Highlighting PLA as a Cost‑Effective Plastic Alternative

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Background and Objectives

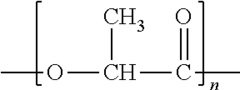

Polylactic acid (PLA) has emerged as a promising alternative to conventional plastics, gaining significant attention in recent years due to its biodegradable and renewable properties. The development of PLA can be traced back to the 1920s when Wallace Carothers first produced a low molecular weight PLA. However, it wasn't until the 1990s that breakthroughs in production techniques allowed for the commercial viability of high molecular weight PLA.

The evolution of PLA technology has been driven by the growing global concern over plastic pollution and the need for sustainable materials. As petroleum-based plastics continue to pose environmental challenges, PLA offers a potential solution derived from renewable resources such as corn starch, cassava roots, or sugarcane. This shift towards bio-based materials aligns with the broader trend of circular economy principles and reduced carbon footprint in manufacturing processes.

The primary objective in highlighting PLA as a cost-effective plastic alternative is to address the dual challenges of environmental sustainability and economic viability. While PLA has shown promise in various applications, from packaging to medical devices, its widespread adoption has been hindered by production costs and performance limitations compared to traditional plastics. Therefore, the focus of technological development is on improving PLA's mechanical properties, thermal stability, and production efficiency to make it more competitive with conventional plastics.

Current research and development efforts are aimed at enhancing PLA's versatility and reducing its production costs. This includes exploring new feedstock sources, optimizing fermentation and polymerization processes, and developing novel additives to improve PLA's properties. The goal is to position PLA as a viable replacement for a broader range of plastic applications, from single-use items to durable goods.

Another critical objective is to address the end-of-life management of PLA products. While PLA is biodegradable under specific conditions, improving its compostability and recyclability is essential for creating a truly circular material. This involves developing better degradation technologies and establishing appropriate waste management infrastructure to handle PLA products effectively.

As we look towards the future, the trajectory of PLA development is expected to intersect with other emerging technologies, such as nanotechnology and advanced manufacturing processes. These synergies could lead to new composite materials and applications that further enhance PLA's cost-effectiveness and performance, potentially revolutionizing the plastics industry and contributing to a more sustainable global economy.

The evolution of PLA technology has been driven by the growing global concern over plastic pollution and the need for sustainable materials. As petroleum-based plastics continue to pose environmental challenges, PLA offers a potential solution derived from renewable resources such as corn starch, cassava roots, or sugarcane. This shift towards bio-based materials aligns with the broader trend of circular economy principles and reduced carbon footprint in manufacturing processes.

The primary objective in highlighting PLA as a cost-effective plastic alternative is to address the dual challenges of environmental sustainability and economic viability. While PLA has shown promise in various applications, from packaging to medical devices, its widespread adoption has been hindered by production costs and performance limitations compared to traditional plastics. Therefore, the focus of technological development is on improving PLA's mechanical properties, thermal stability, and production efficiency to make it more competitive with conventional plastics.

Current research and development efforts are aimed at enhancing PLA's versatility and reducing its production costs. This includes exploring new feedstock sources, optimizing fermentation and polymerization processes, and developing novel additives to improve PLA's properties. The goal is to position PLA as a viable replacement for a broader range of plastic applications, from single-use items to durable goods.

Another critical objective is to address the end-of-life management of PLA products. While PLA is biodegradable under specific conditions, improving its compostability and recyclability is essential for creating a truly circular material. This involves developing better degradation technologies and establishing appropriate waste management infrastructure to handle PLA products effectively.

As we look towards the future, the trajectory of PLA development is expected to intersect with other emerging technologies, such as nanotechnology and advanced manufacturing processes. These synergies could lead to new composite materials and applications that further enhance PLA's cost-effectiveness and performance, potentially revolutionizing the plastics industry and contributing to a more sustainable global economy.

Market Demand Analysis

The market demand for PLA (Polylactic Acid) as a cost-effective plastic alternative has been steadily increasing in recent years, driven by growing environmental concerns and the push for sustainable materials. This biodegradable polymer, derived from renewable resources such as corn starch or sugarcane, has gained significant traction across various industries.

In the packaging sector, PLA has emerged as a viable substitute for traditional petroleum-based plastics. The food and beverage industry, in particular, has shown a strong interest in PLA due to its compatibility with food contact applications and its ability to decompose in industrial composting facilities. This shift is largely attributed to consumer preferences for eco-friendly packaging solutions and regulatory pressures to reduce plastic waste.

