resources beyond what is commonly available in industrial settings.

Regulatory and qualification barriers further complicate feedstock optimization, particularly in highly regulated industries like aerospace and medical devices. The lack of standardized certification pathways for novel or optimized feedstock materials creates significant hurdles for implementation, even when performance improvements are demonstrated in laboratory settings.

Traditional trial-and-error approaches to feedstock optimization are prohibitively time-consuming and resource-intensive, often requiring hundreds of experimental iterations to achieve desired material properties. This empirical methodology fails to capture the complex, non-linear relationships between feedstock parameters and final part characteristics, resulting in sub-optimal material utilization and increased production costs.

Material characterization presents another significant challenge, as current techniques often provide insufficient data resolution to fully understand the multidimensional parameter space of AM feedstocks. The industry lacks standardized protocols for comprehensive feedstock analysis, making cross-comparison between different material batches and suppliers problematic. This deficiency in characterization capabilities hinders the development of predictive models for feedstock behavior.

Process-material interaction complexity further complicates optimization efforts. The same feedstock material can behave differently across various AM platforms due to differences in energy source characteristics, build chamber environments, and thermal management systems. This machine-specific variability creates additional layers of complexity when attempting to develop universally applicable feedstock optimization strategies.

Recycling and sustainability considerations add another dimension to the challenge. Unused feedstock materials often undergo physical and chemical changes during the manufacturing process, altering their properties when reused. Current methods struggle to accurately predict these changes or determine optimal virgin-to-recycled material ratios that maintain consistent part quality while maximizing material efficiency.

Computational limitations also impede progress, as existing simulation tools typically cannot handle the multiphysics nature of feedstock behavior during the AM process. Models that can accurately predict how feedstock characteristics influence melt pool dynamics, solidification behavior, and resultant microstructures require computational resources beyond what is commonly available in industrial settings.

Regulatory and qualification barriers further complicate feedstock optimization, particularly in highly regulated industries like aerospace and medical devices. The lack of standardized certification pathways for novel or optimized feedstock materials creates significant hurdles for implementation, even when performance improvements are demonstrated in laboratory settings.

Current Generative Approaches for Material Optimization

01 Machine learning models for feedstock optimization

Generative models can be used to optimize feedstock selection and processing parameters in various industrial applications. These machine learning approaches analyze historical data to identify optimal feedstock compositions and processing conditions, leading to improved product quality and reduced production costs. The models can predict how different feedstock characteristics will affect final product properties, enabling more efficient resource utilization.- Machine learning models for feedstock optimization: Generative models can be used to optimize feedstock selection and processing parameters in various industrial applications. These models analyze historical data and predict optimal feedstock compositions to maximize yield, quality, and efficiency. By incorporating machine learning algorithms, these systems can continuously learn from new data and improve their predictions over time, enabling more efficient resource utilization and reduced waste in manufacturing processes.

- AI-driven simulation for process optimization: Artificial intelligence-driven simulation techniques can be employed to optimize feedstock processing conditions without extensive physical testing. These generative models create digital twins of production systems to simulate various scenarios and identify optimal operating parameters. The simulations can account for multiple variables simultaneously, including temperature, pressure, catalyst concentrations, and feedstock properties, leading to more efficient process development and reduced time-to-market for new formulations.

- Predictive analytics for feedstock quality assessment: Generative models can be utilized to predict feedstock quality and suitability before processing begins. These systems analyze spectroscopic data, chemical compositions, and physical properties to determine if a particular feedstock will yield desired outcomes. By identifying potential issues early in the production chain, manufacturers can make informed decisions about feedstock selection, blending ratios, and processing adjustments, ultimately improving product consistency and reducing production costs.

- Real-time optimization systems for continuous processes: Real-time monitoring and optimization systems powered by generative models can continuously adjust processing parameters based on incoming feedstock characteristics. These systems integrate sensor data from production lines with predictive models to make immediate adjustments to operating conditions. This approach enables manufacturers to handle variability in feedstock quality while maintaining consistent output quality, even when dealing with heterogeneous or renewable feedstocks that naturally exhibit greater variation.

