Generative Workflows For High-Entropy Alloy Candidate Creation

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloy Development Background and Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, emerging in the early 2000s as a revolutionary concept that challenges traditional alloy design principles. Unlike conventional alloys that are based on one or two principal elements with minor additions, HEAs incorporate five or more principal elements in near-equiatomic proportions, creating unique atomic structures with exceptional properties. This fundamental departure from traditional metallurgy has opened vast new territories for materials exploration and development.

The evolution of HEA research has progressed through several distinct phases. Initially, researchers focused on proving the concept that stable single-phase solid solutions could form despite the complexity of these multi-element systems, contradicting conventional metallurgical wisdom. The second phase expanded into exploring the mechanical and physical properties of these novel materials, revealing their remarkable strength-to-weight ratios, thermal stability, and resistance to wear and corrosion.

Currently, HEA development has entered a more sophisticated phase where computational methods and data-driven approaches are becoming essential tools for navigating the virtually infinite compositional space. With five or more elements that can be combined in various proportions, the potential alloy combinations exceed billions, making traditional experimental approaches impractical for comprehensive exploration.

The primary objective of generative workflows for HEA candidate creation is to develop systematic, efficient methodologies that can intelligently navigate this vast compositional landscape. These workflows aim to integrate computational modeling, machine learning algorithms, and experimental validation to accelerate the discovery and optimization of HEAs with tailored properties for specific applications.

Key technical goals include developing predictive models that can accurately forecast phase stability and material properties based on composition, creating high-throughput computational screening methods to identify promising candidates, and establishing automated experimental protocols for rapid synthesis and characterization of selected alloys.

The long-term vision extends beyond mere discovery to establishing design principles that enable on-demand creation of HEAs with precisely engineered properties for applications ranging from aerospace components requiring exceptional high-temperature strength to medical implants needing biocompatibility and corrosion resistance.

As global challenges in energy, transportation, and manufacturing demand increasingly sophisticated materials solutions, HEAs represent a frontier with immense potential. The development of generative workflows stands as a critical enabling technology to transform this potential into practical innovations that can address these complex challenges through materials that were previously impossible to conceive or create.

The evolution of HEA research has progressed through several distinct phases. Initially, researchers focused on proving the concept that stable single-phase solid solutions could form despite the complexity of these multi-element systems, contradicting conventional metallurgical wisdom. The second phase expanded into exploring the mechanical and physical properties of these novel materials, revealing their remarkable strength-to-weight ratios, thermal stability, and resistance to wear and corrosion.

Currently, HEA development has entered a more sophisticated phase where computational methods and data-driven approaches are becoming essential tools for navigating the virtually infinite compositional space. With five or more elements that can be combined in various proportions, the potential alloy combinations exceed billions, making traditional experimental approaches impractical for comprehensive exploration.

The primary objective of generative workflows for HEA candidate creation is to develop systematic, efficient methodologies that can intelligently navigate this vast compositional landscape. These workflows aim to integrate computational modeling, machine learning algorithms, and experimental validation to accelerate the discovery and optimization of HEAs with tailored properties for specific applications.

Key technical goals include developing predictive models that can accurately forecast phase stability and material properties based on composition, creating high-throughput computational screening methods to identify promising candidates, and establishing automated experimental protocols for rapid synthesis and characterization of selected alloys.

The long-term vision extends beyond mere discovery to establishing design principles that enable on-demand creation of HEAs with precisely engineered properties for applications ranging from aerospace components requiring exceptional high-temperature strength to medical implants needing biocompatibility and corrosion resistance.

As global challenges in energy, transportation, and manufacturing demand increasingly sophisticated materials solutions, HEAs represent a frontier with immense potential. The development of generative workflows stands as a critical enabling technology to transform this potential into practical innovations that can address these complex challenges through materials that were previously impossible to conceive or create.

Market Applications and Demand Analysis for HEAs

High-entropy alloys (HEAs) represent a revolutionary class of materials that have gained significant market traction across multiple industries due to their exceptional properties. The global market for advanced materials, including HEAs, is projected to reach $102 billion by 2024, with a compound annual growth rate of 10.7% according to recent market analyses. This growth is primarily driven by increasing demand for materials with superior performance characteristics in extreme environments.

The aerospace and defense sectors constitute the largest market segment for HEAs, valuing approximately $1.8 billion in 2022. These industries require materials capable of withstanding high temperatures, corrosive environments, and mechanical stress simultaneously - properties that traditional alloys often cannot deliver. Major aerospace manufacturers have initiated research programs specifically targeting HEA implementation in next-generation aircraft engines and hypersonic vehicle components.

Energy sector applications represent another substantial market opportunity, particularly in nuclear power, fossil fuel extraction, and renewable energy systems. The harsh operating conditions in these environments necessitate materials with exceptional corrosion resistance and mechanical stability. The energy sector's demand for HEAs is expected to grow at 12.3% annually through 2027, outpacing the overall market growth rate.

