High-Throughput Experimentation in Food Packaging Innovations

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Food Packaging HTE Background and Objectives

High-throughput experimentation (HTE) represents a paradigm shift in research methodology that has revolutionized numerous scientific fields, including pharmaceuticals, materials science, and catalysis. This approach is now emerging as a transformative force in food packaging innovation. Historically, food packaging development has followed traditional experimental pathways, characterized by sequential testing and iterative improvements—a process both time-consuming and resource-intensive.

The evolution of food packaging technology has progressed from simple containment solutions to sophisticated systems that actively preserve food quality, extend shelf life, and communicate product information. Recent decades have witnessed significant advancements in barrier properties, antimicrobial functionalities, and sustainable materials. However, the acceleration of global challenges—including food security concerns, environmental sustainability imperatives, and evolving consumer preferences—demands a more rapid and efficient approach to innovation.

HTE in food packaging represents the systematic application of parallel experimentation, automation, and advanced data analytics to simultaneously evaluate multiple variables affecting packaging performance. This methodology enables researchers to explore vast experimental spaces with unprecedented speed and precision, potentially compressing years of conventional research into months or even weeks.

The primary objectives of implementing HTE in food packaging innovation are multifaceted. First, to dramatically accelerate the discovery and optimization of novel packaging materials with enhanced functional properties, including improved barrier characteristics, antimicrobial efficacy, and biodegradability. Second, to enable rapid screening of material combinations and processing conditions to identify optimal formulations that meet stringent performance requirements while minimizing environmental impact.

Additionally, HTE aims to establish predictive models and structure-property relationships that can guide future innovations, reducing reliance on empirical testing. This approach seeks to democratize innovation by lowering barriers to entry for smaller companies and research institutions, fostering a more diverse and competitive landscape in packaging development.

The technical trajectory for HTE in food packaging is oriented toward creating platforms that integrate material synthesis, characterization, performance testing, and data analysis into seamless workflows. These systems will increasingly incorporate artificial intelligence and machine learning algorithms to extract meaningful patterns from complex datasets, enabling more informed decision-making and targeted experimentation.

Ultimately, the goal is to establish HTE as a cornerstone methodology that enables the food packaging industry to respond with agility to emerging challenges, from addressing plastic pollution to meeting the demands of an increasingly complex global food supply chain, while simultaneously reducing development costs and time-to-market for innovative solutions.

The evolution of food packaging technology has progressed from simple containment solutions to sophisticated systems that actively preserve food quality, extend shelf life, and communicate product information. Recent decades have witnessed significant advancements in barrier properties, antimicrobial functionalities, and sustainable materials. However, the acceleration of global challenges—including food security concerns, environmental sustainability imperatives, and evolving consumer preferences—demands a more rapid and efficient approach to innovation.

HTE in food packaging represents the systematic application of parallel experimentation, automation, and advanced data analytics to simultaneously evaluate multiple variables affecting packaging performance. This methodology enables researchers to explore vast experimental spaces with unprecedented speed and precision, potentially compressing years of conventional research into months or even weeks.

The primary objectives of implementing HTE in food packaging innovation are multifaceted. First, to dramatically accelerate the discovery and optimization of novel packaging materials with enhanced functional properties, including improved barrier characteristics, antimicrobial efficacy, and biodegradability. Second, to enable rapid screening of material combinations and processing conditions to identify optimal formulations that meet stringent performance requirements while minimizing environmental impact.

Additionally, HTE aims to establish predictive models and structure-property relationships that can guide future innovations, reducing reliance on empirical testing. This approach seeks to democratize innovation by lowering barriers to entry for smaller companies and research institutions, fostering a more diverse and competitive landscape in packaging development.

The technical trajectory for HTE in food packaging is oriented toward creating platforms that integrate material synthesis, characterization, performance testing, and data analysis into seamless workflows. These systems will increasingly incorporate artificial intelligence and machine learning algorithms to extract meaningful patterns from complex datasets, enabling more informed decision-making and targeted experimentation.

Ultimately, the goal is to establish HTE as a cornerstone methodology that enables the food packaging industry to respond with agility to emerging challenges, from addressing plastic pollution to meeting the demands of an increasingly complex global food supply chain, while simultaneously reducing development costs and time-to-market for innovative solutions.

