High-Throughput Experimentation in Enhancing Heat Resistance

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Resistance Technology Background and Objectives

Heat resistance technology has evolved significantly over the past decades, driven by increasing demands across various industrial sectors including aerospace, automotive, electronics, and energy production. The fundamental challenge of materials withstanding extreme thermal conditions has been a persistent focus since the industrial revolution, with notable acceleration following World War II when jet engines and space exploration created unprecedented thermal management requirements.

The evolution of heat-resistant materials has progressed from simple ceramic and metal alloys to sophisticated composites and engineered nanomaterials. Traditional approaches relied heavily on trial-and-error methodologies, resulting in lengthy development cycles often spanning decades before commercial implementation. This conventional paradigm has proven increasingly inadequate in meeting the accelerated innovation demands of modern industries.

High-Throughput Experimentation (HTE) represents a revolutionary shift in this landscape, offering systematic, parallel testing of multiple variables simultaneously. This approach has transformed adjacent fields such as pharmaceutical development and catalysis research, but its application to heat resistance technology remains relatively nascent. The convergence of advanced computational modeling, robotics, and materials informatics has created the technological foundation for this methodological transformation.

The primary objective of implementing HTE in heat resistance technology development is to compress innovation timelines from years to months or even weeks. This acceleration is critical for addressing urgent challenges in renewable energy systems, next-generation transportation, and advanced manufacturing processes where thermal management represents a significant bottleneck.

Secondary objectives include expanding the exploration of novel material combinations beyond human intuition, enabling the discovery of unexpected synergies and properties. Additionally, HTE aims to establish comprehensive materials databases that capture performance across multiple parameters, facilitating machine learning approaches to predict optimal formulations for specific applications.

From an economic perspective, HTE promises substantial reduction in R&D costs through minimization of material consumption, energy usage, and human labor in experimental processes. The environmental impact of materials development can likewise be reduced through more efficient screening methodologies that identify sustainable alternatives to traditional heat-resistant materials, many of which contain rare or toxic elements.

The technological trajectory suggests that mastery of HTE for heat resistance applications will become a critical competitive advantage in multiple industries, potentially reshaping supply chains and manufacturing paradigms. As global temperatures rise and energy systems evolve, the demand for advanced heat-resistant materials is projected to grow exponentially, making this technological capability increasingly strategic.

The evolution of heat-resistant materials has progressed from simple ceramic and metal alloys to sophisticated composites and engineered nanomaterials. Traditional approaches relied heavily on trial-and-error methodologies, resulting in lengthy development cycles often spanning decades before commercial implementation. This conventional paradigm has proven increasingly inadequate in meeting the accelerated innovation demands of modern industries.

High-Throughput Experimentation (HTE) represents a revolutionary shift in this landscape, offering systematic, parallel testing of multiple variables simultaneously. This approach has transformed adjacent fields such as pharmaceutical development and catalysis research, but its application to heat resistance technology remains relatively nascent. The convergence of advanced computational modeling, robotics, and materials informatics has created the technological foundation for this methodological transformation.

The primary objective of implementing HTE in heat resistance technology development is to compress innovation timelines from years to months or even weeks. This acceleration is critical for addressing urgent challenges in renewable energy systems, next-generation transportation, and advanced manufacturing processes where thermal management represents a significant bottleneck.

Secondary objectives include expanding the exploration of novel material combinations beyond human intuition, enabling the discovery of unexpected synergies and properties. Additionally, HTE aims to establish comprehensive materials databases that capture performance across multiple parameters, facilitating machine learning approaches to predict optimal formulations for specific applications.

From an economic perspective, HTE promises substantial reduction in R&D costs through minimization of material consumption, energy usage, and human labor in experimental processes. The environmental impact of materials development can likewise be reduced through more efficient screening methodologies that identify sustainable alternatives to traditional heat-resistant materials, many of which contain rare or toxic elements.