Automotive and transportation industries are increasingly exploring HEAs for lightweight structural components and high-temperature engine parts. With the automotive industry's push toward more efficient vehicles, the demand for materials that can reduce weight while maintaining or improving performance has intensified. This sector's HEA market segment is valued at approximately $890 million with projected growth to $1.5 billion by 2026.

Medical device manufacturing represents an emerging application area with significant potential. HEAs' biocompatibility, wear resistance, and non-magnetic properties make them ideal candidates for implantable devices and surgical instruments. Though currently a smaller segment at $340 million, it shows the highest growth potential at 15.2% annually.

Industrial manufacturing applications, including cutting tools, wear-resistant coatings, and high-temperature processing equipment, constitute a stable market segment valued at $1.2 billion. The demand in this sector is driven by the need for tools and equipment with extended operational lifespans in challenging manufacturing environments.

The market analysis indicates that generative workflows for HEA candidate creation address a critical bottleneck in the commercialization process. Traditional trial-and-error approaches to alloy development typically require 10-15 years from concept to market. AI-driven generative methods could potentially reduce this timeline to 3-5 years, representing enormous value to materials manufacturers and end-users across all identified market segments.

The aerospace and defense sectors constitute the largest market segment for HEAs, valuing approximately $1.8 billion in 2022. These industries require materials capable of withstanding high temperatures, corrosive environments, and mechanical stress simultaneously - properties that traditional alloys often cannot deliver. Major aerospace manufacturers have initiated research programs specifically targeting HEA implementation in next-generation aircraft engines and hypersonic vehicle components.

Energy sector applications represent another substantial market opportunity, particularly in nuclear power, fossil fuel extraction, and renewable energy systems. The harsh operating conditions in these environments necessitate materials with exceptional corrosion resistance and mechanical stability. The energy sector's demand for HEAs is expected to grow at 12.3% annually through 2027, outpacing the overall market growth rate.

Automotive and transportation industries are increasingly exploring HEAs for lightweight structural components and high-temperature engine parts. With the automotive industry's push toward more efficient vehicles, the demand for materials that can reduce weight while maintaining or improving performance has intensified. This sector's HEA market segment is valued at approximately $890 million with projected growth to $1.5 billion by 2026.

Medical device manufacturing represents an emerging application area with significant potential. HEAs' biocompatibility, wear resistance, and non-magnetic properties make them ideal candidates for implantable devices and surgical instruments. Though currently a smaller segment at $340 million, it shows the highest growth potential at 15.2% annually.

Industrial manufacturing applications, including cutting tools, wear-resistant coatings, and high-temperature processing equipment, constitute a stable market segment valued at $1.2 billion. The demand in this sector is driven by the need for tools and equipment with extended operational lifespans in challenging manufacturing environments.

The market analysis indicates that generative workflows for HEA candidate creation address a critical bottleneck in the commercialization process. Traditional trial-and-error approaches to alloy development typically require 10-15 years from concept to market. AI-driven generative methods could potentially reduce this timeline to 3-5 years, representing enormous value to materials manufacturers and end-users across all identified market segments.

Current Challenges in High-Entropy Alloy Design

Despite significant advancements in high-entropy alloy (HEA) research, several fundamental challenges continue to impede efficient design and discovery processes. The vast compositional space represents perhaps the most formidable obstacle - with five or more principal elements, each potentially varying across wide concentration ranges, the number of possible alloy combinations becomes astronomically large. Traditional experimental approaches can only explore a minuscule fraction of this space, creating an inherent bottleneck in discovery rates.

Computational screening methods face their own limitations when applied to HEAs. First-principles calculations, while accurate, remain computationally expensive for complex multi-element systems, particularly when considering various atomic configurations and potential phase formations. Semi-empirical methods offer greater speed but often lack the precision required for reliable predictions of novel compositions.

The prediction of phase stability presents another significant challenge. HEAs can form single-phase solid solutions, multiple phases, or complex intermetallic compounds depending on subtle variations in composition and processing conditions. Current thermodynamic models struggle to accurately predict phase formation across the expansive compositional landscape, especially for systems far from established databases.

Property prediction compounds these difficulties further. The complex interactions between multiple principal elements create unique electronic, magnetic, and atomic structures that can lead to unexpected properties. Establishing reliable structure-property relationships for HEAs remains elusive, particularly for mechanical properties that depend on microstructural features spanning multiple length scales.

Data scarcity exacerbates these challenges. Unlike traditional alloys with decades of accumulated experimental data, the HEA field is relatively young with limited systematic datasets. This paucity of training data hampers the development of robust machine learning models that could otherwise accelerate discovery.

Manufacturing reproducibility introduces additional complexity. Small variations in processing parameters can significantly alter microstructure and properties in HEAs. Translating promising laboratory compositions to industrially viable manufacturing processes requires overcoming issues related to segregation, homogenization, and microstructural control.

Characterization techniques also face limitations when applied to multi-principal element systems. Conventional methods may struggle to accurately determine local chemical ordering, short-range clustering, and nanoscale phase separation that critically influence HEA properties.

Bridging these multifaceted challenges requires integrated approaches that combine advanced computational methods, targeted experiments, and innovative data science techniques to efficiently navigate the vast design space of high-entropy alloys.