The medical and pharmaceutical industries have also recognized the potential of PLA in developing biodegradable implants, drug delivery systems, and disposable medical devices. The biocompatibility and controlled degradation properties of PLA make it an attractive material for these applications, contributing to the growing demand in the healthcare sector.

In the textile industry, PLA fibers are gaining popularity as a sustainable alternative to synthetic fibers. The apparel and home furnishing sectors are increasingly incorporating PLA-based fabrics into their product lines, catering to environmentally conscious consumers.

The automotive industry has shown interest in PLA for interior components and packaging materials, driven by the need to reduce vehicle weight and improve fuel efficiency. However, the adoption in this sector remains limited due to the material's thermal stability constraints.

The global PLA market has experienced substantial growth, with projections indicating continued expansion. Factors contributing to this growth include increasing awareness of environmental issues, government regulations promoting the use of biodegradable materials, and advancements in PLA production technologies that have improved its cost-effectiveness and performance characteristics.

Despite the positive market outlook, challenges remain in scaling up PLA production to meet growing demand while maintaining competitive pricing compared to conventional plastics. The availability of feedstock and the need for specialized composting facilities for proper disposal are additional factors influencing market dynamics.

As industries and consumers increasingly prioritize sustainability, the demand for PLA is expected to continue its upward trajectory. However, the material's long-term success will depend on ongoing improvements in its properties, production efficiency, and the development of appropriate end-of-life management infrastructure.

In the packaging sector, PLA has emerged as a viable substitute for traditional petroleum-based plastics. The food and beverage industry, in particular, has shown a strong interest in PLA due to its compatibility with food contact applications and its ability to decompose in industrial composting facilities. This shift is largely attributed to consumer preferences for eco-friendly packaging solutions and regulatory pressures to reduce plastic waste.

The medical and pharmaceutical industries have also recognized the potential of PLA in developing biodegradable implants, drug delivery systems, and disposable medical devices. The biocompatibility and controlled degradation properties of PLA make it an attractive material for these applications, contributing to the growing demand in the healthcare sector.

In the textile industry, PLA fibers are gaining popularity as a sustainable alternative to synthetic fibers. The apparel and home furnishing sectors are increasingly incorporating PLA-based fabrics into their product lines, catering to environmentally conscious consumers.

The automotive industry has shown interest in PLA for interior components and packaging materials, driven by the need to reduce vehicle weight and improve fuel efficiency. However, the adoption in this sector remains limited due to the material's thermal stability constraints.

The global PLA market has experienced substantial growth, with projections indicating continued expansion. Factors contributing to this growth include increasing awareness of environmental issues, government regulations promoting the use of biodegradable materials, and advancements in PLA production technologies that have improved its cost-effectiveness and performance characteristics.

Despite the positive market outlook, challenges remain in scaling up PLA production to meet growing demand while maintaining competitive pricing compared to conventional plastics. The availability of feedstock and the need for specialized composting facilities for proper disposal are additional factors influencing market dynamics.

As industries and consumers increasingly prioritize sustainability, the demand for PLA is expected to continue its upward trajectory. However, the material's long-term success will depend on ongoing improvements in its properties, production efficiency, and the development of appropriate end-of-life management infrastructure.

PLA Technology Status

Polylactic acid (PLA) has emerged as a promising alternative to traditional petroleum-based plastics, gaining significant attention in recent years due to its biodegradable and renewable properties. The current technological status of PLA production and application has reached a level of maturity that allows for its widespread use in various industries.

The production of PLA has seen substantial advancements, with improvements in fermentation processes and polymerization techniques leading to higher yields and better quality control. Large-scale production facilities have been established globally, with major players like NatureWorks and Total Corbion PLA dominating the market. These facilities have the capacity to produce hundreds of thousands of tons of PLA annually, meeting the growing demand for sustainable plastics.

In terms of material properties, PLA has undergone significant enhancements. Researchers have successfully developed PLA blends and composites that exhibit improved mechanical strength, thermal stability, and barrier properties. These advancements have expanded the range of applications for PLA, making it suitable for use in packaging, textiles, and even durable goods.

The processing technologies for PLA have also evolved, with modifications to existing plastic processing equipment allowing for efficient production of PLA-based products. Injection molding, extrusion, and thermoforming techniques have been optimized for PLA, enabling manufacturers to seamlessly integrate this material into their production lines without significant capital investments.