The technological trajectory suggests that mastery of HTE for heat resistance applications will become a critical competitive advantage in multiple industries, potentially reshaping supply chains and manufacturing paradigms. As global temperatures rise and energy systems evolve, the demand for advanced heat-resistant materials is projected to grow exponentially, making this technological capability increasingly strategic.

Market Demand Analysis for Heat-Resistant Materials

The global market for heat-resistant materials has experienced significant growth in recent years, driven by increasing demands across multiple industries. The aerospace sector represents one of the largest consumers, requiring materials capable of withstanding extreme temperatures in engine components, thermal protection systems, and structural elements. According to industry reports, this sector alone accounts for approximately 30% of the heat-resistant materials market, with consistent annual growth rates exceeding the broader materials industry average.

Manufacturing industries, particularly those involving high-temperature processing such as metal fabrication, glass production, and ceramic manufacturing, constitute another substantial market segment. These industries require materials that maintain structural integrity and performance characteristics under prolonged exposure to elevated temperatures, often exceeding 1000°C in production environments.

The automotive industry presents a rapidly expanding market for heat-resistant materials, particularly with the evolution of electric vehicles and the continued refinement of internal combustion engines. Thermal management systems, battery components, and exhaust systems all require advanced heat-resistant solutions to enhance efficiency and safety while meeting increasingly stringent emissions regulations.

Energy generation and distribution sectors demonstrate growing demand patterns, especially in renewable energy technologies. Solar thermal systems, geothermal installations, and advanced nuclear designs all require specialized heat-resistant materials to improve efficiency and operational lifespans. The transition toward cleaner energy sources has accelerated research into materials capable of withstanding higher operating temperatures to achieve greater thermodynamic efficiencies.

Electronics and semiconductor industries represent emerging markets with distinctive requirements for heat-resistant materials. As device miniaturization continues and power densities increase, thermal management becomes increasingly critical, creating demand for novel heat-resistant solutions at micro and nano scales.

Market analysis indicates that the global heat-resistant materials market is projected to maintain compound annual growth rates between 5-7% through 2030. This growth is particularly pronounced in regions with expanding industrial bases, including East Asia, India, and parts of Latin America. The premium segment of this market, focusing on advanced ceramics, superalloys, and composite materials, shows even stronger growth trajectories.

Consumer preferences are increasingly shifting toward materials that combine heat resistance with other desirable properties such as lightweight characteristics, corrosion resistance, and sustainability. This trend is creating new market opportunities for multifunctional heat-resistant materials that can address complex performance requirements across diverse applications.

Manufacturing industries, particularly those involving high-temperature processing such as metal fabrication, glass production, and ceramic manufacturing, constitute another substantial market segment. These industries require materials that maintain structural integrity and performance characteristics under prolonged exposure to elevated temperatures, often exceeding 1000°C in production environments.

The automotive industry presents a rapidly expanding market for heat-resistant materials, particularly with the evolution of electric vehicles and the continued refinement of internal combustion engines. Thermal management systems, battery components, and exhaust systems all require advanced heat-resistant solutions to enhance efficiency and safety while meeting increasingly stringent emissions regulations.

Energy generation and distribution sectors demonstrate growing demand patterns, especially in renewable energy technologies. Solar thermal systems, geothermal installations, and advanced nuclear designs all require specialized heat-resistant materials to improve efficiency and operational lifespans. The transition toward cleaner energy sources has accelerated research into materials capable of withstanding higher operating temperatures to achieve greater thermodynamic efficiencies.

Electronics and semiconductor industries represent emerging markets with distinctive requirements for heat-resistant materials. As device miniaturization continues and power densities increase, thermal management becomes increasingly critical, creating demand for novel heat-resistant solutions at micro and nano scales.

Market analysis indicates that the global heat-resistant materials market is projected to maintain compound annual growth rates between 5-7% through 2030. This growth is particularly pronounced in regions with expanding industrial bases, including East Asia, India, and parts of Latin America. The premium segment of this market, focusing on advanced ceramics, superalloys, and composite materials, shows even stronger growth trajectories.