Market Demand Analysis for Advanced Food Packaging

The global food packaging market is experiencing significant growth, driven by changing consumer preferences, technological advancements, and increasing concerns about food safety and sustainability. Current market analysis indicates that the advanced food packaging sector is expected to reach $305 billion by 2027, growing at a CAGR of 5.7% from 2022. This growth is particularly pronounced in regions with expanding middle-class populations such as Asia-Pacific and Latin America, where demand for packaged convenience foods is rising rapidly.

High-throughput experimentation (HTE) in food packaging innovations is responding to several key market demands. Foremost among these is the increasing consumer preference for sustainable packaging solutions. Research shows that 73% of global consumers are willing to pay more for products with environmentally friendly packaging. This has created a substantial market opportunity for biodegradable, compostable, and recyclable packaging materials developed through accelerated testing methodologies.

Food safety concerns represent another significant market driver. The WHO estimates that approximately 600 million people fall ill after consuming contaminated food annually. Advanced packaging technologies that incorporate antimicrobial properties, improved barrier functions, and intelligent indicators for food spoilage are seeing increased adoption across various food categories, particularly in fresh produce, dairy, and meat products.

The convenience factor continues to shape market demand, with busy lifestyles fueling the need for packaging that extends shelf life while maintaining food quality. The ready-to-eat meals segment, valued at $92 billion globally, is particularly dependent on innovative packaging solutions that can be developed rapidly through high-throughput methods.

E-commerce growth has created new challenges and opportunities for food packaging. Online food sales increased by 27% during 2020-2021, necessitating packaging that can withstand complex distribution channels while maintaining product integrity. This has accelerated demand for HTE approaches to quickly develop and test packaging solutions specifically designed for e-commerce applications.

Regulatory changes worldwide are also influencing market dynamics. With over 127 countries implementing some form of plastic packaging regulations, there is increasing pressure on manufacturers to develop compliant alternatives quickly. High-throughput experimentation provides a competitive advantage by enabling rapid screening of multiple material formulations against regulatory requirements.

The personalization trend is creating niche markets for specialized packaging solutions. Studies indicate that 36% of consumers are more likely to purchase products with personalized packaging. This fragmentation of market demands necessitates agile development approaches that can efficiently address diverse consumer preferences through parallel experimentation methodologies.

High-throughput experimentation (HTE) in food packaging innovations is responding to several key market demands. Foremost among these is the increasing consumer preference for sustainable packaging solutions. Research shows that 73% of global consumers are willing to pay more for products with environmentally friendly packaging. This has created a substantial market opportunity for biodegradable, compostable, and recyclable packaging materials developed through accelerated testing methodologies.

Food safety concerns represent another significant market driver. The WHO estimates that approximately 600 million people fall ill after consuming contaminated food annually. Advanced packaging technologies that incorporate antimicrobial properties, improved barrier functions, and intelligent indicators for food spoilage are seeing increased adoption across various food categories, particularly in fresh produce, dairy, and meat products.

The convenience factor continues to shape market demand, with busy lifestyles fueling the need for packaging that extends shelf life while maintaining food quality. The ready-to-eat meals segment, valued at $92 billion globally, is particularly dependent on innovative packaging solutions that can be developed rapidly through high-throughput methods.

E-commerce growth has created new challenges and opportunities for food packaging. Online food sales increased by 27% during 2020-2021, necessitating packaging that can withstand complex distribution channels while maintaining product integrity. This has accelerated demand for HTE approaches to quickly develop and test packaging solutions specifically designed for e-commerce applications.

Regulatory changes worldwide are also influencing market dynamics. With over 127 countries implementing some form of plastic packaging regulations, there is increasing pressure on manufacturers to develop compliant alternatives quickly. High-throughput experimentation provides a competitive advantage by enabling rapid screening of multiple material formulations against regulatory requirements.

The personalization trend is creating niche markets for specialized packaging solutions. Studies indicate that 36% of consumers are more likely to purchase products with personalized packaging. This fragmentation of market demands necessitates agile development approaches that can efficiently address diverse consumer preferences through parallel experimentation methodologies.