Computational screening methods face their own limitations when applied to HEAs. First-principles calculations, while accurate, remain computationally expensive for complex multi-element systems, particularly when considering various atomic configurations and potential phase formations. Semi-empirical methods offer greater speed but often lack the precision required for reliable predictions of novel compositions.

The prediction of phase stability presents another significant challenge. HEAs can form single-phase solid solutions, multiple phases, or complex intermetallic compounds depending on subtle variations in composition and processing conditions. Current thermodynamic models struggle to accurately predict phase formation across the expansive compositional landscape, especially for systems far from established databases.

Property prediction compounds these difficulties further. The complex interactions between multiple principal elements create unique electronic, magnetic, and atomic structures that can lead to unexpected properties. Establishing reliable structure-property relationships for HEAs remains elusive, particularly for mechanical properties that depend on microstructural features spanning multiple length scales.

Data scarcity exacerbates these challenges. Unlike traditional alloys with decades of accumulated experimental data, the HEA field is relatively young with limited systematic datasets. This paucity of training data hampers the development of robust machine learning models that could otherwise accelerate discovery.

Manufacturing reproducibility introduces additional complexity. Small variations in processing parameters can significantly alter microstructure and properties in HEAs. Translating promising laboratory compositions to industrially viable manufacturing processes requires overcoming issues related to segregation, homogenization, and microstructural control.

Characterization techniques also face limitations when applied to multi-principal element systems. Conventional methods may struggle to accurately determine local chemical ordering, short-range clustering, and nanoscale phase separation that critically influence HEA properties.

Bridging these multifaceted challenges requires integrated approaches that combine advanced computational methods, targeted experiments, and innovative data science techniques to efficiently navigate the vast design space of high-entropy alloys.

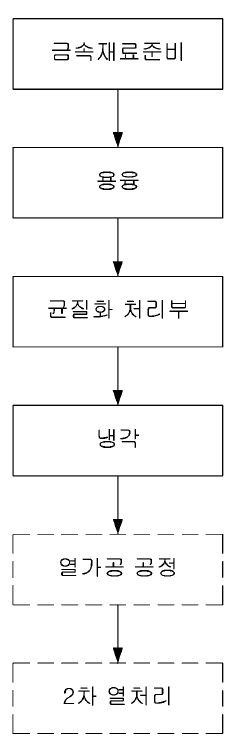

Current Generative Workflow Solutions for HEA Design

01 Machine learning and AI for high-entropy alloy design

Machine learning and artificial intelligence techniques are employed to accelerate the discovery and design of high-entropy alloys. These computational methods can predict material properties, optimize compositions, and identify promising candidates without extensive experimental testing. By analyzing large datasets of existing alloys and their properties, these algorithms can generate new alloy compositions with desired characteristics, significantly reducing the time and resources required for materials development.- Machine learning approaches for high-entropy alloy design: Machine learning algorithms can be used to predict properties and identify promising high-entropy alloy compositions. These approaches leverage existing materials data to generate new candidate alloys with desired characteristics. By analyzing patterns in composition-property relationships, machine learning models can accelerate the discovery of novel high-entropy alloys and reduce the need for extensive experimental testing. These generative workflows combine computational efficiency with materials science expertise to expand the design space for high-entropy alloys.

- Computational modeling and simulation techniques: Computational modeling and simulation techniques provide powerful tools for high-entropy alloy candidate creation. These methods include density functional theory calculations, molecular dynamics simulations, and phase field modeling to predict structural stability, mechanical properties, and phase transformations. By simulating the behavior of different elemental combinations under various conditions, researchers can identify promising high-entropy alloy compositions before experimental validation, significantly reducing development time and costs.

- High-throughput experimental methods: High-throughput experimental methods enable rapid synthesis and characterization of multiple high-entropy alloy candidates. These approaches include combinatorial materials synthesis, automated sample preparation, and parallel testing of material properties. By systematically varying composition and processing parameters, researchers can efficiently explore the vast compositional space of high-entropy alloys and identify promising candidates with enhanced properties such as strength, corrosion resistance, and thermal stability.

- Integration of materials databases and knowledge systems: Integrated materials databases and knowledge systems facilitate the creation of high-entropy alloy candidates by providing access to comprehensive materials data and established scientific principles. These systems combine experimental results, computational predictions, and theoretical models to guide alloy design. By leveraging historical data and applying materials informatics approaches, researchers can identify patterns and relationships that inform the development of new high-entropy alloys with tailored properties for specific applications.

- Evolutionary algorithms and genetic programming: Evolutionary algorithms and genetic programming techniques mimic natural selection processes to optimize high-entropy alloy compositions. These approaches generate initial populations of alloy candidates, evaluate their properties, and iteratively refine compositions through selection, crossover, and mutation operations. By exploring the compositional space in a directed manner, these algorithms can efficiently identify high-entropy alloys with superior combinations of properties while navigating complex composition-structure-property relationships.