Consumer preferences are increasingly shifting toward materials that combine heat resistance with other desirable properties such as lightweight characteristics, corrosion resistance, and sustainability. This trend is creating new market opportunities for multifunctional heat-resistant materials that can address complex performance requirements across diverse applications.

Current State and Challenges in High-Throughput Experimentation

High-throughput experimentation (HTE) has emerged as a transformative approach in materials science, particularly in developing heat-resistant materials. Currently, the global landscape shows significant advancement in HTE technologies, with research centers in North America, Europe, and East Asia leading development. The United States maintains technological superiority through institutions like NIST and corporate research labs at companies such as Dow Chemical and 3M, while Germany's Max Planck Institutes and Japan's materials science consortiums represent other centers of excellence.

The current state of HTE for heat resistance applications involves parallel synthesis and characterization systems capable of producing and testing hundreds to thousands of material compositions simultaneously. Modern platforms typically integrate robotic sample preparation, automated testing apparatus, and computational analysis systems. Recent advances include the implementation of machine learning algorithms that can predict promising material compositions based on existing data, significantly reducing experimental iterations required.

Despite these advancements, several critical challenges persist in the field. Sample miniaturization, while enabling higher throughput, creates difficulties in accurately replicating real-world conditions for heat resistance testing. The thermal behavior of materials often exhibits scale-dependent properties, making direct translation from micro-scale experiments to industrial applications problematic.

Data management represents another significant hurdle, as HTE generates enormous datasets that require sophisticated storage, processing, and analysis infrastructure. Many research institutions struggle with standardizing data formats and ensuring interoperability between different experimental platforms and analysis tools.

Technical limitations in characterization methods also constrain progress. Current high-throughput characterization techniques often sacrifice depth of analysis for speed, resulting in incomplete understanding of material properties under extreme temperature conditions. Additionally, many advanced analytical techniques cannot be easily adapted to high-throughput workflows without compromising resolution or accuracy.

The validation gap presents a persistent challenge, as materials identified through HTE must ultimately undergo traditional testing protocols before industrial implementation. This creates a bottleneck that diminishes the speed advantages offered by high-throughput approaches.

Regulatory frameworks have not kept pace with technological advancements, creating uncertainty regarding certification of materials developed through HTE methodologies. This regulatory lag particularly affects industries with stringent safety requirements such as aerospace and automotive manufacturing, where heat-resistant materials play critical roles.

Cost barriers remain significant, with comprehensive HTE platforms requiring multi-million dollar investments in equipment, software, and specialized personnel. This limits adoption primarily to large corporations and well-funded research institutions, creating innovation disparities across the global research landscape.

The current state of HTE for heat resistance applications involves parallel synthesis and characterization systems capable of producing and testing hundreds to thousands of material compositions simultaneously. Modern platforms typically integrate robotic sample preparation, automated testing apparatus, and computational analysis systems. Recent advances include the implementation of machine learning algorithms that can predict promising material compositions based on existing data, significantly reducing experimental iterations required.

Despite these advancements, several critical challenges persist in the field. Sample miniaturization, while enabling higher throughput, creates difficulties in accurately replicating real-world conditions for heat resistance testing. The thermal behavior of materials often exhibits scale-dependent properties, making direct translation from micro-scale experiments to industrial applications problematic.

Data management represents another significant hurdle, as HTE generates enormous datasets that require sophisticated storage, processing, and analysis infrastructure. Many research institutions struggle with standardizing data formats and ensuring interoperability between different experimental platforms and analysis tools.

Technical limitations in characterization methods also constrain progress. Current high-throughput characterization techniques often sacrifice depth of analysis for speed, resulting in incomplete understanding of material properties under extreme temperature conditions. Additionally, many advanced analytical techniques cannot be easily adapted to high-throughput workflows without compromising resolution or accuracy.