Current HTE Status and Challenges in Food Packaging

High-Throughput Experimentation (HTE) in food packaging has evolved significantly over the past decade, yet its implementation faces substantial challenges. Currently, HTE methodologies are primarily concentrated in materials science laboratories and specialized research institutions rather than being widely adopted across the food packaging industry. The technology utilizes parallel testing systems, automated sample preparation, and high-speed analytical techniques to rapidly evaluate multiple packaging material formulations simultaneously.

The global landscape shows uneven development, with North America and Europe leading HTE implementation in food packaging research, while Asia-Pacific regions are rapidly increasing investments. Major research centers like Fraunhofer Institute in Germany and the Packaging Research Consortium in the United States have established dedicated HTE facilities specifically for food packaging applications, demonstrating the growing recognition of this approach.

A significant technical challenge remains in the miniaturization of testing environments that can accurately simulate real-world food packaging conditions. While HTE excels at screening material properties, translating these results to predict actual food-package interactions under various environmental conditions remains problematic. The complexity of food matrices introduces variables that are difficult to account for in accelerated testing protocols.

Data management represents another substantial hurdle. HTE generates enormous datasets that require sophisticated computational infrastructure and advanced algorithms for meaningful interpretation. Many companies lack the necessary digital infrastructure to effectively leverage the full potential of HTE-generated data, creating a technological bottleneck.

Regulatory considerations further complicate HTE implementation. Food packaging materials must meet stringent safety standards, and accelerated testing methods must be validated to ensure they accurately predict long-term performance and compliance with food contact regulations. Currently, there is limited regulatory guidance specifically addressing HTE methodologies for food packaging safety assessment.

Cost barriers remain significant, particularly for small and medium enterprises. The initial investment in HTE equipment, software, and specialized personnel can be prohibitive, despite the long-term efficiency gains. This has created a technological divide between large corporations with dedicated R&D facilities and smaller market participants.

Standardization issues also persist across the industry. The lack of universally accepted HTE protocols for food packaging applications hampers data comparability between different research groups and companies. Efforts by organizations such as ASTM International and ISO to develop standardized HTE methodologies for packaging materials are ongoing but have not yet reached widespread implementation.

The global landscape shows uneven development, with North America and Europe leading HTE implementation in food packaging research, while Asia-Pacific regions are rapidly increasing investments. Major research centers like Fraunhofer Institute in Germany and the Packaging Research Consortium in the United States have established dedicated HTE facilities specifically for food packaging applications, demonstrating the growing recognition of this approach.

A significant technical challenge remains in the miniaturization of testing environments that can accurately simulate real-world food packaging conditions. While HTE excels at screening material properties, translating these results to predict actual food-package interactions under various environmental conditions remains problematic. The complexity of food matrices introduces variables that are difficult to account for in accelerated testing protocols.

Data management represents another substantial hurdle. HTE generates enormous datasets that require sophisticated computational infrastructure and advanced algorithms for meaningful interpretation. Many companies lack the necessary digital infrastructure to effectively leverage the full potential of HTE-generated data, creating a technological bottleneck.

Regulatory considerations further complicate HTE implementation. Food packaging materials must meet stringent safety standards, and accelerated testing methods must be validated to ensure they accurately predict long-term performance and compliance with food contact regulations. Currently, there is limited regulatory guidance specifically addressing HTE methodologies for food packaging safety assessment.

Cost barriers remain significant, particularly for small and medium enterprises. The initial investment in HTE equipment, software, and specialized personnel can be prohibitive, despite the long-term efficiency gains. This has created a technological divide between large corporations with dedicated R&D facilities and smaller market participants.

Standardization issues also persist across the industry. The lack of universally accepted HTE protocols for food packaging applications hampers data comparability between different research groups and companies. Efforts by organizations such as ASTM International and ISO to develop standardized HTE methodologies for packaging materials are ongoing but have not yet reached widespread implementation.