One of the key challenges that has been addressed in recent years is the cost-effectiveness of PLA production. Innovations in feedstock sourcing, such as utilizing agricultural waste and non-food crops, have helped reduce raw material costs. Additionally, process optimizations and economies of scale have contributed to bringing down the overall production costs, making PLA more competitive with conventional plastics.

The end-of-life management of PLA products has seen notable progress. Industrial composting facilities capable of efficiently breaking down PLA have become more widespread, addressing concerns about proper disposal. Furthermore, chemical recycling technologies for PLA are being developed, offering the potential for closed-loop recycling systems in the future.

In the realm of applications, PLA has made significant inroads in the packaging industry, particularly for food packaging and disposable items. Its use in 3D printing filaments has also gained traction, benefiting from PLA's ease of processing and low warping characteristics. The medical field has embraced PLA for bioabsorbable implants and drug delivery systems, leveraging its biocompatibility and controlled degradation properties.

Despite these advancements, challenges remain in fully realizing PLA's potential as a cost-effective plastic alternative. Ongoing research focuses on further improving PLA's heat resistance, barrier properties, and durability to expand its applicability in more demanding applications. Additionally, efforts are being made to develop more efficient and environmentally friendly production processes to further reduce costs and environmental impact.

The production of PLA has seen substantial advancements, with improvements in fermentation processes and polymerization techniques leading to higher yields and better quality control. Large-scale production facilities have been established globally, with major players like NatureWorks and Total Corbion PLA dominating the market. These facilities have the capacity to produce hundreds of thousands of tons of PLA annually, meeting the growing demand for sustainable plastics.

In terms of material properties, PLA has undergone significant enhancements. Researchers have successfully developed PLA blends and composites that exhibit improved mechanical strength, thermal stability, and barrier properties. These advancements have expanded the range of applications for PLA, making it suitable for use in packaging, textiles, and even durable goods.

The processing technologies for PLA have also evolved, with modifications to existing plastic processing equipment allowing for efficient production of PLA-based products. Injection molding, extrusion, and thermoforming techniques have been optimized for PLA, enabling manufacturers to seamlessly integrate this material into their production lines without significant capital investments.

One of the key challenges that has been addressed in recent years is the cost-effectiveness of PLA production. Innovations in feedstock sourcing, such as utilizing agricultural waste and non-food crops, have helped reduce raw material costs. Additionally, process optimizations and economies of scale have contributed to bringing down the overall production costs, making PLA more competitive with conventional plastics.

The end-of-life management of PLA products has seen notable progress. Industrial composting facilities capable of efficiently breaking down PLA have become more widespread, addressing concerns about proper disposal. Furthermore, chemical recycling technologies for PLA are being developed, offering the potential for closed-loop recycling systems in the future.

In the realm of applications, PLA has made significant inroads in the packaging industry, particularly for food packaging and disposable items. Its use in 3D printing filaments has also gained traction, benefiting from PLA's ease of processing and low warping characteristics. The medical field has embraced PLA for bioabsorbable implants and drug delivery systems, leveraging its biocompatibility and controlled degradation properties.

Despite these advancements, challenges remain in fully realizing PLA's potential as a cost-effective plastic alternative. Ongoing research focuses on further improving PLA's heat resistance, barrier properties, and durability to expand its applicability in more demanding applications. Additionally, efforts are being made to develop more efficient and environmentally friendly production processes to further reduce costs and environmental impact.

Current PLA Solutions

01 Production methods to improve cost-effectiveness

Various production methods are employed to enhance the cost-effectiveness of PLA. These include optimizing polymerization processes, developing efficient catalysts, and improving purification techniques. Such advancements in production methods can lead to reduced manufacturing costs and increased yield, making PLA more economically viable for various applications.- Production methods to improve cost-effectiveness: Various production methods are explored to enhance the cost-effectiveness of PLA. These include optimizing fermentation processes, developing efficient catalysts, and improving polymerization techniques. Such advancements aim to reduce production costs and increase the economic viability of PLA manufacturing.

- Blending PLA with other materials: Blending PLA with other materials, such as natural fibers or other polymers, can improve its properties while maintaining or reducing costs. This approach allows for the creation of cost-effective composites with enhanced mechanical, thermal, or biodegradable properties, expanding PLA's applications in various industries.