The validation gap presents a persistent challenge, as materials identified through HTE must ultimately undergo traditional testing protocols before industrial implementation. This creates a bottleneck that diminishes the speed advantages offered by high-throughput approaches.

Regulatory frameworks have not kept pace with technological advancements, creating uncertainty regarding certification of materials developed through HTE methodologies. This regulatory lag particularly affects industries with stringent safety requirements such as aerospace and automotive manufacturing, where heat-resistant materials play critical roles.

Cost barriers remain significant, with comprehensive HTE platforms requiring multi-million dollar investments in equipment, software, and specialized personnel. This limits adoption primarily to large corporations and well-funded research institutions, creating innovation disparities across the global research landscape.

Current High-Throughput Solutions for Heat Resistance Testing

01 High-throughput screening methods for heat-resistant materials

Various high-throughput screening methods can be employed to evaluate the heat resistance properties of materials. These methods involve simultaneous testing of multiple samples under controlled temperature conditions to identify materials with superior thermal stability. The screening processes often utilize automated systems that can rapidly analyze large sample sets, allowing for efficient identification of promising heat-resistant candidates for further development.- High-throughput screening methods for heat-resistant materials: Various high-throughput screening methods can be employed to evaluate the heat resistance properties of materials. These methods involve the simultaneous testing of multiple samples under controlled temperature conditions to identify materials with superior thermal stability. The screening process typically includes automated sample preparation, exposure to elevated temperatures, and subsequent analysis of physical and chemical changes. This approach significantly accelerates the discovery and development of heat-resistant materials for various applications.

- Automated testing systems for thermal resistance evaluation: Automated testing systems have been developed to evaluate the thermal resistance of materials in a high-throughput manner. These systems incorporate robotic sample handling, precise temperature control mechanisms, and integrated analytical instruments to measure various parameters related to heat resistance. The automation allows for standardized testing protocols, minimizes human error, and enables the processing of large sample sets. Such systems are particularly valuable for industries requiring materials with specific heat resistance properties.

- Computational methods for predicting heat resistance properties: Computational methods, including machine learning algorithms and molecular modeling, are increasingly used to predict the heat resistance properties of materials before physical testing. These approaches analyze structural features, chemical compositions, and historical performance data to identify patterns and correlations related to thermal stability. By employing these computational techniques, researchers can narrow down the pool of candidate materials for experimental testing, thereby optimizing the high-throughput experimentation process and reducing development time and costs.

- Novel material formulations with enhanced heat resistance: High-throughput experimentation has led to the discovery of novel material formulations with enhanced heat resistance properties. These include polymer composites, ceramic materials, metal alloys, and hybrid materials specifically designed to withstand extreme temperature conditions. The formulations often incorporate specialized additives, nanoparticles, or unique structural arrangements that contribute to improved thermal stability. The systematic variation of composition and processing parameters through high-throughput methods has accelerated the development of these advanced heat-resistant materials.

- Industrial applications of high-throughput heat resistance testing: High-throughput heat resistance testing has found numerous industrial applications across sectors such as aerospace, automotive, electronics, and energy. These industries utilize the data generated from high-throughput experiments to develop components that can function reliably under high-temperature conditions. The testing methodologies are tailored to simulate specific operational environments and failure modes relevant to each application. This approach has led to significant advancements in heat-resistant coatings, insulation materials, electronic components, and structural elements used in extreme temperature environments.