Current HTE Solutions for Food Packaging Innovation

01 Automated laboratory systems for high-throughput screening

Automated laboratory systems enable rapid and efficient high-throughput experimentation by integrating robotics, liquid handling systems, and detection technologies. These systems can perform multiple experiments simultaneously, significantly increasing the speed of data collection and analysis. The automation reduces human error and improves reproducibility while allowing researchers to test large numbers of samples or conditions in parallel.- Automated laboratory systems for high-throughput screening: Automated laboratory systems enable rapid and efficient screening of multiple samples simultaneously. These systems incorporate robotics, liquid handling devices, and detection instruments to streamline experimental workflows. By automating repetitive tasks, researchers can significantly increase the number of experiments performed in a given time, accelerating the discovery process while maintaining consistency and reducing human error.

- Data management and analysis platforms for large-scale experiments: Specialized software platforms are essential for managing and analyzing the vast amounts of data generated in high-throughput experimentation. These systems enable efficient data collection, storage, processing, and visualization. Advanced algorithms and machine learning techniques help identify patterns and extract meaningful insights from complex datasets, supporting data-driven decision making in research and development processes.

- Parallel processing techniques for accelerated experimentation: Parallel processing methodologies allow multiple experiments to be conducted simultaneously rather than sequentially. This approach utilizes specialized equipment and protocols designed for handling numerous samples in parallel. By distributing experimental tasks across multiple channels or reaction vessels, researchers can dramatically reduce the time required to explore large parameter spaces, enabling more comprehensive studies and faster innovation cycles.

- Miniaturization technologies for sample and reagent conservation: Miniaturization technologies reduce the volume of samples and reagents required for experiments, enabling more tests to be performed with limited resources. Microfluidic devices, microwell plates, and other small-scale platforms facilitate the handling of nanoliter to microliter volumes. These technologies not only conserve valuable materials but also enhance reaction kinetics, improve sensitivity, and allow for higher experimental densities in limited laboratory space.

- Integration of artificial intelligence with experimental workflows: Artificial intelligence and machine learning algorithms are increasingly integrated with high-throughput experimentation to optimize experimental design and interpret results. These systems can predict outcomes, suggest promising experimental conditions, and autonomously adjust parameters based on real-time data. By combining computational modeling with physical experimentation, researchers can navigate complex parameter spaces more efficiently and accelerate the discovery of novel materials, compounds, or processes.

02 Data management and analysis platforms for high-throughput experiments

Specialized software platforms and computational tools are essential for managing and analyzing the large volumes of data generated by high-throughput experimentation. These systems enable efficient data storage, processing, and visualization, allowing researchers to identify patterns and extract meaningful insights. Advanced analytics, including machine learning algorithms, help in predicting outcomes and optimizing experimental conditions based on historical data.Expand Specific Solutions03 Microfluidic technologies for parallel experimentation

Microfluidic devices provide miniaturized platforms for conducting multiple experiments simultaneously with minimal sample consumption. These technologies enable precise control over experimental conditions and can be integrated with various detection methods for real-time monitoring. The small scale allows for rapid heat and mass transfer, accelerating reaction rates and enabling high-throughput screening of reaction conditions, catalysts, or biological interactions.Expand Specific Solutions04 Parallel synthesis and screening methodologies

Methodologies for parallel synthesis and screening enable the simultaneous preparation and evaluation of multiple compounds or formulations. These approaches include combinatorial chemistry techniques, array-based synthesis, and multiplexed assays that can rapidly identify promising candidates from large libraries. By testing numerous variables in parallel, researchers can accelerate discovery processes and optimize formulations more efficiently than traditional sequential methods.Expand Specific Solutions05 Network-based collaborative platforms for distributed experimentation

Cloud-based collaborative platforms enable distributed high-throughput experimentation across multiple locations or organizations. These systems facilitate real-time data sharing, remote monitoring of experiments, and collaborative analysis of results. By connecting researchers and instruments across different sites, these platforms maximize resource utilization and enable larger-scale experimentation than would be possible at a single location.Expand Specific Solutions

Key Industry Players in Food Packaging HTE

The high-throughput experimentation (HTE) in food packaging innovations market is currently in a growth phase, characterized by increasing adoption of advanced technologies across the value chain. The global market size is estimated to be expanding at a CAGR of 7-9%, driven by consumer demand for sustainable packaging solutions and extended shelf life. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Tetra Laval and DuPont de Nemours have established robust R&D infrastructures, while specialized players such as MULTIVAC and Kobe Steel are focusing on material science innovations. Companies including Unilever, Ferrero, and Air Liquide are investing in collaborative research platforms to accelerate packaging development cycles. Emerging players like MycoTechnology are disrupting the market with novel bio-based packaging solutions, indicating a shift toward more sustainable technologies in this competitive landscape.