- Recycling and upcycling of PLA: Developing efficient recycling and upcycling processes for PLA can significantly improve its cost-effectiveness. These methods include chemical recycling, mechanical recycling, and the conversion of PLA waste into valuable products, reducing overall material costs and environmental impact.

- Optimization of PLA processing techniques: Improving PLA processing techniques, such as extrusion, injection molding, and 3D printing, can enhance cost-effectiveness. This involves optimizing processing parameters, developing new equipment, and creating innovative processing methods to reduce energy consumption and increase production efficiency.

- Development of high-performance PLA grades: Creating high-performance PLA grades with improved properties can increase the material's value proposition and cost-effectiveness. This includes developing PLA with enhanced heat resistance, mechanical strength, or barrier properties, allowing it to compete with more expensive conventional plastics in various applications.

02 Blending PLA with other materials

Blending PLA with other materials, such as natural fibers or other polymers, can improve its properties while maintaining or reducing costs. This approach allows for the creation of composite materials that combine the biodegradability of PLA with enhanced mechanical or thermal properties, potentially expanding its use in various industries.Expand Specific Solutions03 Recycling and upcycling of PLA

Developing efficient recycling and upcycling processes for PLA can significantly improve its cost-effectiveness. These processes aim to recover and reuse PLA materials, reducing waste and lowering the overall cost of PLA-based products. Advancements in chemical and mechanical recycling techniques contribute to the circular economy of PLA.Expand Specific Solutions04 Application-specific PLA formulations

Creating application-specific PLA formulations can enhance its cost-effectiveness in targeted industries. By tailoring the properties of PLA to meet specific requirements of different applications, such as packaging, medical devices, or textiles, manufacturers can optimize material usage and improve performance, potentially reducing overall costs.Expand Specific Solutions05 Large-scale production and economies of scale

Implementing large-scale production techniques and achieving economies of scale can significantly reduce the cost of PLA. This involves optimizing manufacturing processes, improving supply chain efficiency, and increasing production capacity. As production volumes increase, the per-unit cost of PLA decreases, making it more competitive with traditional petroleum-based plastics.Expand Specific Solutions

Key PLA Industry Players

The market for PLA as a cost-effective plastic alternative is in a growth phase, with increasing demand driven by environmental concerns and regulatory pressures. The global PLA market size is projected to expand significantly, reflecting its potential as a sustainable solution. Technologically, PLA is maturing rapidly, with companies like Total Research Corp, 3M Innovative Properties Co., and Sichuan University leading research efforts. Innovations from Stora Enso Oyj and Avantium Knowledge Centre BV are advancing PLA's properties and applications. While challenges remain in scalability and performance, collaborations between academic institutions like the University of Leeds and industry players are accelerating progress, positioning PLA as a viable alternative in various sectors.

International Paper Co.

Technical Solution: International Paper Co. has developed a PLA-based packaging solution that combines PLA with their traditional paper products. This hybrid approach leverages the company's expertise in paper manufacturing while incorporating the benefits of PLA. The technology involves coating paper products with a thin layer of PLA, creating a compostable and recyclable packaging material. This innovation addresses the need for sustainable packaging solutions in various industries, including food and beverage, consumer goods, and e-commerce.

Strengths: Combines the benefits of paper and PLA, leveraging existing paper manufacturing infrastructure. Weaknesses: May have limitations in moisture resistance compared to pure plastic packaging.

Stora Enso Oyj

Technical Solution: Stora Enso has developed a range of PLA-based products under their "NaturaTM" line. This includes PLA-coated paperboard for food packaging and disposable tableware. The company's approach involves using their expertise in wood fiber products to create bio-based barriers and coatings using PLA. They have also invested in research to improve the heat resistance and barrier properties of PLA-based materials, making them suitable for a wider range of applications in the packaging industry.

Strengths: Strong integration with existing wood-based product lines, extensive research in improving PLA properties. Weaknesses: Higher production costs compared to traditional plastic packaging materials.