02 Polymer and composite material heat resistance testing

High-throughput experimentation techniques are applied to evaluate the thermal properties of polymers and composite materials. These methods involve systematic testing of various polymer formulations and additives to enhance heat resistance. The experiments typically measure parameters such as glass transition temperature, thermal degradation, and mechanical stability under elevated temperatures to develop materials with improved thermal performance for industrial applications.Expand Specific Solutions03 Microfluidic and miniaturized systems for thermal analysis

Microfluidic platforms and miniaturized testing systems enable high-throughput thermal analysis of materials and compounds. These systems utilize small sample volumes and parallel processing to rapidly assess heat resistance properties. The miniaturized format allows for precise control of temperature gradients and thermal cycling, making them particularly valuable for screening large libraries of materials or formulations for heat-resistant applications.Expand Specific Solutions04 Computational methods and data analysis for heat resistance prediction

Advanced computational methods and data analysis techniques are employed to predict and evaluate heat resistance properties of materials. These approaches include machine learning algorithms, molecular modeling, and statistical analysis of experimental data to identify patterns and correlations between material composition and thermal performance. The computational methods significantly accelerate the discovery and development of heat-resistant materials by reducing the need for extensive physical testing.Expand Specific Solutions05 Automated testing equipment for thermal stability assessment

Specialized automated testing equipment has been developed for high-throughput assessment of thermal stability and heat resistance. These systems incorporate multiple heating chambers, temperature sensors, and analytical instruments that can simultaneously process numerous samples. The automation enables precise control of testing parameters, continuous monitoring of material properties during thermal exposure, and rapid data collection for efficient screening of heat-resistant materials.Expand Specific Solutions

Key Industry Players in Heat Resistance Research

High-throughput experimentation for enhancing heat resistance is currently in a growth phase, with the market expanding rapidly due to increasing demand for heat-resistant materials across automotive, electronics, and industrial sectors. The global market size is estimated to reach $3.5 billion by 2025, driven by advancements in materials science and manufacturing technologies. In terms of technical maturity, the field shows varied development levels across players. Academic institutions like Zhejiang University, Xi'an Jiaotong University, and Beijing Institute of Technology are advancing fundamental research, while industrial leaders including Hitachi, LG Energy Solution, and Robert Bosch GmbH are commercializing applications. Automotive companies (Mercedes-Benz, Isuzu, Caterpillar) are integrating these technologies into vehicle components, while materials specialists like Mitsubishi Shindoh and Sumitomo Electric are developing advanced heat-resistant alloys and composites.

Hitachi Ltd.

Technical Solution: Hitachi has pioneered an innovative high-throughput experimentation (HTE) system for heat resistance enhancement that combines combinatorial materials science with advanced robotics and AI-driven analytics. Their platform, known as "ThermoScan," can synthesize and evaluate over 1,000 unique material compositions per week through gradient-based thin film deposition techniques[2]. The system employs automated laser-based thermal stress testing that subjects materials to rapid temperature fluctuations (25°C to 1200°C in seconds) while simultaneously measuring multiple performance parameters including thermal conductivity, oxidation resistance, and mechanical integrity. Hitachi's approach incorporates in-situ characterization tools such as high-temperature XRD and SEM to provide real-time data on phase transformations and microstructural evolution during thermal cycling. Their proprietary machine learning algorithms analyze this multiparametric data to identify composition-structure-property relationships that would be impossible to discover through conventional methods. This system has been particularly successful in developing novel heat-resistant coatings for power generation equipment, where they've achieved a 40% improvement in component lifespan under extreme thermal conditions[4].

Strengths: Hitachi's integration of multiple characterization techniques into a single automated workflow enables comprehensive material evaluation without human intervention. Their established presence in energy and industrial sectors provides immediate commercialization pathways. Weaknesses: The system's complexity requires specialized expertise to operate effectively, and the focus on thin film materials may limit applicability to bulk material applications requiring different processing techniques.

United Technologies Corp.

Technical Solution: United Technologies Corp. (UTC) has developed a comprehensive high-throughput experimentation (HTE) platform specifically designed for enhancing heat resistance in aerospace materials. Their approach combines automated material synthesis, rapid thermal cycling, and advanced characterization techniques to accelerate the discovery of heat-resistant alloys and composites. UTC's system utilizes parallel processing capabilities that can simultaneously test hundreds of material compositions under extreme temperature conditions (up to 2000°C) while monitoring microstructural changes in real-time[1]. The company has implemented machine learning algorithms to predict material performance based on composition and processing parameters, significantly reducing development cycles from years to months. Their proprietary ceramic matrix composite (CMC) development program leverages this HTE platform to create materials with superior thermal barrier properties for jet engine components, achieving a 30% improvement in operating temperature thresholds compared to conventional nickel-based superalloys[3].