02 Computational modeling and simulation techniques

Advanced computational modeling and simulation techniques are used to predict the structure, stability, and properties of high-entropy alloys before physical synthesis. These methods include density functional theory calculations, molecular dynamics simulations, and phase diagram predictions that help researchers understand phase formation, microstructure evolution, and thermodynamic stability. By simulating various compositions and processing conditions, researchers can identify promising high-entropy alloy candidates with enhanced properties.Expand Specific Solutions03 High-throughput experimental methods

High-throughput experimental methods enable rapid synthesis and characterization of multiple high-entropy alloy compositions simultaneously. These approaches include combinatorial materials synthesis, automated testing platforms, and parallel processing techniques that accelerate the discovery process. By systematically varying composition and processing parameters across sample libraries, researchers can efficiently explore the vast compositional space of high-entropy alloys and identify promising candidates with superior properties.Expand Specific Solutions04 Integration of materials databases and knowledge systems

Comprehensive materials databases and knowledge systems are integrated into high-entropy alloy design workflows to leverage existing information and guide new discoveries. These systems compile experimental data, computational results, and literature findings to identify patterns and relationships between composition, processing, structure, and properties. By mining these databases, researchers can extract design rules, identify compositional trends, and generate new high-entropy alloy candidates based on established knowledge.Expand Specific Solutions05 Automated workflow systems for alloy development

Automated workflow systems streamline the process of high-entropy alloy development by connecting various stages from design to validation. These systems integrate computational prediction, experimental synthesis, characterization, and data analysis into a cohesive pipeline. By automating routine tasks, managing data flow between different tools, and implementing feedback loops, these workflows enable more efficient exploration of the high-entropy alloy design space and accelerate the discovery of novel compositions with enhanced properties.Expand Specific Solutions

Leading Research Groups and Companies in HEA Development

The high-entropy alloy (HEA) candidate creation market is currently in its growth phase, characterized by increasing research intensity and expanding applications. The global market for advanced alloys, including HEAs, is projected to reach approximately $3.5 billion by 2025, with generative workflows representing an emerging technological approach. While the technology remains in early maturity stages, significant advancements are being driven by key players across multiple regions. Academic institutions like Central South University, University of Science & Technology Beijing, and Lehigh University are pioneering fundamental research, while industrial entities including Hitachi, LG Electronics, and Dassault Systèmes are developing practical applications. Research collaborations between government agencies (Agency for Defense Development), universities, and corporations are accelerating innovation in this field, particularly in automotive, aerospace, and energy sectors where HEAs offer superior mechanical properties and thermal stability.

Hitachi Ltd.

Technical Solution: Hitachi has developed a sophisticated generative workflow for high-entropy alloy discovery that leverages their expertise in materials informatics and artificial intelligence. Their system, known as the Adaptive Materials Design Platform, combines physics-based modeling with deep learning to accelerate the discovery of novel HEAs. The workflow begins with a massive materials database that includes both published literature and Hitachi's proprietary experimental data. Their approach employs a unique combination of generative adversarial networks (GANs) and reinforcement learning to explore the vast compositional space of multi-element alloys. The system can generate thousands of virtual alloy candidates and predict their properties, including phase stability, mechanical strength, corrosion resistance, and thermal behavior. A key innovation in Hitachi's workflow is the incorporation of manufacturing process parameters directly into the design loop, ensuring that generated alloy compositions are not only theoretically optimal but also practically producible using existing technologies. The platform includes automated experimental design capabilities that suggest the most informative experiments to validate computational predictions, maximizing knowledge gain while minimizing experimental costs. Hitachi has successfully applied this workflow to develop novel HEAs for extreme environment applications in energy, transportation, and industrial equipment sectors.

Strengths: The integration of manufacturing process parameters ensures practical implementability of theoretical designs. The reinforcement learning approach allows the system to continuously improve its predictions based on experimental feedback. The platform's ability to suggest optimal experiments accelerates the validation process and reduces development costs. Weaknesses: The system requires extensive computational resources for accurate property predictions across diverse compositional spaces. The reliance on existing data may limit discovery of truly revolutionary compositions that lie far from known material systems.

University of Science & Technology Beijing

Technical Solution: The University of Science & Technology Beijing has developed a comprehensive generative workflow for high-entropy alloy discovery that combines computational thermodynamics, machine learning, and high-throughput experimentation. Their approach begins with a first-principles calculation framework to evaluate the thermodynamic stability and phase formation tendencies of multi-component alloy systems. This is coupled with a deep learning model trained on an extensive database of alloy compositions and their corresponding properties. The system employs a novel feature engineering approach that captures both elemental attributes and interaction effects between constituent elements. Their workflow incorporates a generative adversarial network (GAN) architecture that can propose new alloy compositions with targeted property profiles while maintaining thermodynamic feasibility. A distinctive aspect of their approach is the integration of processing-structure-property relationships, where the influence of manufacturing parameters on final alloy properties is explicitly modeled. The platform includes an automated experimental design module that uses Bayesian optimization to suggest the most informative experiments for model validation and refinement. The University has successfully applied this workflow to discover several novel HEAs with exceptional combinations of strength, ductility, and corrosion resistance for applications in aerospace, energy, and advanced manufacturing sectors.