PLA Innovations Analysis

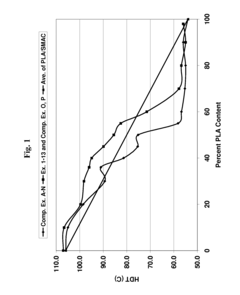

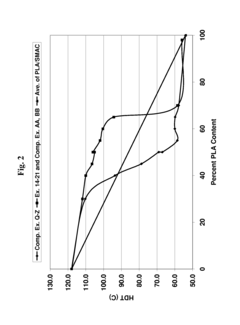

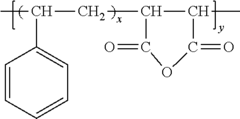

Heat resistant polylactic acid compositions

PatentInactiveUS20120208947A1

Innovation

- Reacting PLA with an oligomeric chain extender and a styrene-maleic anhydride copolymer (SMAC) to form a new polymer composition that increases the heat deflection temperature beyond the limitations of pure PLA, achieving a heat deflection temperature of at least 65°C at 66 psi, thereby enhancing its thermal stability.

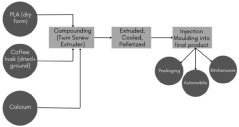

The compounding of PLA and coffee husk using the process of extrusion as an alternative for traditional plastic and inorganic additives

PatentPendingIN202321019499A

Innovation

- Compounding Polylactic acid (PLA) with coffee husk and calcium using the extrusion process to create a biodegradable and cost-effective material, CoPLA, which replaces traditional plastics in various applications.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial aspect to consider when evaluating its potential as a cost-effective plastic alternative. PLA, derived from renewable resources such as corn starch or sugarcane, offers several environmental advantages over traditional petroleum-based plastics.

One of the primary benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and organic matter within a few months to a year. This characteristic significantly reduces the long-term environmental burden associated with plastic waste accumulation in landfills and oceans.

PLA production also has a lower carbon footprint compared to conventional plastics. The manufacturing process of PLA consumes less energy and produces fewer greenhouse gas emissions. Studies have shown that PLA production can result in up to 75% less CO2 emissions than traditional plastic manufacturing.

Furthermore, PLA's renewable sourcing contributes to reduced dependence on fossil fuels. As it is derived from plant-based materials, PLA helps conserve non-renewable resources and promotes a more sustainable circular economy.

However, it is essential to note that PLA's environmental benefits are not without challenges. The production of PLA feedstock, such as corn or sugarcane, requires agricultural land and resources. This can potentially lead to competition with food crops and raise concerns about land use changes and biodiversity impacts.

Additionally, while PLA is biodegradable, it requires specific industrial composting conditions to break down efficiently. In conventional landfills or marine environments, PLA may not degrade as rapidly, potentially contributing to plastic pollution if not properly managed.

The end-of-life management of PLA products also presents challenges. Current recycling infrastructure is not widely equipped to handle PLA, which can contaminate existing plastic recycling streams. Developing separate collection and processing systems for PLA is necessary to maximize its environmental benefits.

Despite these challenges, ongoing research and development efforts are focused on improving PLA's environmental performance. Innovations in feedstock sourcing, such as using agricultural waste or algae, aim to reduce the environmental impact of raw material production. Advancements in PLA formulations are also enhancing its degradability in various environments and improving its compatibility with existing recycling systems.

In conclusion, while PLA offers significant environmental advantages over traditional plastics, a comprehensive life cycle assessment is crucial to fully understand its environmental impact. As technology and infrastructure continue to evolve, PLA's potential as an environmentally friendly plastic alternative is likely to improve, further solidifying its position as a sustainable material choice.

One of the primary benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and organic matter within a few months to a year. This characteristic significantly reduces the long-term environmental burden associated with plastic waste accumulation in landfills and oceans.

PLA production also has a lower carbon footprint compared to conventional plastics. The manufacturing process of PLA consumes less energy and produces fewer greenhouse gas emissions. Studies have shown that PLA production can result in up to 75% less CO2 emissions than traditional plastic manufacturing.

Furthermore, PLA's renewable sourcing contributes to reduced dependence on fossil fuels. As it is derived from plant-based materials, PLA helps conserve non-renewable resources and promotes a more sustainable circular economy.

However, it is essential to note that PLA's environmental benefits are not without challenges. The production of PLA feedstock, such as corn or sugarcane, requires agricultural land and resources. This can potentially lead to competition with food crops and raise concerns about land use changes and biodiversity impacts.

Additionally, while PLA is biodegradable, it requires specific industrial composting conditions to break down efficiently. In conventional landfills or marine environments, PLA may not degrade as rapidly, potentially contributing to plastic pollution if not properly managed.

The end-of-life management of PLA products also presents challenges. Current recycling infrastructure is not widely equipped to handle PLA, which can contaminate existing plastic recycling streams. Developing separate collection and processing systems for PLA is necessary to maximize its environmental benefits.