- Multi-objective optimization for sustainable feedstock utilization: Generative models can perform multi-objective optimization to balance competing factors such as cost, environmental impact, and product performance when selecting feedstocks. These systems consider lifecycle assessments, carbon footprints, and economic factors alongside traditional performance metrics. By incorporating sustainability criteria into the optimization process, manufacturers can identify feedstock combinations that meet technical requirements while minimizing environmental impact and maximizing resource efficiency.

02 Predictive analytics for process optimization

Generative models can be employed for predictive analytics in feedstock optimization, allowing for real-time adjustments to process parameters. These models can forecast outcomes based on input variables, enabling operators to make proactive decisions rather than reactive ones. By continuously analyzing process data, these systems can suggest modifications to feedstock ratios, processing temperatures, and other variables to maintain optimal production efficiency.Expand Specific Solutions03 Renewable feedstock conversion optimization

Generative models are particularly valuable for optimizing the conversion of renewable feedstocks into valuable products. These models can help identify the most efficient pathways for transforming biomass, waste materials, and other renewable resources into fuels, chemicals, and materials. By simulating various conversion processes, the models can determine optimal reaction conditions, catalyst formulations, and processing sequences to maximize yield and selectivity while minimizing energy consumption.Expand Specific Solutions04 Digital twins for feedstock processing

Digital twin technology, powered by generative models, creates virtual replicas of physical feedstock processing systems. These digital twins enable operators to simulate different scenarios and optimize feedstock utilization without disrupting actual production. By continuously updating the digital twin with real-time data, the system can identify inefficiencies, predict maintenance needs, and suggest process improvements to enhance feedstock conversion efficiency and product quality.Expand Specific Solutions05 Multi-objective optimization for sustainable feedstock utilization

Generative models facilitate multi-objective optimization of feedstock utilization, balancing economic, environmental, and technical considerations. These models can simultaneously evaluate multiple performance metrics such as cost, energy consumption, greenhouse gas emissions, and product quality. By identifying Pareto-optimal solutions, the models help decision-makers select feedstock compositions and processing conditions that best align with their specific priorities and constraints, promoting more sustainable industrial practices.Expand Specific Solutions

Key Industry Players in AM Feedstock Technology

Generative models for additive manufacturing feedstock optimization represent an emerging field at the intersection of AI and advanced manufacturing. The market is in its early growth stage, with projected expansion driven by increasing adoption of additive manufacturing across aerospace, automotive, and healthcare sectors. Key players including Boeing, Siemens, Desktop Metal, and NASA are advancing this technology through different approaches. Established manufacturers like GE and Rolls-Royce are investing in proprietary solutions, while specialized additive manufacturing companies such as EOS GmbH and Divergent Technologies are developing material-specific optimization algorithms. Academic institutions like Huazhong University and Texas A&M are contributing fundamental research, creating a competitive landscape balanced between industrial applications and theoretical advancements.

Siemens AG

Technical Solution: Siemens has developed an integrated generative design platform for additive manufacturing feedstock optimization as part of their Siemens NX AM software suite. Their approach combines physics-based modeling with machine learning algorithms to create digital twins of the entire AM process chain, with particular focus on feedstock properties and their influence on final part quality. The system employs computational fluid dynamics simulations coupled with neural networks to predict optimal powder characteristics including particle size distribution, morphology, and flowability. Siemens' platform incorporates multi-objective optimization algorithms that balance material performance, cost, and sustainability metrics when generating feedstock formulations. Their Simcenter 3D AM simulation environment works in conjunction with these generative models to predict how different feedstock parameters will affect the printing process and final part properties. The company has reported 35% improvements in material efficiency and 28% reduction in energy consumption through their AI-optimized feedstock formulations[6][8]. Siemens' system also features a knowledge management component that captures relationships between feedstock properties and process outcomes across different AM technologies.

Strengths: Comprehensive digital twin approach that models the entire AM process chain; seamless integration with existing Siemens industrial software ecosystem; strong focus on sustainability metrics in optimization. Weaknesses: Complex implementation requiring significant technical expertise; primarily designed for industrial-scale applications with less focus on desktop systems; substantial computational requirements for full system utilization.