Tetra Laval Holdings & Finance SA

Technical Solution: Tetra Laval has pioneered high-throughput experimentation (HTE) in food packaging through their Tetra Pak division's Advanced Materials Testing Platform. This system enables simultaneous testing of multiple packaging material formulations under varying conditions, significantly accelerating innovation cycles. Their approach combines automated material deposition systems with parallel testing chambers that can simulate diverse environmental conditions (temperature, humidity, pressure) while monitoring barrier properties, mechanical strength, and food-material interactions in real-time. The platform incorporates machine learning algorithms that analyze performance data across thousands of test conditions to identify optimal packaging solutions for specific food products. Tetra Laval has particularly focused on developing sustainable packaging alternatives, using HTE to rapidly screen bio-based polymers and recyclable multilayer structures that maintain food safety and shelf life while reducing environmental impact.

Strengths: Industry-leading throughput capacity allowing testing of 500+ material combinations weekly; proprietary data analytics system that accelerates material selection; extensive food-specific testing protocols. Weaknesses: High capital investment requirements; primarily optimized for liquid food packaging applications; requires specialized technical expertise to operate effectively.

MULTIVAC Sepp Haggenmüller SE & Co. KG

Technical Solution: MULTIVAC has developed an integrated High-Throughput Experimentation (HTE) platform called PackScience™ that focuses on optimizing packaging processes rather than just materials. Their system combines rapid prototyping of packaging designs with automated testing stations that evaluate seal integrity, vacuum efficiency, and material performance across multiple configurations simultaneously. The platform features modular testing chambers that can simulate retail and distribution conditions while monitoring package performance through embedded sensor arrays. MULTIVAC's approach integrates digital twin technology to create virtual models of packaging systems, allowing for thousands of simulated experiments before physical testing. Their HTE methodology incorporates specialized robotics for handling diverse package formats and sizes, enabling comparative testing of up to 200 different package configurations in a single experimental run. The system is particularly valuable for modified atmosphere packaging optimization, where gas composition, sealing parameters, and material selection must be precisely balanced.

Strengths: Exceptional process parameter optimization capabilities; seamless integration with production equipment for scale-up; comprehensive data collection across the entire packaging process. Weaknesses: Less focused on fundamental material development; higher complexity in experimental setup; requires significant floor space for full implementation.

Critical HTE Technologies for Food Packaging Research

Food packaging products and methods

PatentActiveUS20230356513A1

Innovation

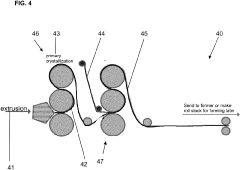

- A compatibilized polymer blend with a specific heterophasic morphology, comprising PET, hexanedioic acid-co-1,3-benzenedimethanamine, polytrimethylene furandicarboxylate, polyvinyl alcohol, and polyethyleneimine, along with post-consumer resin components, is developed to create a formable sheet and packaging structure that exceeds industry requirements for oxygen barrier, moisture barrier, hot fill capability, and trimability, using sustainable materials.

Food packaging with quality indicators for foodstuffs

PatentInactiveIN201911053892A

Innovation

- A food packaging system featuring a transparent strip and an indicator patch on the outside of the container that changes color based on the quality, health, and contaminants of the foodstuff, using UV light, bacteriological, fluorescent, or pH indicators to detect changes in the food's condition, allowing users to assess the food's quality without opening the package.

Sustainability Considerations in HTE Food Packaging

Sustainability has emerged as a critical consideration in the development of High-Throughput Experimentation (HTE) methodologies for food packaging innovations. As environmental concerns intensify globally, the packaging industry faces mounting pressure to reduce its ecological footprint while maintaining functionality and safety standards. HTE approaches must therefore incorporate sustainability metrics from the earliest stages of material screening and design.