Strengths: The integration of first-principles calculations provides a solid physical foundation for predictions beyond purely data-driven approaches. The explicit modeling of processing-structure-property relationships enables more realistic property predictions. The Bayesian optimization approach for experimental design maximizes knowledge gain while minimizing experimental costs. Weaknesses: The computational demands of first-principles calculations limit the throughput for very large compositional spaces. The accuracy of predictions depends heavily on the quality and diversity of the initial training data, particularly for novel elemental combinations.

Key Algorithms and Models for HEA Candidate Generation

High-entropy alloy, and method for producing the same

PatentActiveUS20200392613A1

Innovation

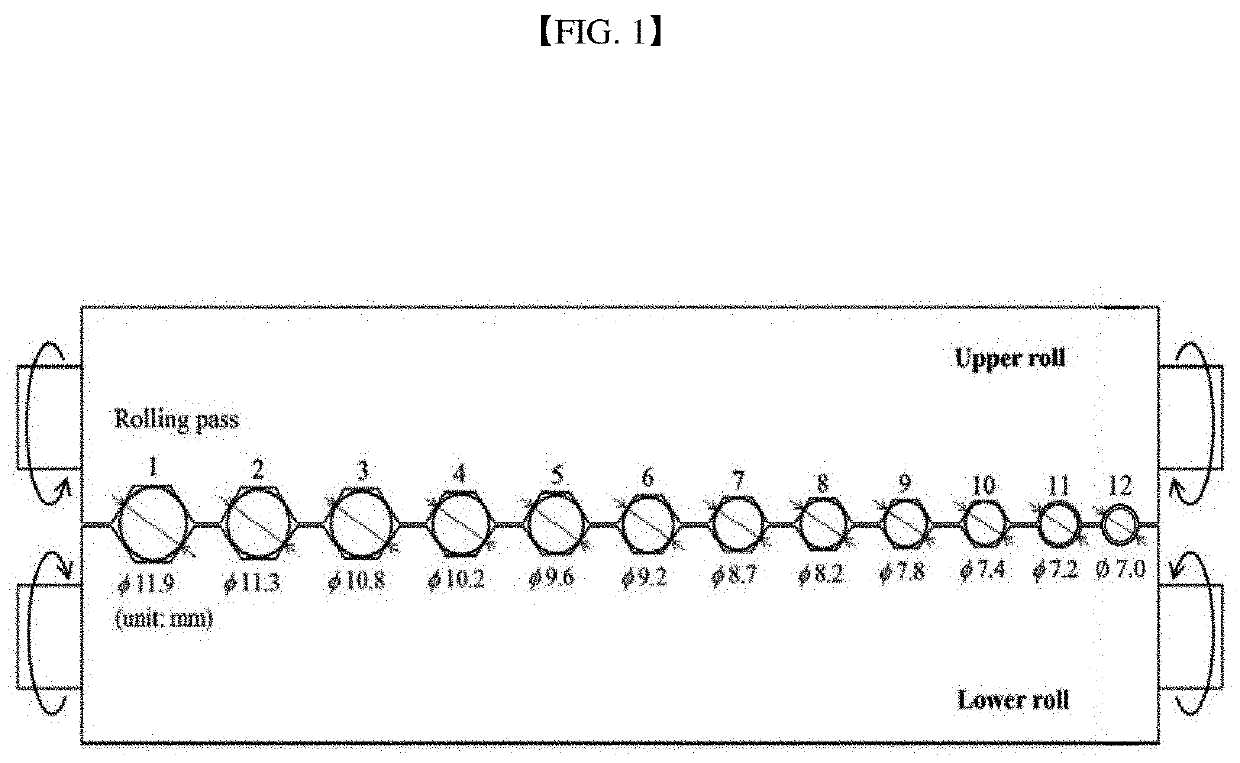

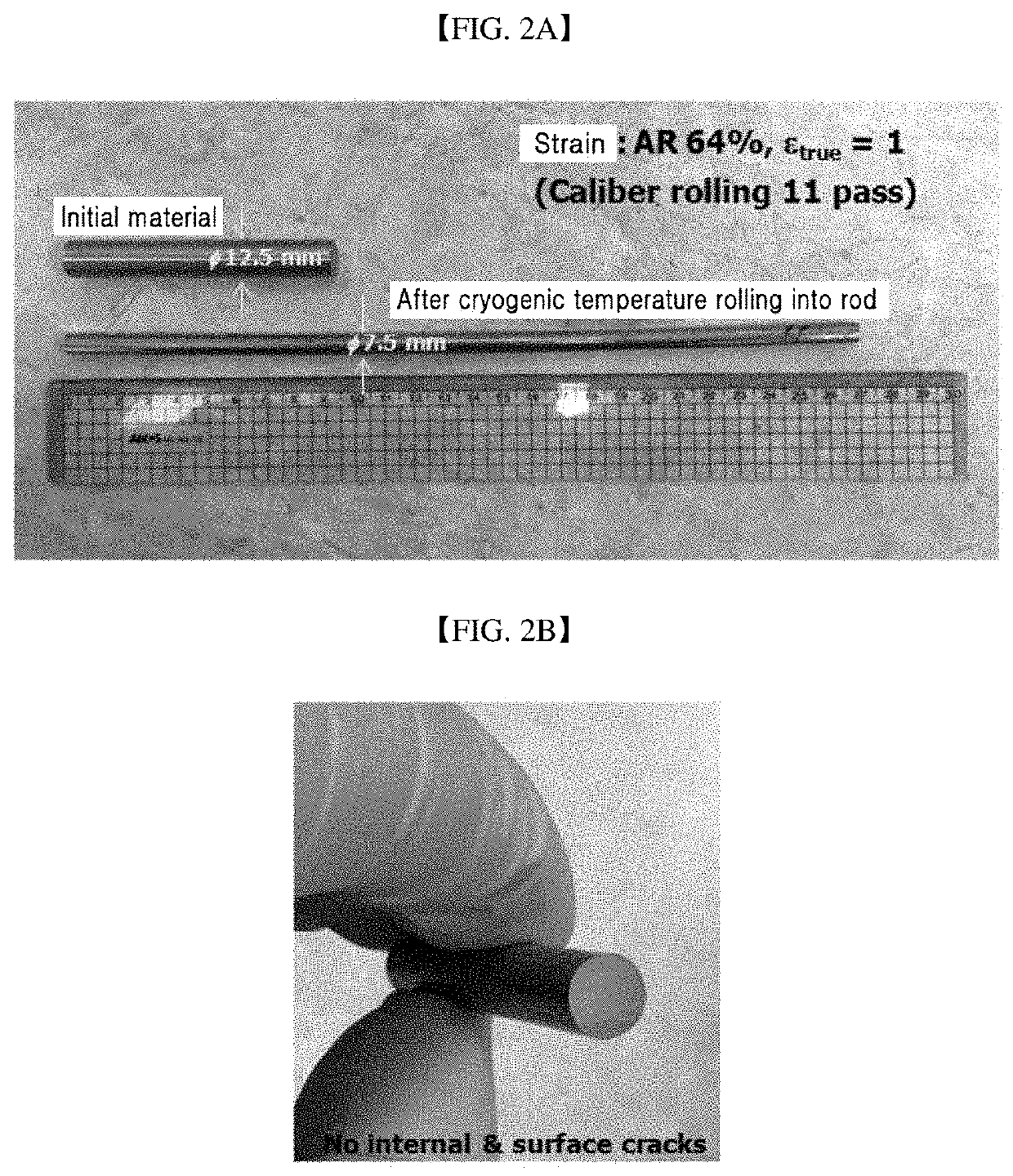

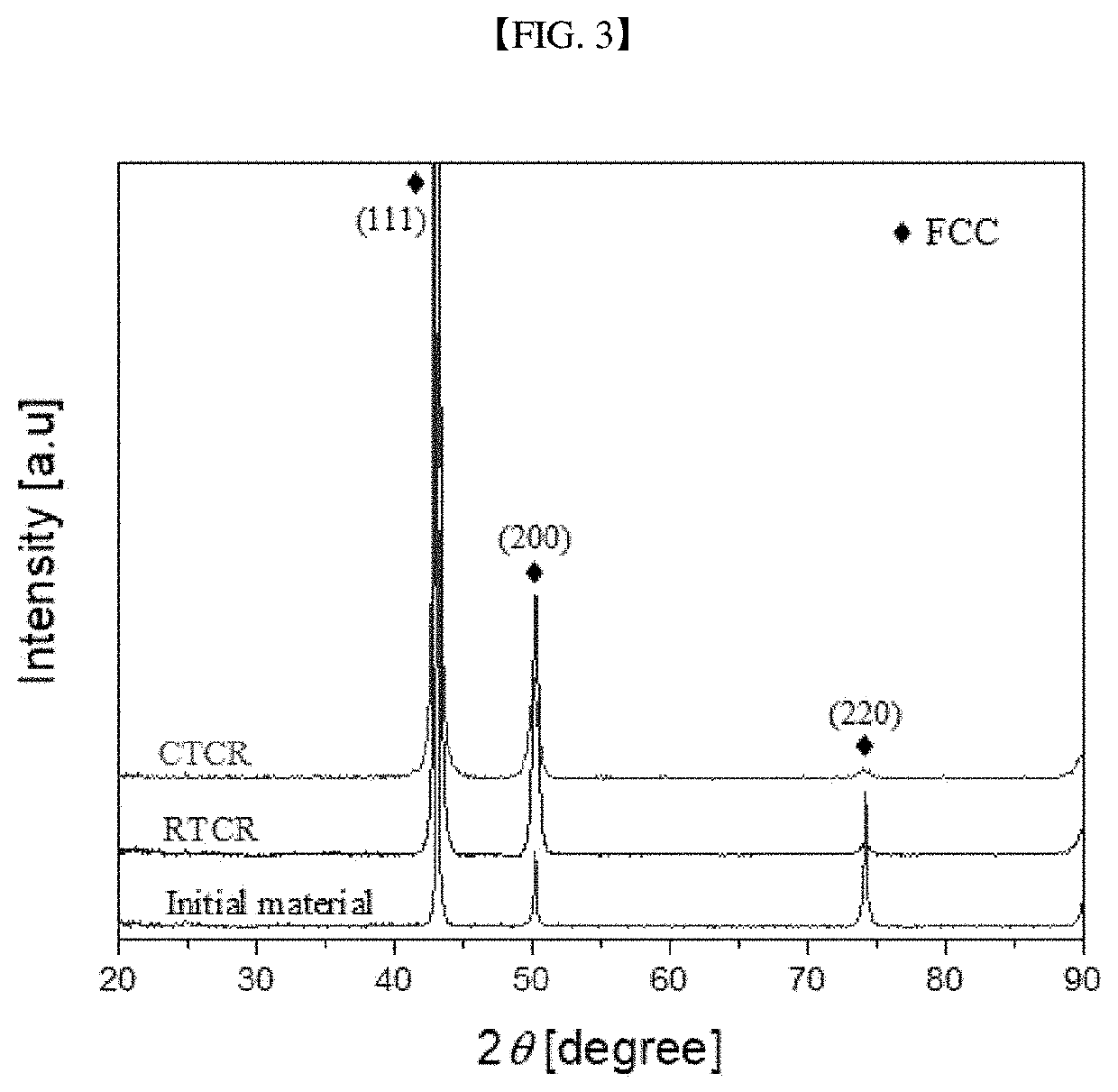

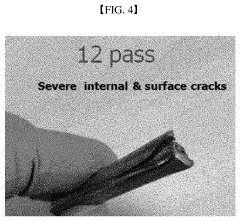

- A method involving annealing and homogenizing an initial alloy containing Co, Cr, Fe, Mn, and Ni, followed by cryogenic temperature rolling with a multi-pass caliber roller to form intersecting twins and secondary fine twins, enhancing grain refinement and hydrogen embrittlement resistance without severe plastic deformation.

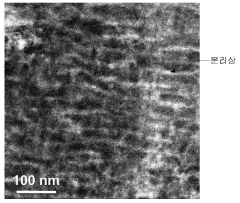

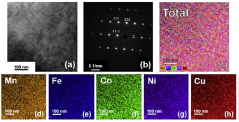

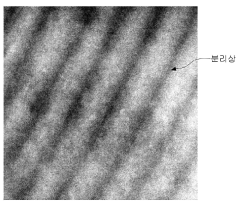

High entropy alloy having nanoscale compositionally modulated layered structure and method for manufacturing the same