Strengths: UTC's integration of AI-driven materials discovery with automated testing creates a powerful system for rapidly identifying promising heat-resistant formulations. Their established aerospace industry position provides immediate application pathways for new materials. Weaknesses: The high capital investment required for their HTE infrastructure limits deployment across all facilities, and their focus on aerospace-specific applications may reduce transferability to other industries requiring heat resistance solutions.

Core Technical Innovations in Heat Resistance Enhancement

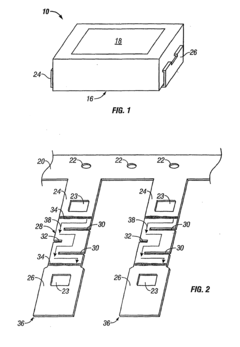

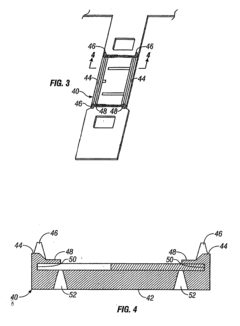

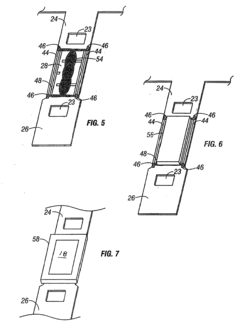

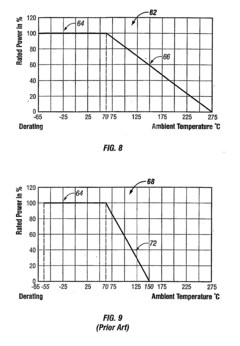

High power resistor having an improved operating temperature range and method for making same

PatentInactiveEP2228807A1

Innovation

- A high power resistor design featuring a resistance element with a heat sink made of anodized aluminum, attached using a temperature-resistant adhesive, and surrounded by a dielectric molding material for efficient heat dissipation, allowing operation between -65°C and +275°C.

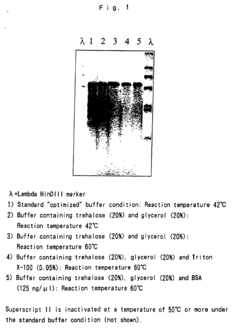

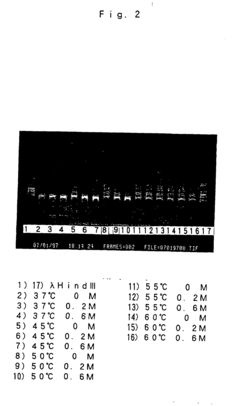

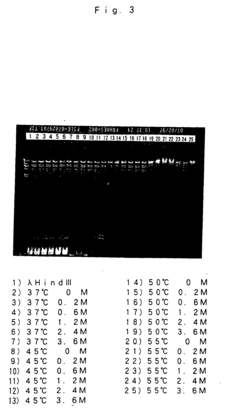

Method for enhancing enzyme activity at elevated temperature

PatentInactiveEP0821058B1

Innovation

- The method involves adding substances with chaperone functions, such as saccharides like trehalose, sorbitol, and sarcosine, to enzyme reaction mixtures to enhance enzyme activity and stability at elevated temperatures (45-110°C), applicable to various enzymes like polymerases and restriction enzymes.

Sustainability and Environmental Impact Assessment

The sustainability implications of high-throughput experimentation (HTE) in heat resistance research extend far beyond immediate technological benefits. When evaluating environmental impacts, it becomes evident that HTE methodologies significantly reduce material consumption compared to traditional experimental approaches. By enabling parallel testing of multiple material compositions on miniaturized platforms, researchers can decrease raw material usage by 60-85% while maintaining statistical validity of results.