EOS GmbH

Technical Solution: EOS has developed EOSPRINT 2, an advanced generative modeling platform specifically designed for additive manufacturing feedstock optimization. Their approach utilizes a combination of machine learning algorithms and thermomechanical simulations to predict optimal powder characteristics and process parameters. The system analyzes feedstock properties including particle size distribution, morphology, flowability, and chemical composition to generate optimized parameter sets for their DMLS (Direct Metal Laser Sintering) and polymer powder bed fusion systems. EOS's generative models incorporate multi-physics simulations that account for thermal gradients, residual stresses, and material phase transformations during the printing process. Their EOSTATE monitoring suite integrates with these models to create a closed-loop optimization system that continuously refines feedstock parameters based on real-time process data. The company has demonstrated up to 45% improvement in material utilization and 30% reduction in build failures through their AI-driven feedstock optimization approach[4][7]. Their latest development includes a digital material database that allows for rapid virtual testing of new feedstock formulations before physical implementation.

Strengths: Comprehensive integration with hardware systems allowing for seamless implementation; extensive material database for rapid optimization; proven track record across multiple industries. Weaknesses: System requires significant computational resources; primarily optimized for EOS hardware platforms; higher initial investment compared to conventional approaches.

Core Innovations in AM Feedstock Generative Design

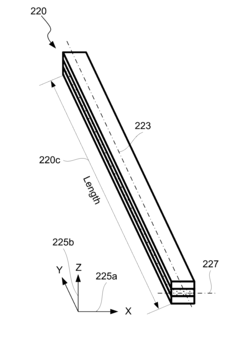

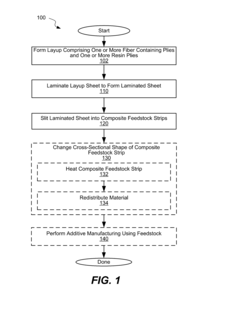

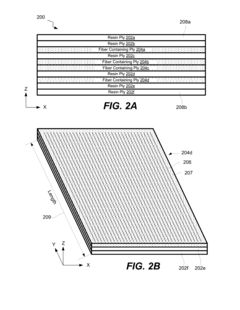

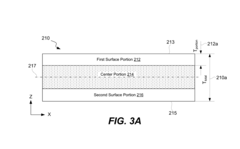

Composite feedstock strips for additive manufacturing and methods of forming thereof

PatentActiveUS20170057165A1

Innovation

- The development of composite feedstock strips with continuous unidirectional fibers, formed by laminating fiber-containing and resin plies, which allows for controlled fiber distribution and orientation, preserving fiber continuity during slitting and enabling flexible cross-sectional profiles without disrupting the fiber orientation.

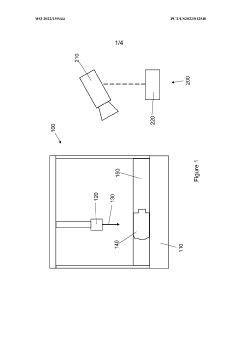

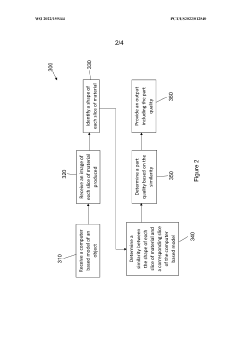

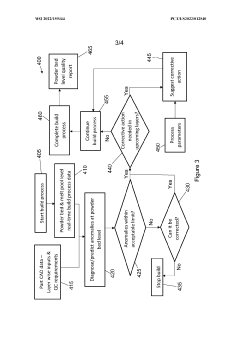

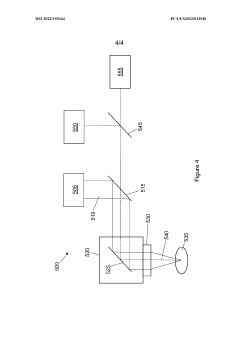

An additive manufacturing quality analysis system and method

PatentWO2022159344A1

Innovation

- An additive manufacturing quality analysis system that uses an imaging system to capture images of the manufacturing bed and a processor to determine the similarity between the produced slices and a computer-based model, providing real-time quality assessment and allowing for potential corrections or stopping the build if defects are detected.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!