PatentActiveKR1020210065220A

Innovation

- A nanolayer structure high-entropy alloy is developed by uniformly distributing phases with the same crystal structure but different compositions at nanoscale intervals through homogenization and cooling, incorporating elements like Fe, Ni, Co, Mn, Cu, and V, with optional C, N, and B to enhance strength and ductility.

Computational Resources and Infrastructure Requirements

The computational demands for generative workflows in high-entropy alloy (HEA) candidate creation are substantial and require careful infrastructure planning. High-performance computing (HPC) clusters with multi-core processors and significant RAM allocations (minimum 128GB per node) are essential for running complex simulations and machine learning algorithms simultaneously. GPU acceleration, particularly using NVIDIA A100 or newer architectures, has proven critical for deep learning models that predict alloy properties and generate novel compositions, offering 5-10x performance improvements over CPU-only implementations.

Storage requirements are equally demanding, with typical research projects necessitating 50-100TB of high-speed storage for materials databases, simulation results, and model checkpoints. A tiered storage architecture combining NVMe drives for active computations with larger capacity HDDs for archival purposes optimizes both performance and cost-effectiveness. Network infrastructure must support at least 100Gbps interconnects between compute nodes to prevent bottlenecks during parallel computations and data transfers.

Specialized software stacks represent another crucial infrastructure component. Implementations typically require integration of materials science packages (VASP, LAMMPS), machine learning frameworks (PyTorch, TensorFlow), and custom generative algorithms. Container technologies like Docker and Singularity have become standard for ensuring reproducibility across different computing environments, while workflow management systems such as Airflow or Luigi are necessary to orchestrate complex multi-stage computational pipelines.

Cloud computing presents a viable alternative to on-premises infrastructure, with platforms like AWS, Google Cloud, and Microsoft Azure offering specialized machine learning instances and scalable storage. Cost analyses indicate that hybrid approaches—maintaining core infrastructure on-premises while bursting to cloud resources during peak demand—often provide the optimal balance between performance and cost-effectiveness for HEA research groups.

Energy consumption represents a significant operational consideration, with comprehensive HEA generative workflows typically consuming 50-100 kW during peak operation. Implementing scheduling algorithms that prioritize non-time-critical tasks during off-peak hours can reduce both energy costs and environmental impact. Additionally, implementing checkpoint-restart capabilities in computational workflows provides resilience against hardware failures and optimizes resource utilization in shared computing environments.