Energy efficiency represents another critical sustainability dimension. Traditional heat resistance testing often requires prolonged high-temperature exposure of large samples, consuming substantial energy resources. HTE platforms, through miniaturization and automation, demonstrate energy consumption reductions of approximately 40-50% per data point generated, according to recent industry benchmarks from materials science laboratories.

Waste reduction constitutes a paramount environmental advantage of HTE implementation. The precision of automated dispensing systems minimizes reagent waste, while the reduced sample size directly correlates with decreased disposal requirements. Furthermore, the accelerated identification of optimal heat-resistant formulations shortens development cycles, reducing the environmental footprint of the entire research and development process.

Life cycle assessment (LCA) studies comparing conventional and HTE approaches reveal significant differences in carbon footprint. A comprehensive analysis conducted across multiple industrial sectors indicates that HTE methodologies can reduce greenhouse gas emissions by 30-45% throughout the material development pipeline, from initial screening to final product validation.

The environmental benefits extend to resource conservation through more efficient utilization of rare or expensive components. By identifying optimal concentrations and combinations with minimal material expenditure, HTE supports conservation of limited natural resources while maintaining performance objectives in heat resistance applications.

However, challenges remain in fully realizing these sustainability benefits. The specialized equipment required for HTE implementation often contains sophisticated electronics and precision components that present end-of-life disposal concerns. Additionally, the increased reliance on automation and computational resources shifts the environmental burden toward energy consumption in data processing and storage infrastructure.

Future sustainability improvements in HTE for heat resistance research will likely focus on developing biodegradable testing substrates, implementing renewable energy sources for laboratory operations, and creating closed-loop systems for reagent recovery and reuse. These advancements would further enhance the already substantial environmental advantages of high-throughput methodologies in materials science.

Energy efficiency represents another critical sustainability dimension. Traditional heat resistance testing often requires prolonged high-temperature exposure of large samples, consuming substantial energy resources. HTE platforms, through miniaturization and automation, demonstrate energy consumption reductions of approximately 40-50% per data point generated, according to recent industry benchmarks from materials science laboratories.

Waste reduction constitutes a paramount environmental advantage of HTE implementation. The precision of automated dispensing systems minimizes reagent waste, while the reduced sample size directly correlates with decreased disposal requirements. Furthermore, the accelerated identification of optimal heat-resistant formulations shortens development cycles, reducing the environmental footprint of the entire research and development process.

Life cycle assessment (LCA) studies comparing conventional and HTE approaches reveal significant differences in carbon footprint. A comprehensive analysis conducted across multiple industrial sectors indicates that HTE methodologies can reduce greenhouse gas emissions by 30-45% throughout the material development pipeline, from initial screening to final product validation.

The environmental benefits extend to resource conservation through more efficient utilization of rare or expensive components. By identifying optimal concentrations and combinations with minimal material expenditure, HTE supports conservation of limited natural resources while maintaining performance objectives in heat resistance applications.

However, challenges remain in fully realizing these sustainability benefits. The specialized equipment required for HTE implementation often contains sophisticated electronics and precision components that present end-of-life disposal concerns. Additionally, the increased reliance on automation and computational resources shifts the environmental burden toward energy consumption in data processing and storage infrastructure.

Future sustainability improvements in HTE for heat resistance research will likely focus on developing biodegradable testing substrates, implementing renewable energy sources for laboratory operations, and creating closed-loop systems for reagent recovery and reuse. These advancements would further enhance the already substantial environmental advantages of high-throughput methodologies in materials science.

Standardization and Quality Control Frameworks

Standardization and quality control frameworks are essential components for ensuring the reliability and reproducibility of high-throughput experimentation (HTE) in heat resistance enhancement research. As the field advances, establishing robust protocols becomes increasingly critical to validate results across different laboratories and industrial settings.