The integration of life cycle assessment (LCA) principles into HTE workflows represents a significant advancement in sustainable packaging development. By evaluating environmental impacts across the entire product lifecycle—from raw material extraction through manufacturing, distribution, use, and disposal—researchers can identify and prioritize materials and designs with minimal ecological impact. HTE platforms equipped with automated LCA capabilities can rapidly assess thousands of potential packaging formulations against multiple sustainability parameters simultaneously.

Biodegradability and compostability testing has been successfully adapted to HTE formats, enabling accelerated screening of novel bio-based polymers and composites. Miniaturized testing chambers with controlled environmental conditions can simulate various end-of-life scenarios, providing data on degradation rates and byproducts for numerous material candidates in parallel. This approach has significantly reduced the time required to develop packaging materials that meet both performance and environmental standards.

Renewable resource utilization represents another crucial dimension of sustainable HTE in food packaging. Advanced robotic systems can now formulate and test diverse combinations of plant-based polymers, agricultural byproducts, and other renewable inputs. Machine learning algorithms analyze the resulting data to identify promising formulations that maximize renewable content while maintaining essential barrier properties and mechanical strength.

Energy efficiency in manufacturing processes has become an integral component of HTE sustainability assessments. Micro-scale processing techniques simulate industrial production methods while monitoring energy consumption, enabling researchers to optimize process parameters for minimal energy use. This approach has led to the development of packaging materials that not only incorporate sustainable raw materials but also require less energy to produce.

Waste reduction strategies in HTE laboratories themselves demonstrate commitment to sustainability principles. Miniaturization of experiments, recovery and reuse of test materials, and digital modeling to reduce physical testing all contribute to minimizing the environmental impact of the research process. These practices align with circular economy concepts and reinforce the industry's dedication to comprehensive sustainability.

The economic viability of sustainable packaging solutions remains a critical consideration in HTE research. High-throughput cost modeling tools now enable simultaneous evaluation of environmental benefits and economic factors, helping identify innovations that can achieve market acceptance while advancing sustainability goals. This balanced approach ensures that environmentally superior packaging solutions can successfully transition from laboratory to commercial implementation.

The integration of life cycle assessment (LCA) principles into HTE workflows represents a significant advancement in sustainable packaging development. By evaluating environmental impacts across the entire product lifecycle—from raw material extraction through manufacturing, distribution, use, and disposal—researchers can identify and prioritize materials and designs with minimal ecological impact. HTE platforms equipped with automated LCA capabilities can rapidly assess thousands of potential packaging formulations against multiple sustainability parameters simultaneously.

Biodegradability and compostability testing has been successfully adapted to HTE formats, enabling accelerated screening of novel bio-based polymers and composites. Miniaturized testing chambers with controlled environmental conditions can simulate various end-of-life scenarios, providing data on degradation rates and byproducts for numerous material candidates in parallel. This approach has significantly reduced the time required to develop packaging materials that meet both performance and environmental standards.

Renewable resource utilization represents another crucial dimension of sustainable HTE in food packaging. Advanced robotic systems can now formulate and test diverse combinations of plant-based polymers, agricultural byproducts, and other renewable inputs. Machine learning algorithms analyze the resulting data to identify promising formulations that maximize renewable content while maintaining essential barrier properties and mechanical strength.

Energy efficiency in manufacturing processes has become an integral component of HTE sustainability assessments. Micro-scale processing techniques simulate industrial production methods while monitoring energy consumption, enabling researchers to optimize process parameters for minimal energy use. This approach has led to the development of packaging materials that not only incorporate sustainable raw materials but also require less energy to produce.

Waste reduction strategies in HTE laboratories themselves demonstrate commitment to sustainability principles. Miniaturization of experiments, recovery and reuse of test materials, and digital modeling to reduce physical testing all contribute to minimizing the environmental impact of the research process. These practices align with circular economy concepts and reinforce the industry's dedication to comprehensive sustainability.

The economic viability of sustainable packaging solutions remains a critical consideration in HTE research. High-throughput cost modeling tools now enable simultaneous evaluation of environmental benefits and economic factors, helping identify innovations that can achieve market acceptance while advancing sustainability goals. This balanced approach ensures that environmentally superior packaging solutions can successfully transition from laboratory to commercial implementation.