Storage requirements are equally demanding, with typical research projects necessitating 50-100TB of high-speed storage for materials databases, simulation results, and model checkpoints. A tiered storage architecture combining NVMe drives for active computations with larger capacity HDDs for archival purposes optimizes both performance and cost-effectiveness. Network infrastructure must support at least 100Gbps interconnects between compute nodes to prevent bottlenecks during parallel computations and data transfers.

Specialized software stacks represent another crucial infrastructure component. Implementations typically require integration of materials science packages (VASP, LAMMPS), machine learning frameworks (PyTorch, TensorFlow), and custom generative algorithms. Container technologies like Docker and Singularity have become standard for ensuring reproducibility across different computing environments, while workflow management systems such as Airflow or Luigi are necessary to orchestrate complex multi-stage computational pipelines.

Cloud computing presents a viable alternative to on-premises infrastructure, with platforms like AWS, Google Cloud, and Microsoft Azure offering specialized machine learning instances and scalable storage. Cost analyses indicate that hybrid approaches—maintaining core infrastructure on-premises while bursting to cloud resources during peak demand—often provide the optimal balance between performance and cost-effectiveness for HEA research groups.

Energy consumption represents a significant operational consideration, with comprehensive HEA generative workflows typically consuming 50-100 kW during peak operation. Implementing scheduling algorithms that prioritize non-time-critical tasks during off-peak hours can reduce both energy costs and environmental impact. Additionally, implementing checkpoint-restart capabilities in computational workflows provides resilience against hardware failures and optimizes resource utilization in shared computing environments.

Validation Methods and Experimental Verification Approaches

The validation of generative workflows for high-entropy alloy (HEA) candidates requires robust methodologies to ensure that computational predictions align with real-world performance. Traditional experimental verification approaches include X-ray diffraction (XRD) for phase identification, scanning electron microscopy (SEM) for microstructural analysis, and transmission electron microscopy (TEM) for atomic-scale characterization. These techniques provide essential data on crystal structure, phase composition, and elemental distribution within the alloy matrix.

Advanced validation methods have emerged to bridge the gap between computational predictions and experimental reality. High-throughput experimentation (HTE) platforms enable rapid synthesis and testing of multiple alloy compositions simultaneously, significantly accelerating the validation process. These platforms typically incorporate automated sample preparation, characterization, and data analysis workflows, allowing researchers to validate hundreds of alloy candidates in the time traditionally required for a single composition.

Mechanical property validation represents another critical aspect of HEA verification. Nanoindentation techniques provide localized hardness and elastic modulus measurements, while tensile and compression testing offer insights into bulk mechanical behavior. Creep testing and fatigue analysis further validate the alloy's performance under sustained or cyclic loading conditions, essential for applications in extreme environments.

Corrosion resistance validation employs electrochemical techniques such as potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) to assess the alloy's behavior in aggressive environments. These methods quantify corrosion rates and mechanisms, validating computational predictions of environmental stability.

Machine learning approaches have revolutionized validation methodologies by establishing correlations between computational predictions and experimental outcomes. Active learning frameworks iteratively refine prediction models by strategically selecting the most informative experiments, optimizing resource allocation during the validation process. This approach has proven particularly valuable for HEAs, where the vast compositional space makes exhaustive experimental validation impractical.

Uncertainty quantification represents an emerging validation paradigm, where statistical methods assess the reliability of computational predictions. By propagating uncertainties from input parameters through the computational workflow, researchers can establish confidence intervals for predicted properties, guiding experimental design and resource allocation. Bayesian inference frameworks further enhance this approach by updating prediction models based on experimental feedback, continuously improving prediction accuracy as more validation data becomes available.

Advanced validation methods have emerged to bridge the gap between computational predictions and experimental reality. High-throughput experimentation (HTE) platforms enable rapid synthesis and testing of multiple alloy compositions simultaneously, significantly accelerating the validation process. These platforms typically incorporate automated sample preparation, characterization, and data analysis workflows, allowing researchers to validate hundreds of alloy candidates in the time traditionally required for a single composition.

Mechanical property validation represents another critical aspect of HEA verification. Nanoindentation techniques provide localized hardness and elastic modulus measurements, while tensile and compression testing offer insights into bulk mechanical behavior. Creep testing and fatigue analysis further validate the alloy's performance under sustained or cyclic loading conditions, essential for applications in extreme environments.

Corrosion resistance validation employs electrochemical techniques such as potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) to assess the alloy's behavior in aggressive environments. These methods quantify corrosion rates and mechanisms, validating computational predictions of environmental stability.

Machine learning approaches have revolutionized validation methodologies by establishing correlations between computational predictions and experimental outcomes. Active learning frameworks iteratively refine prediction models by strategically selecting the most informative experiments, optimizing resource allocation during the validation process. This approach has proven particularly valuable for HEAs, where the vast compositional space makes exhaustive experimental validation impractical.

Uncertainty quantification represents an emerging validation paradigm, where statistical methods assess the reliability of computational predictions. By propagating uncertainties from input parameters through the computational workflow, researchers can establish confidence intervals for predicted properties, guiding experimental design and resource allocation. Bayesian inference frameworks further enhance this approach by updating prediction models based on experimental feedback, continuously improving prediction accuracy as more validation data becomes available.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!