Despite these challenges, ongoing research and development efforts are focused on improving PLA's environmental performance. Innovations in feedstock sourcing, such as using agricultural waste or algae, aim to reduce the environmental impact of raw material production. Advancements in PLA formulations are also enhancing its degradability in various environments and improving its compatibility with existing recycling systems.

In conclusion, while PLA offers significant environmental advantages over traditional plastics, a comprehensive life cycle assessment is crucial to fully understand its environmental impact. As technology and infrastructure continue to evolve, PLA's potential as an environmentally friendly plastic alternative is likely to improve, further solidifying its position as a sustainable material choice.

PLA Regulatory Framework

The regulatory framework surrounding PLA (Polylactic Acid) plays a crucial role in its adoption as a cost-effective plastic alternative. As governments and international organizations increasingly focus on sustainable materials, PLA has gained significant attention in policy discussions and regulatory developments.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the European Union (EU) have been instrumental in shaping the regulatory landscape for bioplastics, including PLA. The EU, in particular, has implemented directives and regulations that promote the use of biodegradable and compostable materials, creating a favorable environment for PLA adoption.

In the United States, the Food and Drug Administration (FDA) has approved PLA for food contact applications, which has significantly expanded its potential market. The FDA's recognition of PLA as a safe material has paved the way for its use in packaging and food service industries, contributing to its cost-effectiveness through increased demand and production scale.

Many countries have introduced legislation to reduce single-use plastics, indirectly benefiting PLA as an alternative. For instance, France's ban on certain single-use plastic products has created opportunities for PLA-based alternatives in various consumer goods sectors.

Waste management regulations also play a critical role in PLA's regulatory framework. Countries and regions with well-established industrial composting infrastructure have implemented standards and certifications for compostable materials, including PLA. These standards ensure that PLA products meet specific biodegradability and compostability criteria, enhancing their environmental credibility and market acceptance.

However, the regulatory landscape for PLA is not without challenges. The lack of harmonized global standards for biodegradability and compostability can create confusion and hinder cross-border trade. Additionally, some regions face difficulties in integrating PLA into existing recycling streams, leading to potential regulatory hurdles in waste management systems.

As the demand for sustainable materials grows, many governments are introducing incentives and support mechanisms for bioplastics production and use. These may include tax breaks, research grants, or preferential procurement policies, all of which can contribute to making PLA more cost-competitive against traditional plastics.

The evolving regulatory framework for PLA reflects a broader shift towards circular economy principles in policy-making. As regulations continue to adapt to environmental concerns and technological advancements, they are likely to further solidify PLA's position as a viable and cost-effective alternative to conventional plastics.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the European Union (EU) have been instrumental in shaping the regulatory landscape for bioplastics, including PLA. The EU, in particular, has implemented directives and regulations that promote the use of biodegradable and compostable materials, creating a favorable environment for PLA adoption.

In the United States, the Food and Drug Administration (FDA) has approved PLA for food contact applications, which has significantly expanded its potential market. The FDA's recognition of PLA as a safe material has paved the way for its use in packaging and food service industries, contributing to its cost-effectiveness through increased demand and production scale.

Many countries have introduced legislation to reduce single-use plastics, indirectly benefiting PLA as an alternative. For instance, France's ban on certain single-use plastic products has created opportunities for PLA-based alternatives in various consumer goods sectors.

Waste management regulations also play a critical role in PLA's regulatory framework. Countries and regions with well-established industrial composting infrastructure have implemented standards and certifications for compostable materials, including PLA. These standards ensure that PLA products meet specific biodegradability and compostability criteria, enhancing their environmental credibility and market acceptance.

However, the regulatory landscape for PLA is not without challenges. The lack of harmonized global standards for biodegradability and compostability can create confusion and hinder cross-border trade. Additionally, some regions face difficulties in integrating PLA into existing recycling streams, leading to potential regulatory hurdles in waste management systems.

As the demand for sustainable materials grows, many governments are introducing incentives and support mechanisms for bioplastics production and use. These may include tax breaks, research grants, or preferential procurement policies, all of which can contribute to making PLA more cost-competitive against traditional plastics.

The evolving regulatory framework for PLA reflects a broader shift towards circular economy principles in policy-making. As regulations continue to adapt to environmental concerns and technological advancements, they are likely to further solidify PLA's position as a viable and cost-effective alternative to conventional plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!