Regulatory Compliance for Novel Food Packaging Materials

The regulatory landscape for novel food packaging materials is increasingly complex, requiring manufacturers to navigate a multifaceted compliance framework. In the context of high-throughput experimentation for food packaging innovations, regulatory compliance becomes a critical consideration that must be integrated early in the research and development process. Different regions maintain distinct regulatory frameworks, with the FDA in the United States, EFSA in Europe, and similar bodies in Asia establishing specific requirements for food contact materials.

These regulatory bodies typically require comprehensive safety assessments before novel packaging materials can enter the market. For high-throughput experimentation approaches, this necessitates the development of accelerated testing protocols that can satisfy regulatory requirements while maintaining the efficiency advantages of high-throughput methodologies. Migration testing represents a particular challenge, as regulatory bodies mandate strict limits on the transfer of packaging components into food.

Recent developments in regulatory science have begun to acknowledge the potential of high-throughput screening methods for safety assessment. The FDA's Predictive Toxicology Roadmap and EFSA's guidance on the risk assessment of nanomaterials in food contact applications demonstrate evolving regulatory perspectives that may eventually accommodate more efficient testing paradigms. However, significant gaps remain between current high-throughput capabilities and established regulatory protocols.

Manufacturers pursuing innovations through high-throughput experimentation must implement robust documentation systems that track material compositions, processing conditions, and performance characteristics across thousands of experimental iterations. This documentation becomes essential for regulatory submissions and must be designed to facilitate the extraction of relevant data for compliance purposes.

Global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI), are working to standardize requirements across jurisdictions, potentially simplifying the regulatory pathway for novel packaging materials. However, regional differences persist, requiring companies to develop flexible compliance strategies that can adapt to various regulatory environments.

Sustainability considerations add another dimension to regulatory compliance, with increasing scrutiny of environmental impacts throughout the packaging lifecycle. High-throughput experimentation must therefore incorporate assessments of biodegradability, recyclability, and overall environmental footprint to address emerging regulatory requirements in this domain.

Forward-looking regulatory strategies for high-throughput experimentation in food packaging should include early engagement with regulatory authorities, participation in standards development organizations, and investment in analytical methods that can bridge the gap between high-throughput screening and traditional compliance testing. This proactive approach can help ensure that innovations developed through high-throughput methods can successfully navigate the regulatory landscape and reach commercial application.

These regulatory bodies typically require comprehensive safety assessments before novel packaging materials can enter the market. For high-throughput experimentation approaches, this necessitates the development of accelerated testing protocols that can satisfy regulatory requirements while maintaining the efficiency advantages of high-throughput methodologies. Migration testing represents a particular challenge, as regulatory bodies mandate strict limits on the transfer of packaging components into food.

Recent developments in regulatory science have begun to acknowledge the potential of high-throughput screening methods for safety assessment. The FDA's Predictive Toxicology Roadmap and EFSA's guidance on the risk assessment of nanomaterials in food contact applications demonstrate evolving regulatory perspectives that may eventually accommodate more efficient testing paradigms. However, significant gaps remain between current high-throughput capabilities and established regulatory protocols.

Manufacturers pursuing innovations through high-throughput experimentation must implement robust documentation systems that track material compositions, processing conditions, and performance characteristics across thousands of experimental iterations. This documentation becomes essential for regulatory submissions and must be designed to facilitate the extraction of relevant data for compliance purposes.

Global harmonization efforts, such as those led by the Global Food Safety Initiative (GFSI), are working to standardize requirements across jurisdictions, potentially simplifying the regulatory pathway for novel packaging materials. However, regional differences persist, requiring companies to develop flexible compliance strategies that can adapt to various regulatory environments.

Sustainability considerations add another dimension to regulatory compliance, with increasing scrutiny of environmental impacts throughout the packaging lifecycle. High-throughput experimentation must therefore incorporate assessments of biodegradability, recyclability, and overall environmental footprint to address emerging regulatory requirements in this domain.

Forward-looking regulatory strategies for high-throughput experimentation in food packaging should include early engagement with regulatory authorities, participation in standards development organizations, and investment in analytical methods that can bridge the gap between high-throughput screening and traditional compliance testing. This proactive approach can help ensure that innovations developed through high-throughput methods can successfully navigate the regulatory landscape and reach commercial application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!