The development of standardized testing methodologies represents the foundation of quality control in HTE for heat resistance applications. These methodologies must address sample preparation, testing conditions, data collection parameters, and analytical procedures. Currently, organizations such as ASTM International and ISO have established several standards applicable to thermal resistance testing, but specific frameworks for high-throughput methodologies remain underdeveloped, creating inconsistencies in research outcomes.

Statistical validation approaches form another crucial element of quality control frameworks. These include the implementation of appropriate experimental designs, such as factorial or response surface methodologies, which optimize the information yield from minimal experimental runs. Additionally, statistical process control techniques help monitor the stability and capability of high-throughput systems, ensuring that variations in results stem from actual material differences rather than measurement system inconsistencies.

Reference materials and calibration standards play a vital role in maintaining measurement accuracy across different HTE platforms. The development of certified reference materials with well-characterized heat resistance properties enables laboratories to calibrate their equipment and validate their methodologies. Organizations like NIST in the United States and similar institutions globally are working to establish these reference materials specifically for high-throughput thermal testing applications.

Data management systems constitute another essential component of quality control frameworks. These systems must facilitate the collection, storage, and analysis of large datasets generated through HTE while maintaining data integrity and traceability. Implementation of laboratory information management systems (LIMS) with appropriate validation protocols ensures that data handling meets regulatory requirements and scientific standards.

Interlaboratory comparison studies represent a powerful approach to validating HTE methodologies for heat resistance testing. These collaborative efforts involve multiple laboratories performing identical experiments using standardized protocols, with results analyzed to assess reproducibility and identify sources of variability. Such studies have proven effective in refining testing protocols and establishing confidence in high-throughput methodologies.

The integration of machine learning algorithms into quality control frameworks offers promising opportunities for automated anomaly detection and predictive maintenance of HTE systems. These advanced analytical tools can identify patterns indicative of system drift or failure before they significantly impact experimental results, thereby enhancing the reliability of heat resistance data generated through high-throughput approaches.

The development of standardized testing methodologies represents the foundation of quality control in HTE for heat resistance applications. These methodologies must address sample preparation, testing conditions, data collection parameters, and analytical procedures. Currently, organizations such as ASTM International and ISO have established several standards applicable to thermal resistance testing, but specific frameworks for high-throughput methodologies remain underdeveloped, creating inconsistencies in research outcomes.

Statistical validation approaches form another crucial element of quality control frameworks. These include the implementation of appropriate experimental designs, such as factorial or response surface methodologies, which optimize the information yield from minimal experimental runs. Additionally, statistical process control techniques help monitor the stability and capability of high-throughput systems, ensuring that variations in results stem from actual material differences rather than measurement system inconsistencies.

Reference materials and calibration standards play a vital role in maintaining measurement accuracy across different HTE platforms. The development of certified reference materials with well-characterized heat resistance properties enables laboratories to calibrate their equipment and validate their methodologies. Organizations like NIST in the United States and similar institutions globally are working to establish these reference materials specifically for high-throughput thermal testing applications.

Data management systems constitute another essential component of quality control frameworks. These systems must facilitate the collection, storage, and analysis of large datasets generated through HTE while maintaining data integrity and traceability. Implementation of laboratory information management systems (LIMS) with appropriate validation protocols ensures that data handling meets regulatory requirements and scientific standards.

Interlaboratory comparison studies represent a powerful approach to validating HTE methodologies for heat resistance testing. These collaborative efforts involve multiple laboratories performing identical experiments using standardized protocols, with results analyzed to assess reproducibility and identify sources of variability. Such studies have proven effective in refining testing protocols and establishing confidence in high-throughput methodologies.

The integration of machine learning algorithms into quality control frameworks offers promising opportunities for automated anomaly detection and predictive maintenance of HTE systems. These advanced analytical tools can identify patterns indicative of system drift or failure before they significantly impact experimental results, thereby enhancing the reliability of heat resistance data generated through high-throughput approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!